Beer coolers are an essential component of the beer-drinking experience, ensuring that the beverage is served at the perfect temperature. The process of cooling beer involves a delicate balance of various factors, including the temperature and carbonation of the beer, as well as the pressure applied to it. In this article, we will explore the different types of beer coolers, their functioning, and the science behind keeping our favourite brew chilled. From glycol cooling systems to the intricacies of draught beer systems, we will uncover the secrets behind the refreshing beer we love.

| Characteristics | Values |

|---|---|

| Beer storage | Kept in kegs in a cold room or cellar |

| Beer temperature | Between 4°C and 16°C |

| Tubing material | Insulated plastic or vinyl/polyethylene |

| Tubing length | Up to 25m |

| Chilling method | Glycol cooling system or remote refrigeration system |

| Glycol type | Propylene glycol |

| Glycol properties | Non-toxic, food-grade antifreeze |

| Cooling process | Beer passes through pipes to a cold plate, then through the tap system |

| Cold plate material | Cast aluminum |

What You'll Learn

Glycol cooling systems

The glycol cooling system is ideal for long-draw dispensing setups, where the beer kegs are stored away from the bar counter. It is also a good option for those wanting longer beer runs, as it can accommodate beer lines of 25 feet or more.

The glycol system works by forcing a cold liquid (glycol) through pipes to a cold plate, usually made of cast aluminum. The glycol then runs through the tap system, keeping the beer cold. The glycol never comes into contact with the beer. The glycol is non-evaporating and non-toxic, with a freezing point lower than that of water, ensuring it remains a liquid at operating temperatures.

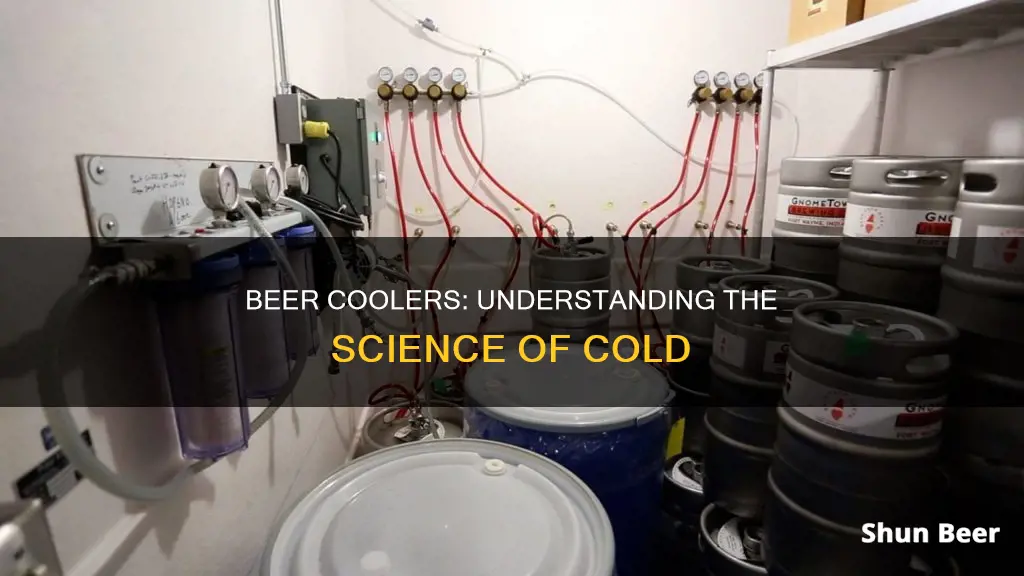

The main components of a glycol cooling system are the power pack, the trunk line, and the beer tower. The power pack is a refrigeration unit that pumps and circulates the glycol through the system, maintaining the correct temperature. The trunk line is an assembly of beer lines and glycol lines, bound together and wrapped in insulation. The beer lines are connected to the kegs, and the glycol lines run from the power pack to the beer tower, keeping the beer chilled. The beer tower is where the beer is dispensed from, with the beer lines attached to a shank or faucet inside.

Exploring Beer Enhancement With Bazooka Tubes

You may want to see also

Beer line refrigeration

The beer is kept cold at its source, in a keg stored in a walk-in cooler or fridge, ensuring it starts its journey at the ideal temperature. From the keg, the beer travels through insulated tubing, often made of vinyl or polyethylene, towards the tap. This tubing can be quite long, especially in larger establishments, and may need to be chilled to maintain the desired temperature.

To keep the beer cold during transport, long-draw draft systems are employed. These systems use insulated beer lines that are chilled to prevent the beer from pouring foamy and to inhibit bacterial growth. This is where beer line refrigeration comes into play.

One common method of beer line refrigeration is the use of a glycol cooling system. Glycol, a food-grade liquid antifreeze, is pumped through pipes to a cold plate, usually made of cast aluminium. This cold plate cools the beer as it passes through the pipes on its way to the tap. The glycol system ensures that the beer remains cold and doesn't warm up during its journey.

Another important aspect of beer line refrigeration is the maintenance of optimal pressure. Too much or too little carbon dioxide pressure can lead to foamy pours, flat beer, or overcarbonation. The amount of pressure applied depends on various factors, including the temperature of the beer, the elevation, and the length of tubing.

By combining effective cooling systems with precise pressure control, establishments can ensure that their beer remains cold, fresh, and carbonated from the moment it leaves the keg to when it is poured into the glass.

Sprite vs Beer: A Healthy Alternative?

You may want to see also

The role of keg couplers

A keg coupler is a crucial component of any draft beer system. It is a small but vital piece of equipment that connects the gas and beer lines to the keg. The keg coupler can be thought of as a "key" that attaches to the valve of a keg, which is the "lock". They cannot work independently of each other. The keg coupler allows compressed air to enter the keg and push the beer out.

There are six main types of keg couplers: D-type, U-type, G-type, S-type, A-type, and M-type. Each type is designed to fit specific keg valves, depending on the brand/style of beer, where it was brewed, and the size of the keg. For example, the D-type coupler, also known as the American Sankey coupler, fits U.S. Sankey keg valves and is the most common type in North America. On the other hand, the U-type coupler, or Irish/Guinness keg coupler, is used for beers originating from Ireland, such as Guinness and Harp Lager.

The keg coupler connects to two tubes: one that brings gas to the keg and another that allows the beer to flow out to the faucet. The gas used is typically pure bottled carbon dioxide or nitrogen, which is controlled by a regulator to maintain the appropriate amount of pressure. The beer then travels through vinyl or polyethylene tubing, which may be chilled to ensure the beer remains cold on its journey to the faucet.

The keg coupler plays a vital role in ensuring that the beer served is properly chilled and carbonated, with an appropriate foamy head. By maintaining the correct pressure and temperature, the coupler helps to prevent foamy pours and ensures that the beer is not overcarbonated or flat.

Beer Sleeves: Do They Keep Drinks Cool?

You may want to see also

Cellar cooling systems

The basic principle behind cellar cooling systems is to force chilled air into a designated area, typically a cellar, to keep beverages at the optimal temperature. This area is usually a cellar, but it can also be a room or a dedicated cabinet. The desired temperature range for beer is between 50 and 55 degrees Fahrenheit, while other beverages like wine, lager, and pilsners have slightly different ideal temperature ranges.

These cooling systems are designed to maintain a consistent temperature, preventing spoilage and ensuring that drinks are served at the perfect temperature. In addition, these systems can also help control humidity levels, which is crucial for preventing corks from drying out in wine bottles.

There are different types of cellar cooling systems available, including glycol cooling systems and remote line coolers. Glycol cooling systems use a cold liquid, typically glycol, which is forced through pipes to a cold plate, usually made of cast aluminum. This process keeps the beer cold as it passes through the pipes to the tap system. Remote line coolers, on the other hand, have lines running from each barrel to the cooler, where the beverage is chilled before being dispensed.

Lovastatin and Beer: A Safe Mix?

You may want to see also

Active vs passive cooling

When it comes to keeping beer cool, there are two main types of cooling systems: active and passive. Both aim to achieve the same goal of maintaining the perfect serving temperature, but they differ in their methods and applications.

Passive cooling is a natural process that relies on the inherent thermal management properties of materials and systems. In the context of beer cooling, passive cooling can be achieved through the use of insulated containers, such as coolers or keg buckets, which help maintain the temperature of the beer without the use of external energy sources. Additionally, in long-draw draft systems, insulated beer lines are used to keep the beer cool as it travels from the kegs to the tap, preventing it from pouring foamy and warm. This is a cost-effective and energy-efficient solution, as it does not require additional energy input to maintain the desired temperature.

Active cooling, on the other hand, employs external devices such as fans, pumps, or refrigeration systems to enhance heat transfer and maintain the desired temperature. In beer cooling, active cooling is commonly used in the form of walk-in coolers or refrigerators, which use refrigeration systems to keep the beer kegs at a consistent temperature. Active cooling is also utilized in glycol cooling systems, where a cold liquid (glycol) is forced along pipes to a chill plate, usually made of cast aluminum, to keep the beer cold as it passes through. While active cooling provides more precise temperature control, it also consumes more energy and is generally more costly than passive cooling.

Both active and passive cooling systems play a crucial role in ensuring that beer is served at the optimal temperature, with passive cooling being more cost-effective and energy-efficient, while active cooling offers more precise temperature control for scenarios with high heat loads.

Morning Beer: Should You Drink Before Work?

You may want to see also

Frequently asked questions

A beer cooler is a refrigeration system that creates or replicates a cold room environment to chill beer.

A beer cooler works by absorbing heat from inside a cabinet and transferring it outside. This is done through the use of coolants. In a glycol cooling system, beer passes through pipes to a cold plate and cools. The cooling process involves pushing a cold liquid (glycol) along pipes on a cold plate, which is usually made of cast aluminium, and then through the tap system, keeping the beer cold.

It takes 10-12 minutes to chill drinks in an ice chest when covered with ice. When immersed in ice water, it only takes 4-6 minutes.

The ideal temperature for a beer cooler depends on the type of beer. Varieties like pilsners and lager blades are best served between four and eight degrees Celsius, while blades are best served between eight and ten degrees Celsius.

Long-draw draft systems deliver draught beer from the cooler to the draft tower through insulated beer lines. These beer lines are kept chilled to prevent the beer from pouring foamy and to prevent the formation of bacteria.