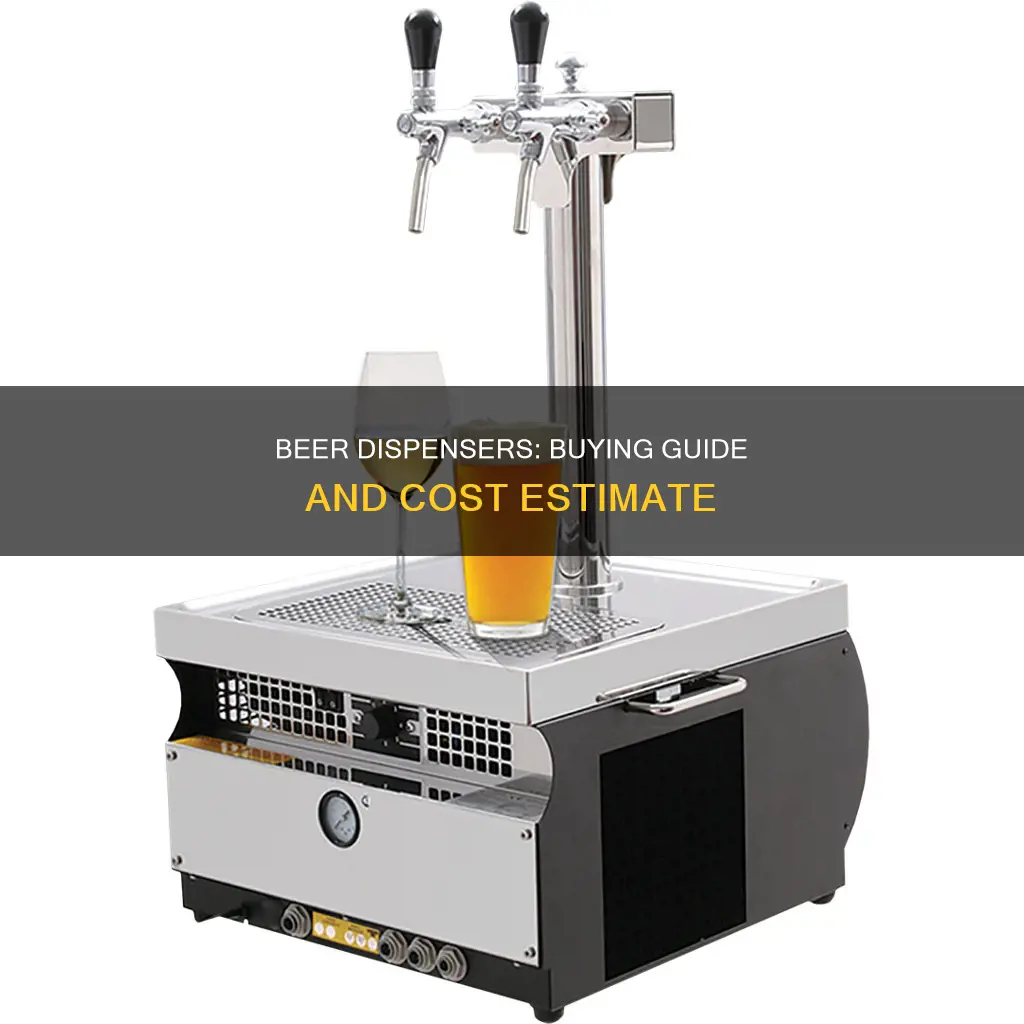

The cost of a beer dispenser varies depending on the type, quality, and features offered by the product. Basic home beer dispensers can be purchased for as little as $43, with more advanced models with features such as LED lights and ice tubes ranging from $86 to $444. Commercial beer dispensers, on the other hand, can cost upwards of $669, with some self-serve beer systems for bars and restaurants costing several thousand dollars. These systems often include multiple taps, digital temperature control, and other features tailored to the needs of businesses. Installation costs for draft systems can range from $700 to $1000 per tap, and additional expenses such as licensing and support fees may also apply. Ultimately, the price of a beer dispenser depends on the specific needs and budget of the buyer.

What You'll Learn

Self-serve beer dispensers

Customers are issued an RFID card or wristband, which they can load with a dollar amount or link to a credit card. They then place the card in the slot above the tap of their desired beverage and the system recognises the card, granting access. The customer can see their available funds on the main display, as well as a real-time meter that goes down as they pour.

For customers, the most obvious benefit is the amount of time saved. They can dispense their chosen beverage in the quantity they want, whenever they want, without having to queue at the bar. For business owners, self-pour taps bring increased profit from boosted beverage consumption. Customers tend to taste many drinks before finding their favourite, which increases the overall amount spent relative to a regular bar. Self-pour technology also reduces product waste, as there are no free samples, and staff no longer need to spend time pulling pints.

The cost of self-serve beer systems varies depending on the size and scope of the system. Installation of a draft system is usually performed by local companies specialising in draft systems and prices run from $700 to $1000 per tap installed. There are also fixed costs for items such as cabinets, the onsite server, and network equipment, which range from $2100 for a few taps to $3500 for larger projects. Table units with taps installed are convenient for customers and can cost anywhere from $1000 to $9000. Beer wall taps can cost up to $1300 per tap, and you will also need to budget for an administration monitor or full EPOS system, which can cost up to $3000.

If you're interested in finding out more about self-serve beer dispensers, you can contact companies such as PourMyBeer or iPourIt for a free quote and more information.

Kegs of Beer: Where and How to Buy Them

You may want to see also

Commercial vs. home beer dispensers

Commercial beer dispensers are designed for use in bars, restaurants, and other commercial settings, while home beer dispensers are smaller, more compact devices designed for personal use at home. Here are some key differences between the two:

Size and Capacity

Commercial beer dispensers are typically larger and more bulky to accommodate higher volumes of beer. They often hold half-barrel kegs or multiple kegs at once, making them ideal for busy bars or restaurants. In contrast, home beer dispensers are designed to be more compact and fit easily on kitchen countertops or home bars. They usually hold smaller kegs or cans/bottles of beer, making them suitable for personal use or small gatherings.

Features and Functionality

Commercial dispensers often have advanced features such as digital temperature control, self-closing doors, and lockable castors for durability and convenience in commercial environments. Some even have self-pour technology, allowing customers to serve themselves and reducing the need for additional staff. On the other hand, home beer dispensers may have basic features like adjustable temperature settings, drip trays, and recyclable kegs. Some home dispensers also offer smart capabilities, such as connecting to smartphones and providing notifications when the beer is running low.

Installation and Maintenance

Commercial beer dispensers often require professional installation and may need to be hardwired into the establishment's electrical system. They are designed for frequent and continuous use, so maintenance and cleaning are important to ensure optimal performance. Home beer dispensers, on the other hand, usually have a plug-and-play design and can be easily set up and maintained by the user. While some home dispensers may require carbonation canisters or additional accessories, many are designed to be user-friendly and straightforward to use.

Cost

Given their advanced features and higher capacity, commercial beer dispensers tend to be significantly more expensive than home beer dispensers. Commercial dispensers with self-pour technology can cost several thousand dollars, while basic home beer dispensers can be purchased for a few hundred dollars or less.

Aesthetics and Design

Commercial beer dispensers often have a more industrial look, focusing on functionality and durability. In contrast, home beer dispensers come in a variety of styles, from sleek and modern designs to old-fashioned pub-style taps, allowing users to choose a dispenser that fits their home décor and personal preferences.

In summary, commercial beer dispensers are built for heavy-duty use in bars and restaurants, offering advanced features, higher capacities, and a more professional appearance. Home beer dispensers, on the other hand, are designed for personal use, offering convenience, compact sizes, and a variety of styles to suit different tastes and budgets.

Buying Beer in Wisconsin: Late-Night Shopping Rules Explained

You may want to see also

Beer dispenser features

There are a variety of beer dispenser features to consider when making a purchase. The type of dispenser that is best suited for your needs will depend on several factors, including whether it is for commercial or residential use, the desired capacity and level of automation, and any additional features that may enhance the user experience.

Commercial vs Residential

Beer dispensers can be designed for either commercial or residential use, with commercial dispensers typically being more robust and featuring multiple taps, while residential dispensers are often smaller, single-tap units designed to fit on a countertop.

Capacity

The capacity of a beer dispenser will depend on the size of the unit and the type of container it uses. Dispensers that utilise kegs will have a larger capacity than those that use cans or bottles, with some residential units being able to accommodate 1/6, 1/4, or 1/2 barrels.

Automation

Some beer dispensers feature automated pouring technology, which can be beneficial for both commercial and residential users. For commercial users, this can increase serving efficiency and reduce labour costs, while for residential users, it can provide the convenience of not having to manually pour each drink.

Additional Features

Beer dispensers can also include a range of additional features, such as:

- Temperature control to ensure the beer is served at the optimal temperature

- Drip trays to catch any excess liquid and keep the dispensing area clean

- CO2 cylinders to maintain carbonation and keep the beer fresh

- LED lights that illuminate the dispenser, enhancing the visual appeal

- Portable designs that make it easy to transport the dispenser to different locations

Buying Beer on Thanksgiving in New Mexico

You may want to see also

Beer dispenser costs

The cost of a beer dispenser varies depending on the type, quality, and features included. Here is an overview of the costs associated with purchasing a beer dispenser:

Self-Serve Beer Systems for Businesses:

Self-serve beer systems are becoming increasingly popular in bars, pubs, and restaurants. These systems offer benefits such as reduced wait times for customers and decreased labour costs for businesses. The cost of a self-serve beer system can vary depending on the number of taps, features, and installation requirements.

- Fixed Costs: These are one-time payments that cover the cost of the taps, cabinets, onsite server, and network equipment. They can range from $2,100 for a few taps to $3,500 for larger projects.

- Table Units: These are taps installed on tables for convenient customer access. They typically include mounted screens, a flow controller, and an RFID reader. The cost of table units can range from $1,000 to $9,000.

- Beer Wall Taps: Beer walls can be installed on any wall and typically include multiple taps per screen. The cost of beer wall taps can be up to $1,300 per tap.

- Administration Monitor/Full EPOS: This is the system used by staff to oversee self-serve beer operations. It can be a mobile device or a full workstation and typically includes a cash drawer and card reader. The cost of an EPOS system can range from $350 to $3,000.

- Network Cabling and Power Sockets: The cost of installing the necessary cabling and power sockets can range from $2,500 to $4,500, depending on the contractor and the existing infrastructure.

- Running Beer Lines: Installing new beer lines and cellar equipment can cost around $1,000 per beer line.

- License and Support Fees: Some companies may charge monthly or annual fees for the use of their technology and tech support, starting at about $21 per month per tap.

Residential Beer Dispensers:

For home users who want to enjoy draft beer at home, there are various options available at different price points.

- Kegerators: These are refrigerators designed to store and dispense kegs of beer. They can range in price from a few hundred dollars to over $1,000, depending on the size, features, and quality. For example, the Ivation Full Size Kegerator is priced at $443.99, while the VEVOR Beer Kegerator is priced at $669.99.

- Portable Draft Beer Systems: These are smaller, more compact systems that are easy to transport and set up. They typically use smaller kegs or cans/bottles of beer. The cost of portable draft beer systems can vary from a few dozen dollars to a few hundred dollars. For instance, the FIZZICS DraftPour Beer Dispenser is priced at $186.61, while the GREEN HOUSE Mini Kegerator is a more affordable option at $83.14.

- Beer Towers: Beer towers are large dispensers that hold multiple litres of beer and are often used for parties or events. They typically include an ice tube to keep the beer cold and can have additional features such as LED lights. The cost of beer towers can range from a few dozen dollars to a few hundred dollars, depending on the size and features. For example, the Hammer + Axe Beverage Drink Dispenser is priced at $49.99, while the Lallisa 4 Pack Beer Dispenser is a more expensive option at $149.99.

Buying Beer on Sundays in North Dakota: Is It Legal?

You may want to see also

Beer dispenser maintenance

Kegerators

Kegerators are refrigerated beer dispensers that can hold one or multiple kegs of beer. To set up a kegerator, you will need to assemble the following components: casters, beer dispenser, tap tower(s), faucet, regulator, CO2 cylinder, coupler, and tubing lines. The process typically involves the following steps:

- Install casters (if applicable) on the bottom of the unit.

- Secure the tap tower(s) onto the beer dispenser.

- Mount the faucet to each tap tower.

- Connect the gas line tubing to the CO2 regulator with the shut-off valve closed.

- Attach the regulator to the closed CO2 cylinder, securing it with a tool if necessary.

- Locate the tank mount and secure the cylinder inside.

- Tap each keg by connecting its coupler, gas line tubing, and beer line according to the manufacturer's instructions.

- Place the keg(s) inside the unit, and it is ready to serve.

To maintain a kegerator, it is important to keep the outside of the keg refrigerator clean using normal cleaning agents. The beer lines should also be cleaned regularly, as they can collect deposits of yeast and sugars that can impact the taste of the beer and cause excess foaming. It is recommended to clean the beer lines after every 1/2 keg, using a beer line cleaning kit and a cleaning solution to eliminate deposits and sanitise the lines.

Jockey Boxes

Jockey boxes are portable solutions for serving beer and resemble coolers. They typically have 1-4 taps to connect to kegs. To set up a jockey box, you will need the box, beer line, coils, two shanks for each tap, a faucet for each set of shanks, and a CO2 cylinder with its regulator. The assembly process involves:

- Closing the faucet(s) to prevent spillage.

- Placing the coils inside the box and attaching the shanks according to the manufacturer's instructions (they may already be pre-assembled).

- Attaching the beer line to the shank at the back of the box and then to the keg coupler.

- Attaching the keg coupler to the keg, pulling and twisting to tap it, and then attaching the coupler to the CO2 tank.

- Adjusting the tank pressure to the proper setting (typically around 25 psi).

- Filling the jockey box about 2/3 with ice and then topping it up with water.

- Opening the faucet(s) and serving the beer.

Outdoor Kegerators

Outdoor kegerators are similar to their indoor counterparts but are designed to withstand outdoor conditions. The setup process is generally the same as for indoor kegerators.

Common Issues and Troubleshooting

- Beer won't dispense or is dispensing slowly: Check if the keg is empty and replace it if necessary. Ensure the gas cylinder is not empty and that the gas is turned on. Verify that the keg is tapped correctly and that the beer lines are not frozen.

- Foamy beer: Ensure the draft cooler is maintained at the correct temperature (36-38 degrees Fahrenheit). Avoid using frozen glasses, as this can cause foaming and numb customers' taste buds. Check that the beer lines are at the proper serving temperature for the specific beer. Train staff on how to properly dispense beer. Adjust the pressure in your system to the recommended range for the type of beer (10-12 PSI for US ales and lagers, 25-30 PSI for stouts and other styles). Clean the beer tap system if the lines are dirty.

- Flat and tasteless beer: Ensure the beer is stored and served at the correct temperature (36-38 degrees Fahrenheit for barrels, with lines refrigerated or insulated). Use specific bar glass chemicals to clean glasses, as standard detergents can leave a film. Ensure there is enough pressure in your system by checking the gas cylinder's PSI and securing the coupler. Do not use an air compressor for pressure, as air will not carbonate the beer. Check for obstructions in the tap lines.

- Beer won't hold a head: Use wet beer glasses instead of dry ones. Ensure the pressure matches the beer temperature by consulting the supplier for proper temperatures and pressures. Check that the coils in the beer lines are not warmer than the beer in the keg and inspect the insulation for damage.

- Cloudy beer: Avoid over-chilling the beer in the keg or beer lines, as this can cause ice to form and make the beer cloudy. Regularly clean the beer lines and taps to prevent yeast and sediment buildup. Inspect and maintain carbon dioxide cylinders to prevent rust and contamination.

- Unusual taste or smell: Clean the beer lines and faucets regularly to prevent buildup. Ensure the beer lines are flushed properly between kegs with clean water. Check the temperature settings of the beer dispenser and the keg, and look for hot spots. Inspect the gas cylinders for rust or contamination and replace if necessary. Use specific beer glass chemicals and sanitizers to clean the glasses. Serve beer before its freshness date (non-pasteurized beer: 45-60 days; pasteurized beer: 90-120 days).

Kwik Trip Neenah: Beer Buying Experience

You may want to see also

Frequently asked questions

Self-serve beer dispensers can be made up of several parts, and the size and scope of each part influence the price of the system. Installation of a draft system is typically performed by local companies that specialize in draft systems and prices run about $700-$1000 per tap installed. Fixed costs for self-serve beer taps range from $2100 for a few taps to $3500 for larger projects.

The cost of a self-pour beer system can vary depending on the number of taps, the type of system, and the company providing the system. Table units with mounted screens, a flow controller, and an RFID reader can range from $1000 to $9000. Beer wall taps can cost up to $1300 per tap.

The cost of a draft beer system for a bar can vary depending on the specific equipment and parts needed. KegWorks offers a range of equipment for draft beer systems, including keg couplers, draft faucets, towers, drip trays, and beer line cleaning equipment.

There are several affordable options for beer dispensers available on Amazon, ranging from $43 to $187. These include the OGGI Beer Tower, the FIZZICS DraftPour Beer Dispenser, and the GREEN HOUSE Cocktail and Draft Beer Dispenser.