Carbon dioxide is an essential substance in drink production, particularly in drink carbonation. It is a gas produced by yeast during fermentation, which creates the 'fizz' or 'condition' characteristic of beer. The carbonation gives beer its distinct refreshing aspect and contributes to its mouthfeel. Different styles of beer have distinct volumes of CO2 required, and the average CO2 volume is between 2.2 and 2.6. Traditional English ales served from casks have very low levels of CO2, usually around 1.8 volumes, while wheat and fruit beers, such as Berliner weiss beers and Belgian wit beers, have very high levels of CO2 to give them a light and refreshing palate, with CO2 levels ranging from three to four volumes.

Do different beers have different carbon dioxide content?

| Characteristics | Values |

|---|---|

| Carbon dioxide (CO2) is produced by | Yeast during fermentation |

| CO2 gives beer its | "Fizz" or "condition" |

| CO2 is added to beer | Naturally or by forced carbonation |

| Natural carbonation | Results from the fermentation process |

| Forced carbonation | CO2 is pumped into a sealed container with beer |

| Beer with high CO2 content | Is often served very cold |

| Beer with low CO2 content | Has a complex palate |

| CO2 content in beer is measured in | Volumes of gas at standard temperature and pressure or grams of CO2 per litre of beer |

| Cask-conditioned beers have CO2 levels of | Around 1.2 vols |

| Keg beers have CO2 levels of | 2–2.6 vols |

| Bottled and canned beers have CO2 levels of | Slightly higher than keg beers |

| Average CO2 volume in beer | 2.2–2.6 |

What You'll Learn

Carbonation methods: natural vs forced

The two main types of carbonation are natural carbonation and forced carbonation. The former occurs when yeast converts sugars into CO2, and the latter involves skipping this process and forcing premade CO2 into the liquid using pressure.

Natural Carbonation

Natural carbonation will occur when yeast converts sugars into CO2. If this process happens within a sealed container, the CO2 will create pressure and will eventually be absorbed into the liquid. An example of this process is the classic way of making champagne. By adding sugar to fermented juice (containing yeast) and quickly corking it, the yeast/sugar conversion will create CO2, and the pressure will be kept within the bottle and absorbed into the wine.

In the context of beer, natural carbonation can be achieved by priming the beer with priming sugar, kegging it, and then letting it sit for up to two weeks. During this process, oxygen is harmful to the beer, and it is important to purge the headspace in the keg to ensure freshness. Natural conditioning takes more time but conserves CO2.

Forced Carbonation

Forced carbonation expedites the natural carbonation process by skipping the first step. Instead of letting sugar and yeast create the CO2, forced carbonation uses premade CO2, which is forced into the liquid using pressure. This method provides more control over the volume of CO2 in the beer, and it is faster, usually taking around two days.

An example of forced carbonation is putting a finished beer product into a large pressure tank, sealing it closed, and then injecting CO2 gas. Once the gas is infused into the liquid, it can be canned or put on tap. While this method is quicker, it requires additional equipment and a pre-rendered CO2 gas supply.

Comparison

Both natural and forced carbonation methods have their advantages and disadvantages. Natural carbonation takes longer but conserves CO2, while forced carbonation is faster but uses more CO2. The choice of method depends on the specific product and the desired timeline.

Explore the Difference Between Ales and Lagers

You may want to see also

CO2 content and measurement

When it comes to beer, the carbon dioxide (CO2) content can vary depending on several factors, including the style of beer, the brewing process, and the carbonation level desired by the brewer. Different beers can indeed have different carbon dioxide contents, and this can affect both the taste and the mouthfeel that drinkers experience.

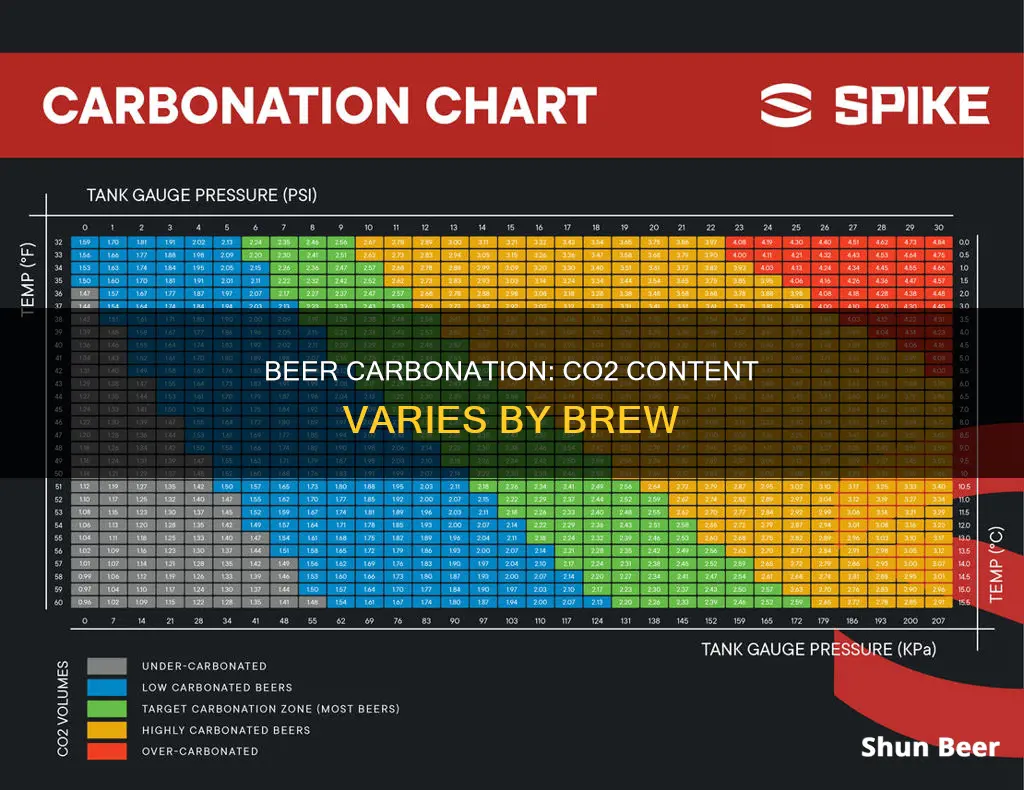

The carbonation level in beer is typically measured in volumes of CO2, which refers to the number of volumes (or volumes per liter) of CO2 dissolved in the liquid at a specific temperature and pressure. One volume of CO2 means that there is enough gas dissolved to fill the same volume as the liquid at the same temperature and pressure. For example, a beer with a carbonation level of 2.5 volumes would have 2.5 times the volume of CO2 dissolved in the liquid.

The carbonation level can be measured using a variety of instruments and methods. One common method is to use a carbon dioxide meter, which typically measures the amount of CO2 in terms of parts per million (PPM). Another device, a carbonation tester, is often used to measure the volumes of CO2. This usually involves drawing a sample of beer into a testing chamber and measuring the pressure and temperature to calculate the carbonation level.

Different styles of beer will have different target carbonation levels. For example, a light lager might have a lower carbonation level, resulting in a smoother, less fizzy mouthfeel, while a Belgian-style ale might have a higher carbonation level, creating a more effervescent sensation. Some beers, like German wheat beers, may have even higher carbonation levels, giving them a very lively and bubbly character.

Brewers have a few options to measure and control the CO2 content during the brewing process. One method is to force carbonate the beer, where the brewer injects CO2 into the beer under pressure. This method allows for precise control over the carbonation level and is commonly used for beers that require higher carbonation levels. Another approach is natural carbonation, where the beer undergoes a secondary fermentation in the package (bottle or keg), creating a more subtle and nuanced carbonation profile.

Beer vs Lager: What's the Difference?

You may want to see also

Beer styles and CO2 requirements

The carbon dioxide content in beer varies across different styles. The average CO2 volume in beer is between 2.2 and 2.6. However, some styles are flatter, like English Ale, while others are more carbonated, like the Weiss.

Porters and Stouts, along with British ales, tend to have lower carbonation levels, with Belgian ales falling between the two. Beers like fruit Lambics and German wheat beer have traditionally high carbonation levels.

The bottling temperature of the "green" (uncarbonated) beer also affects CO2 levels. A colder bottling temperature means more CO2 is dissolved in the beer. For example, a "green" lager kept at 40 degrees Fahrenheit will have almost 50% more CO2 than a "green" ale kept at 60 degrees Fahrenheit. This explains why a finished lager often has more foam than a finished ale.

The carbonation level in beer also depends on the type and amount of bottling sugar used. Different sugars, such as dried or liquid malt extract, are less efficient for yeast and give the brewer more room to work with.

Additionally, the amount of air left in each bottle during bottling affects carbonation levels. Leaving less air causes pressure to build up more quickly, reducing yeast activity and resulting in less CO2. On the other hand, leaving more air leads to faster fermentation and more CO2 but also increases the risk of exploding bottles due to higher pressure.

The serving temperature of beer also influences CO2 levels and foam production. Beers with lower CO2 levels can be served at higher temperatures, as there is less gas dissolved in the beer. Serving these beers colder increases the dissolved CO2, reducing the gas available for effervescence and foam. For example, a stout served at near-freezing temperatures may taste flat and fail to produce a solid head. Conversely, a highly carbonated beer like a Lambic served at room temperature will bubble and foam excessively. This is why many English bitters are served at "cellar" temperature (55°F), which is warmer than typical fridge temperatures.

Stout vs Porter: Unveiling Beer's Dark Secrets

You may want to see also

CO2's role in flavour and mouthfeel

Carbon dioxide (CO2) is a crucial component of beer, influencing not only its fizz and bubbles but also its flavour and mouthfeel. The amount of CO2 in a beer affects its carbonation level, aroma, and flavour, and brewers carefully control CO2 levels during the brewing process to achieve the desired texture and drinking experience.

CO2 plays a pivotal role in shaping the flavour and texture of beer, contributing to its overall profile and drinkability. When dissolved in beer, CO2 forms carbonic acid, which gives a refreshing and slightly acidic bite, enhancing the beer's crispness. The presence of CO2 also accentuates the aroma of the beer by releasing volatile aromatic compounds that contribute to its bouquet and complexity.

The carbonation level of beer significantly influences its mouthfeel, affecting the perceived body, effervescence, and overall sensation on the palate. Beers with higher carbonation levels often feel lighter and more refreshing, creating a thin mouthfeel, while those with lower carbonation can exhibit a fuller, creamier, and smoother texture.

The interplay of carbonation, aroma, and flavour creates a multi-dimensional drinking experience. The right balance of CO2 levels stimulates the senses and encourages further exploration of the beer's flavours and nuances. A well-carbonated beer with the right amount of fizz and bubbles enhances the overall sensory experience, making it a delightful drinking experience.

Additionally, CO2 plays a role in preserving the integrity of beer. Properly carbonated beer acts as a natural barrier to oxygen and other contaminants, helping to maintain its freshness and stability over time. The presence of CO2 also influences the shelf life of beer, as it helps to slow down the degradation process and maintain its quality and appeal.

Pilsner vs Lager Beer: What's the Difference?

You may want to see also

CO2 suppliers and quality management

Carbon dioxide (CO2) is an essential substance in drink production, particularly in drink carbonation. CO2 is used in beer, soda, and wine. When mixed with water, it produces carbonic acid, which impacts the flavour of drinks and provides the 'fizz' in your mouth. CO2 is commonly sourced as a by-product from various chemical industries, such as ethanol production, fuel combustion, and natural gas production.

The quality of CO2 is typically managed by the supplier, but brewers also play a role in ensuring their CO2 supply is contaminant-free and appropriately handled. Suppliers should routinely test feed gas sources for compositional changes and monitor quality throughout production. Purity monitoring systems should be in place to screen incoming lots for quality.

Standards of purity are regulated by bodies such as the Compressed Gas Association (CGA) and the FDA in the US. Beverage-grade CO2 should be at least 99.9% pure, with the remaining 0.1% including molecules such as water, oxygen, and hydrocarbons. Suppliers should provide a certificate of analysis (COA) to document the purity of their CO2.

Brewers should also implement preventative maintenance measures. For example, liquid CO2 transfer lines and compressor oils should be compatible with food-grade standards, and hoses from feed storage tanks should be carefully chosen to avoid leaching of plasticizers. Additionally, CO2 supply lines should never have condensation or standing liquid.

CO2 measurement is crucial for safety in drink production plants and pubs/restaurants that hold cylinders of CO2. High levels of exposure can lead to dangerous symptoms such as headaches, disorientation, and loss of consciousness. Gas sensors are often used to monitor CO2 levels and ensure a safe working environment.

CO2 in Beer

CO2 is released during the fermentation process in beer production and affects the flavour, sensory effects, foam head, and shelf life of the beer. Different styles of beer have distinct volumes of CO2 required, with the average CO2 volume between 2.2 and 2.6. Cask-conditioned beers typically have lower CO2 levels than keg beers, contributing to a gentler "tingle" sensation.

Exploring Diverse Beer Markets: A Global Perspective

You may want to see also

Frequently asked questions

Yes, different beers have different carbon dioxide content. The volume of CO2 in a beer can range from 1.2 for cask-conditioned beers to 2.6 for keg beers, with bottled and canned beers slightly higher. Wheat and fruit beers, such as Berliner Weisse and Belgian Wit beers, have very high levels of CO2, ranging from three to four volumes. Traditional English ales, on the other hand, have very low levels of CO2, typically around 1.8 volumes.

The carbon dioxide content in beer varies due to different styles and methods of brewing, as well as the desired flavour profile and sensory effects. Brewers adjust the CO2 levels to achieve the desired balance of sweetness and bitterness, as well as the "fizz" or "refreshing" sensation in the mouthfeel.

Carbon dioxide is essential to the quality and flavour of beer. It provides the "fizz" or carbonation, enhances the beer's mouthfeel, and contributes to its sensory effects. The level of carbonation can influence the perception of complex or less complex palates. Additionally, the solubility of CO2 increases with decreasing temperature, so serving beers at different temperatures can also impact the taste experience.