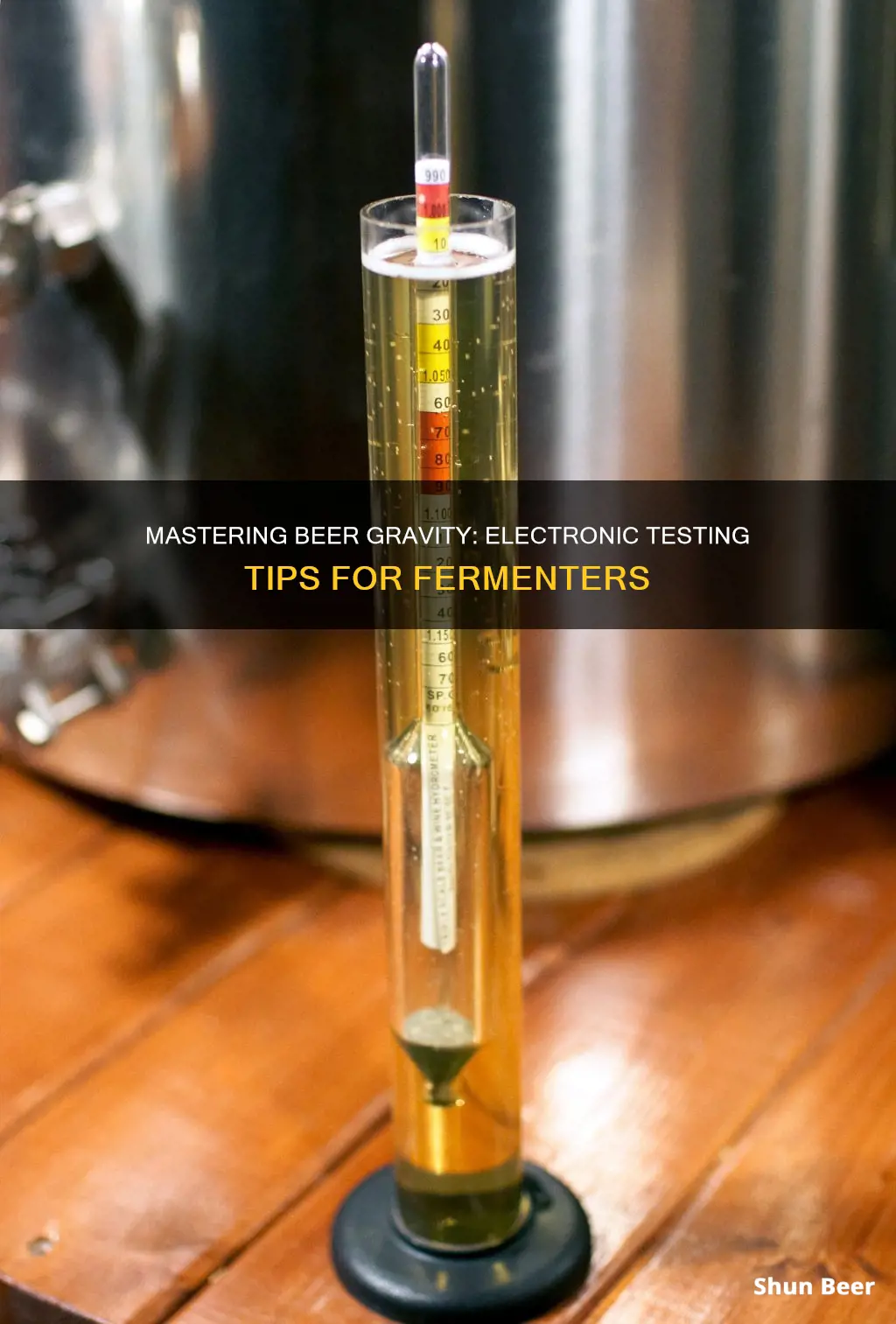

Testing the specific gravity, or gravity, of your beer during fermentation is a crucial step in the brewing process. This measurement helps you determine the alcohol content and overall quality of your brew. While traditional methods involve using a hydrometer, modern brewers can also use electronic devices to measure gravity. These electronic tools provide a quick and accurate way to check the gravity of your beer, ensuring that fermentation is progressing as expected. This guide will explore how to use electronic devices to test beer gravity during fermentation, offering a convenient and efficient approach to monitoring your brew.

What You'll Learn

- Digital Hydrometer Accuracy: Calibrate and verify digital hydrometer readings for precise beer gravity measurements

- Temperature Control: Maintain consistent temperature for accurate fermentation gravity readings

- Digital Hydrometer Calibration: Regularly calibrate digital hydrometers to ensure reliable beer gravity measurements

- Digital Hydrometer Placement: Position the digital hydrometer correctly for accurate beer gravity readings

- Digital Hydrometer Battery Life: Monitor and replace batteries in digital hydrometers for continuous beer gravity testing

Digital Hydrometer Accuracy: Calibrate and verify digital hydrometer readings for precise beer gravity measurements

The digital hydrometer is a valuable tool for homebrewers, offering a convenient and accurate way to measure beer gravity during fermentation. However, to ensure reliable results, proper calibration and verification of these devices are essential. Here's a step-by-step guide to achieving accurate digital hydrometer readings:

Calibration Process:

- Prepare a Calibration Solution: Obtain a specific gravity solution with a known concentration. This can be purchased from brewing supply stores or created using a calibration kit. The solution should ideally be close to the expected gravity of your beer at the desired stage of fermentation.

- Immerse the Hydrometer: Carefully lower the digital hydrometer into the calibration solution, ensuring it is fully submerged. Allow it to stabilize for a few seconds, as some models may require a specific immersion time for accurate readings.

- Record the Reading: Note the displayed value on the hydrometer's screen. Compare this reading with the known concentration of the solution. If there's a significant discrepancy, you may need to adjust the calibration.

- Adjust and Repeat: If the reading is off, you can adjust the hydrometer's settings or the calibration solution's concentration to match the expected value. Repeat the immersion and recording process until you achieve a precise match.

Verifying Accuracy:

After calibration, it's crucial to verify the digital hydrometer's accuracy to ensure reliable measurements throughout the fermentation process. Here's how:

- Compare with Traditional Hydrometer: For a comprehensive verification, compare the digital hydrometer's readings with those of a traditional liquid-filled hydrometer. This comparison will help you understand the digital hydrometer's performance and identify any potential issues.

- Use Multiple Solutions: Prepare a series of specific gravity solutions with varying concentrations, covering the expected range of beer gravity during fermentation. Measure each solution using both the digital and traditional hydrometers.

- Analyze Results: Compare the readings from both instruments. The digital hydrometer should provide values that are consistent with the traditional method. If there are consistent deviations, consider recalibrating or seeking a replacement.

Regular calibration and verification are essential to maintain the accuracy of your digital hydrometer. By following these steps, homebrewers can ensure that their beer gravity measurements are precise, leading to better control over the fermentation process and ultimately, a higher-quality brew. Remember, accurate measurements are the foundation of successful homebrewing!

Exploring the Surprising Chemistry: What Happens When You Drop a Cigarette in Beer?

You may want to see also

Temperature Control: Maintain consistent temperature for accurate fermentation gravity readings

Temperature control is a critical aspect of monitoring beer fermentation, especially when using electronic gravity testers. The goal is to maintain a consistent temperature throughout the fermentation process to ensure accurate and reliable gravity readings. Here's a detailed guide on how to achieve this:

Understanding the Impact of Temperature: Beer fermentation is a temperature-sensitive process. Yeast, the microorganisms responsible for fermentation, thrive within a specific temperature range. If the temperature deviates significantly, it can affect yeast activity, leading to inconsistent fermentation and inaccurate gravity measurements. Gravity readings are essential for brewers as they provide insights into the beer's density, which is directly related to its alcohol content and overall quality.

Setting Up a Controlled Environment: To ensure temperature consistency, consider the following steps. Firstly, choose a fermentation chamber or a dedicated space for the process. This area should be well-insulated to minimize heat exchange with the surrounding environment. Invest in a reliable temperature controller or a precision temperature regulator that can maintain a set temperature accurately. These devices are crucial for keeping the fermentation vessel at a stable temperature. Additionally, use a high-quality thermometer with a probe that can be placed directly in the fermenter to monitor the temperature in real-time.

Monitoring and Adjusting: Regularly monitor the temperature during fermentation. Take temperature readings at various points to identify any fluctuations. If you notice a temperature drift, take immediate action. Adjust the temperature controller settings to counteract the change and bring the temperature back to the desired range. For example, if the temperature rises, you might need to lower the set point, and if it drops, raise it slightly. This process ensures that the yeast remains active and healthy, promoting efficient fermentation.

Maintaining Consistency: Consistency is key to accurate gravity measurements. Aim to keep the fermentation temperature within a narrow range, typically around the optimal temperature for your chosen yeast strain. This consistency will result in reliable gravity readings, allowing you to track the fermentation progress effectively. It's important to note that different yeast strains may have varying temperature preferences, so always refer to your yeast's specific requirements.

By implementing these temperature control measures, you can ensure that your electronic gravity tester provides precise and reliable readings, enabling you to make informed decisions during the brewing process. Remember, temperature management is a vital component of successful beer fermentation and quality control.

Uncorking the Sweetness: Exploring the Art of Chocolate-Infused Beer

You may want to see also

Digital Hydrometer Calibration: Regularly calibrate digital hydrometers to ensure reliable beer gravity measurements

Digital hydrometers are essential tools for homebrewers and commercial breweries, offering a convenient and accurate way to measure the specific gravity of beer during fermentation. However, like any measuring device, they require regular calibration to ensure reliable and precise results. Calibration is a critical process that ensures your digital hydrometer provides accurate readings, which is crucial for adjusting the brewing process and achieving the desired beer quality. Here's a detailed guide on how to calibrate your digital hydrometer for beer gravity measurements:

Understanding the Calibration Process:

Calibration is the process of adjusting a measuring device to match a known standard. For digital hydrometers, this typically involves setting the device to a specific gravity value that is easily verifiable. The goal is to ensure that your hydrometer's reading aligns with a trusted reference point, providing you with accurate specific gravity measurements. Regular calibration is essential because digital hydrometers can drift over time due to various factors like temperature changes, battery power, and normal wear and tear.

Gathering the Materials:

To calibrate your digital hydrometer, you'll need a few essential items. Firstly, obtain a high-quality hydrometer calibration solution. This solution is specifically formulated to provide a stable and known specific gravity. You can purchase it from brewing supply stores or online retailers. Additionally, you'll require a clean, dry container with a volume that allows for accurate measurements. A graduated cylinder or a beaker is ideal for this purpose.

Calibration Steps:

- Prepare the Calibration Solution: Fill your chosen container with the calibration solution, ensuring it is at room temperature. Room temperature is important as it minimizes the impact of temperature variations on the calibration process.

- Immerse the Hydrometer: Carefully lower the digital hydrometer into the calibration solution, ensuring it is fully submerged. Allow it to rest for a few moments to stabilize.

- Read the Specific Gravity: Note the specific gravity value displayed on the hydrometer's screen. This reading should be close to the known specific gravity of the calibration solution.

- Adjust and Repeat: If the reading is off, you may need to adjust the hydrometer's settings. This process can vary depending on the model, so consult the manufacturer's instructions. After adjustment, repeat the immersion and reading process until you achieve a precise match with the calibration solution's known specific gravity.

Regular Maintenance:

Calibration should be performed regularly, ideally before each use, to ensure the highest accuracy. Over time, digital hydrometers may require more frequent calibration, especially if they are used intensively or in varying environmental conditions. Keep a record of your calibration dates and results to identify any patterns or issues.

Troubleshooting:

If you encounter persistent accuracy issues, consider the following: Check for battery power, as weak batteries can affect readings. Ensure the hydrometer is clean and free of debris. Verify that the calibration solution is of high quality and not expired. If problems persist, consult the manufacturer's support or seek advice from experienced brewers who can provide guidance tailored to your specific hydrometer model.

By following these calibration procedures, you can maintain the accuracy and reliability of your digital hydrometer, ensuring that your beer gravity measurements are consistently precise, which is vital for the success of your brewing endeavors.

Uncork the Mystery: Why Pepper Enhances Beer's Flavor

You may want to see also

Digital Hydrometer Placement: Position the digital hydrometer correctly for accurate beer gravity readings

When using a digital hydrometer to measure beer gravity during fermentation, proper placement is crucial for accurate readings. Here's a detailed guide on how to position the hydrometer correctly:

Understanding the Hydrometer: Begin by familiarizing yourself with the digital hydrometer. These devices typically have a probe that needs to be submerged in the beer to measure its specific gravity. The hydrometer's accuracy relies on direct contact with the beer's surface.

Preparation: Before taking a reading, ensure the beer is well-mixed and at room temperature. Stir the beer gently to distribute any sediment or yeast that might affect the measurement. Allow a few minutes for the beer to stabilize, ensuring a consistent temperature throughout.

Hydrometer Placement: The key to accurate readings is proper placement. Here's the step-by-step process:

- Submerge the Probe: Carefully lower the hydrometer's probe into the beer, ensuring it makes full contact with the liquid's surface. The probe should be fully submerged, with no part exposed above the beer level.

- Stabilize and Read: Hold the hydrometer steady and allow the probe to make contact with the beer. Ensure the hydrometer is level and stable. Read the specific gravity value displayed on the digital screen. Take multiple readings at different points in the fermentation process for consistency.

Tips for Accuracy:

- Always wipe the hydrometer's probe with a clean cloth before and after use to prevent contamination.

- Avoid touching the beer's surface with the hydrometer to prevent air bubbles from affecting the reading.

- Calibrate your digital hydrometer regularly to ensure it provides accurate measurements.

By following these placement techniques, you can ensure reliable and precise beer gravity measurements throughout the fermentation process, allowing you to monitor the progress and make informed adjustments to your brewing process.

Uncovering the Mystery: Why Beer Often Lands on Bottom Shelves

You may want to see also

Digital Hydrometer Battery Life: Monitor and replace batteries in digital hydrometers for continuous beer gravity testing

Digital hydrometers are invaluable tools for homebrewers, offering precise and instant readings of beer gravity, which is crucial for monitoring fermentation progress. However, like any electronic device, these hydrometers rely on batteries to function. The battery life of a digital hydrometer is an often-overlooked aspect of the brewing process, but ensuring its longevity and proper maintenance can significantly impact the accuracy and reliability of your beer gravity measurements. Here's a comprehensive guide to monitoring and replacing batteries in your digital hydrometer for continuous beer gravity testing.

Understanding Battery Life:

Digital hydrometers typically use small, button cell batteries, often lithium or silver oxide, which provide the necessary power for temperature compensation and display illumination. The battery life can vary depending on factors such as usage frequency, ambient temperature, and the specific model of the hydrometer. On average, a well-maintained digital hydrometer can operate for several months on a set of batteries. However, it's essential to monitor this regularly, especially if you frequently use your hydrometer during the brewing process.

Monitoring Battery Life:

- Regular Checks: Make it a habit to check the battery compartment of your digital hydrometer periodically. Over time, you'll develop a sense of when the batteries are running low. Look for any signs of corrosion or leakage around the battery contacts, as this can affect performance.

- Display Behavior: Pay attention to the behavior of your hydrometer's display. If the readings become less stable or the display flickers, it could indicate low battery power. In such cases, it's best to replace the batteries promptly.

- Temperature Compensation: Note that some digital hydrometers have built-in temperature compensation features. If your hydrometer shows inconsistent readings or fails to compensate for temperature changes, it might be due to weak batteries affecting the sensor's performance.

Replacing Batteries:

- When you notice a decline in performance or it's time for a routine replacement, follow these steps:

- Ensure you have the correct type and size of replacement batteries. Refer to your hydrometer's manual or the manufacturer's website for specific battery recommendations.

- Power down your hydrometer and turn it upside down to release any residual power.

- Open the battery compartment, usually located at the back of the device, by pressing a small release button or sliding a latch.

- Carefully remove the old batteries and insert the new ones, ensuring they are inserted correctly and securely.

- Close the compartment and turn the hydrometer back on to test its functionality.

Tips for Longevity:

- Store your hydrometer in a cool, dry place when not in use to minimize power drain.

- Avoid exposing it to extreme temperatures, as this can affect battery performance and the hydrometer's overall accuracy.

- Consider investing in a spare set of batteries to have on hand, ensuring you're always prepared for beer gravity testing.

By actively monitoring and replacing the batteries in your digital hydrometer, you can maintain consistent and accurate beer gravity measurements throughout the fermentation process, contributing to the overall success of your brewing endeavors. Regular maintenance ensures that your hydrometer remains a reliable tool in your homebrewing arsenal.

Brewing at Home: Exploring the Beer-Crock Pot Combo

You may want to see also

Frequently asked questions

Beer gravity, also known as specific gravity, is a measure of the density of the wort (unfermented beer) and is expressed as a ratio compared to the density of pure water at the same temperature. It is crucial to monitor during fermentation as it provides valuable insights into the brewing process. Gravity readings help determine the efficiency of fermentation, the alcohol by volume (ABV) of the final product, and the overall quality of the beer.

Electronic refractometers are commonly used tools for measuring beer gravity. These devices measure the refractive index of the wort, which is directly related to its density. Place a small sample of the wort on a clean refractometer, ensure it's at room temperature, and read the gravity value displayed on the device. This method provides quick and accurate results, allowing brewers to make real-time adjustments during fermentation.

The ideal gravity range can vary depending on the beer style and the brewer's preferences. Generally, most beers ferment between an initial gravity (OG) of 1.040 and 1.120. For example, an American Lager might ferment in the lower range (1.040-1.060), while a Belgian Tripel could have a higher initial gravity (1.080-1.120). Monitoring the gravity throughout fermentation helps identify any deviations from the expected range, indicating potential issues like contamination or incorrect ingredient measurements.

Testing gravity regularly is essential for successful brewing. It is recommended to take gravity readings at least once a day, preferably at the same time each day, to establish a consistent baseline. Additionally, take readings at different stages of fermentation, such as after the boil, during the fermentation vessel's filling, and just before bottling or kegging. This frequency ensures you capture the beer's progress accurately and make informed decisions about the brewing process.

If the gravity readings deviate significantly from the expected range, it may indicate a problem with the brewing process. Possible causes include contamination, incorrect ingredient measurements, or issues with the fermentation vessel's cleanliness. In such cases, it's crucial to investigate further and take corrective actions. This might involve adjusting the recipe, sanitizing equipment, or extending the fermentation time to achieve the desired gravity and beer quality.