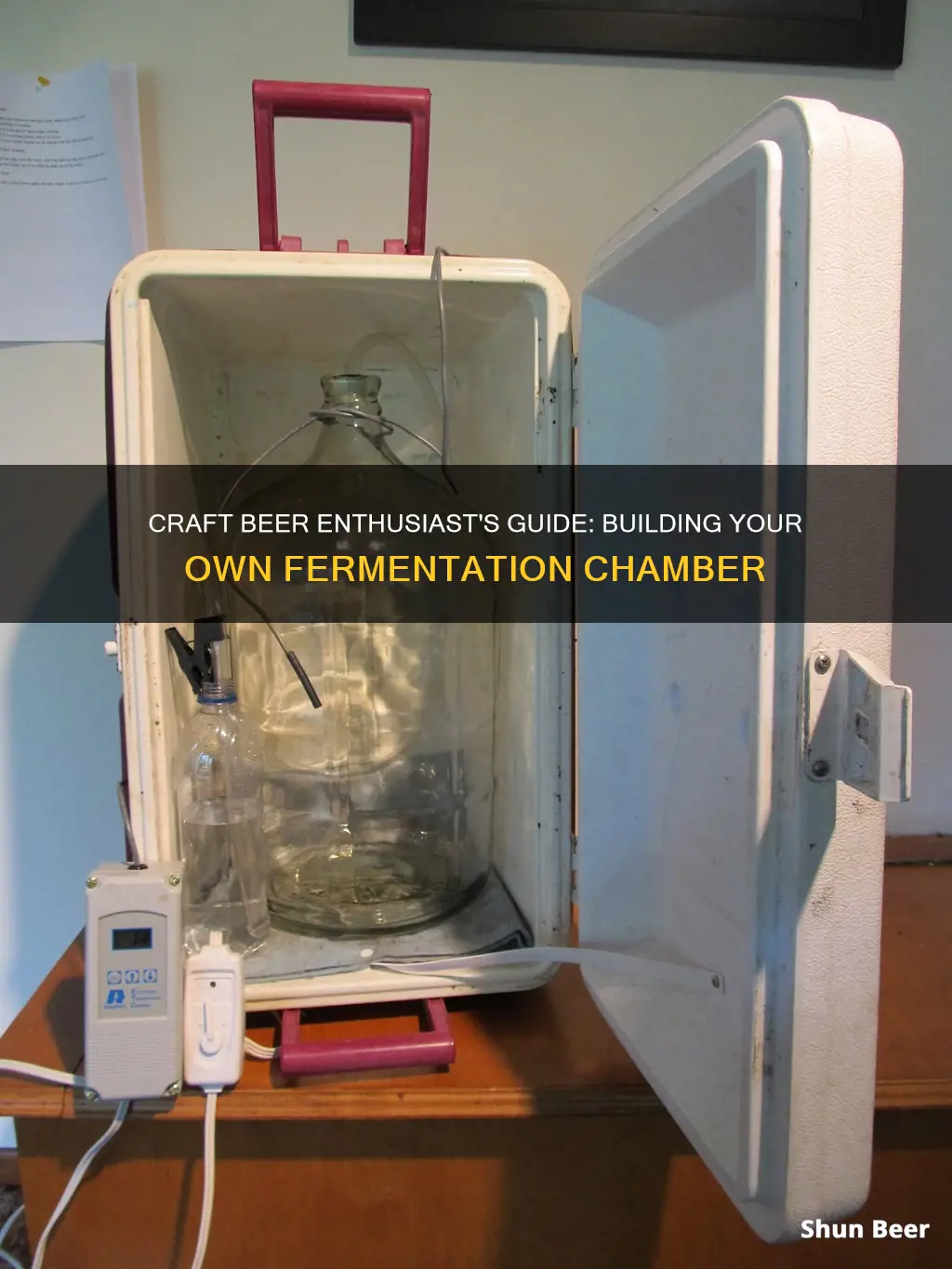

Building a beer fermentation chamber is an exciting project for any homebrewer looking to take their craft to the next level. This guide will provide a step-by-step overview of the process, covering essential components such as materials, design considerations, and setup instructions. From choosing the right size and insulation to selecting appropriate temperature control systems, we'll ensure your chamber is optimized for efficient fermentation. Whether you're a beginner or an experienced brewer, this comprehensive guide will equip you with the knowledge to create a professional-grade fermentation environment for your beer.

What You'll Learn

- Materials: Gather insulation, a fermenter, a lid, and a temperature controller

- Insulation: Use foam or fiberglass to maintain a consistent temperature

- Fermenter: Choose a suitable size and material for your beer batch

- Temperature Control: Maintain a stable fermentation temperature with a heating pad or cooler

- Airflow: Ensure proper ventilation to prevent off-flavors and maintain yeast health

Materials: Gather insulation, a fermenter, a lid, and a temperature controller

To build a beer fermentation chamber, you'll need to gather specific materials to ensure a controlled and efficient environment for your brewing process. Here's a detailed breakdown of the essential components:

Insulation: Proper insulation is crucial to maintaining the desired temperature and preventing heat loss. You can opt for various insulation materials, such as polystyrene foam, fiberglass, or even a combination of both. Ensure that the insulation is thick enough to provide adequate thermal resistance. Consider the size of your fermenter and choose insulation that can envelop the entire chamber, including the sides and bottom.

Fermenter: The fermenter is the primary container where the magic happens. It should be made of food-grade material, such as stainless steel or glass, to ensure the safety and quality of your beer. Choose a size that suits your brewing needs, typically ranging from 5 to 60 gallons. Ensure the fermenter has a wide mouth or a lid that can accommodate a temperature controller and other accessories.

Lid: A well-fitted lid is essential to seal the fermenter and maintain the desired temperature. It should be made of a material that allows for temperature control, such as a metal lid with insulation or a glass lid with a thermometer. The lid should also have a secure closure mechanism to prevent air leaks and maintain the integrity of the fermentation process.

Temperature Controller: This device is the heart of your fermentation chamber's temperature regulation. It allows you to set and maintain a precise temperature, which is crucial for yeast activity and flavor development. You can choose between various types, such as a digital controller with a PID (Proportional-Integral-Derivative) function or a simple thermostat. Ensure it is compatible with your fermenter's lid and can control the temperature accurately.

By gathering these materials, you'll have the foundation for building an effective beer fermentation chamber. Remember to consider the size and compatibility of each component to ensure a seamless brewing experience.

Mastering the Art of Beer Application: A Guide to Pouring Perfection

You may want to see also

Insulation: Use foam or fiberglass to maintain a consistent temperature

Insulation is a critical component of any beer fermentation chamber, as it helps to maintain a consistent temperature, which is essential for the fermentation process. The goal is to create an environment that mimics the ideal fermentation conditions, typically around 65-75°F (18-24°C). Using insulation materials like foam or fiberglass can significantly contribute to achieving and sustaining this temperature range.

Insulation with Foam:

One popular choice for insulation in beer fermentation chambers is spray foam. This type of insulation is applied as a liquid and expands to fill the space, creating a dense, airtight barrier. Spray foam is excellent for sealing gaps and crevices, ensuring that the temperature-controlled environment inside the chamber is not compromised. It provides a high level of thermal resistance, meaning it can effectively prevent heat transfer, keeping the chamber cool during summer months and warm in colder climates. When using spray foam, it's important to follow the manufacturer's instructions for application and ensure proper ventilation during and after the process.

Fiberglass Insulation:

Fiberglass insulation is another traditional and effective option. It consists of tiny glass fibers that are bonded together to form a lightweight, rigid material. Fiberglass can be installed in various forms, such as batts or loose-fill, making it versatile for different chamber designs. This insulation material is known for its excellent thermal properties, providing high resistance to heat flow. It is also durable and can withstand the moisture and humidity levels present in a fermentation chamber. When installing fiberglass, it's crucial to wear protective gear, as the glass fibers can be irritant, and ensure proper ventilation to avoid inhaling any fibers.

Both foam and fiberglass insulation offer effective ways to regulate temperature in your beer fermentation chamber. The choice between the two may depend on personal preference, the specific design of your chamber, and the climate in which it will be used. Proper insulation will not only help maintain the desired fermentation temperature but also contribute to energy efficiency, reducing the overall cost of operating your brewing setup.

Mastering the Art of Pork Butt: Beer's Role in Pan Cooking

You may want to see also

Fermenter: Choose a suitable size and material for your beer batch

When building a beer fermentation chamber, one of the most critical decisions you'll make is choosing the right fermenter for your beer batch. The fermenter is the vessel where the magic happens, where yeast transforms sugars into alcohol and carbon dioxide. Selecting the appropriate size and material is essential to ensure optimal fermentation and the quality of your brew.

Size matters when it comes to fermenters. The volume of your fermenter should be proportional to the size of your beer batch. For homebrewing, a typical batch might range from 5 to 10 gallons (19 to 38 liters). As a general rule, a larger batch requires a proportionally larger fermenter to accommodate the increased volume of wort (the sugary liquid extracted from malted grains). A 6- to 8-gallon (23 to 30-liter) fermenter is a common choice for beginners, offering enough space for most homebrewing projects. However, if you plan to brew larger batches or experiment with different styles, consider a 10- to 15-gallon (38 to 57-liter) fermenter, which provides more headspace and flexibility.

The material of the fermenter is another crucial factor. Traditional glass carboys are a popular choice for homebrewers, offering a clear view of the fermentation process and easy cleaning. Glass is inert, meaning it doesn't react with the wort or yeast, ensuring a pure and consistent fermentation. However, glass can be heavy and fragile, and some brewers prefer the convenience of plastic or stainless steel fermenters. Plastic fermenters, often made from food-grade materials like PET or HDPE, are lightweight, durable, and less prone to breakage. They are also more affordable and easier to store. Stainless steel fermenters, typically used in commercial breweries, offer excellent durability and hygiene. They are rust-resistant and can withstand high temperatures, making them ideal for extended fermentation periods.

Additionally, consider the shape and design of the fermenter. Some fermenters have a narrow neck, which can be beneficial for transferring wort and cleaning, while others have a wide mouth, making it easier to add ingredients or inspect the fermentation process. Choose a shape that suits your brewing setup and personal preferences.

In summary, selecting the right fermenter size and material is a critical aspect of building a beer fermentation chamber. It ensures that your beer batch has enough space to ferment properly and that the material of the fermenter doesn't interfere with the brewing process. By considering the batch size, material options, and design features, you can make an informed decision to create the perfect environment for your beer to ferment and mature.

Uncorking the Mystery: Does Ginseng Brew Beer's Fermentation?

You may want to see also

Temperature Control: Maintain a stable fermentation temperature with a heating pad or cooler

When building a beer fermentation chamber, temperature control is crucial to ensure the yeast performs optimally and the beer develops the desired flavors. One effective method to maintain a stable fermentation temperature is by utilizing a heating pad or cooler. Here's a detailed guide on how to implement this:

Heating Pad System:

- Select a heating pad specifically designed for food-grade applications. These pads are typically made of flexible, food-safe materials and can be cut to fit your chamber's dimensions.

- Place the heating pad on the bottom or side of your fermentation chamber, ensuring it is positioned to provide even heat distribution.

- Connect the heating pad to a temperature-controlled power supply or a thermostat. This allows you to regulate the heat output and maintain a consistent temperature.

- Monitor the temperature regularly during fermentation. You can use a digital thermometer to ensure it stays within the ideal range for yeast activity, usually between 65°F and 75°F (18°C and 24°C). Adjust the heat settings as needed to keep the temperature stable.

- Consider using a temperature controller with a feedback loop to automatically regulate the heat, ensuring precise temperature management.

Cooling System:

- For warmer climates or during summer months, a cooling system is essential. You can use a small refrigerator or a dedicated cooling unit designed for fermentation chambers.

- Place the cooling unit inside the chamber, ensuring proper ventilation to prevent overheating.

- Connect the cooling system to a thermostat or temperature controller to maintain the desired fermentation temperature.

- Regularly check and adjust the temperature settings to keep the fermentation process optimal.

By implementing these temperature control methods, you can create an environment that promotes healthy yeast activity and the development of complex beer flavors. Remember, consistency is key, so regular monitoring and adjustments will contribute to the success of your beer fermentation process.

Mastering the Art of Beer Aeration: When to Use an Airlock

You may want to see also

Airflow: Ensure proper ventilation to prevent off-flavors and maintain yeast health

When building a beer fermentation chamber, airflow is a critical aspect that can significantly impact the quality of your brew. Proper ventilation is essential to prevent the development of off-flavors and to maintain the health of the yeast, which is the key to a successful fermentation process. Here's a detailed guide on how to ensure optimal airflow in your fermentation chamber:

Ventilation Design: Start by designing your fermentation chamber with adequate ventilation in mind. Consider the size of the chamber and the volume of air that needs to be exchanged. A well-ventilated chamber should have a sufficient number of air inlets and outlets to facilitate a constant flow of fresh air. This can be achieved by strategically placing air intakes and exhaust ports. Ensure that the ventilation system is designed to handle the specific requirements of your brewing process, including the expected temperature and humidity levels.

Air Exchange Rate: Aim for a high air exchange rate to maintain a healthy environment for the yeast. The air exchange rate refers to the number of times the air in the chamber is replaced per hour. A higher exchange rate means that stale air is continuously replaced with fresh air, preventing the buildup of odors and off-flavors. As a general guideline, aim for an exchange rate of at least 5-10 times per hour. This can be achieved by using fans or blowers to actively move air through the chamber.

Filtration and Purification: Implement a filtration system to remove any impurities and odors from the incoming air. This is crucial to prevent unwanted flavors and aromas from affecting your beer. Consider using carbon filters or HEPA filters to trap particles and absorb odors. Additionally, you can introduce a purification system, such as an air purifier or a UV light, to further ensure that the air entering the fermentation chamber is clean and free from potential contaminants.

Temperature and Humidity Control: Proper temperature and humidity management is essential for yeast health and flavor development. Yeast has specific temperature requirements, and maintaining the right conditions will encourage optimal fermentation. Use a temperature-controlled environment to keep the chamber at the desired yeast-friendly temperature. Additionally, monitor and control humidity levels to prevent excessive moisture buildup, which can lead to off-flavors and potential mold growth.

Regular Maintenance: Regular maintenance is key to ensuring long-term success. Clean and inspect your ventilation system periodically to remove any built-up dust, debris, or mold. Check for any blockages or obstructions in the air intake and exhaust systems. By maintaining a clean and well-functioning ventilation setup, you can consistently provide the yeast with a healthy and flavorful environment.

Fermenter Filling: Essential Tips for Perfect Beer Brewing

You may want to see also

Frequently asked questions

A beer fermentation chamber is a dedicated space designed for the fermentation process of brewing beer. It provides an optimal environment for yeast to convert sugars into alcohol and carbon dioxide, playing a crucial role in the art of homebrewing.

Temperature is a critical factor in beer fermentation. Different beer styles require specific temperature ranges to encourage the desired fermentation activity. Maintaining the right temperature ensures proper yeast function, flavor development, and carbonation levels.

Setting up a fermentation chamber involves several steps. First, choose a suitable container or vessel with an appropriate volume for your batch size. Ensure it has an airlock to allow carbon dioxide to escape while preventing contaminants. Then, prepare your wort (the sugary liquid before fermentation) and transfer it to the chamber. Finally, add the yeast and monitor the fermentation process.

There are numerous yeast strains available for beer fermentation, each contributing unique characteristics to the final product. Common strains include Ale Yeast (e.g., Saccharomyces cerevisiae), Lager Yeast (e.g., Saccharomyces pastorianus), and Brettanomyces yeasts for wild and sour beers. The choice depends on the beer style and desired flavor profile.

The duration of beer fermentation varies depending on the yeast strain, temperature, and beer style. Generally, primary fermentation can take anywhere from 5 to 14 days. Secondary fermentation, where flavors are refined, may last an additional 1-2 weeks. It's essential to monitor the process and adjust conditions as needed to ensure a successful fermentation.