Cleaning a beer funnel is an essential step in maintaining the quality and taste of your beer. It ensures that your brewing process is efficient and that your beer is free from any unwanted flavors or odors. This guide will provide a step-by-step process to effectively clean your beer funnel, ensuring it is ready for the next brewing session.

What You'll Learn

Gather Materials: Need funnel, brush, cleaning solution, and water

To effectively clean a beer funnel, you'll need to gather the right tools and materials. Start by ensuring you have a funnel specifically designed for beer or similar applications. These funnels are typically made of durable materials like stainless steel or heat-resistant glass, which can withstand the cleaning process without damage. Next, you'll require a brush that is suitable for cleaning narrow spaces and small openings. A wire brush or a soft-bristled brush will be ideal for this purpose.

In addition to the physical tools, you'll need a cleaning solution specifically formulated for beer equipment. These solutions are designed to break down and remove any residual beer, yeast, or other contaminants that may have accumulated in the funnel. You can find these solutions at most homebrew supply stores or online. Alternatively, a mild dish soap mixed with warm water can be used as a general cleaning agent, but it may not be as effective as a dedicated beer cleaning solution.

Water is also an essential component of the cleaning process. You'll need a steady supply of clean, fresh water to rinse the funnel and ensure that all cleaning agents are removed. It's important to use water that is free from any contaminants, as it will help prevent the introduction of new bacteria or minerals into the cleaned funnel.

Having all these materials ready will ensure that you have everything necessary to thoroughly clean your beer funnel, promoting better beer quality and extending the life of your brewing equipment.

Uncovering the Yeast's Role: Does Beer Ferment with Yeast?

You may want to see also

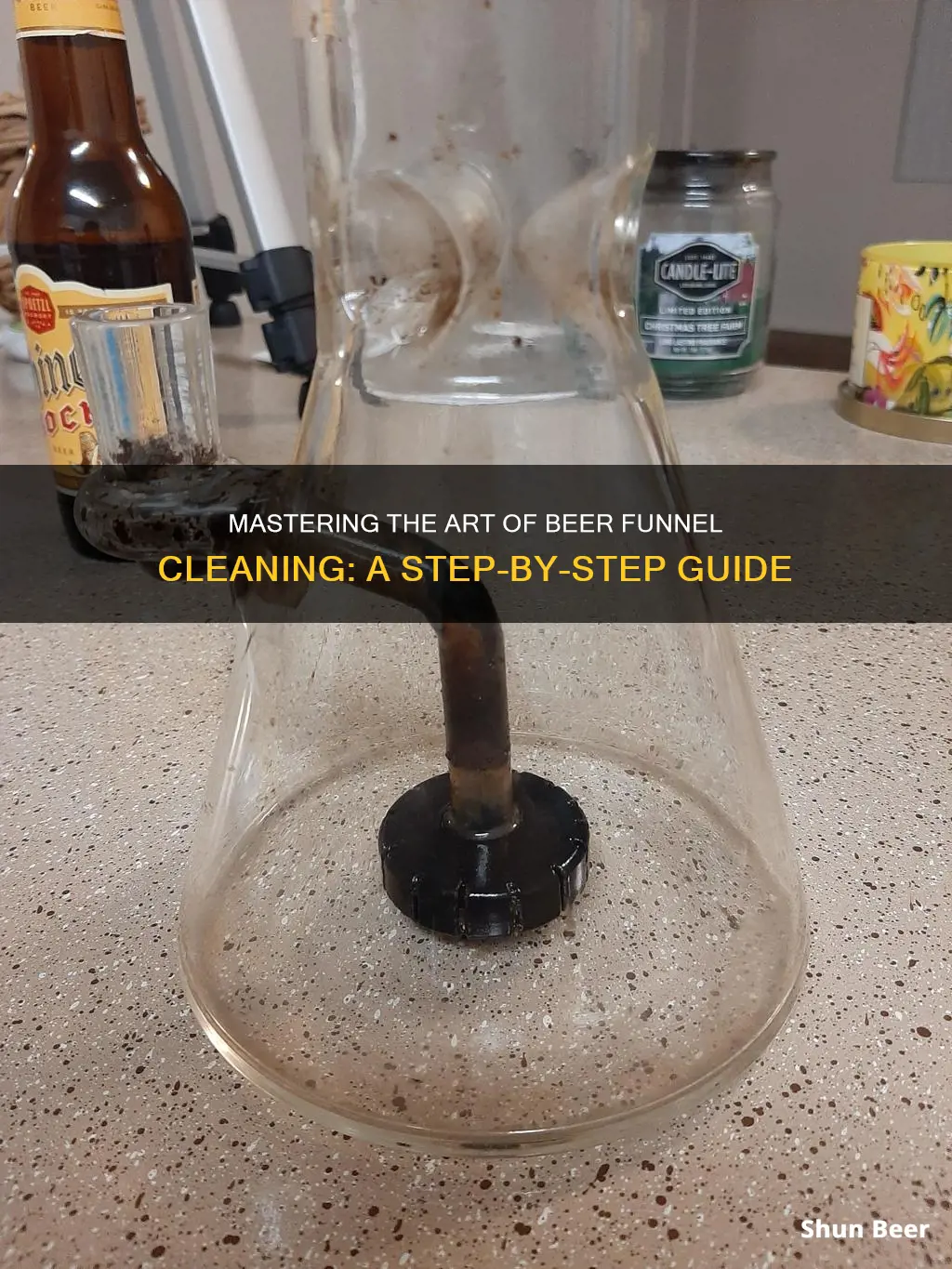

Disassemble: Remove parts, clean each separately

Disassembly is a crucial step in the cleaning process for any beer funnel, ensuring that no residue or dirt remains. Here's a detailed guide on how to disassemble and clean each part separately:

- Detaching the Funnel: Start by carefully removing the beer funnel from the tap or spigot. Most beer funnels have a base with a rubber gasket and a spout that connects to the tap. Gently twist or pull the funnel to detach it, being mindful of the gasket to avoid any damage.

- Separating the Parts: Once detached, you'll have a few key components: the main funnel body, the gasket, and possibly a strainer or filter if your funnel has one. Carefully separate these parts. For the funnel body, look for any screws or clips that hold it together, and remove them to access the interior. This step is especially important if your funnel has a complex design with multiple chambers or filters.

- Cleaning the Funnel Body: With the parts separated, focus on cleaning the funnel body. Use a soft-bristled brush or a bottle brush to scrub the interior, ensuring you remove any beer residue, yeast, or dirt. Pay attention to the corners and crevices, as these areas can trap particles. Rinse the funnel thoroughly with warm water to remove any loose debris.

- Cleaning the Gasket and Strainers: The gasket is a critical component, so treat it with care. Soak it in warm, soapy water to loosen any built-up residue. Use a soft brush to gently scrub the gasket, ensuring it's clean and free of any mold or bacteria. If your funnel has a strainer, remove it and clean it similarly, paying attention to the small holes to prevent clogging.

- Drying and Reassembly: After cleaning, ensure all parts are thoroughly dried to prevent water spots and mold growth. You can use a clean towel or air-dry them. Once dry, carefully reassemble the funnel, ensuring all parts fit snugly together. Check that the gasket is properly seated to create an airtight seal.

Disassembling and cleaning each component separately allows for a thorough cleaning process, ensuring your beer funnel is in top condition for every use. This methodical approach guarantees that no part is overlooked, providing a consistent and enjoyable beer-pouring experience.

Uncorking the Mystery: Does Beer Need Oxygen During Fermentation?

You may want to see also

Rinse Thoroughly: Use hot water to remove residue

Rinsing a beer funnel is an essential step in the cleaning process, ensuring that no residue or leftover beer remains that could affect the taste of your next brew. This simple yet crucial step helps to prevent any unwanted flavors or aromas from carrying over to your next batch of beer. Here's a detailed guide on how to effectively rinse your beer funnel:

Begin by disassembling the funnel if it has removable parts. This could include the strainer, handle, or any other detachable components. This step is important as it allows for a more thorough cleaning, ensuring that no dirt or residue is left behind. Use a soft brush or a cleaning tool to gently scrub the inside of the funnel, paying extra attention to the areas where the beer might have accumulated. This initial cleaning helps to loosen any built-up residue.

Once you've disassembled the funnel, it's time to rinse. Fill the funnel with hot water, ensuring it's hot enough to create steam. The heat is crucial as it helps to dissolve and remove any remaining beer or residue. Let the hot water run through the funnel, allowing it to flow freely. This process not only cleans the funnel but also helps to remove any lingering odors. After a few minutes, drain the water and repeat the process to ensure a thorough rinse.

For an even more effective clean, consider using a mild detergent or dish soap. Add a small amount to the hot water and let it sit for a few minutes. The detergent will help to break down any stubborn residue. After soaking, use a soft cloth or sponge to wipe down the inside of the funnel, removing any remaining soap residue. This step ensures that no chemicals are left behind, which could affect the taste of your beer.

Finally, rinse the funnel with clean, cold water to remove any traces of detergent. This step is important to ensure that the funnel is completely clean and ready for its next use. Once you've rinsed thoroughly, dry the funnel and its parts with a clean towel. This completes the cleaning process, leaving your beer funnel in pristine condition.

Top-Fermented Beer: Exploring Unique Styles and Brewing Techniques

You may want to see also

Sanitize: Apply disinfectant to ensure hygiene

Sanitizing a beer funnel is an essential step to ensure the health and safety of your brewing process. It's a simple yet crucial task that can often be overlooked. The primary goal is to eliminate any harmful bacteria or microorganisms that may have accumulated during the brewing process, which can affect the taste and quality of your beer. Here's a detailed guide on how to properly sanitize your beer funnel:

Understanding the Importance of Sanitization: Before diving into the process, it's crucial to understand why sanitization is necessary. Beer funnels, especially those used for home brewing, can become breeding grounds for bacteria, yeast, and other microorganisms. These unwanted guests can lead to off-flavors, cloudiness, and even spoilage. Proper sanitization ensures that your brewing equipment is free from these contaminants, resulting in a cleaner, more consistent, and delicious beer.

Choosing the Right Disinfectant: The market offers a variety of disinfectants, but not all are suitable for brewing equipment. It's essential to choose a disinfectant that is safe for food contact and won't leave any harmful residues. Common and effective choices include iodine-based solutions, such as iodine tablets or liquid iodine, and quaternary ammonium compounds (QUATs), which are often found in brewing-specific sanitizers. Always follow the manufacturer's instructions and recommended dilution ratios for the chosen disinfectant.

Sanitization Process:

- Rinse Thoroughly: Start by rinsing the beer funnel under hot running water. This initial step helps to remove any loose debris or residual beer that might interfere with the sanitization process. Ensure you rinse from all angles to ensure no part of the funnel is overlooked.

- Prepare the Disinfectant Solution: Follow the instructions on your chosen disinfectant to prepare the appropriate solution. This might involve mixing a specific amount of disinfectant with water. Always use clean, sterile water to avoid introducing any additional contaminants.

- Immerse and Agitate: Place the beer funnel into the disinfectant solution and ensure it is fully submerged. Allow it to soak for the recommended time, which can vary depending on the disinfectant. During this time, gently agitate the funnel to ensure the disinfectant reaches all surfaces, including the interior and exterior.

- Rinse and Air Dry: After the soaking period, remove the funnel from the disinfectant solution and rinse it thoroughly with hot water. This step ensures that any remaining disinfectant is washed away, leaving no chemical residue. Allow the funnel to air dry completely before using it again.

Regular Maintenance: Sanitization should be a regular part of your brewing routine. Before each brewing session, ensure you sanitize your funnel to maintain a consistent and high-quality beer. Additionally, consider regular deep cleaning and sanitization of your entire brewing setup to prevent the buildup of stubborn bacteria and mineral deposits.

By following these steps, you can effectively sanitize your beer funnel, ensuring a clean and safe brewing environment. Remember, proper sanitization is a key factor in achieving the best possible results in your brewing endeavors.

The Sweet Side of Beer: Exploring Sugary Brews

You may want to see also

Reassemble: Put parts back, ensuring a tight seal

Reassembling a beer funnel after cleaning is an important step to ensure the proper functioning and longevity of the equipment. Here's a detailed guide on how to put the parts back together, focusing on achieving a tight seal:

- Inspect the Components: Before reassembling, inspect each part carefully. Check for any signs of damage, cracks, or wear. Ensure that all pieces are present and in good condition. This step is crucial to identify any potential issues that might affect the reassembly process.

- Prepare the Funnel Body: Start by placing the funnel body, which is the main container, in a stable position. Ensure it is clean and dry. The funnel body should have a smooth interior surface and a wide opening to accommodate the other parts.

- Attach the Filter: Position the filter or strainer at the bottom of the funnel body. This component is designed to catch sediment and debris from the beer. Carefully align the filter with the opening, ensuring it fits snugly. The filter should create a tight seal to prevent any unwanted particles from passing through.

- Secure the Handle (if applicable): If your beer funnel has a handle, attach it to the funnel body. Handles are typically attached to the side or top of the funnel. Ensure a secure connection by aligning the handle's mounting points with the corresponding holes or slots on the funnel. Tighten any screws or fasteners to create a firm bond.

- Achieve a Tight Seal: The key to a well-reassembled beer funnel is a secure seal. Check that all connections are tight and free from any gaps. Pay close attention to the filter and funnel body interface, as an improper seal here can lead to leaks. Gently press or twist the parts together to ensure they are firmly in place.

- Test the Assembly: After reassembling, test the funnel by pouring a small amount of liquid (not beer) to ensure there are no leaks. Check all connections and make any necessary adjustments to tighten them further if needed.

By following these steps, you can ensure that your beer funnel is reassembled correctly, providing a reliable and efficient brewing experience. Remember, a tight seal is essential to prevent any unwanted substances from entering the beer during the brewing process.

Craft Beer Slushie: A Guide to Making Your Own Frozen Brew

You may want to see also

Frequently asked questions

Cleaning a beer funnel is essential to maintain hygiene and ensure the quality of your brew. Start by disassembling the funnel into its components: the base, the screen, and the spout. Rinse each part with warm water to remove any loose particles. For a deeper clean, use a mild detergent or dish soap and warm water. Soak the funnel for 10-15 minutes, then scrub the screen and spout with a soft brush to remove any residue. Rinse thoroughly with hot water to eliminate any soap residue. Finally, allow the funnel to air dry completely before reassembling and using it again.

While it is possible to clean a beer funnel in a dishwasher, it is generally recommended to hand-wash it to ensure a more thorough clean. Dishwashers may not be able to reach all the nooks and crannies, especially around the screen and spout. Hand-washing allows you to scrub the funnel more effectively and ensure no residue or dirt is left behind. However, if you do choose to use the dishwasher, place the funnel on the top rack and use a gentle cycle with hot water to achieve the best results.

For stubborn residue or buildup, you can use a mixture of vinegar and water. Fill the funnel with a 50/50 solution of white vinegar and warm water, let it soak for 30 minutes, then scrub the screen and spout with a brush. The vinegar will help dissolve any mineral deposits or leftover beer residue. After scrubbing, rinse the funnel thoroughly with hot water and allow it to air dry. This method is especially useful for maintaining the funnel's performance and preventing clogs.

It is recommended to clean your beer funnel after every brewing session to maintain optimal hygiene. Regular cleaning prevents the buildup of bacteria, mold, and mineral deposits, which can affect the taste and quality of your beer. Additionally, cleaning the funnel after use ensures that any leftover beer or sediment is removed, reducing the risk of off-flavors in future brews. Establishing a consistent cleaning routine will help you keep your brewing equipment in top condition.