Knowing whether your beer is fermenting is an essential part of the brewing process. Fermentation is the process where yeast converts sugars in the wort (the liquid extracted from malted grains) into alcohol and carbon dioxide. There are several signs that can indicate fermentation is occurring. One of the most common is a change in the appearance of the beer; it will often become hazy as the yeast and other particles settle. Another sign is a change in the beer's temperature; fermentation typically occurs at a temperature between 65°F and 75°F (18°C and 24°C). You may also notice a decrease in the specific gravity of the beer, as the yeast consumes the sugars. Additionally, you can use a hydrometer to measure the specific gravity before and after fermentation to track the progress. Lastly, if you see bubbles forming in the airlock of your fermenter, it's a good indication that fermentation is active.

How to Know if Your Beer is Fermenting

| Characteristics | Values |

|---|---|

| Color Change | Beer will typically darken slightly during fermentation. This is due to the conversion of sugars to alcohol and the formation of new compounds. |

| Carbonation | Fermentation produces carbon dioxide, leading to increased carbonation. You might notice a hissing sound or see bubbles forming in the beer. |

| Alcohol Content | The alcohol by volume (ABV) will gradually rise as fermentation progresses. This is a good indicator of successful fermentation. |

| Clarity | Unfermented beer can be cloudy due to yeast and sediment. After fermentation, the beer should become clearer as the yeast settles. |

| Taste and Aroma | Fermentation transforms the beer's flavor and aroma. You might notice a change in bitterness, sweetness, or the emergence of fruity or estery notes. |

| Yeast Activity | Active yeast will be visible near the surface of the beer, forming a "yeast cake." This is a sign of healthy fermentation. |

| Temperature | Fermentation temperature is crucial. Most beer styles ferment best between 65°F and 75°F (18°C and 24°C). Monitoring temperature is essential for control. |

| Time | Fermentation duration varies depending on the style and recipe. Generally, it takes 1-2 weeks for primary fermentation and another week or two for secondary fermentation (if applicable). |

What You'll Learn

- Visual Changes: Cloudiness or sedimentation indicates active fermentation

- Smell: A fruity or estery aroma suggests fermentation

- Temperature: Fermentation occurs best at a specific temperature range

- Carbonation: Rising bubbles indicate fermentation and carbonation

- Alcohol Content: Measuring alcohol by volume confirms fermentation

Visual Changes: Cloudiness or sedimentation indicates active fermentation

When brewing beer, monitoring the fermentation process is crucial to ensure the desired outcome. One of the most accessible ways to do this is by observing visual changes in your beer. Cloudiness or sedimentation in the fermentation vessel is a clear indicator that fermentation is actively taking place. This phenomenon occurs due to the yeast consuming sugars and producing alcohol and carbon dioxide. As a result, the yeast cells and their byproducts remain suspended in the beer, causing it to appear cloudy.

During the fermentation process, the yeast works diligently to break down the sugars present in the wort (the sugary liquid extracted from malted grains). This breakdown results in the formation of alcohol and carbon dioxide, which are essential components of the final beer product. As the yeast performs its magical transformation, it also creates a small amount of sediment, which is essentially the yeast cells and their waste products. This sedimentation is a natural part of the fermentation process and is a sign that the yeast is actively working.

The cloudiness or sedimentation in the beer can be observed in the fermentation vessel, such as a fermenter or a carboy. As the fermentation progresses, you might notice a gradual change in the beer's appearance. Initially, the beer may appear clear, but over time, it will start to develop a hazy or cloudy texture. This cloudiness is not a sign of contamination but rather a visual confirmation of the yeast's activity. It indicates that the yeast is efficiently converting the sugars into alcohol, and the beer is on its way to becoming a delicious, fermented beverage.

It's important to note that the level of cloudiness can vary depending on the style of beer being brewed and the specific yeast strain used. Some beer styles, like wheat beers, naturally have a hazy appearance due to the presence of proteins and other suspended particles. In such cases, the cloudiness is expected and not an indication of a problem. However, if the cloudiness is sudden or excessive, it might suggest an issue with the fermentation process or the yeast strain.

For homebrewers, observing these visual changes can be an exciting part of the brewing journey. It provides a tangible way to connect with the process and ensures that the beer is fermenting correctly. Additionally, monitoring cloudiness can help brewers make informed decisions about when to bottle or keg the beer, as fermentation typically slows down or stops once the beer reaches the desired alcohol content and clarity.

Freezing Beer: Does It Always Make It Taste Bad?

You may want to see also

Smell: A fruity or estery aroma suggests fermentation

When it comes to homebrewing, one of the most crucial aspects is monitoring the fermentation process to ensure your beer is developing as intended. One of the key indicators of successful fermentation is the aroma of your beer. A fruity or estery scent is a positive sign that your beer is undergoing the desired fermentation process. This characteristic smell is often associated with the presence of esters, which are compounds produced by yeast during fermentation.

During the fermentation process, yeast consumes sugars and converts them into alcohol and carbon dioxide. As this occurs, it can lead to the formation of various compounds, including esters. These esters contribute to the unique flavors and aromas that distinguish different types of beer. For example, a fruity aroma might indicate the presence of esters derived from fruity esters like ethyl acetate, which can give your beer a pleasant, apple-like or banana-like scent. Similarly, an estery odor could suggest the presence of ethyl butyrate, which is often associated with a buttery or creamy note.

The intensity of this fruity or estery aroma can vary depending on the yeast strain and the brewing process. Some yeast strains are more prone to producing these fruity esters, while others may result in a more neutral or clean fermentation profile. It's essential to be familiar with the characteristics of the yeast you're using to anticipate the potential aroma of your beer. Additionally, the brewing process, including the yeast's feeding schedule and the temperature at which fermentation occurs, can also influence the development of these aromas.

If you notice a distinct fruity or estery scent during the fermentation process, it's a good sign that your beer is fermenting correctly. However, it's important to note that an overly strong or unpleasant odor could indicate an issue with the fermentation process or the presence of off-flavors. In such cases, it might be necessary to investigate further and address any potential problems to ensure the quality of your beer.

Monitoring the aroma of your beer during fermentation is a simple yet effective way to gauge the health of your brew. By paying attention to these fruity or estery notes, you can gain valuable insights into the fermentation process and take appropriate actions to refine your brewing skills. Remember, each batch of beer is unique, and understanding the nuances of fermentation will help you create exceptional brews that showcase your creativity and passion for the craft.

The tangy twist: Uncovering the appeal of lemon in beer

You may want to see also

Temperature: Fermentation occurs best at a specific temperature range

Fermentation is a delicate process that requires precise control of temperature to ensure the best results. For beer fermentation, maintaining the right temperature is crucial as it directly impacts the yeast's activity and the overall flavor development. The ideal temperature range for fermentation is typically between 65°F and 72°F (18°C and 22°C). This range is chosen because it allows the yeast to work efficiently without being stressed or inhibited.

At temperatures below 65°F, the yeast's activity slows down significantly, leading to a prolonged fermentation process. This can result in a lack of carbonation and a dull flavor profile in the final beer. On the other hand, temperatures above 72°F can be detrimental as well. When the temperature exceeds this range, the yeast may become inactive or even die, causing the fermentation to stall. This can lead to a flat beer with an off-putting taste.

To monitor the fermentation temperature, it is recommended to use a fermentation thermometer or a digital temperature controller. These tools provide accurate readings and allow you to maintain a consistent temperature throughout the fermentation process. It's important to keep the fermenter in a controlled environment, such as a cool, dark place, to minimize temperature fluctuations.

During the fermentation process, it's a good practice to take temperature readings at different times to ensure the yeast is working optimally. If the temperature deviates from the ideal range, you may need to adjust it accordingly. For example, if the temperature is too low, you can gently warm the fermenter, but be cautious not to exceed the upper limit.

In summary, temperature control is a critical aspect of beer fermentation. By keeping the temperature within the optimal range, you can ensure a healthy and efficient fermentation process, resulting in a delicious, well-balanced beer. Remember, consistency and precision in temperature management are key to achieving the desired beer style and character.

The Surprising Reason People Cover Beer Bottles with Bags

You may want to see also

Carbonation: Rising bubbles indicate fermentation and carbonation

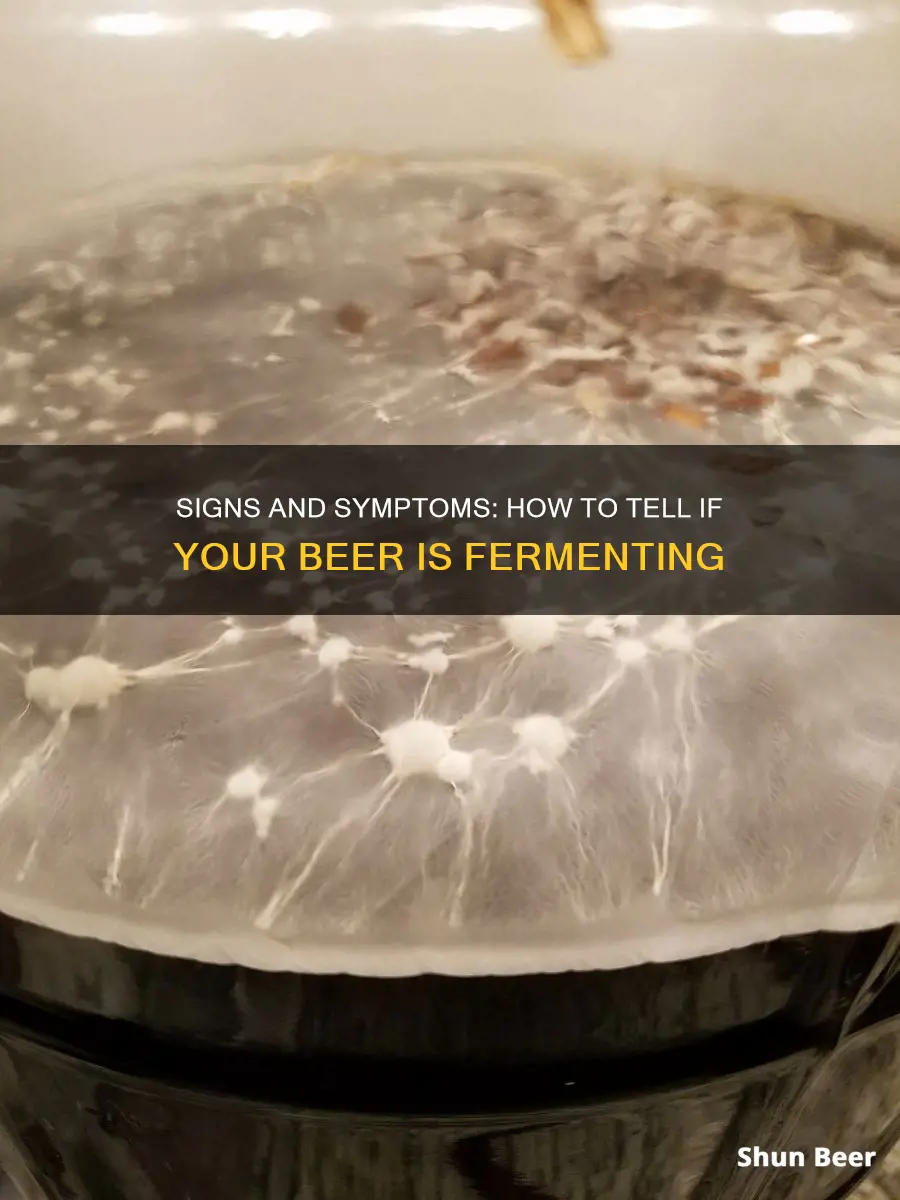

Carbonation is a crucial aspect of the brewing process, and monitoring the carbonation level is essential to ensure your beer is fermenting correctly. As yeast consumes sugars and produces alcohol, it also creates carbon dioxide, which gets dissolved in the liquid. This process is known as fermentation, and it's a key step in transforming your wort into a delicious, bubbly beer.

One of the most straightforward ways to check for carbonation is by observing the beer's appearance. When the fermentation process is active, you'll notice the formation of small bubbles on the surface of the liquid. These bubbles are a sign that the yeast is actively working and producing carbon dioxide. As the fermentation progresses, the number of bubbles may increase, and you might even see a slight foam forming on top of the beer. This visual indicator is a good sign that your beer is on the right track.

The intensity of bubbling can vary depending on the style of beer and the specific yeast strain used. Some beers, like wheat beers, tend to produce more noticeable bubbles due to their lighter body and higher carbonation levels. Others, such as stouts or porters, might have a more subtle bubbling action. It's essential to be familiar with the characteristics of the beer style you're brewing to interpret these signs accurately.

Additionally, you can perform a simple at-home test to measure carbonation levels. Fill a glass partially with your beer and gently invert it. If the beer is properly carbonated, you should hear a soft, steady hiss as the carbon dioxide escapes from the liquid. This test can give you a quick indication of the beer's carbonation status. However, keep in mind that this method might not provide a precise measurement, and professional brewing equipment is generally more reliable for accurate carbonation monitoring.

Monitoring carbonation is a critical part of the brewing process, as it directly impacts the beer's final quality. Proper carbonation adds to the overall taste, mouthfeel, and freshness of the beverage. If the carbonation level is too low, the beer might taste flat, while excessive carbonation can lead to a sharp, biting sensation. Achieving the right balance requires careful attention to the fermentation process and the use of appropriate brewing techniques.

Beet Beer Blend: A Sweet, Earthy Twist on Your Favorite Brew

You may want to see also

Alcohol Content: Measuring alcohol by volume confirms fermentation

To determine if your beer is fermenting, one of the most reliable methods is to measure the alcohol by volume (ABV) content. This measurement is a direct indicator of the beer's fermentation progress and final alcohol level. Here's how you can use ABV to confirm fermentation:

Understanding ABV: Alcohol by volume is a standard measure of the volume of alcohol in a beverage relative to the total volume of the beverage. It is expressed as a percentage. For example, a beer with an ABV of 5% means that 5% of the beer's volume is alcohol. This measurement is crucial for brewers and homebrewers alike, as it provides insight into the beer's strength and the success of the fermentation process.

Measuring ABV: You can measure the ABV of your beer using various methods. One common approach is to use a hydrometer, which is a simple and affordable tool for homebrewers. A hydrometer measures the specific gravity of the beer, which is the ratio of the density of the beer to the density of water. By comparing the specific gravity reading to a standard hydrometer scale, you can calculate the ABV. Another method is to use a refractometer, which measures the sugar concentration in the beer, and then convert this to ABV.

Monitoring ABV Changes: As your beer ferments, the ABV will gradually increase. Initially, the beer will have a low ABV, typically around 1-2% during the early stages of fermentation. As the yeast consumes the sugars and produces alcohol, the ABV will rise. When the fermentation process is complete, the ABV will stabilize at the target level you set for your beer recipe. For example, a typical American Lager might have an ABV of around 4-5%, while a stronger ale could aim for 7-8% or higher.

Using ABV to Troubleshoot: If you notice that the ABV is not increasing as expected, it could indicate a problem with your fermentation. This might be due to issues like insufficient yeast, a faulty fermentation vessel, or an improper temperature control environment. Monitoring the ABV regularly allows you to identify and address these problems early in the brewing process. Additionally, if the ABV is too high, it may suggest over-fermentation, which can lead to off-flavors and a harsh taste.

By regularly measuring and monitoring the alcohol by volume, you can accurately determine when your beer has finished fermenting and has reached the desired alcohol content. This simple yet effective method is a valuable tool for both professional brewers and homebrew enthusiasts, ensuring consistent and high-quality beer production.

Mastering the Art of Beer Head: Tips and Tricks

You may want to see also

Frequently asked questions

Fermentation is a process that can be monitored through several signs. One of the most common indicators is a change in the beer's appearance. During fermentation, the beer will often become hazy or cloudy due to the formation of yeast and sediment. If you notice this change, it's a good sign that fermentation is taking place. Additionally, you can observe the beer's temperature; fermentation typically occurs between 65°F and 75°F (18°C and 24°C), so a drop in temperature is another sign to look out for.

Yes, the aroma of the beer can provide valuable insights. Fermenting beer often has a distinct, fruity, or estery smell, which is caused by the yeast consuming sugars and producing alcohol and carbon dioxide. This smell can vary depending on the yeast strain and the style of beer being made. If the beer starts to develop a strong, pungent, or sour odor, it might indicate an issue with the fermentation process or an infection.

Absolutely! Carbonation is a direct result of fermentation. As the yeast consumes sugars and produces alcohol, it also creates carbon dioxide, which dissolves in the beer, creating bubbles. If you notice an increase in carbonation, it's a good indication that fermentation is active. You can perform a simple float test by placing a few drops of beer in a glass of water. If the beer floats, it's likely well-fermented and ready for packaging.

Yeast is a crucial ingredient in beer fermentation. It is responsible for converting sugars (usually maltose) into alcohol and carbon dioxide. Different yeast strains produce unique flavors and characteristics in the beer. During fermentation, yeast activity can be monitored by observing the beer's clarity, temperature, and carbonation. Healthy yeast activity will result in a successful fermentation, while a lack of yeast activity or an issue with the yeast can lead to a stuck fermentation, where the process slows down or stops.