Fermenting beer is a complex process that involves the transformation of sugars into alcohol and carbon dioxide. One of the most visible and distinctive aspects of this process is the formation of a frothy, bubbly layer known as krausen. However, the question of whether fermenting beer always produces krausen is an intriguing one. While krausen is a common and expected outcome in many beer styles, there are instances where it may not form. This paragraph will explore the factors that influence the formation of krausen and discuss the conditions under which it may not occur, providing a comprehensive understanding of this fascinating aspect of beer fermentation.

| Characteristics | Values |

|---|---|

| Definition | The formation of a frothy, bubbly layer at the top of the beer during fermentation |

| Commonality | Not always; it depends on the beer style and fermentation process |

| Factors Influencing | - Yeast type: Some yeasts are more likely to produce krausen, such as ale yeasts (e.g., Saccharomyces cerevisiae) and certain lager yeasts. - Brewing techniques: The specific gravity of the wort, temperature, and yeast health can impact krausen formation. - Beer style: Certain styles, like wheat beers and some IPAs, are more prone to krausen due to their ingredients and fermentation characteristics. |

| Benefits | - Signifies active fermentation and healthy yeast activity. - Can contribute to the beer's flavor and aroma development. - May enhance the beer's appearance, making it more visually appealing. |

| Challenges | - Excessive krausen can lead to a messy fermentation process and potential yeast issues. - Some brewers may prefer to manage or control krausen to ensure a cleaner fermentation. |

| Management | - Controlling temperature and yeast type can help manage krausen. - Using specific yeast strains or adding yeast nutrients might influence krausen production. - Proper sanitation and wort preparation are essential to prevent contamination. |

What You'll Learn

- Fermentation Process: Yeast converts sugars into alcohol and CO2, a key step in beer production

- Krausen Formation: The initial foam and bubbling at the top of the wort during fermentation

- Temperature Impact: Warmer temperatures can accelerate krausen formation, but may also affect flavor

- Oxygen Influence: Oxygen exposure during fermentation can affect krausen development and beer quality

- Fermentation Time: Longer fermentation periods may produce more pronounced krausen, but can also impact flavor

Fermentation Process: Yeast converts sugars into alcohol and CO2, a key step in beer production

The fermentation process is a fundamental stage in the art of brewing beer, where the magic of transforming simple sugars into the complex beverage we know as beer truly comes to life. At the heart of this transformation is the yeast, a microscopic organism that plays a pivotal role in the creation of alcohol and carbon dioxide (CO2). This process is not merely a chemical reaction but a delicate dance of biology, where yeast acts as the catalyst, breaking down sugars and initiating the journey towards the creation of beer.

When malted grains, rich in starches and sugars, are crushed and mixed with hot water in a process called mashing, the enzymes within the grains spring into action. These enzymes break down complex carbohydrates, such as starches, into simpler sugars, primarily maltose. This sugary liquid, known as wort, is then separated from the spent grain, setting the stage for the yeast's arrival.

Here, the yeast takes center stage. It is introduced into the wort, where it begins its metabolic feast. Yeast, in a process called fermentation, consumes the sugars, particularly maltose, and through a series of biochemical reactions, converts them into ethanol (alcohol) and CO2. This conversion is not just a simple substitution but a complex metabolic pathway. The yeast's cellular machinery breaks down the sugar molecules, releasing energy in the process, and as a byproduct, it produces alcohol and CO2.

The alcohol, or ethanol, is what gives beer its characteristic kick, while the CO2 is responsible for the carbonation that makes beer sparkle. This fermentation process is a delicate balance, as the yeast's activity must be carefully controlled to ensure the desired flavor and alcohol content. Different strains of yeast can produce varying flavors and alcohol levels, making the selection of yeast a critical decision in the brewing process.

In the context of the question, 'does fermenting beer always produce krausen?' it is essential to understand that krausen is a visible sign of fermentation, a frothy, bubbly liquid that forms on the surface of the wort during the early stages of fermentation. This occurs because CO2 is released as a gas and becomes trapped in the liquid, forming bubbles. However, not all beers produce krausen, as the fermentation process can vary depending on the style, yeast used, and brewing techniques employed. Some beers may ferment quietly, without much visible activity, while others may exhibit a more vigorous krausen, indicating a robust and active fermentation.

The Fermentation Process: Uncovering the Magic Behind Beer

You may want to see also

Krausen Formation: The initial foam and bubbling at the top of the wort during fermentation

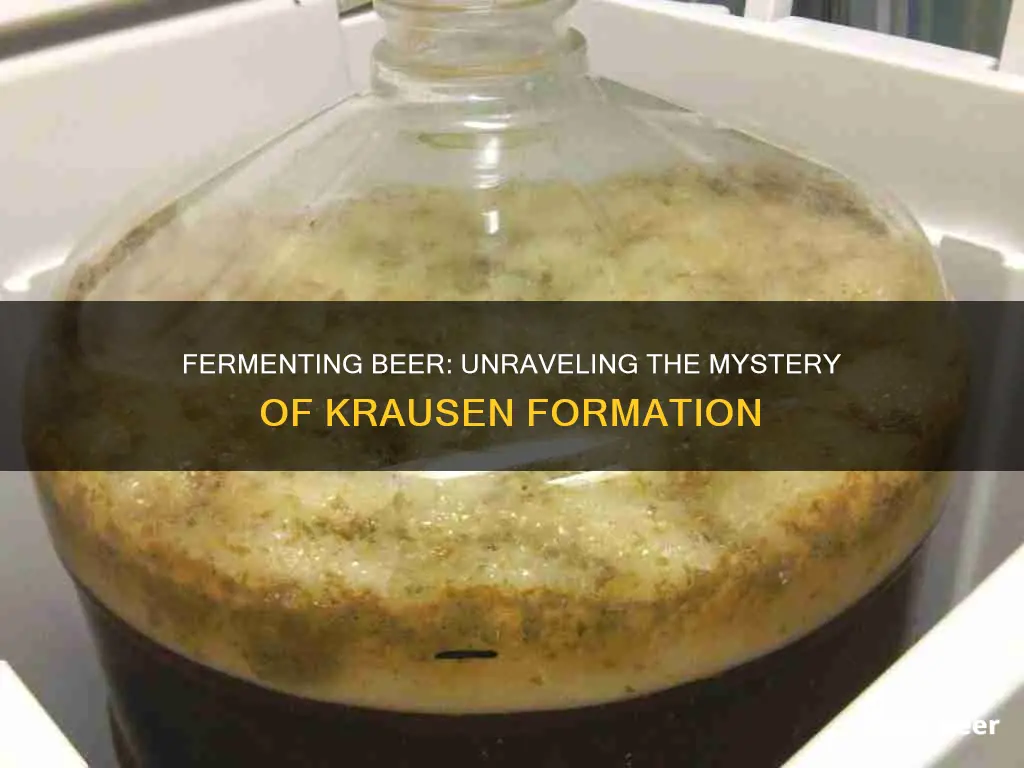

The formation of krausen is a fascinating and crucial aspect of the beer-making process, often visible as the initial foam and bubbling at the top of the wort during fermentation. This phenomenon is a result of the yeast's activity, which begins to consume sugars and produce alcohol and carbon dioxide as byproducts. As the yeast population increases, so does the rate of fermentation, leading to a rapid release of carbon dioxide gas. This gas becomes trapped in the wort, forming bubbles that rise to the surface, creating the krausen.

This initial bubbling is a sign of healthy fermentation and is a desirable outcome for brewers. The krausen is essentially the beer's first 'birth', where it transitions from a liquid to a semi-solid state due to the carbon dioxide being released. The intensity and duration of this bubbling can vary depending on the yeast strain, fermentation temperature, and the specific recipe used. For example, a warmer fermentation temperature might lead to a more vigorous krausen, while a cooler environment could result in a slower, more subtle bubbling process.

The krausen formation is not just a visual indicator but also plays a role in the beer's final characteristics. The foam can influence the beer's clarity, head retention, and even its flavor profile. A robust krausen often indicates a higher level of yeast activity, which can contribute to a more robust flavor and a higher alcohol content. However, excessive bubbling can also lead to a loss of flavor compounds and aroma esters, which are essential for the beer's overall quality.

Understanding and managing krausen formation is an art that brewers have honed over centuries. Techniques such as adjusting fermentation temperatures, using specific yeast strains, and adding clarifying agents can all influence the krausen's behavior. For instance, a cooler fermentation can slow down the krausen, allowing for better flavor development, while a warmer temperature might speed up the process but could also lead to a more aggressive yeast activity.

In summary, the krausen formation is a critical and often visible sign of fermentation, offering insights into the beer's health and final attributes. It is a natural and desirable process that brewers aim to optimize, ensuring a successful beer-making journey from wort to the final product.

Exploring the Effects: Beer Bong Experiment Results

You may want to see also

Temperature Impact: Warmer temperatures can accelerate krausen formation, but may also affect flavor

The temperature of the fermentation process plays a crucial role in the formation of krausen, a visible foam that rises to the surface of the beer during fermentation. Warmer temperatures can significantly impact this process, offering both advantages and challenges.

One of the primary effects of warmer temperatures is the acceleration of krausen formation. As the temperature increases, the yeast responsible for fermentation becomes more active. This heightened activity leads to a faster rise in alcohol content and the rapid production of carbon dioxide, which is a key component of krausen. Consequently, you'll notice a more rapid development of the foam, often within the first few days of fermentation. This can be particularly beneficial for brewers aiming to achieve a robust and visible krausen, as it indicates a healthy and efficient fermentation process.

However, there's a trade-off to this increased activity. Warmer temperatures can also have a detrimental effect on the flavor profile of the beer. The yeast, when active at higher temperatures, may produce more esters and higher alcohol byproducts, which can result in a beer with an off-putting flavor. These off-flavors might include fruity notes, especially esters like ethyl acetate, which can give the beer a sweet, apple-like aroma, or even a nail polish remover-like smell. Additionally, higher temperatures can lead to a more pronounced alcohol flavor, making the beer taste stronger and less balanced.

To manage this, brewers often employ various techniques. One approach is to use specific yeast strains that are more tolerant of warmer temperatures, thus allowing for a faster fermentation without compromising flavor. Another strategy is to gradually cool the fermentation vessel as the process progresses, providing a more controlled environment for the yeast to work in. This ensures that the beer develops a desirable flavor profile while still benefiting from the accelerated krausen formation.

In summary, while warmer temperatures can expedite the formation of krausen, they also present challenges in terms of flavor. Brewers must carefully manage temperature and yeast selection to strike a balance, ensuring a healthy fermentation process and a beer with the desired taste and aroma.

Fishy Brew: Uncovering the Truth Behind Beer's Surprising Ingredient

You may want to see also

Oxygen Influence: Oxygen exposure during fermentation can affect krausen development and beer quality

The process of fermentation in brewing is a complex and delicate art, and one of the key factors that can influence the outcome is oxygen exposure. While it might seem counterintuitive, the role of oxygen during fermentation is crucial and can significantly impact the development of krausen, a crucial aspect of the brewing process.

When yeast ferments wort, it undergoes a series of biochemical reactions, primarily converting sugars into alcohol and carbon dioxide. This process is highly sensitive to oxygen levels. Initially, during the early stages of fermentation, a small amount of oxygen is beneficial. It helps activate the yeast, promoting a faster and more efficient fermentation process. This initial oxygen exposure can lead to a more robust and active yeast population, which is essential for a healthy fermentation. However, as the fermentation progresses, the presence of oxygen becomes a double-edged sword.

As the yeast population increases, the demand for nutrients and the production of waste products also rise. In the absence of sufficient oxygen, these waste products, including ethanol and sulfur compounds, can accumulate, negatively impacting the beer's quality. This is where the concept of 'oxygen starvation' comes into play. When oxygen becomes scarce, the yeast may struggle to perform its functions optimally, leading to a slower fermentation and potentially off-flavors in the final product. This is why brewers often carefully manage oxygen levels to ensure a balanced and efficient fermentation process.

The impact of oxygen on krausen formation is particularly noteworthy. Krause, a frothy, creamy layer that forms on the surface of the wort during fermentation, is a visual indicator of a healthy and active yeast population. Adequate oxygen supply encourages the yeast to produce more carbon dioxide, which contributes to the formation of a robust krausen. This is essential for the clarity and flavor development of the beer. However, excessive oxygen exposure can lead to a rapid and uncontrolled fermentation, resulting in a less stable krausen and potentially affecting the beer's overall quality and mouthfeel.

In summary, oxygen exposure during fermentation plays a critical role in the development of krausen and the overall beer quality. While a controlled amount of oxygen at the beginning of fermentation can stimulate yeast activity, excessive or insufficient oxygen levels can lead to undesirable outcomes. Brewers must carefully manage oxygen levels to ensure a healthy fermentation process, ultimately resulting in a high-quality, flavorful beer. Understanding this delicate balance is key to mastering the art of brewing.

Uncorking Breakfast: The Surprising Delight of Beer-Infused Pancakes

You may want to see also

Fermentation Time: Longer fermentation periods may produce more pronounced krausen, but can also impact flavor

Fermentation time plays a crucial role in the beer-making process and can significantly influence the formation of krausen, a key component of the beer's appearance and flavor profile. While longer fermentation periods are often associated with more pronounced krausen, they can also have an impact on the overall taste of the beer.

When it comes to fermentation, time is a critical factor. Generally, a longer fermentation period allows for a more complete transformation of sugars into alcohol and the production of various beer flavors and aromas. During this extended process, yeast continues to metabolize sugars, resulting in a more robust flavor development. This can lead to a more pronounced krausen, which is the frothy, creamy layer that forms on the surface of the beer during fermentation. The longer fermentation time provides the yeast with ample opportunity to work its magic, creating a more complex and visually appealing beer.

However, it's important to note that longer fermentation periods can also have drawbacks. As the yeast continues to ferment, it may produce higher levels of esters, which are compounds responsible for fruity and spicy notes in beer. While these esters can contribute to a unique flavor profile, excessive amounts can result in an off-putting aroma. Additionally, longer fermentation may lead to a higher alcohol content, which, while desirable in some beer styles, can also impact the beer's drinkability and overall balance.

Brewers often aim for a delicate balance when it comes to fermentation time. They want to maximize the benefits of longer fermentation, such as enhanced flavor and krausen, while minimizing the potential negative effects, such as excessive esters or alcohol levels. Achieving this balance requires careful monitoring and adjustment of fermentation conditions, including temperature, yeast type, and nutrient levels.

In summary, while longer fermentation periods can indeed produce more pronounced krausen, they also come with considerations regarding flavor impact. Brewers must carefully manage fermentation time to ensure the desired outcome, balancing the benefits of extended fermentation with the potential drawbacks to create a beer that is both visually appealing and deliciously flavorful.

Uncork the Mystery: Why Beer Belongs on the Top Shelf

You may want to see also

Frequently asked questions

No, not all beer fermentation processes result in the formation of krausen. Krausen is the frothy, bubbly layer that forms on the surface of the beer during fermentation, which is primarily composed of carbon dioxide and alcohol. While it is a common and desirable characteristic of many beer styles, especially lagers and wheat beers, it is not an inevitable byproduct of fermentation. The presence or absence of krausen depends on various factors, including the beer style, yeast strain, fermentation temperature, and the specific brewing process. Some beers, like certain stouts or porters, may have a more subtle or minimal krausen formation due to their unique ingredient profiles and brewing techniques.

There are several reasons why a beer might not exhibit significant krausen formation. Firstly, the type of yeast used can influence the fermentation process. Some yeast strains are more active and produce a lot of carbon dioxide, leading to a robust krausen. Others may be more passive and result in a less bubbly fermentation. Additionally, the fermentation temperature plays a crucial role. Warmer temperatures can slow down fermentation, reducing the amount of krausen. Conversely, cooler temperatures might enhance krausen formation. The brewing process, such as the addition of specific ingredients or the use of specific brewing techniques, can also impact krausen production.

The absence of krausen does not necessarily indicate a lower-quality beer. Krausen is more of an indicator of the fermentation process and the beer's potential for carbonation rather than its overall quality. Well-fermented beers can still be of excellent quality even without a prominent krausen. However, in some cases, a lack of krausen might suggest an issue with the fermentation process, such as a stuck fermentation or an imbalance in the yeast-to-sugar ratio. In these instances, it could potentially impact the beer's flavor, mouthfeel, and overall drinking experience.

Yes, brewers have various techniques to influence krausen formation. To encourage a robust krausen, brewers might use specific yeast strains known for their high carbonation potential. Adjusting the fermentation temperature can also impact krausen; warmer temperatures often promote more krausen activity. Additionally, the addition of specific ingredients, like certain hops or specialty grains, can affect the fermentation process and krausen formation. Conversely, if a brewer aims for a less bubbly beer, they might use yeast strains with lower carbonation potential or employ specific brewing techniques to control the fermentation environment.