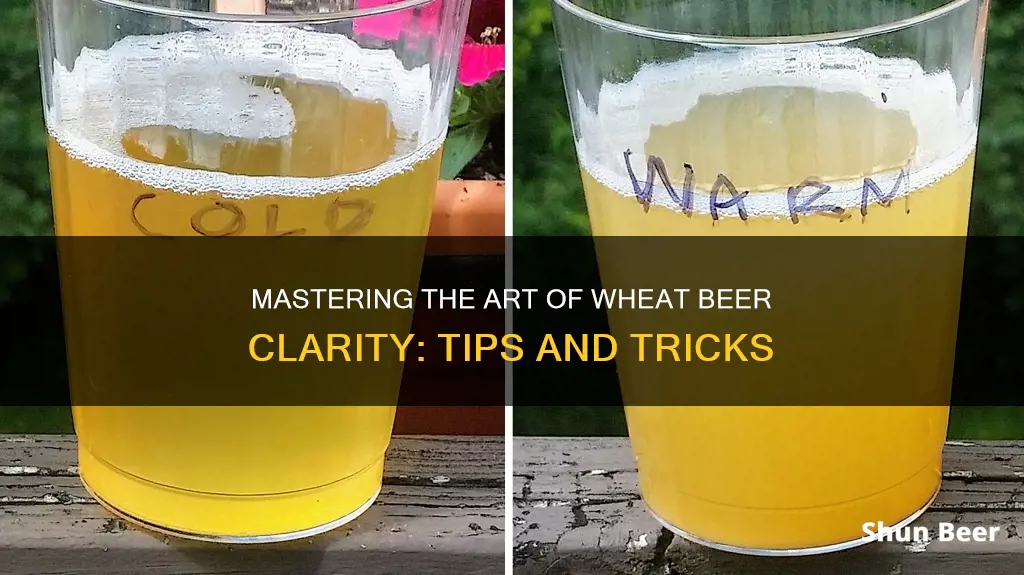

Wheat beer, a popular style known for its smooth, cloudy appearance and subtle flavors, requires a unique process for clearing. Unlike lagers, which are typically filtered, wheat beers rely on a natural process called maturation to achieve clarity. This process involves allowing the beer to age and mature, during which time the yeast and other particles settle to the bottom of the fermentation vessel. To clear wheat beer, one can employ several techniques, including chilling the beer to slow down the yeast's activity, gently stirring the beer to encourage sedimentation, and using a fine mesh strainer or decanter to separate the clear liquid from the sediment. These methods help preserve the beer's unique character while ensuring a smooth and enjoyable drinking experience.

What You'll Learn

Ingredients: Use malt extract, yeast, water, and hops for brewing

To brew a clear wheat beer, you'll need to pay close attention to the ingredients and the brewing process. Here's a detailed breakdown of the essential components:

Malt Extract: This is the foundation of your beer. You'll typically use a combination of malted barley and wheat malt. The malt extract provides the sugars necessary for fermentation and contributes to the beer's overall flavor and color. Choose a high-quality malt extract to ensure a robust base for your wheat beer.

Yeast: Yeast is the microorganism responsible for fermentation. For wheat beer, you want a yeast strain that can handle the unique characteristics of wheat malt. German ale yeasts, such as Wyeast 3522 or White Labs WLP650, are commonly used for wheat beers. These yeasts produce a clean, crisp flavor and help create a clear, refreshing beer.

Water: Water is a crucial ingredient, as it affects the beer's overall character. Use filtered water to control mineral content and ensure the best possible brewing results. The mineral composition of your water can impact the beer's clarity and flavor, so consider adjusting the water profile to suit your recipe.

Hops: Hops provide bitterness, flavor, and aroma to the beer. For wheat beer, you can use a variety of hops, but German hops like Hallertau Mittelfrüh and Saaz are traditional choices. These hops offer a delicate bitterness and a subtle, floral aroma that complements the wheat malt. Adjust the hop schedule to control bitterness and create a balanced beer.

When brewing wheat beer, the goal is to create a light, crisp, and refreshing beverage. The ingredients and their proportions should reflect this style. Malt extract and wheat malt provide the necessary sugars and body, while yeast and hops contribute to the unique character of wheat beer. Remember that precision in ingredient measurement and timing is key to achieving a clear and well-balanced wheat beer.

The Surprising Truth: Can You Bake with Beer?

You may want to see also

Boil: Simmer grains for 60 minutes to extract flavors

When brewing wheat beer, the boiling process is crucial for extracting the desired flavors and aromas from the grains. This step allows the brewer to unlock the unique characteristics of wheat malt and create a balanced, flavorful beer. Here's a detailed guide on how to approach the boiling process for optimal results:

Boiling Time: The key to a successful boil is timing. Simmer the grains for a generous 60 minutes. This extended boiling period is essential for extracting the complex flavors and aromas that wheat malt has to offer. During this time, the heat will cause the starches in the grains to convert, releasing sugars that will later be fermented by yeast.

Temperature Control: Maintain a steady boil throughout the 60 minutes. Aim for a temperature range of 155°F to 165°F (68°C to 74°C). This moderate heat ensures that the enzymes responsible for starch conversion remain active, maximizing flavor extraction. Avoid excessive boiling, as it may lead to over-extraction and a harsher, more bitter beer.

Agitation and Sparging: Constant agitation is vital to ensure even extraction. Use a large pot or brew kettle and stir the grains vigorously to prevent sticking and promote uniform contact with the boiling water. After the 60-minute boil, you'll want to sparge, which involves rinsing the grains with hot water to extract the remaining sugars and flavors. Use a spray ball or similar device to ensure a gentle, even spray of water over the grains.

Cooling and Flavor Development: As the boil concludes, immediately cool the wort (the liquid extracted from the grains) to a safe fermentation temperature. This rapid cooling helps preserve the delicate flavors and aromas. The cooling process also triggers the precipitation of proteins and other solids, making it easier to separate the liquid from the solid components later in the brewing process.

By following this extended boiling procedure, you'll be able to harness the full potential of wheat malt, resulting in a wheat beer with a rich, balanced flavor profile. This technique ensures that the beer has a smooth mouthfeel and a characteristic wheat beer clarity, making it a popular choice for beer enthusiasts.

The Ancient Art of Beer Storage: Unlocking the Mystery of Barrels

You may want to see also

Fermentation: Allow yeast to ferment at 65-75°F for 1-2 weeks

Fermentation is a crucial step in the brewing process, especially for wheat beer, as it directly impacts the beer's flavor, clarity, and overall quality. When brewing wheat beer, the fermentation process is typically carried out using ale yeast, which thrives in warmer temperatures. The ideal fermentation temperature range for wheat beer is between 65-75°F (18-24°C). This temperature range allows the yeast to work optimally, producing the desired flavors and aromas while also contributing to the beer's clarity.

During fermentation, the yeast consumes the sugars present in the wort (the sugary liquid extracted from malted grains) and converts them into alcohol and carbon dioxide. For wheat beer, this process is particularly important as it helps to develop the characteristic fruity and spicy notes that wheat beers are known for. The yeast strains commonly used for wheat beer fermentation include American ale yeasts like Wyeast 3522 or White Labs WLP650, which are known for their ability to produce a clean and crisp flavor profile.

Maintaining the correct fermentation temperature is essential to ensure a successful brew. If the temperature is too low, the yeast may become inactive, leading to a slow fermentation process and potentially off-flavors. On the other hand, if the temperature is too high, it can cause the yeast to over-ferment, resulting in a harsh, acidic taste. Therefore, it is crucial to monitor the fermentation temperature regularly and make adjustments if necessary.

The duration of fermentation for wheat beer typically ranges from 1 to 2 weeks. During this time, the yeast will work diligently to convert the available sugars, and the beer will gradually develop its unique characteristics. It is important to note that proper sanitization techniques should be employed before and during fermentation to prevent any unwanted microbial contamination, which could negatively impact the beer's clarity and flavor.

After the fermentation process, the beer is ready for the next stage, which often involves conditioning and carbonation. This is where the beer's clarity can be further enhanced through natural settling, allowing any remaining yeast and sediment to drop out. Proper storage and aging will also contribute to the overall clarity of the final product. Following these steps and closely monitoring the fermentation process will result in a well-crafted, clear, and delicious wheat beer.

Bohemian Lager: Unveiling the Unique Style of Beer

You may want to see also

Carbonation: Add sugar to carbonate the beer naturally

To naturally carbonate your wheat beer and achieve a refreshing, crisp finish, you can employ a simple technique involving sugar. This method is a great way to enhance the beer's carbonation without the need for commercial carbonation equipment. Here's a step-by-step guide:

Ingredients and Preparation:

- Start with a batch of your homemade wheat beer. Ensure it is properly fermented and at room temperature (around 20-25°C or 68-77°F).

- You'll need granulated sugar, preferably white sugar, as it dissolves easily and provides a consistent carbonation source.

- A large glass or plastic container with a tight-fitting lid is essential for the carbonation process.

Carbonation Process:

- Pour the beer into the container, leaving some headspace at the top. This is crucial to allow for the carbon dioxide (CO2) to dissolve and form bubbles.

- Add a measured amount of sugar. A common ratio is 1/2 cup (approximately 100 grams) of sugar per liter of beer. Adjust this based on your desired level of carbonation. Stir vigorously until the sugar is completely dissolved.

- Secure the lid tightly. This step is vital to trap the CO2 inside the container.

- Place the container in a warm environment, such as a sunny spot or near a radiator, for 2-3 days. The warmth encourages the CO2 to dissolve into the beer, creating carbonation.

- After the carbonation period, open the container carefully to release the built-up pressure. You might want to do this outdoors or in a well-ventilated area to avoid any mess.

- Taste the beer and adjust the carbonation level if needed. If it's too flat, add more sugar and repeat the process. If it's too bubbly, let it sit for a while to allow some CO2 to escape naturally.

Tips for Success:

- The sugar acts as a food source for yeast, which can continue to ferment and produce CO2 even after the primary fermentation is complete.

- Keep an eye on the beer's temperature during the carbonation process. Warmer temperatures speed up the carbonation, while cooler temperatures slow it down.

- Experiment with different sugar-to-beer ratios to find your preferred level of carbonation.

- Always handle the beer with clean equipment to avoid any off-flavors.

By following this natural carbonation method, you can enjoy a delicious, homebrewed wheat beer with a satisfying level of fizz, all without the complexity of specialized equipment.

The Perfect Pour: Can You Chill Beer in a Hydro Flask?

You may want to see also

Filtration: Filter the beer to remove sediment before serving

To achieve a clear and crisp wheat beer, filtration is a crucial step in the brewing process and an essential technique for home brewers. This method is particularly effective for removing sediment, which can be a common issue with wheat beers due to their high-grain content and yeast activity. Here's a detailed guide on how to filter your wheat beer to ensure a smooth and enjoyable drinking experience.

The first step is to choose the right filtration method. Gravity filtration is a popular choice for home brewers as it is simple and effective. You will need a brewing kit that includes a large glass or plastic container (the brew pot), a smaller container for the filtered beer, a strainer or cheesecloth, and a siphoning tool. Start by pouring the beer into the brew pot, ensuring that you leave some space at the top to allow for sediment settling.

Next, carefully pour the beer into the smaller container, using the siphoning tool. As you pour, hold the strainer or cheesecloth over the top of the smaller container to catch any sediment. This process may take a bit of practice, but it ensures that the beer is free from any solid particles. The sediment will remain in the brew pot, and you can dispose of it or, if you're feeling adventurous, use it to start a new batch of beer.

For an even clearer beer, you can repeat the filtration process. After the initial pour, let the beer sit for a few minutes to allow any remaining sediment to settle. Then, carefully pour the beer again, using the same strainer or cheesecloth. This double-filtration technique can significantly improve the clarity of your wheat beer.

Remember, the goal is to separate the beer from the sediment without losing too much of the beer's flavor and carbonation. Gravity filtration is a gentle process that preserves the beer's character while effectively removing any unwanted particles. With practice, you'll be able to master the art of filtering, resulting in a beautifully clear and refreshing wheat beer.

Unlocking Beer's Potential: The Art of Secondary Fermentation

You may want to see also

Frequently asked questions

Clearing wheat beer is a process that helps remove sediment and cloudiness, resulting in a clearer and more visually appealing beverage. It is crucial for achieving a smooth and crisp taste, especially in traditional wheat beers like German Hefeweizen.

At-home clearing can be achieved through a process called 'maturation' or 'aging'. Start by chilling the beer to around 40°F (4°C). Then, pour it into a fine-mesh strainer or cheesecloth-lined sieve, catching the liquid in a clean container. Allow the beer to rest for a few days or up to a week, during which it will naturally clarify. This method is simple and effective for small batches.

Yes, adding a small amount of yeast or a clarifying agent can significantly improve clarity. Yeast can be pitched directly into the beer or added after fermentation. Clarifying agents like bentonite clay or isinglass can also be used, but they require careful handling and may not be suitable for all beer styles.

Absolutely! Bottling or kegging wheat beer is a common practice that allows for natural clearing. After fermentation, transfer the beer to the packaging vessel and leave it undisturbed. Over time, the beer will clarify as the yeast settles at the bottom. For kegging, ensure the keg is properly sealed and agitated to distribute the yeast evenly.