Double fermentation is a technique used in brewing to add complexity and depth to the flavor profile of beer. This process involves a second fermentation, typically with a different yeast strain, after the primary fermentation has concluded. The first fermentation converts sugars into alcohol and carbon dioxide, while the second fermentation can introduce new flavors and aromas, often resulting in a more robust and unique beer. This method is particularly popular in the production of Belgian-style ales and some types of wheat beers, where the secondary fermentation can enhance the beer's character and mouthfeel. Understanding the process and selecting the right yeast for the second fermentation is crucial to achieving the desired outcome.

What You'll Learn

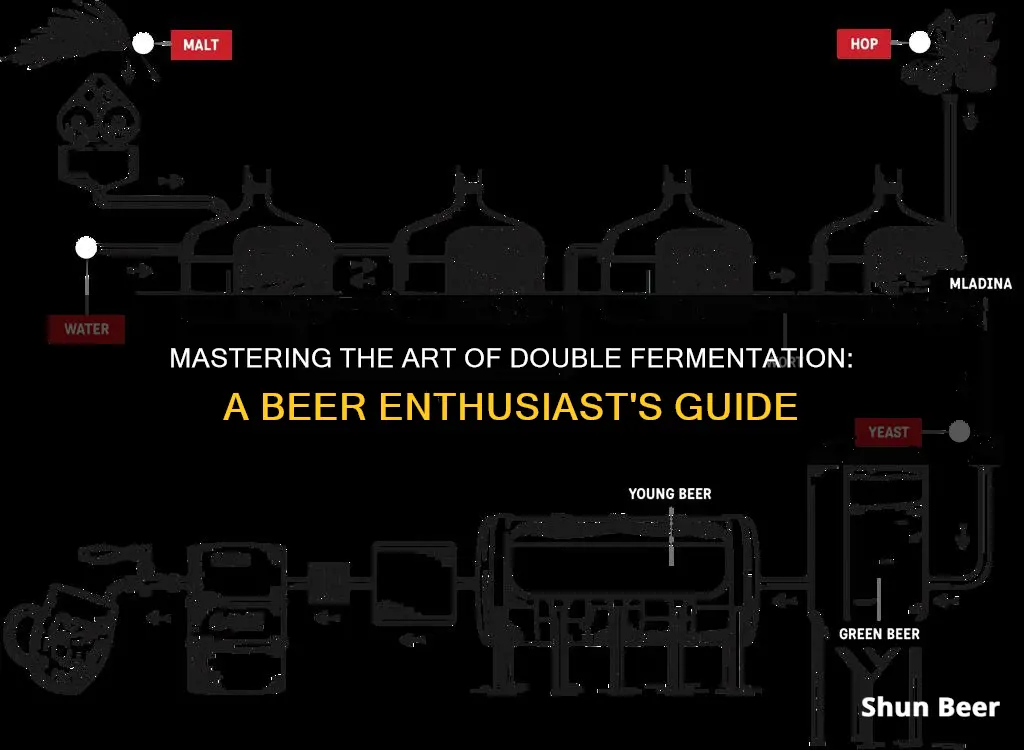

- Ingredients: Use malted grains, yeast, water, and hops for fermentation

- Preparation: Mash grains, lauter, and sparge to extract sugars

- Fermentation Process: Pitch yeast, monitor temperature, and control oxygen

- Secondary Fermentation: Increase alcohol content and flavor complexity

- Aging and Bottling: Age beer, bottle, and carbonate for optimal taste

Ingredients: Use malted grains, yeast, water, and hops for fermentation

When it comes to brewing beer, the ingredients are key to achieving the desired flavor and character. For a double fermentation process, you'll need a few essential components: malted grains, yeast, water, and hops. Each of these ingredients plays a crucial role in the fermentation process and contributes to the unique taste of your beer.

Malted grains are the foundation of your beer. These grains, such as barley, wheat, or rye, have been soaked, germinated, and dried, which activates enzymes that break down starches into fermentable sugars. This process is called malting, and it's essential for providing the yeast with the necessary nutrients to ferment. Choose high-quality malted grains with a suitable protein content and enzyme activity to ensure a successful fermentation.

Yeast is the microorganism responsible for fermentation. It consumes the sugars derived from the malted grains and produces alcohol and carbon dioxide as byproducts. There are various types of yeast, each with its own characteristics and flavor profiles. For double fermentation, you might consider using a primary yeast strain for the initial fermentation and then adding a secondary yeast strain to further develop the beer's flavor and aroma. This technique allows for more complexity and can result in a smoother, more refined beer.

Water is often overlooked but is a critical ingredient in brewing. The mineral content and pH level of the water can significantly impact the beer's taste and quality. Different brewing water profiles can enhance or complement the flavors of your malted grains and hops. Adjusting the water chemistry can help bring out the desired characteristics of your beer, such as bitterness, sweetness, or fruitiness.

Hops are another essential ingredient, providing bitterness, flavor, and aroma to the beer. They also act as a natural preservative. Hops can be added at various stages of the brewing process, including during the boil, as a hopback, or even in the fermentation vessel. Different hop varieties offer distinct flavor profiles, ranging from citrusy and fruity to earthy and resinous. Experimenting with hop additions can create unique and personalized beer styles.

In summary, for a successful double fermentation beer, you need to carefully select and combine malted grains, yeast, water, and hops. Each ingredient contributes to the beer's overall character, and the right balance of these elements will result in a delicious and well-crafted beverage. Remember that brewing is an art, and experimentation is key to finding your perfect beer recipe.

The Great Beer Conundrum: To Add 'S' or Not to Add 'S

You may want to see also

Preparation: Mash grains, lauter, and sparge to extract sugars

The process of mashing grains is a crucial step in brewing beer, as it involves breaking down the starches in the grains to extract fermentable sugars. This is a complex process that requires precision and attention to detail. Here's a step-by-step guide to mashing grains, lauter, and sparging:

Mashing: Begin by grinding the grains to a consistent size, ensuring a uniform mash. Place the ground grains into a mash tun or a large container. Add hot water to the grains, maintaining a specific temperature known as the "mash temperature." This temperature is critical as it determines the efficiency of the enzyme action. Typically, a temperature range of 145°F to 155°F (63°C to 68°C) is used for most beer styles. Stir the grains gently to ensure even extraction, a process known as "mashing in." Allow the grains to rest at this temperature for a predetermined amount of time, usually around 60-90 minutes, to allow the enzymes to break down the starches.

Lautering: After mashing, the process of lauter begins. This step involves separating the liquid (wort) from the spent grain. Raise the temperature of the mash to around 165°F (74°C) to stop the enzyme activity and begin the lautering process. Place a lauter tun or a hopback over the mash tun. Use a lauter tun with a false bottom to allow for better control of the separation process. Gently run the sparge water through the grains, ensuring a thorough extraction of sugars. The sparge water temperature should be higher than the mash temperature to encourage the remaining sugars to dissolve. Collect the wort in a separate container, leaving the spent grain in the lauter tun.

Sparging: Sparging is the final step in the mashing process, where hot water is sprinkled over the grains to extract any remaining sugars. This step ensures a complete extraction of fermentable sugars from the grains. Use a spray ball or a similar device to evenly distribute the sparge water over the grains. Maintain a temperature of around 165°F (74°C) for the sparge water. Continue sparging until you have extracted as much sugar as possible, typically until the specific gravity of the wort reaches a certain target. This target will vary depending on the beer style you are brewing.

By carefully controlling the temperature, time, and water-to-grain ratio during mashing, lauter, and sparging, you can ensure a successful extraction of sugars, which will form the basis of your beer's flavor and alcohol content. This preparation step is fundamental to the brewing process and sets the stage for the subsequent fermentation and aging of the beer.

Uncorking the Magic: Beer's Microbial Fermentation Journey

You may want to see also

Fermentation Process: Pitch yeast, monitor temperature, and control oxygen

The double fermentation technique in brewing is an advanced process that can significantly enhance the flavor and character of your beer. This method involves two separate fermentation stages, each contributing unique attributes to the final product. Here's a detailed guide on how to execute this process effectively:

Pitching Yeast:

The first step in double fermentation is pitching yeast. This involves transferring your fermented wort (the sugary liquid extracted from malted grains) into a secondary fermentation vessel. When pitching, it's crucial to use a healthy and active yeast culture. Start by preparing the yeast by rehydrating it according to the manufacturer's instructions. This ensures the yeast is active and ready to work. Then, carefully pour the yeast-rich wort into your secondary fermenter, leaving some headspace at the top. The pitch rate, or the amount of yeast pitched, should be optimized for the volume of your wort. Too little yeast may result in a slow fermentation, while an excess can lead to off-flavors. Aim for a rate that balances these factors.

Temperature Monitoring:

Temperature control is critical during fermentation, especially in double fermentation. Yeast activity is highly temperature-dependent. For the first fermentation, maintain a temperature range of 65-72°F (18-22°C). This range typically supports the yeast's primary fermentation, producing alcohol and carbon dioxide. After the first fermentation is complete, lower the temperature to around 55-60°F (13-15°C) for the secondary fermentation. This cooler temperature range encourages the yeast to consume more glucose, resulting in a more robust flavor and aroma. Regularly monitor the temperature using a reliable thermometer and adjust the fermentation vessel's position or use a cooling system if needed.

Oxygen Control:

Oxygen is essential for yeast during fermentation, but excessive oxygen can lead to off-flavors and potential contamination. In the first fermentation, ensure the wort is well-oxygenated by stirring or using an oxygenator. This step is crucial for yeast activation and a healthy fermentation start. During the secondary fermentation, oxygen control becomes even more critical. As the yeast consumes more glucose, the production of alcohol and carbon dioxide increases. This process can deplete the oxygen levels in the wort. To prevent this, consider using an oxygen-rich solution or sparging (adding oxygen-rich water) to maintain adequate oxygen levels. Additionally, ensure that the secondary fermenter is sealed properly to prevent external contaminants from entering.

Monitoring and Adjustments:

Throughout the double fermentation process, closely monitor the fermentation vessel for any signs of trouble. Check for signs of yeast activity, such as bubbling and carbonation. Adjust the temperature as needed to maintain the desired range. If you notice any off-flavors or odors, take corrective action promptly. This may include adjusting the yeast pitch rate, temperature, or oxygen levels. Regularly sample the beer to assess its progress and make any necessary adjustments to ensure a successful double fermentation.

Double fermentation is an art that requires precision and attention to detail. By carefully pitching yeast, monitoring temperature, and controlling oxygen, you can create a unique and flavorful beer that showcases the benefits of this advanced brewing technique.

Uncorking the Mystery: Does Lactic Acid Fermentation Beer Bubble with CO2?

You may want to see also

Secondary Fermentation: Increase alcohol content and flavor complexity

Secondary fermentation is a crucial step in the double fermentation process of brewing beer, as it allows brewers to enhance the flavor profile and increase the alcohol content of their beer. This stage involves transferring the beer from the primary fermentation vessel to a secondary container, where a second yeast strain or a different yeast type can be introduced. The primary goal is to further develop the beer's character and create a more complex and desirable flavor profile.

During the secondary fermentation, the beer continues to ferment, but with a different yeast or a yeast strain that is specifically chosen for its unique characteristics. This additional fermentation process can last anywhere from a few days to several weeks, depending on the desired outcome and the yeast's activity. The yeast in the secondary stage may produce different esters, alcohols, and other compounds, contributing to the beer's flavor and aroma. For example, a yeast like WLP099 can produce fruity esters, adding a pleasant fruitiness to the beer, while a yeast like Wyeast 3522 can contribute to a more robust and spicy character.

One of the key benefits of secondary fermentation is the ability to increase the beer's alcohol content. By introducing a yeast that ferments a higher percentage of sugars, brewers can boost the ABV (alcohol by volume). This is particularly useful for creating stronger, more robust beers or for achieving a specific style requirement. For instance, a Belgian ale yeast like Wyeast 3522 can ferment up to 75% of available sugars, resulting in a higher alcohol content compared to the primary fermentation.

Additionally, secondary fermentation allows brewers to fine-tune the beer's flavor and aroma. Different yeast strains or blends can introduce unique esters, phenols, and other flavor compounds. This process can create a more balanced and harmonious beer, where the various flavor elements come together harmoniously. For example, a yeast like WLP032 can produce a distinct banana and clove character, while Wyeast 3787 contributes to a more spicy and peppery profile.

It's important to note that secondary fermentation requires careful planning and monitoring. Brewers should consider the yeast's temperature preferences, the desired duration of the secondary stage, and the potential for off-flavors or unwanted compounds. Proper sanitation and oxygen management are crucial to ensure a successful double fermentation. By understanding the yeast's behavior and the impact of secondary fermentation, brewers can create unique and exceptional beers with increased alcohol content and flavor complexity.

Mastering Beer Fermentation: Tips for Accurate Temperature Control

You may want to see also

Aging and Bottling: Age beer, bottle, and carbonate for optimal taste

Aging and Bottling: Unlocking the Potential of Your Beer

The art of brewing is a delicate balance of science and creativity, and the aging and bottling process is a crucial step in crafting exceptional beer. When it comes to double fermentation, a technique often associated with Belgian-style beers, the aging and bottling phase can significantly impact the final product's flavor, carbonation, and overall character. Here's a comprehensive guide to mastering this stage:

Aging:

- Patience is key during the aging process. After the initial fermentation, allowing the beer to mature is essential. This step can be done in various ways, depending on your desired outcome. For a classic Belgian ale, consider a secondary fermentation in the bottle, which adds complexity and a unique flavor profile. Age the beer at a cool, consistent temperature, typically around 50-55°F (10-13°C). This temperature range slows down the fermentation process, allowing for a longer aging period, which can result in a smoother, more nuanced beer.

- For a more robust and complex beer, like a Belgian Tripel or Dubbel, aging can take several weeks to a few months. During this time, the beer develops a rich, fruity aroma and a well-rounded flavor. The longer aging process also contributes to a higher alcohol content, making these beers a delightful challenge for beer enthusiasts.

- If you're aiming for a crisp and refreshing beer, consider a shorter aging period. A young, vibrant beer can be bottled after just a few weeks, resulting in a lively, effervescent beverage.

Bottling:

- Bottling is an art that requires precision and attention to detail. Before bottling, ensure your beer is properly carbonated. This step is crucial, as it determines the beer's overall character. You can carbonate the beer in the bottle or use a bottling bucket, which is a more controlled environment.

- When bottling, use a sanitized bottle and cap to prevent any off-flavors. Fill the bottles to within an inch of the top, leaving space for carbonation. After bottling, store the beer horizontally for a day or two to allow the yeast to settle at the bottom of the bottle. This ensures a natural carbonation process.

- For a truly exceptional beer, consider dry hopping or adding a small amount of sugar to the bottle. This technique can enhance the beer's aroma and carbonation, creating a delightful sensory experience.

Carbonation:

- Carbonation is a critical aspect of beer enjoyment. After bottling, the beer will undergo a natural carbonation process, but you can also force carbonate it for a more immediate and intense result. Force carbonation involves adding a small amount of sugar and a carbonation agent to the beer, then sealing the bottles and allowing the carbon dioxide to dissolve. This process can be done at home with the right equipment and is a fun way to experiment with carbonation levels.

- The level of carbonation can vary depending on your preferences. A highly carbonated beer might be preferred for a refreshing summer drink, while a less carbonated version could be ideal for a complex, flavorful beer.

Mastering the aging and bottling process is an art that allows you to showcase the unique characteristics of your double-fermented beer. With patience, attention to detail, and a bit of experimentation, you can create beers that delight and surprise, offering a truly exceptional drinking experience. Remember, the key to success is understanding the nuances of each beer style and tailoring your aging and bottling techniques accordingly.

Mastering Beer Fermentation: A Guide to CO2 Fermentation Techniques

You may want to see also

Frequently asked questions

Double fermentation is a technique used in homebrewing and small-batch production where the beer undergoes two separate fermentation processes. The primary fermentation involves yeast converting sugars into alcohol and carbon dioxide, which is the standard process. The second fermentation, often called a "secondary fermentation," is an optional step where the beer is fermented again, typically with a different yeast strain or by adding a small amount of additional yeast to the beer already in the fermenter.

Double fermentation offers several advantages. Firstly, it allows brewers to experiment with different yeast strains and flavors, creating unique and complex beer profiles. The secondary fermentation can enhance the beer's aroma, flavor, and mouthfeel, resulting in a more refined and balanced beverage. Additionally, it can help clarify the beer by encouraging the formation of a protective layer of yeast and alcohol, which can improve shelf life and reduce the risk of spoilage.

The process typically involves transferring the beer from the primary fermenter to a secondary fermenter or a larger vessel. This transfer should be done carefully to avoid disturbing the yeast and sediment. After transferring, you can pitch a different yeast strain or add a small amount of additional yeast to initiate the secondary fermentation. Maintain proper temperature control and monitor the fermentation process closely.

While double fermentation can be beneficial, it also carries some risks. Over-fermentation is a common concern, as the additional yeast can lead to an excessive production of alcohol and carbon dioxide, potentially causing the beer to become too carbonated or even explode. Additionally, managing the temperature and oxygen levels during the secondary fermentation is crucial to prevent off-flavors and ensure a successful outcome. Proper sanitation and monitoring are essential to avoid contamination and maintain the desired beer quality.