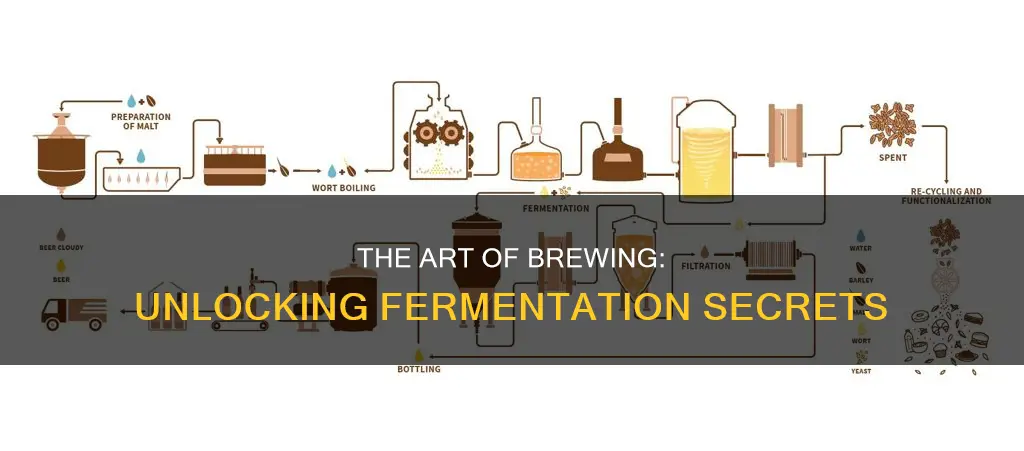

The process of brewing beer involves several intricate steps, and fermentation is a crucial phase that transforms the liquid from a sweet, sugary brew to the beverage we know and love. This stage is where the magic happens as yeast consumes the sugars left over from the malted grains and converts them into alcohol and carbon dioxide, creating the characteristic flavors and aromas of beer. Understanding the fermentation process is essential for brewers to control the outcome and create the desired beer style, whether it's a crisp, refreshing lager or a rich, dark stout.

What You'll Learn

- Malting: Grains are soaked, germinated, and dried to create malt, the base ingredient for beer

- Mashing: Malts are crushed and mixed with hot water to extract sugars

- Boiling: Hops are added to the wort for bitterness and flavor

- Fermentation: Yeast converts sugars into alcohol and carbon dioxide, creating the beer's character

- Bottling: Beer is packaged, often with added priming sugar for natural carbonation

Malting: Grains are soaked, germinated, and dried to create malt, the base ingredient for beer

Malting is a crucial process in the art of brewing, transforming simple grains into the foundation of beer production. This intricate procedure begins with the selection of specific grains, primarily barley, although wheat, rye, and other malted grains can also be used. The process involves a series of steps that unlock the grain's potential, releasing enzymes that will later convert starches into fermentable sugars.

The first step in malting is soaking. Grains are thoroughly cleaned and then soaked in water for a period, typically several hours or even overnight. This soaking process activates the enzymes within the grain, initiating the germination process. Germination is essential as it breaks down the starches in the grain into simpler sugars, primarily maltose, which will serve as the energy source for the yeast during fermentation.

After soaking, the grains are drained and spread out in a controlled environment to allow the germination process to continue. This environment is carefully monitored to ensure the right temperature and humidity levels, which are critical for successful germination. During this phase, the grains' color may darken, and they might develop a slightly sweeter aroma due to the breakdown of proteins and the production of enzymes.

Once the germination reaches the desired stage, the malted grains are separated from the germination medium and dried. This drying process is crucial as it halts the germination and stabilizes the malt. The grains are dried in specialized dryers, often using hot air, to ensure even drying and prevent any loss of quality. The malt is then crushed to remove the husk and expose the inner kernel, which is now ready for the next stage of brewing.

This process of malting is a delicate balance of science and art, requiring precise control over temperature, moisture, and time. It is a fundamental step in the beer-making process, setting the stage for the subsequent stages of brewing, mashing, and fermentation, where the magic of transforming grain into beer truly comes to life.

The Surprising Reason Green Olives Belong in Beer

You may want to see also

Mashing: Malts are crushed and mixed with hot water to extract sugars

Mashing is a crucial step in the beer-making process, where the magic of transforming grain into liquid gold begins. It involves a careful and precise technique to extract the sugars from the malted grains, which will later be fermented by yeast to create alcohol. This process is an art and a science, requiring attention to detail and a deep understanding of the ingredients and their interactions.

The mashing process starts with the malt, which is a crucial ingredient in beer production. Malted grains, typically barley, are carefully selected and prepared to ensure they are ready for the next stage. These grains are first crushed or milled to break their hard outer shells, exposing the starchy interior. This step is essential as it increases the surface area of the grain, allowing for better contact with the hot water in the subsequent stages.

Once crushed, the malt is mixed with hot water in a process known as mashing. This mixture is called the 'mash' and is maintained at a specific temperature, usually around 65-67°C (150-153°F). The temperature is carefully controlled as it directly affects the efficiency of sugar extraction. At this temperature, the enzymes in the malt, known as amylases, begin to break down the complex starches in the grain into simpler sugars, primarily maltose. This process is called saccharification, and it is a critical step in the fermentation process.

During mashing, the mixture is agitated to ensure even contact between the grains and the hot water. This agitation helps to extract as much sugar as possible from the malt. The duration of the mash can vary, typically lasting between 60 to 90 minutes, depending on the style of beer being produced and the desired sugar profile. After this period, the mixture is drained, separating the sweet liquid (the wort) from the spent grain.

The wort, now rich in sugars, is then cooled and prepared for the next stage: lautering and boiling. Lautering is the process of separating the wort from the grain husks, ensuring a clear and sugary liquid. This is followed by boiling, where the wort is heated to sterilize it and activate the hops, which contribute bitterness and flavor to the beer. This boiling process also begins the process of concentrating the sugars, setting the stage for the final fermentation step.

Mastering Beer Flavor: The Art of When to Add Hops

You may want to see also

Boiling: Hops are added to the wort for bitterness and flavor

The boiling stage is a crucial step in the beer-making process, as it is during this phase that the hops are introduced to the wort, contributing their distinct bitterness and aromatic qualities. Hops, a flower cluster of the hop plant, have been used for centuries in brewing to balance the sweetness of the malt and add a range of flavors, from citrusy and fruity to earthy and resiny.

When the wort reaches a rolling boil, the brewers carefully add the hops in a specific sequence, often following a schedule known as a 'hop schedule'. This schedule ensures that the hops are added at the right time to extract the desired flavors and aromas without contributing excessive bitterness. The first addition of hops, often called the 'bitter' or 'bittering' hops, is typically added at the beginning of the boil to provide the initial bitterness. This is followed by additional hop additions at various stages of the boil, each contributing a different flavor profile. For example, late hop additions can provide a more subtle, aromatic flavor, while dry-hopping, where hops are added towards the end of the boil, can create a more pronounced hop character in the final beer.

The duration of the boil also plays a significant role in the beer's characteristics. A longer boil can extract more bittering compounds from the hops, resulting in a more bitter beer. Conversely, a shorter boil might preserve more of the hop's volatile aromas, leading to a more fragrant, floral beer. Brewers often use this technique to create a balance between bitterness and aroma, ensuring the beer's overall quality.

After the hops have been added, the wort is then cooled, typically using a heat exchanger or a cooling jacket, to a temperature that is safe for yeast to ferment. This step is essential to prevent any unwanted microbial growth and to maintain the integrity of the beer's flavor. The boiling process, combined with the careful addition of hops, significantly influences the beer's final character, making it a critical phase in the art of brewing.

Fermenter Filling: Essential Tips for Perfect Beer Brewing

You may want to see also

Fermentation: Yeast converts sugars into alcohol and carbon dioxide, creating the beer's character

Fermentation is a crucial step in the beer-making process, where the magic of transforming simple sugars into the complex beverage we love happens. This process is primarily driven by a tiny but mighty microorganism called yeast. Yeast is a single-celled organism that plays a pivotal role in the fermentation process, acting as a catalyst for the conversion of sugars into alcohol and carbon dioxide. This transformation is not just a chemical reaction but a complex biological process that significantly influences the final character and quality of the beer.

During fermentation, yeast consumes the sugars present in the wort (the sugary liquid extracted from malted grains) and, in a series of biochemical reactions, breaks down these sugars into two primary products: ethanol (alcohol) and carbon dioxide (CO2). This process is highly efficient and selective, as yeast has evolved to optimize the breakdown of specific sugars found in malted grains, primarily maltose. The efficiency of this conversion is a critical factor in determining the beer's final alcohol content and flavor profile.

The yeast's role in fermentation is not just about creating alcohol; it also contributes to the beer's unique characteristics. Different strains of yeast produce distinct flavors and aromas, which are essential in defining the style and quality of the beer. For instance, ale yeasts tend to produce fruity and estery notes, while lager yeasts are known for their clean and crisp profiles. This diversity in yeast strains allows brewers to craft a wide range of beer styles, from the crisp and refreshing lagers to the rich and complex stouts.

The fermentation process also influences the beer's carbonation level. As yeast ferments, it releases carbon dioxide, which, when captured and dissolved in the beer, creates the characteristic fizz. The amount of CO2 produced and its solubility in the beer determine the beer's carbonation level, which is a critical aspect of the drinking experience. Breweries often control the fermentation conditions, such as temperature and duration, to manage the yeast's activity and, consequently, the beer's carbonation.

In summary, fermentation is a complex and fascinating process that transforms sugars into alcohol and carbon dioxide, shaping the beer's character. Yeast, the unsung hero of this process, plays a critical role in breaking down sugars, producing alcohol, and contributing to the unique flavors and aromas that define different beer styles. Understanding the science behind fermentation allows brewers to craft beers with consistent quality and character, ensuring that every sip is a delightful experience.

Troubleshooting Stuck Fermentation: Tips for Rescuing Your Beer

You may want to see also

Bottling: Beer is packaged, often with added priming sugar for natural carbonation

The process of bottling beer is a crucial step in the brewing journey, as it allows for the final product to be packaged and distributed. Once the beer has been fermented and the yeast has completed its work, it's time to prepare the bottles for the final stage of carbonation. This is where the concept of priming sugar comes into play, a technique that has been used for centuries to carbonate beer naturally.

Before bottling, brewers carefully measure and add a specific amount of priming sugar to each bottle. This sugar is typically a type of malt extract or dextrose, which is designed to be rapidly fermented by yeast. The addition of priming sugar serves a dual purpose. Firstly, it provides a source of energy for the yeast, allowing them to continue their work and produce carbon dioxide even after the primary fermentation in the brew kettle. This ensures that the beer remains carbonated and refreshing. Secondly, the yeast's activity in the bottle creates a secondary fermentation, which is responsible for the natural carbonation that beer enthusiasts love.

When the bottles are filled, the priming sugar is dissolved in the small amount of beer left in the bottle, creating a carbonated environment. This is a delicate process, as too much sugar can lead to excessive carbonation, while too little may result in flat beer. The yeast then begins to work on this new sugar source, producing carbon dioxide and alcohol, which are trapped in the bottle due to the pressure created by the yeast's activity. This natural carbonation process can take a few days to a week, depending on the style of beer and the yeast used.

After bottling, the beer is stored at a controlled temperature to allow the yeast to work efficiently. During this time, the beer may develop some sediment, which is normal and can be shaken out when the beer is served. The natural carbonation process is a fascinating aspect of homebrewing and craft beer, as it mimics the traditional methods used by ancient brewers. This technique not only adds a unique flavor profile but also contributes to the beer's overall character and mouthfeel.

In summary, bottling beer with added priming sugar is an art that requires precision and an understanding of yeast behavior. It allows brewers to create naturally carbonated beer, which is highly sought after by beer enthusiasts worldwide. This final step in the brewing process ensures that the beer's character is preserved and that the final product is ready to be enjoyed.

Crafting the Perfect Beer Garden: A Microbrewery's Guide

You may want to see also

Frequently asked questions

The fermentation time for beer can vary significantly depending on several factors, including the style of beer, the yeast used, and the brewing process. Typically, the primary fermentation phase lasts around 7 to 14 days, during which the yeast consumes the sugars and produces alcohol and carbon dioxide. However, some brewers might perform a secondary fermentation or aging process, which can extend the total fermentation period to several weeks or even months.

Several elements can impact the fermentation time: yeast type, starting gravity (sugar content), temperature control, and the desired beer style. Different yeast strains have varying fermentation rates, with some being faster and others slower. Temperature is crucial; warmer temperatures generally speed up fermentation, while cooler temperatures slow it down. The style of beer also plays a role; for example, a robust stout might take longer to ferment compared to a light lager.

Yes, there are ways to encourage faster fermentation. One common method is to use a campden tablet (potassium metabisulfite) to raise the specific gravity, which can stimulate yeast activity. Increasing the yeast temperature (within safe limits) can also accelerate the process. Additionally, ensuring proper aeration and nutrient availability for the yeast can help speed up fermentation. However, it's essential to monitor the beer's progress and not rush the process, as rushing can lead to off-flavors and quality issues.