Cleaning a beer fermenter is an essential step in the brewing process to ensure the quality and consistency of your beer. Proper sanitization and maintenance of the fermenter will help prevent off-flavors, off-colors, and unwanted microbial growth. This guide will provide a step-by-step process for effectively cleaning your beer fermenter, covering everything from preparing the necessary supplies to sanitizing the equipment. By following these instructions, you can maintain a clean and healthy brewing environment, resulting in a delicious and well-crafted beer.

What You'll Learn

- Prepare the Equipment: Gather cleaning supplies like brushes, scrubbers, and sanitizers

- Rinse Thoroughly: Use hot water to remove loose particles and residue

- Disinfect: Apply a suitable disinfectant to kill bacteria and yeast

- Dry Completely: Ensure no moisture remains to prevent contamination

- Maintain Regularly: Establish a cleaning schedule to keep the fermenter in top condition

Prepare the Equipment: Gather cleaning supplies like brushes, scrubbers, and sanitizers

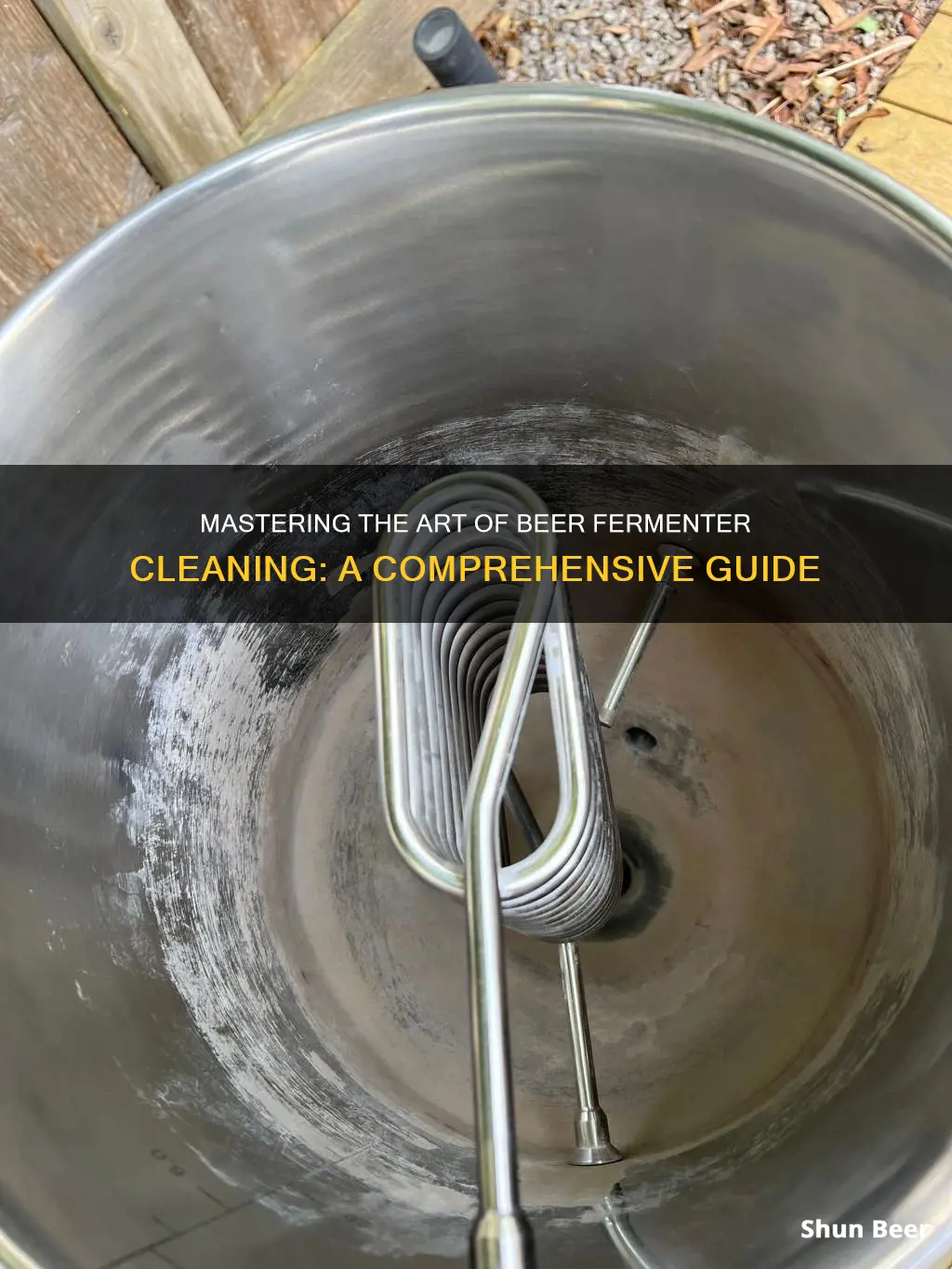

When it comes to cleaning a beer fermenter, having the right equipment is crucial to ensure a thorough and effective process. Here's a detailed guide on preparing your tools:

Gathering the Essentials:

Start by assembling a set of cleaning supplies specifically designed for brewing equipment. This includes various brushes, scrubbers, and sanitizers. For brushes, consider both stiff-bristled brushes for heavy-duty cleaning and softer, more flexible brushes for delicate areas. These brushes should be durable and resistant to the chemicals used in brewing. Additionally, obtain a high-quality scrubber with a sturdy handle and replaceable scrubber pads to ensure you can tackle different cleaning tasks.

Sanitizers are an essential part of the process, as they eliminate bacteria and prevent contamination. Choose a food-grade sanitizer suitable for brewing applications. It's important to follow the manufacturer's instructions for dilution and application methods. You might also want to invest in a dedicated brewing brush, which is designed to reach into narrow spaces and crevices, ensuring a comprehensive clean.

Organizing Your Toolkit:

Arrange your cleaning supplies in a way that makes sense for your workflow. Keep the brushes and scrubbers easily accessible, ensuring you can quickly switch between different cleaning tasks. Having a designated area for your sanitizer will also make it convenient to prepare and apply during the cleaning process. Consider labeling your tools or creating a system to quickly identify the right item for the job.

By gathering these specialized tools, you'll be well-prepared to tackle the cleaning process, ensuring a spotless and safe brewing environment. Remember, proper equipment is essential for achieving the desired beer quality and consistency.

The Magic of Beer in Carne Asada: Unlocking Flavor Secrets

You may want to see also

Rinse Thoroughly: Use hot water to remove loose particles and residue

When it comes to cleaning a beer fermenter, one of the most crucial steps is to rinse it thoroughly. This process ensures that any loose particles, residue, and leftover yeast or proteins are completely removed, leaving a clean and healthy environment for your next brew. Here's a detailed guide on how to effectively rinse your fermenter:

Start by disassembling the fermenter if it's a multi-piece setup. This allows for better access to all areas and ensures a comprehensive clean. Use hot water as the primary cleaning agent. The heat helps to dissolve and remove any stubborn residue. Fill the fermenter with hot water, ensuring it covers all surfaces, including the sides, bottom, and any crevices. Let the water sit for a few minutes to allow it to warm up and loosen any particles. The temperature of the water should be comfortable to the touch, as extremely hot water might damage certain components.

Now, begin the rinsing process. Use a clean brush or sponge to scrub the interior of the fermenter, paying extra attention to areas where yeast or proteins tend to accumulate, such as the sparge arm and the bottom of the fermenter. Rinse the fermenter from the inside out to ensure no residue is left behind. For a thorough clean, consider using a strainer or sieve to capture any loose particles that might be dislodged during the process. This step is essential to prevent these particles from affecting the flavor of your beer.

After scrubbing and rinsing, it's time to flush the system. Run hot water through the fermenter, ensuring it flows through all parts, including the sparge arm and any pipes or hoses. This final flush helps to remove any remaining loose particles and ensures that the water used for the next step is clean.

By following this thorough rinsing process, you'll create a clean and sanitized environment for your beer fermentation, ensuring a crisp and flavorful final product. Remember, proper cleaning and sanitization are fundamental to the art of brewing.

The Sweet & Bitter: Exploring Orange-Infused Beer Styles

You may want to see also

Disinfect: Apply a suitable disinfectant to kill bacteria and yeast

Disinfection is a critical step in the process of cleaning a beer fermenter to ensure the production of high-quality beer. The goal is to eliminate any harmful bacteria and yeast that could contaminate the beer and affect its flavor and quality. Here's a detailed guide on how to effectively disinfect your fermenter:

Choose the Right Disinfectant: The first step is to select an appropriate disinfectant. For beer brewing, it's recommended to use a chlorine-based disinfectant, such as sodium hypochlorite (bleach) or calcium hypochlorite (bleaching powder). These are commonly used in the brewing industry due to their effectiveness and ease of use. Alternatively, you can opt for a specialized brewery disinfectant, which is designed specifically for brewing equipment and is often more convenient for regular use.

Prepare the Disinfectant Solution: Follow the instructions on the chosen disinfectant's packaging to prepare the correct concentration. Typically, a higher chlorine concentration is required for disinfection, especially for brewing equipment. For example, you might need to mix a specific ratio of bleach with water. Always wear protective gloves and ensure proper ventilation when handling chemicals.

Rinse and Immerse: After preparing the disinfectant solution, thoroughly rinse your fermenter to remove any residual dirt or beer residue. This step is crucial to prevent the disinfectant from reacting with the beer's components. Then, immerse the entire fermenter, including the lid and any accessories, into the disinfectant solution. Make sure all surfaces are fully covered. Allow the fermenter to soak for the recommended time, which can vary depending on the disinfectant and the brewing guidelines.

Agitate and Scrub: During the soaking period, gently agitate the fermenter to ensure the disinfectant reaches all areas. For stubborn deposits or areas with visible contamination, use a soft-bristled brush or a non-abrasive scrubber to carefully clean these spots. Avoid harsh scrubbing that might damage the fermenter's surface.

Rinse Thoroughly: After the soaking period, remove the fermenter from the disinfectant solution and rinse it thoroughly with clean water. Ensure that no chemical residue remains, as this could affect the beer's taste. Rinsing should be done in a separate area to prevent cross-contamination.

By following these steps, you can effectively disinfect your beer fermenter, creating a clean and sterile environment for your brewing process. Remember, proper disinfection is essential to maintain the integrity of your beer and the overall quality of your brewing operation.

Beer Faucet Repair: Step-by-Step Guide to Reassemble Your Tap

You may want to see also

Dry Completely: Ensure no moisture remains to prevent contamination

When it comes to cleaning a beer fermenter, one of the most critical steps is ensuring it is completely dry. Moisture left on the surface of the fermenter can lead to contamination, which can ruin your brewing efforts. Here's a detailed guide on how to ensure your fermenter is dry and ready for its next use:

After you've finished brewing and transferred your beer to the fermenter, the first step is to rinse it thoroughly. Use warm water to remove any residual yeast, sugar, or other brewing byproducts. This initial rinse is crucial to prevent any unwanted flavors or odors from lingering. Once rinsed, it's time to dry.

The key to drying is to use a clean, lint-free cloth or towel. Ensure the surface of the fermenter is completely free of any water droplets. You can tilt the fermenter and gently pour out any excess water, but be cautious not to spill. Then, with a soft cloth, wipe down the entire surface, including the interior and exterior. Pay attention to the corners and crevices, as these areas can trap moisture.

For an even more thorough drying process, you can use a hairdryer on a low setting. Hold the hairdryer a few inches away from the fermenter and direct the airflow towards the water spots. This method is especially useful for larger fermenters or those with complex shapes. Just be mindful not to hold the hairdryer in one spot for too long to avoid overheating the plastic.

Once you've dried the fermenter, it's a good idea to inspect it for any remaining moisture. You can do this by gently touching the surface; if it feels dry, it's ready. If you notice any wet spots, repeat the drying process until the entire surface is dry.

Remember, taking the time to dry your beer fermenter properly is essential for maintaining the quality of your brew and preventing any unwanted microbial growth. By following these steps, you'll ensure that your fermenter is clean, dry, and ready for its next brewing adventure.

Chili Con Beer: A Tasty Twist or a Recipe Disaster?

You may want to see also

Maintain Regularly: Establish a cleaning schedule to keep the fermenter in top condition

Maintaining a regular cleaning schedule for your beer fermenter is crucial to ensuring the quality and consistency of your brews. Over time, yeast, bacteria, and other microorganisms can accumulate in the fermenter, leading to off-flavors, odors, and even contamination. Establishing a routine cleaning process will help you avoid these issues and keep your fermenter in optimal condition. Here's a step-by-step guide to creating an effective cleaning schedule:

- Understand the Fermenter's Components: Before setting a schedule, familiarize yourself with the parts of your fermenter. This includes the main fermenter vessel, the lid or airlock, the spigot, and any additional components like a false bottom or agitator. Each part may require specific cleaning techniques to ensure a thorough clean. For example, the spigot should be regularly cleaned to prevent the buildup of yeast and debris, which can cause clogs.

- Determine the Cleaning Frequency: The frequency of your cleaning routine will depend on several factors, including the brewing frequency, the size of your fermenter, and the brewing style. For homebrewers, a general guideline is to clean your fermenter after every 2-3 batches. However, if you're brewing more frequently or using a small fermenter, more frequent cleaning may be necessary. Regularly monitoring the fermenter's condition and adjusting the schedule accordingly is essential.

- Create a Step-by-Step Cleaning Process:

- Rinse: Start by rinsing the fermenter with hot water to remove any loose yeast or debris. This initial rinse helps prevent the spread of microorganisms during the cleaning process.

- Disassemble: Carefully disassemble the fermenter, following the manufacturer's instructions. Clean each component separately to ensure a thorough clean.

- Soak: Fill the fermenter with a hot, soapy solution (a common choice is a mixture of warm water and a mild dish soap). Let it soak for 15-20 minutes to loosen and dissolve any built-up yeast and residue.

- Scrub: Use a soft-bristled brush or a specialized fermenter cleaning brush to scrub all surfaces, including the interior walls, bottom, and any removable parts. Pay attention to corners and crevices where debris can accumulate.

- Rinse Thoroughly: After scrubbing, rinse the fermenter multiple times with hot water to remove any soap residue. Ensure no soap remains, as it can leave a bitter taste in the beer.

- Sanitize: Sanitize the fermenter using a food-safe sanitizer. This step is crucial to kill any remaining microorganisms. Follow the instructions for the chosen sanitizer, typically involving a soak or spray application.

Implement and Adjust: Once you've established your cleaning routine, stick to it. Consistency is key to maintaining a healthy fermenter. If you notice any lingering odors or flavors between cleanings, consider an early intervention clean. Additionally, pay attention to any changes in your brewing process or water quality, as these factors can impact the fermenter's cleanliness. Adjust your schedule as needed to accommodate these changes.

By following a structured cleaning schedule, you'll ensure that your beer fermenter remains in excellent condition, producing high-quality brews consistently. Regular maintenance will save you time and effort in the long run and contribute to the overall success of your brewing endeavors.

The Surprising Reason Crab Pots Need Beer: A Fisherman's Tale

You may want to see also

Frequently asked questions

Cleaning your beer fermenter is crucial to ensure the quality and consistency of your brew. It is recommended to clean it after every fermentation cycle, especially if you're using it for multiple batches. Regular cleaning prevents the buildup of bacteria, yeast remnants, and any off-flavors that might affect the taste of your beer.

The most effective way to clean a beer fermenter is by using a hot water sanitization process. Start by rinsing the fermenter with hot water to remove any loose particles. Then, fill the fermenter with hot water (around 160°F) and add a suitable sanitizer like iodine or a quaternary ammonium compound (QUAT). Let it soak for 10-15 minutes, ensuring all surfaces are covered. Finally, rinse thoroughly with clean water to remove any sanitizer residue.

While it's possible to use a dishwasher, it's generally not recommended for beer fermenters due to the risk of damage. Dishwashers can be too harsh and may not provide the necessary level of cleaning and sanitization. It's best to use a dedicated cleaning method like the hot water sanitization process mentioned above, which ensures a thorough and safe clean for your brewing equipment.