Homebrewing is a rewarding hobby that is easier to start than you might think. The basic process of brewing beer has remained unchanged for millennia, and with the right equipment and ingredients, anyone can do it.

There are two main types of homebrewing: all-grain brewing and extract brewing. All-grain brewing involves extracting sugars from milled grains, while extract brewing uses ready-made malt extract, skipping the sugar extraction process. Although all-grain brewing offers more flexibility and creativity, extract brewing is quicker, produces quality beer, and is perfect for beginners as it requires minimal equipment and procedures.

To start homebrewing, you will need a few essential items, including a fermenter, beer recipe kit or individual ingredients, and various cleaning and sanitizing agents and equipment. The brewing process involves several steps, from steeping grains and boiling the wort to fermentation and bottling or kegging.

With the right knowledge, equipment, and ingredients, anyone can brew delicious beer at home. So, are you ready to join the community of homebrewers and create your own concoctions?

| Characteristics | Values |

|---|---|

| Purpose | Add bitterness, flavour and aroma to beer |

| Hop types | Bittering, flavouring, dual-use, aroma |

| Hop varieties | Chinook, Columbus, Simcoe, Cascade, Fuggle, Kent Golding, Saaz, Hallertau, Tettnanger, Spalt, Strissel Spalt, Goldings, Fuggles, W.G.V, Cascade, Columbus, Centennial, Willamette, Amarillo, Pacific Gem, Motueka, Nelson Sauvin, Brewer's Gold, Brewer's Favorite, Wye Target, Wye Challenger, Wye Northdown, Wye Saxon, Wye Yeoman |

| Hop plant components | Alpha acids, beta acids, essential oils |

| Alpha acids | Responsible for bittering capabilities |

| Beta acids | Add flavour to beer |

| Essential oils | Add aroma to beer |

| Hopping methods | Mash hopping, first wort hops, boil hops, late hop additions, hop back, dry hopping, hop bursting, hop steeping, hop tea technique, Randall |

| Dry hopping | Adding hops after the beer has fermented |

What You'll Learn

Sanitise your equipment

Sanitising your equipment is an important step in the beer-making process. Sanitising your equipment protects your beer from mould, bacteria, and wild yeast that could be in the air, on dust, or covering every surface. While cleaning removes the dirt, sanitising kills the microbes.

There are a few different ways to sanitise your equipment. The first is oxygen-based sanitizers, such as One Step and PBW. These are great for new brewers as they are fuss-free and hard to mess up. However, they must be used fresh and within about 30 minutes of mixing. They are also ineffective in a spray bottle, so equipment must be soaked.

The second option is iodine-based sanitizers, such as IOStar and BTF Iodophor. These are cost-effective as a little bit of the product mixes up a big batch. They will also last for weeks to months if stored in a sealed container. However, they stain easily, so be careful not to spill them. You must also let items air dry before use, as any leftover liquid can affect the flavour of your beer.

The third option is acid-based sanitizers, such as Star San, which is a favourite among brewers. This is a phosphoric acid-based sanitizer that is very effective on clean equipment. It is also easy to mix, as it comes in a bottle with measurement lines. A diluted batch can be stored for months. To check if a stored batch is still good, you can check the pH (it must be below 3 to be effective) or the haziness (if it's hazy, it may be losing its effectiveness). Star San also foams, which makes it easier to coat your equipment.

Other methods of sanitisation include heat, such as boiling water or using a microwave oven, autoclaving (steam under pressure), fractional sterilisation (heating a liquid to 175–212 °F (80–100 °C) for 30 minutes, three days in a row), dry heat, incineration, ultraviolet (UV) lights, and chemical agents such as soap, chlorine bleach, iodine, alcohol, and acids and bases.

It is important to note that sanitising solutions should be treated with respect, as they may be hazardous in their concentrated form. Always follow the recommended instructions for mixing, coating, contact time, and air-drying. Once diluted, these solutions are food safe.

Hops in Beer: Necessary or Overrated?

You may want to see also

Prepare the grains

The first step in dry hopping is to select the hop variety to use. You normally want to use a hop variety that is considered a "flavour" or "aroma" hop. It is common for these hops to have relatively low alpha-acid ratings, often around 6% or less. Some hop varieties commonly used for dry hopping include Cascade, Crystal, Willamette, East Kent Golding, Fuggle, Saaz, Hallertau and Tettnanger.

Of course, one of the beauties of homebrewing is that you do not have to follow anyone's suggestions; you can try whatever you want. This being said, some home brewers dry-hop with high alpha-acid varieties like Centennial and Chinook. Personal preferences vary, and you should experiment to see what you like. In general, if you like the results of using a particular hop variety in the last 5–10 minutes of the boil, you will probably like the results of dry hopping with the same variety.

If you are dry hopping with whole leaf hops, you will need to prepare them differently than if you were using pellets. Whole leaf hops will need to be dried before they can be used for dry hopping. To do this, you will need to pick the cones and then dry them. The cones should be light and dry and should spring back after a squeeze. They should also have a pungent smell between cut grass and onion.

Once you have picked your cones, you have two options: throw them directly into a brew to make a wet-hopped beer, or dry them to use later. If you choose to dry your hops, you can more easily predict the alpha-acid contribution as dried hops are about 10% water, the equivalent of commercial hops.

Important factors to consider when drying hops are time, light, heat, and moisture. Drying shouldn't last more than three days, and heating temperatures shouldn't exceed 140°F (60°C). Drying your hops will drive off some wanted aromatics, but temperatures above this threshold will drive off many more complexities.

There are a few different methods that can be used for drying hops:

- Using a food dehydrator is the easiest way to dry out your hops, as it ensures air movement but does not get excessively hot.

- Using a well-ventilated oven: spread the hops out on a pan and make sure that you get adequate airflow through the oven, checking on them at least every 20 minutes.

- Using a hop-drying screen: if you have a small amount of hops to dry, spread them out over a window screen or a house air filter. Place them in a warm, dry location and use landscape fabric over the top to keep them in the dark. Occasionally fluff the hops so that moist inner cones are brought to the outside of the pile. Leave them for a few days with a fan under or next to them to maintain airflow.

The hops need a moisture content of 8 to 10 per cent by weight to prevent moulding. To see if they’re dry enough, try breaking the central stem of the cone; it should be brittle enough to snap in half. When dry, the yellow powdery lupulin should easily fall from the cone, and the leaves should have a papery and springy texture.

Once your hops are dried, you will need to weigh them out and separate them into one- to two-ounce bags so you will only have to defrost the amount you need when it’s time to brew again.

Once you’ve divided up your hops into plastic freezer bags, food saver bags, or airtight jars, push as much air out of the containers as possible. A vacuum seal is ideal for this process, but not necessary. Label them with the type of hop and toss them into the freezer for safe keeping.

Dry Hopping Beer in a Carboy: The Ultimate Guide

You may want to see also

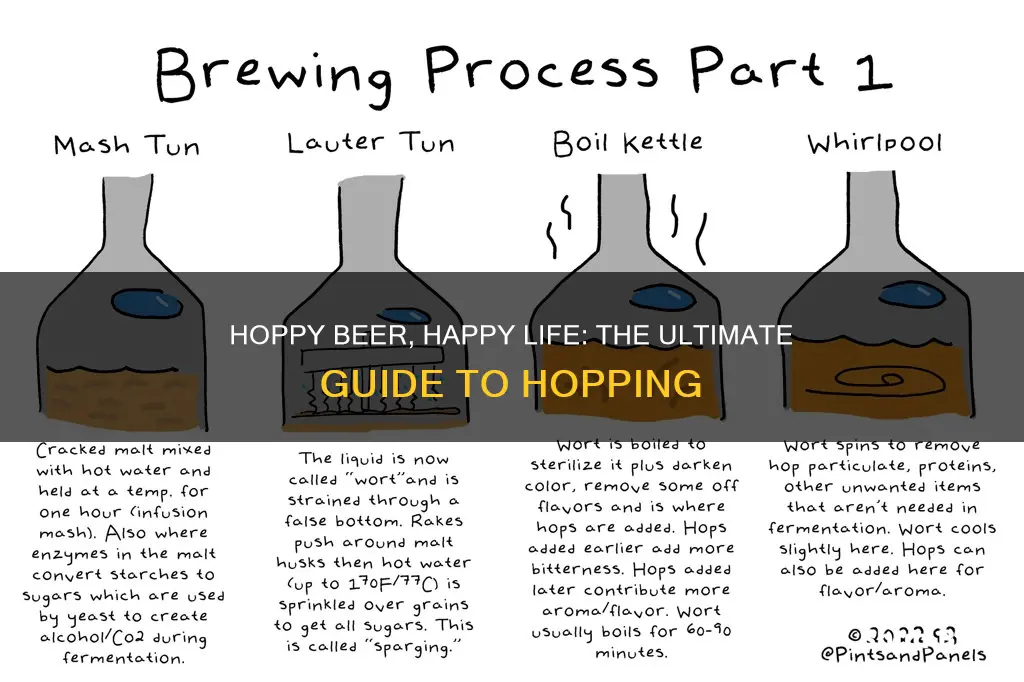

Boil the wort

Boiling the wort is an important step in the beer-making process. It is important to understand the role of boiling and how it factors into the overall process of making beer.

The wort is the "beer starter". It is a sweet, malty liquid that is made by converting the starches of malted grains into sugar. Hot water is added to the mash to allow the enzymes to finish the conversion from starch to sugar. The boiling of the wort is a vital step because it sterilises the liquid and halts the starch-to-sugar conversion process.

The boiling process affects many qualities of the beer, including gravity, colour, bitterness, flavour, purity, and clarity. Boiling produces bittering in beer by dissolving hop resins and isomerising alpha acids, which are not initially in a form that is soluble in wort or bitter. The longer the hops are boiled, the more bitterness they will add to the beer.

It is also important to boil the wort to evaporate off certain undesirable compounds, such as dimethyl sulfide (DMS), which has a noticeable vegetal aroma and flavour. A vigorous boil will evaporate the DMS and drive it off into the air as steam.

Additionally, boiling the wort plays a major role in sanitising the wort and killing any wild yeast, harmful bacteria, and other microorganisms that could cause souring and undesirable flavours.

The boiling process also helps to coagulate proteins and polyphenols, which can cause haze in the beer. The heat and agitation of boiling cause these larger proteins and polyphenols to separate from the attached water molecules and collect together, forming hot break material that floats throughout the wort.

Finally, boiling the wort can also affect the colour of the final beer. Boiling darkens the wort and the beer, and reducing the boiling time will result in a lighter colour.

In summary, boiling the wort is a critical step in the beer-making process. It sterilises the wort, halts the starch-to-sugar conversion, adds bitterness, removes undesirable compounds, sanitises the wort, clarifies the beer, and affects the colour of the final product.

Hops to Beer: Acres of Fun and Flavor

You may want to see also

Cool the wort

The wort needs to be cooled to fermentation temperature as quickly as possible to avoid bacterial contamination. The ideal temperature range is between 65 and 72 °F (18 and 22 °C). There are several methods to achieve this:

- Cooling in a Water Bath: Place the brewpot in a sink or tub of cold water. Stir the wort occasionally, and change the water as it warms. This method can take up to 30 minutes.

- Counterflow Chiller: This device uses cold water to cool the hot wort as it passes through a coil of copper tubing. It is the fastest and most efficient method for cooling wort.

- Immersion Chiller: This is a coil of copper tubing that is placed directly into the brewpot to cool the wort. It is less expensive than a counterflow chiller but takes longer to cool the wort.

- Ice Bath: Fill your sink or tub with ice and a small amount of water. Place the brewpot in the ice bath and stir the wort occasionally until it reaches the desired temperature.

Once the wort has cooled to the desired temperature, it is ready to be transferred to the fermenter.

Hops and Cannabis: THC in Beer Explored

You may want to see also

Ferment the beer

Fermenting is a crucial step in the beer-making process, and it involves adding hops to your beer. This process is known as "dry hopping", and it can be done in several ways and at different stages of fermentation.

Dry hopping is the process of adding hops (either dried whole leaf or pellets) to your beer after primary fermentation. This technique allows you to add aroma and flavour to your beer without making it bitter. Hops contain alpha acids, which, when heated during the boil, undergo isomerization, resulting in bitter beer. By adding hops after fermentation, you preserve the delicate volatile oils that give your beer its desired aroma and flavour.

There are a few things to consider when dry hopping your beer. Firstly, you can use either whole leaf hops or pellet hops. Whole leaf hops tend to float on top of the liquid, while pellet hops disintegrate into a sludge that sinks to the bottom. Pellet hops are more convenient, readily available, and efficient, as they have a longer shelf life and absorb less beer. However, whole leaf hops can add a unique vegetal flavour to your beer. Commercial breweries typically use pellet hops due to their advantages, but some still use whole leaf hops for specific flavours.

Another consideration is the timing of dry hopping. You can choose to dry hop during active primary fermentation (usually on days 0-5) or after fermentation has finished (days 5-8). Dry hopping during active fermentation is a newer trend, believed to enhance flavours and aromas through chemical reactions between the yeast and hops, resulting in different tropical flavours. This technique is often used for New England-style IPAs. On the other hand, dry hopping after fermentation is a more traditional method, allowing the beer to retain more aroma as the vigorous CO2 activity has finished.

The amount of hops you use will depend on your personal preference and the desired intensity of flavour and aroma. A general rule of thumb is to use one ounce of hops for every five gallons of average-strength beer. However, you can use up to four to five ounces for a stronger aroma or in higher-gravity beers.

When adding dry hops to your beer, there is no need to sanitise them as the alcohol in the beer will prevent contamination. Additionally, hops are naturally antimicrobial. If you are using a straining bag, it is recommended to sanitise it by boiling before use.

Finally, you can choose to contain the hops in a bag or let them roam free in your beer. Using a bag makes it easier to remove the hops later, but it may reduce the surface area of the hops in contact with the beer, potentially impacting the flavour and aroma extraction.

Choosing Hops for Beer: A Guide to Aromatic Excellence

You may want to see also

Frequently asked questions

Dry hopping is the process of adding hops after the beer has fermented. Hops are typically added in the secondary fermenter or keg and left for a period of several days to several weeks. Dry hopping is used to add a hoppy aroma to the beer, as no bitterness is added with this method.

Bittering hops have higher concentrations of alpha acids and are responsible for the bitter flavour of a beer. Aroma hops usually have a lower concentration of alpha acids and are the primary contributors of hop aroma and (non-bitter) flavour.

Some popular high alpha acid hops include Chinook, Columbus and Simcoe.