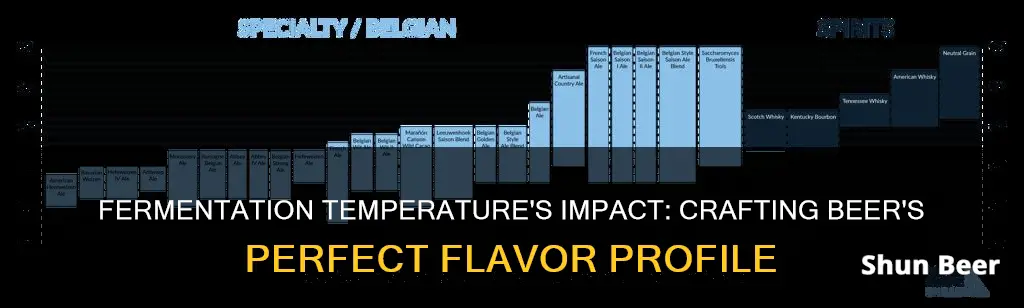

The temperature at which fermentation occurs is a critical factor in the brewing process, significantly impacting the final beer's characteristics. Fermentation temperature affects beer flavor, aroma, and overall quality. Higher temperatures can lead to faster fermentation, resulting in a more robust and bolder flavor profile. Conversely, lower temperatures may slow down the process, producing a cleaner and more delicate beer. Understanding the relationship between fermentation temperature and beer quality is essential for brewers to create consistent and desirable products.

| Characteristics | Values |

|---|---|

| Flavor and Aroma | Warmer fermentation temperatures can lead to more robust and fruity flavors, while cooler temperatures may result in a cleaner, more neutral beer. Higher temps can also enhance the presence of esters, which contribute to a banana or apple-like character. |

| Mouthfeel | Fermentation temperature can impact the beer's mouthfeel. Warmer conditions might produce a smoother, creamier texture, while cooler temps can make the beer feel more crisp and refreshing. |

| Alcohol Content | The temperature during fermentation can influence the final alcohol by volume (ABV) of the beer. Higher temps can lead to a higher ABV, as the yeast ferments more efficiently. |

| Cloudiness | Warmer fermentation can sometimes result in a hazy or cloudy appearance due to the presence of proteins and other compounds that are more stable at higher temperatures. |

| Color Intensity | Fermentation temperature may affect the color of the beer. Warmer conditions can sometimes lead to a darker, more roasted flavor profile, while cooler temps might preserve the natural color of the malt. |

| Flavor Balance | Optimal fermentation temps help achieve a well-balanced beer. Too high or too low temperatures can cause off-flavors, such as a "cardboard" or "spicy" taste. |

| Yeast Activity | Yeast activity is highly temperature-dependent. Warmer temps encourage faster fermentation, while cooler temperatures slow down the process, allowing for more controlled fermentation and potential for complex flavors. |

| Carbonation | The carbonation level can be influenced by fermentation temperature. Warmer conditions might result in higher carbonation, while cooler temps may produce a more subtle fizz. |

| Body and Dryness | Fermentation temperature can impact the beer's body and dryness. Warmer temps can create a fuller-bodied beer, while cooler fermentation may result in a lighter, drier finish. |

What You'll Learn

- Enzyme Activity: Fermentation temperature impacts enzyme kinetics, altering beer flavor and aroma profiles

- Sugar Fermentation: Higher temps increase sugar fermentation rate, affecting alcohol content and flavor intensity

- Flavor Development: Optimal temp range enhances flavor compounds, creating desired beer character and complexity

- Aroma Compounds: Temperature affects the formation of volatile compounds, influencing beer's aroma and character

- Cloudiness: Warmer fermentation may lead to cloudier beer due to protein aggregation and yeast activity

Enzyme Activity: Fermentation temperature impacts enzyme kinetics, altering beer flavor and aroma profiles

Enzyme activity plays a pivotal role in the fermentation process of beer, and temperature is a critical factor that significantly influences this activity. The impact of fermentation temperature on enzyme kinetics is a complex interplay of science and art, as it directly affects the flavor and aroma profiles of the final product. Here's an in-depth look at this fascinating aspect of brewing:

Understanding Enzyme Kinetics: Enzymes are biological catalysts that accelerate chemical reactions in living organisms. In the context of beer fermentation, enzymes break down complex carbohydrates like maltose into simpler sugars, primarily glucose. This process is essential for the yeast to metabolize and produce alcohol and carbon dioxide. The rate at which these enzymes catalyze reactions is influenced by temperature, following the principles of enzyme kinetics.

Temperature's Effect on Enzyme Activity: As the fermentation temperature rises, enzyme activity increases exponentially. This heightened activity leads to a faster breakdown of maltose, resulting in a quicker conversion of sugars. While this might seem beneficial, it can have unintended consequences. Higher temperatures can cause enzymes to denature, meaning they lose their structural integrity and, consequently, their ability to function optimally. This denaturation can lead to off-flavors and aromas in the beer.

Impact on Flavor and Aroma: The temperature-enzyme relationship has a direct bearing on the beer's sensory characteristics. Here's how:

- Sweetness: Warmer temperatures can lead to a faster fermentation process, potentially resulting in a less sweet beer. This is because the enzymes work more rapidly, converting sugars to alcohol at a faster rate, leaving fewer residual sugars.

- Aromatic Compounds: Enzymes also contribute to the formation of aromatic compounds during fermentation. Higher temperatures might enhance the production of certain esters and volatile compounds, which are responsible for fruity and floral aromas. However, excessive heat can lead to an overproduction of these compounds, resulting in an off-putting 'green' or 'spicy' character.

- Body and Mouthfeel: Temperature can also influence the beer's body and mouthfeel. Warmer fermentation can lead to a lighter-bodied beer, as the enzymes may not fully break down polysaccharides, leaving some residual body-contributing compounds.

Optimizing Fermentation Temperature: Brewers carefully control fermentation temperature to achieve the desired flavor and aroma profiles. They often employ a technique called 'temperature management' to regulate the process. This involves gradually increasing the temperature to an optimal range for enzyme activity and then maintaining it for a specific duration. This controlled approach ensures that enzymes work efficiently without denaturing, resulting in a well-balanced beer.

In summary, fermentation temperature is a critical variable in brewing, as it directly influences enzyme activity, which, in turn, shapes the beer's flavor, aroma, and overall character. Brewers must carefully consider these temperature effects to craft beers with the desired sensory attributes.

Crafting Beer's Perfect Flavor: Tips for a Tasty Brew

You may want to see also

Sugar Fermentation: Higher temps increase sugar fermentation rate, affecting alcohol content and flavor intensity

Sugar fermentation is a crucial process in brewing beer, as it directly influences the final product's alcohol content and flavor profile. When it comes to temperature, higher fermentation temperatures can significantly impact the rate of sugar fermentation, which in turn affects the beer's overall characteristics.

During sugar fermentation, yeast consumes sugars, primarily maltose, and converts them into ethanol (alcohol) and carbon dioxide. The temperature plays a pivotal role in this process. As the fermentation temperature increases, the yeast's metabolic activity accelerates. This heightened activity results in a faster breakdown of sugars, leading to a quicker fermentation process. Brewers often aim for a rapid fermentation to achieve a crisp and clean beer, especially in styles like pale lagers, where a swift fermentation contributes to the desired flavor and clarity.

However, the trade-off with higher temperatures is the potential for increased alcohol content. Warmer conditions encourage the yeast to produce more ethanol, which can lead to a higher alcohol by volume (ABV) in the final beer. This is particularly relevant for styles like IPAs or stouts, where brewers might aim for a more robust and alcoholic character. By adjusting the fermentation temperature, brewers can control the alcohol level, ensuring the beer meets the desired style guidelines.

Moreover, temperature variations during fermentation can impact the beer's flavor intensity. Higher temperatures may enhance the development of certain flavor compounds, such as esters and higher alcohols, which can contribute to fruity or spicy notes. For instance, a slightly warmer fermentation can result in a more complex and flavorful beer, especially in Belgian-style ales. Conversely, cooler temperatures might produce a cleaner and more neutral beer, which is often preferred in traditional German-style lagers.

In summary, sugar fermentation temperature is a critical factor in brewing, allowing brewers to manipulate the beer's alcohol content and flavor profile. Higher temperatures accelerate the fermentation process, increase alcohol production, and can influence the development of specific flavor characteristics. Understanding these effects enables brewers to create a wide range of beer styles, catering to diverse consumer preferences.

Sweet Surprise: The Impact of Sugar on Beer Flavor

You may want to see also

Flavor Development: Optimal temp range enhances flavor compounds, creating desired beer character and complexity

The temperature at which beer is fermented plays a crucial role in the development of its flavor profile. Fermentation is a complex process where yeast converts sugars derived from malted grains into alcohol and carbon dioxide. During this process, various flavor compounds are produced, and their concentrations can be significantly influenced by temperature.

Optimal fermentation temperatures are typically between 65°F and 72°F (18°C and 22°C). At these ranges, the yeast's activity is vigorous and efficient, leading to a robust and flavorful beer. Higher temperatures can cause the yeast to become less active, resulting in a slower fermentation process and potentially leading to off-flavors. On the other hand, lower temperatures might not allow the yeast to fully express its potential, resulting in a less complex flavor profile.

Within this optimal range, different beer styles can benefit from slightly varying temperatures. For instance, ales, which are generally fermented at higher temperatures, often thrive at the upper end of this range (around 70°F). This warmth encourages the production of fruity and estery notes, contributing to the characteristic flavors of styles like wheat beers and certain pale ales. In contrast, lagers, which are fermented at slightly lower temperatures, around 65-68°F, develop more crisp and clean flavors, often associated with pilsners and lagers.

The temperature also affects the rate of fermentation. Warmer temperatures accelerate the process, which can be advantageous for achieving a faster turn-around time in brewing. However, it's crucial to maintain a consistent temperature to prevent the formation of off-flavors, such as ethyl acetate, which has a nail polish remover-like character. Conversely, cooler temperatures slow down fermentation, allowing for more nuanced flavor development and the potential for a smoother, more balanced beer.

In summary, the optimal fermentation temperature range is essential for enhancing flavor compounds and creating the desired character and complexity in beer. It influences the yeast's activity, the rate of fermentation, and the overall flavor profile, making it a critical factor in the art of brewing.

Brewing Basics: Adding Hops for Flavor and Aroma

You may want to see also

Aroma Compounds: Temperature affects the formation of volatile compounds, influencing beer's aroma and character

The temperature at which beer fermentation occurs plays a pivotal role in the development of aroma compounds, which are essential for the beer's overall character and flavor profile. Fermentation temperature directly influences the activity of yeast, which is responsible for converting sugars into alcohol and carbon dioxide. This process, known as alcoholic fermentation, is a delicate balance that can significantly impact the beer's sensory qualities.

At lower fermentation temperatures, typically around 50-60°F (10-15°C), the yeast's activity slows down. This reduced activity can lead to a slower fermentation process, allowing more time for the formation of certain aroma compounds. During this cooler fermentation, the yeast may produce esters, which contribute to fruity and spicy notes in the beer. For example, iso-amyl alcohol, a precursor to the ester isobutyl alcohol, can be formed, resulting in a banana-like aroma. Additionally, lower temperatures can enhance the formation of volatile compounds like ethyl acetate, which gives off a sweet, apple-like scent. These compounds are highly volatile and evaporate during the brewing process, contributing to the beer's aroma.

Conversely, higher fermentation temperatures, often above 65°F (18°C), accelerate yeast activity. This rapid fermentation can lead to a quicker conversion of sugars but may also result in a less complex aroma profile. At these temperatures, the yeast may produce fewer esters and volatile compounds, leading to a beer with a more neutral aroma. However, it's important to note that the specific yeast strain used in brewing can also influence the aroma development at different temperatures. Some yeast strains are more active at higher temperatures, while others thrive in cooler conditions.

Understanding the relationship between fermentation temperature and aroma compounds is crucial for brewers aiming to create beers with distinct and desirable flavor profiles. By manipulating the fermentation temperature, brewers can control the yeast's activity and, consequently, the formation of volatile compounds. This allows for the production of beers with a wide range of aromas, from fruity and spicy to crisp and clean, all derived from the same base ingredients.

In summary, fermentation temperature significantly impacts the formation of aroma compounds in beer. Lower temperatures encourage the development of fruity esters and volatile compounds, while higher temperatures may result in a more neutral aroma. Brewers can harness this knowledge to craft beers with unique and appealing sensory characteristics, ensuring that each brew has its own distinct personality.

Mastering the Art of Hex Beer Nut: A Comprehensive Guide

You may want to see also

Cloudiness: Warmer fermentation may lead to cloudier beer due to protein aggregation and yeast activity

Cloudiness in beer can be an undesirable trait, often indicating the presence of unwanted particles or a lack of clarity. One significant factor that influences the clarity of beer is the fermentation temperature. Warmer fermentation temperatures can have a notable impact on the beer's appearance, leading to cloudier beer. This phenomenon is primarily attributed to two key processes: protein aggregation and yeast activity.

During the brewing process, proteins are present in the wort, which is the sugary liquid extracted from the malt. At higher temperatures, these proteins can undergo denaturation, where their structure changes, causing them to clump together. This protein aggregation results in the formation of small particles that remain suspended in the beer, leading to cloudiness. While some cloudiness can be desirable in certain styles, such as wheat beers, excessive cloudiness is generally undesirable.

Yeast plays a crucial role in fermentation, converting sugars into alcohol and carbon dioxide. However, at warmer temperatures, yeast activity can become more vigorous and less controlled. This increased activity can lead to the production of more carbon dioxide and the release of additional byproducts, including proteins and other compounds that contribute to cloudiness. As the yeast works more actively, it can cause the beer to become more turbid, especially if the yeast is not properly controlled or if the fermentation vessel is not adequately sanitized.

To mitigate the effects of warmer fermentation on cloudiness, brewers often employ specific techniques. One approach is to use cold-stream mashing, where the wort is cooled rapidly after mashing to prevent excessive protein denaturation. Additionally, proper yeast management is essential. Using yeast strains specifically designed for warmer temperatures or adjusting the yeast's activity through temperature control can help reduce cloudiness. Finally, ensuring thorough sanitization of the fermentation equipment is crucial to prevent any unwanted microbial growth that could contribute to cloudiness.

In summary, warmer fermentation temperatures can lead to cloudier beer due to protein aggregation and increased yeast activity. Brewers have various strategies to manage these issues, ensuring that the final product meets the desired clarity standards. Understanding these temperature-related effects is essential for brewers to produce high-quality, clear beers.

The Ancient Art of Beer Storage: Unlocking the Mystery of Barrels

You may want to see also

Frequently asked questions

Fermentation temperature plays a crucial role in shaping the final beer's profile. Higher temperatures can lead to faster fermentation, resulting in a more neutral beer with less esters and higher alcohol content. Lower temperatures, on the other hand, may slow down the process, allowing for the development of fruity and estery notes, which are common in styles like Belgian ales and some wheat beers.

Absolutely! Warmer fermentation temperatures can promote the formation of proteins and other compounds that cloud the beer, leading to a hazy appearance. Cooler temperatures often result in clearer beers, especially in the case of lagers, where a slow, controlled fermentation is desired.

The ideal temperature range varies depending on the style. For ales, a range of 65-75°F (18-24°C) is often recommended to encourage a robust flavor and aroma development. Lagers typically benefit from cooler temperatures between 50-55°F (10-13°C) to slow fermentation and develop clean, crisp flavors.

Temperature directly impacts yeast metabolism and activity. Warmer conditions can activate more yeast enzymes, leading to faster fermentation and potentially higher alcohol levels. Cooler temperatures may slow down the process, allowing for more controlled fermentation and the development of desired flavors and aromas.

Yes, pushing fermentation temperatures beyond the optimal range can lead to off-flavors and potential spoilage. Very high temperatures might cause a 'hot' or 'spicy' flavor, while extremely low temperatures can slow down fermentation too much, leading to a lack of carbonation and flavor development.