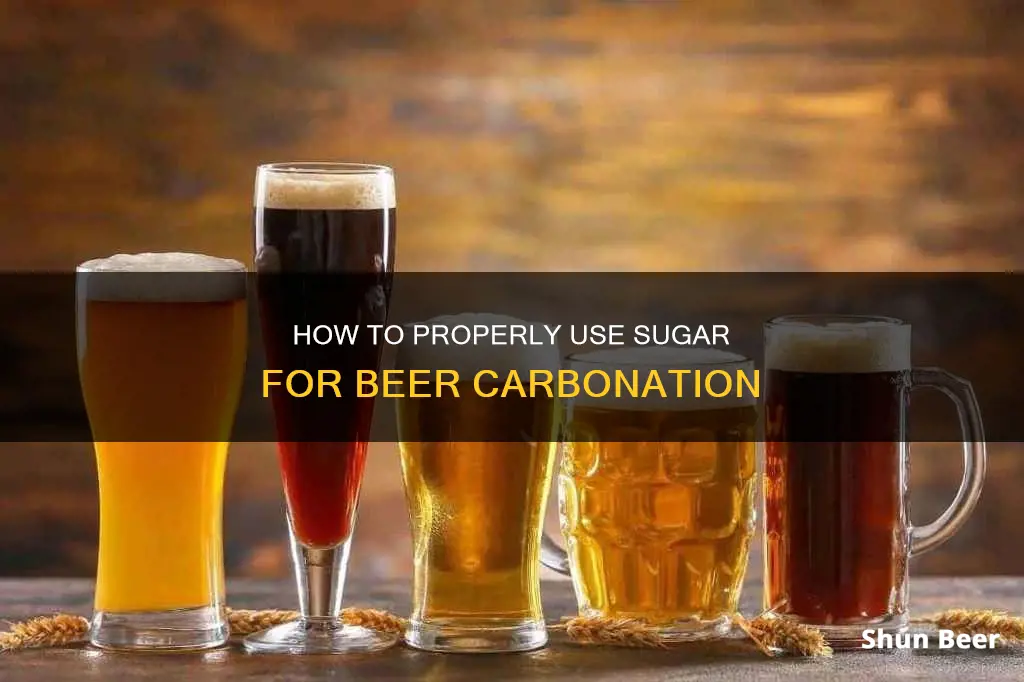

Carbonation is an essential part of the beer-making process, and it involves adding fizz to your beer, enhancing its flavour and creating a refreshing, thirst-quenching drink. To carbonate your beer, you need to add a priming solution, which is a mixture of water and sugar, to your flat beer before bottling it. This kickstarts a secondary fermentation process, where the yeast consumes the sugar and produces carbon dioxide, which is then absorbed back into the beer, creating carbonation. The amount of sugar in the priming solution will determine the level of carbonation in your beer.

When it comes to dissolving sugar before adding it to your beer, it is recommended that you do so. This is because dissolving the sugar in boiling water helps to ensure that it mixes evenly throughout your beer and also acts as a sterilisation process, reducing the risk of introducing bacteria to your brew.

| Characteristics | Values |

|---|---|

| Purpose of adding sugar to beer | To create carbonation and enhance flavour and aroma |

| When to add sugar | After primary fermentation, during the bottling stage |

| Types of sugar used | Corn sugar, table sugar, dry malt extract, honey, demerara sugar, agave nectar, treacle, maple syrup, molasses, Belgian candi syrup |

| Amount of sugar used | Depends on the desired level of carbonation, type of beer, volume of beer, and temperature of beer |

| How to add sugar | Dissolve sugar in boiling water, then add to beer |

| Benefits of sugar carbonation | Customisable carbonation levels, cost-effective, enhances flavour and aroma |

| Drawbacks of sugar carbonation | Risk of over-carbonation, time-consuming, requires additional equipment |

What You'll Learn

Carbonation Drops vs Priming Sugar

Carbonation is described in terms of volumes of carbon dioxide (CO2). The more volumes of gas, the more carbonated the liquid. For example, English cask beer can be about 1.5 volumes, whereas champagne can be up to 7.0 volumes.

Bottle conditioning is the process of naturally carbonating beer by adding a priming solution (water + sugar) to flat beer before bottling to initiate a "re-fermentation" in the bottle. The CO2 produced from the re-fermentation is absorbed into the beer, creating carbonation. The amount of carbonation in the finished beer can be controlled by adjusting the amount of priming sugar in the solution.

Priming Sugar

Priming sugar is typically measured and added to hot water, dissolved, and then placed in bottles with fermented beer. The most popular types of sugar used to create a priming solution are corn sugar (dextrose), table sugar (sucrose), and dry malt extract (DME). While all three provide a source of nutrition for the yeast that will carbonate your brew, each requires a special calculation for maximum efficacy as a primer.

Carbonation Drops

Carbonation drops are small balls of hardened sugar that are placed into beer bottles during the bottling process. The residual yeast in the beer will begin to consume the carbonation balls and become active again. As the yeast eats the sugar, it produces carbon dioxide, which is absorbed by the beer until you remove the bottle cap. This process can increase the alcohol content of your beer by a small amount (usually less than 0.2%).

Carbonation drops are made primarily of sugar, usually dextrose (corn sugar), glucose, sucrose (table sugar), or a combination. They are easy and fast to use, reliable, and create less mess. However, they are slightly more expensive than priming sugar and make it difficult to fine-tune the amount of carbonation in a beer.

So, Which Is Better?

The choice between carbonation drops vs. priming sugar ultimately depends on your personal preference and brewing style. Carbonation drops are quick, easy, simple, and less messy, but priming sugar is a bit less expensive and offers more control over carbonation levels.

Dark Beer's Sweet Secret: Sugar Content Surprise

You may want to see also

The Importance of Carbonation

Carbonation is an essential process in brewing beer, and it involves adding carbon dioxide (CO2) to the beer to create that signature fizz. While it is possible to drink beer without carbonation, carbonation enhances the flavours and aromas of the beer, giving it a thirst-quenching zing. It also activates the trigeminal nerve in the mouth, and different levels of carbonation create different sensations.

How Carbonation Works

Carbonation occurs when a priming solution, typically made by dissolving sugar in water, is added to the beer before bottling. This solution provides food for the yeast, which then creates effervescence (CO2) over a period of about two weeks as the beer ages in the bottle. The CO2 is absorbed back into the beer, creating carbonation. The amount of carbonation can be controlled by adjusting the amount of priming sugar in the solution.

Choosing the Right Sugar

Different types of sugar can be used for carbonation, including corn sugar (dextrose), table sugar (sucrose), dry malt extract (DME), honey, and various other sugar substitutes. Corn sugar is the most common choice as it is inexpensive, easy for the yeast to digest, and does not significantly influence the taste of the beer. Table sugar is another popular option due to its low cost and wide availability, although some brewers claim it produces inconsistent results. Dry malt extract is slightly different as it is an unfermented wort in powder form, which can add flavour and body to the beer.

Calculating the Right Amount of Sugar

The amount of sugar used in carbonation will depend on several factors, including the type of beer, the desired level of carbonation, the volume of beer, and the temperature of fermentation. Online calculators and charts can be used to estimate the amount of sugar needed, and it is important to measure by weight rather than volume for consistency.

Benefits of Carbonation

In addition to enhancing flavour and aroma, carbonation has other benefits for beer. It can help extend the shelf life of the beer by delaying oxidation, which can give beer a stale, cardboard-like flavour. Carbonation also helps to create a smooth mouthfeel, with different styles of beer requiring varying levels of carbonation to achieve the desired effect. For example, IPAs have higher carbonation to carry the hop aromas, while stouts depend on lower levels of carbonation for a smoother, velvety mouthfeel.

Best Low-Sugar Beers: The Sweetness Spectrum

You may want to see also

Choosing the Right Sugar

The choice of sugar for carbonating beer is important, as it can affect the mouthfeel, flavour, and aroma of the finished product. While any kind of fermentable sugar can be used to carbonate beer, different sugars will produce different results. Here are some popular options:

- Corn Sugar (Dextrose): This is the most common choice for carbonating beer because it is cheap, leaves no added flavour, and does not influence the taste of the finished beer. It is also very soluble and easy for the yeast to digest. Corn sugar is typically sold in pre-packaged amounts suitable for bottle carbonation. For five gallons of beer, four ounces of corn sugar should yield approximately 2.5 volumes of CO2, which is about average for an American Pale Ale.

- Table Sugar (Sucrose): Table sugar is a good alternative if you don't have corn sugar, but it is important to measure it by weight rather than volume, as different brands may have varying levels of fineness. Table sugar also carbonates slightly more than corn sugar, so it may not be suitable if your packaging is close to its limit.

- Malt Extract: This is a common choice for brewers who want to avoid introducing adjuncts to their brewing process. However, it requires more malt extract than cane or corn sugar, and special care must be taken during the boil process to avoid boil overs.

- Honey: Honey is difficult to work with as a priming agent because it can vary widely in density, composition, and viscosity. It is generally avoided for bottling, but it can be used for priming meads or honey wines. Darker brews typically pair better with darker honeys.

- Brown Sugar, Molasses, and Sorghum: These darker sugars can add significant aftertaste to the beer, which may be desirable for some beers, especially darker varieties.

When choosing a priming sugar, it is important to consider the desired carbonation level for the specific beer style being brewed. Different sugars will produce different levels of carbonation, so adjustments may be necessary to achieve the desired level. Additionally, it is always recommended to measure sugar by weight rather than volume for consistency.

Beer and Sugar: What's the Connection?

You may want to see also

How to Make a Priming Solution

Ingredients

To make a priming solution, you'll need:

- Priming sugar (corn sugar/dextrose, table sugar/sucrose, dry malt extract (DME), or honey)

- Water

Steps

- Bring 16 ounces (0.47 litres) of water to a boil in a clean saucepan.

- Add your chosen priming sugar to the water.

- Stir the solution until the sugar is completely dissolved.

- Cover the saucepan and set aside while you prepare your bottling bucket.

- Add the priming solution to your bottling bucket.

- Carefully siphon your brew from your carboy into the bottling bucket and mix it with the priming solution.

Tips

- The amount of priming sugar you use will depend on the type of sugar and your desired level of carbonation. You can use a carbonation priming chart or a priming sugar calculator to determine the right amount.

- Make sure all your equipment is sanitised before beginning.

- Siphon carefully to avoid pulling any of the trub (sediment) into the bottling bucket, as this can alter the flavour and clarity of your beer.

- After bottling, store the beer at 70-75°F (21-24°C) for 2-3 weeks or until fully carbonated.

Alternative Method: Carbonating by Batch

If you prefer, you can add the priming solution directly to your beer bottles instead of a bottling bucket. Here's how:

- Boil your chosen priming sugar in about a pint of water on the stove for 10 minutes.

- Pour the solution into your bottling bucket.

- Siphon your beer on top of the solution in the bottling bucket, stirring to combine.

- Connect your hose to the bottling bucket's spigot and the bottling wand to the other side.

- Fill your sanitised bottles to about 1 to 1.5 inches from the top, then cap them with sanitised caps.

- Allow the bottles to carbonate at room temperature for at least two weeks.

Sugar Secrets: Priming Beer with Precise Sugar Grams

You may want to see also

Carbonating by Batch

Step 1: Boil the Priming Sugar

Start by boiling your chosen priming sugar in about a pint of water on the stove. You can use corn sugar, table sugar, or dry malt extract for this process. Boil the mixture for about 10 minutes to ensure the sugar is fully dissolved.

Step 2: Transfer the Solution

Once the sugar is dissolved, carefully transfer the solution to your bottling bucket. Make sure the bottling bucket is clean and sanitised to avoid any contamination.

Step 3: Siphon the Beer

Now, it's time to siphon your beer into the bottling bucket. Carefully pour the beer on top of the priming sugar solution. It is important to mix the beer at this stage to ensure the sugar is evenly distributed throughout the batch. This step will help prevent gushers and flat beers.

Step 4: Connect the Hose and Bottling Wand

Connect your hose to the bottling bucket's spigot on one end and the bottling wand to the other end. Make sure the bottles you will be using are sanitised and clean.

Step 5: Fill the Bottles

Using the bottling wand, carefully fill your sanitised bottles with the beer mixture. Fill the bottles to about 1 to 1.5 inches from the top, leaving some headspace for proper carbonation.

Step 6: Cap the Bottles

After filling the bottles, cap them securely with sanitised caps. This will ensure no contamination occurs during the carbonation process.

Step 7: Store and Carbonate

Store the bottled beer at room temperature for at least two weeks to allow for carbonation. For high-gravity beers, you may need to wait longer. During this time, the yeast will remain active and feed on the priming sugar, producing carbon dioxide and creating carbonation in your beer.

Step 8: Chill and Enjoy

After the carbonation period, chill one bottle and test it. If it is not ready, let the remaining bottles age for a few more days. If the first bottle is carbonated to your liking, you can chill the rest and enjoy your freshly brewed, carbonated beer!

Coke vs Beer: Which Drink Contains More Sugar?

You may want to see also

Frequently asked questions

Yes, sugar must be dissolved in water and boiled to sterilise the mixture before being added to beer for carbonation.

Corn sugar, table sugar, and dry malt extract are the most popular types of sugar used to create a priming solution.

The amount of sugar used depends on the volume and temperature of the beer, the type of sugar, and the desired level of carbonation.