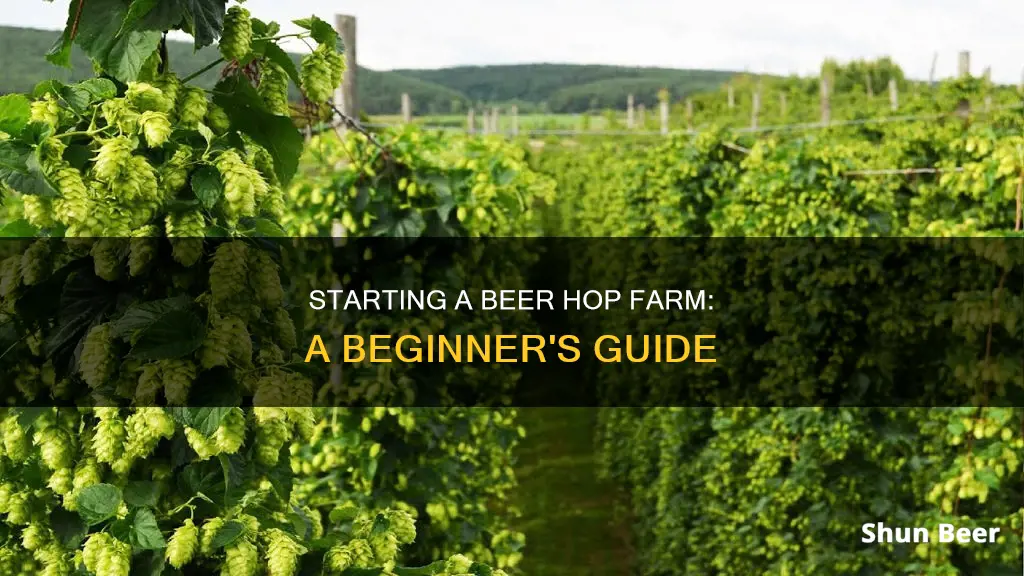

Hops are an essential ingredient in beer, providing both flavour and preservation. With the popularity of craft beer on the rise, there is a growing demand for hops in a variety of flavours. Starting a hop farm can be a profitable business venture, but it requires careful planning and a substantial investment of time, money and management. This introduction will cover the key considerations for anyone interested in starting a hop farm, from choosing a location and preparing the site to planting, nurturing and harvesting hops.

| Characteristics | Values |

|---|---|

| Land | Well-drained, fertile soil with good sun exposure. |

| Land size | Depends on hops variety, market, and production goals. |

| Climate | Hot, humid summers are ideal. |

| Hop variety | Choose types in demand and suitable for your climate. |

| Trellis system | Essential for supporting vertical growth. |

| Irrigation system | Implement efficient systems like drip irrigation for consistent watering. |

| Planting techniques | Use the right methods for hop varieties and trellis training. |

| Harvesting techniques | Cut low and use a hop picker for flower extraction. |

| Drying hops | Ensure moisture content is optimal to prevent mold. |

| Storage | Keep dried hops in a cool, dark place for quality preservation. |

| Marketing | Engage with local breweries, set up online sales, and network through regional hop-growing associations. |

| Scaling | Increase acreage and invest in advanced equipment as you gain experience. |

| Sustainable practices | Adopt organic methods, conserve water, and use eco-friendly pest control. |

| Cost | $200,000 for 10 acres. |

What You'll Learn

Land acquisition and quality assurance

Land acquisition is one of the most crucial steps in starting a hop farm. It is essential to assess the size of the land needed, considering the hops variety, market demand, and production goals. The cost of land can vary depending on size, location, and zoning regulations, with prices ranging from $1,200 per acre in some western states to $4,500-$6,500 per acre in the Northeast. It is also important to factor in additional costs such as zoning regulations, access to irrigation systems, and legal counsel for transactions.

When selecting land for a hop farm, it is crucial to focus on well-draining, fertile soil with good sun exposure. A soil test can confirm the quality of the soil. Additionally, ensuring that the land receives adequate sunlight is essential, with a daily sun exposure of 6-8 hours being optimal for hop growth.

Quality assurance in hop production is vital to guarantee the consistency and quality of the final product. This includes implementing a robust quality management system that adheres to industry standards and certifications, such as ISO 9001 and HACCP. Regular analysis of key indicators, such as gland fill, cone weight, dry matter, alpha acids, beta acids, and oils, is essential to determine the optimal harvest time.

Furthermore, establishing standardised production processes, including extraneous matter tests and moisture level checks, ensures that the hops meet specifications at every stage. Implementing a comprehensive traceability system, such as lot numbering, also enables brewers to have complete information about the hops they are using, including where they were grown, how they were harvested and dried, and any chemicals applied.

By focusing on quality assurance, hop farmers can build trust with their customers and ensure the consistency and quality of their product, which is essential in the highly competitive craft beer market.

Identifying Hops in Beer: A Guide to Flavor and Aroma

You may want to see also

Choosing hop varieties

Choosing the right hop varieties is a crucial step in starting a beer hop farm. With hundreds of varieties available, each with its unique characteristics, the selection process can be daunting. Here are some factors to consider when choosing hop varieties for your farm:

Climate Suitability

When selecting hop varieties, it is essential to consider your local climate. Different hop varieties thrive in specific climatic conditions. For example, the Chinook variety grows well in dry, hot climates, while Golding hops prefer mild and moist climates. Understanding your climate will help you choose varieties that will grow successfully.

Market Demand

Another critical factor is selecting hop varieties that are in demand. Research the current market trends and craft brewing developments to identify the most sought-after hop varieties. Understanding the preferences of your target customers, such as craft brewers or home brewing enthusiasts, will help guide your selection.

Flavour and Aroma Profiles

Hops play a significant role in imparting flavour and aroma to beer. Different hop varieties offer distinct flavour profiles, ranging from citrusy and earthy to spicy and floral. Consider the desired flavour profile for your beer and choose hop varieties that align with those characteristics.

Growth Characteristics

Each hop variety has unique growth requirements and characteristics. Some varieties, like the Chinook, are known for their vigorous growth and can reach impressive heights. Others may have specific soil or sunlight requirements. Understanding the growth habits of different varieties will help you select those that align with your farm's conditions and trellis system.

Disease Resistance

When choosing hop varieties, consider their resistance to common diseases and pests. Some varieties are more susceptible to issues like downy mildew or verticillium wilt. Selecting disease-resistant varieties can reduce the need for chemical treatments and promote healthier plants.

Maturity and Yield

Different hop varieties have varying maturity rates and yields. Some varieties, like the Cascade, are known for their high yield and relatively quick maturity. In contrast, others may take longer to establish but offer a more substantial long-term yield. Consider your production goals and select varieties that align with your desired output.

By carefully considering these factors, you can choose hop varieties that are well-suited to your farm's unique conditions and align with market demands. Remember that you can always start with a few select varieties and expand your offerings as you gain experience in hop farming.

Hops' Role in Brewing: Aromatic and Bitter Beer Balancing

You may want to see also

Building a trellis system

Planning and Materials

Before you begin construction, it's important to decide on the location of your trellis system. Choose an area in your yard that receives ample sunlight throughout the day, preferably facing south. The area should also be slightly elevated and have good drainage.

In terms of materials, you can opt for a premade trellis system like the IBEX Hops Growing System, or you can build your own. If you decide to build your own, you'll need the following materials:

- Wooden posts (pressure-treated and ground contact rated)

- Wooden boards (pressure-treated)

- Heavy-duty twine or stainless steel wire

- Galvanized tent stakes, eye hooks, and J-hooks

- Galvanized or stainless steel screws

- Buckets or containers for planting

- Quick-drying concrete

Construction Process

- Set the posts: Mark the spots for your posts, ensuring they are level and facing each other. The distance between the posts will depend on the number of plants you plan to grow. For four plants, a distance of 12 feet between the posts is recommended. Set each post in concrete and let it cure for at least four hours.

- Create the horizontal boards: Cut the wooden boards to the desired length and attach eye hooks and J-hooks. The hooks should be installed in a specific order to ensure they face each other when the boards are turned towards each other.

- Attach the horizontal boards: Use decking screws to attach the horizontal boards to the top and outside of the posts. This will prevent the weight of the hop plants from pulling the boards off.

- Set the planting buckets: Hops can act as an invasive species, so it's important to contain their root systems. Drill drainage holes in the buckets and place them in the ground, spacing them evenly on each side of the trellis. Fill the buckets with a mix of dirt and compost soil.

- String the twine: Start by tying a loop at one end of the twine and attaching it to a J-hook. Stretch the twine across the span of posts to the corresponding eye hook on the other side. Drop the twine down to the bucket and securely tie it to a tent stake inside the bucket.

- Plant your hop rhizomes: Train your hop plants to reach up towards the twine. Once they have grown tall enough, they will continue to move up the trellis on their own.

- Harvest your hops: The twine used for training the hops is usually not reusable. Simply cut the twine at the hooks and let it fall to the ground.

Additional Considerations

- Cost: The cost of building a trellis system can vary depending on the materials used. Premade trellis systems like the IBEX Hops Growing System can be expensive, costing around $775. Building your own trellis with wooden posts and twine can be a more economical option, with materials costing around $180.

- Maintenance: Hop plants require regular maintenance, including pest management and pruning. It's important to train the hop vines to grow upwards and provide support as they climb.

- Harvesting: Consider the ease of harvesting when building your trellis system. Commercial hop farms use tall poles and wire cables, with guy wires to keep the structure secure. The trellis system should also allow for easy access to the hop cones during harvesting.

Genesee Bock Beer: Hoppy or Not?

You may want to see also

Irrigation system

When it comes to irrigation, it is critical to ensure proper hydration for your hops. Hops require a significant amount of water, especially during their first year of growth. The older the plant, the less frequent the watering.

Hops in the Burlington, VT, region, for example, require 24-28 inches (651,696-760,312 gallons) of water per acre per year. This translates to regular weekly irrigation, with split applications of 2-3 days per week being ideal. Keep in mind that higher amounts may be needed when establishing a new yard.

The timing of water application is just as crucial as the amount. Hops need most of their water between the training and flowering stages for optimal vegetative growth.

To determine the necessary irrigation amounts, consider the potential evapotranspiration (PET) rates for your specific location. You can then subtract weekly precipitation from the calculated weekly irrigation requirement.

Drip irrigation is highly recommended for hops. This method ensures efficient water usage, applying water directly to the plants. It can also help reduce the risk of pests and insects in your yard. Additionally, drip irrigation is environmentally friendly, as it minimizes runoff and leaked water loss on the farm.

In contrast, overhead sprinkler systems can lead to the development of downy mildew and powdery mildew on hops, which negatively impacts growth, viability, taste, and can even destroy the entire crop.

By implementing an effective irrigation system, you can promote healthy bine growth, flower development, and overall yield while also contributing to the sustainability and efficiency of your hop farm.

The Magic of Hops: Unlocking Beer's Bitter Notes

You may want to see also

Harvesting and processing

Harvesting Techniques

The harvesting process begins with cutting the bines low to the ground, using specialized equipment such as the WOLF Hop Harvester, which removes the hop flowers cleanly without any stems or leaves. The timing of the harvest is crucial, as you want to ensure the hops are picked at their peak maturity to achieve optimal oil levels. The harvest typically occurs from mid-August through September, with aromatic varieties maturing first. It is important to monitor the cones closely and harvest when they feel light, dry, and spring back after a gentle squeeze.

Drying and Conditioning

Once harvested, the hops need to be dried to prevent moulding. This process should not exceed three days to prevent oxidation and isomerization. The drying process can be done using various methods, such as drying screens, oven drying, or specialized kiln drying. The goal is to reduce the moisture content of the hops to the optimal range to inhibit mould growth. The hops are then conditioned in specialized vented chambers to maintain their quality.

Storage and Packaging

After drying and conditioning, the hops are ready for storage. They should be kept in a cool, dark place to preserve their quality. Proper packaging is essential to maintain freshness. Hop pellets, for example, are sealed in nitrogen-flushed oxygen barrier bags and then boxed and refrigerated until shipped.

Processing and Pelletizing

The dried hops are then processed and pelletized. This involves grinding the hop leaves into a fine powder and forcing them through a die under extreme pressure to form dense pellets. This process ensures that the hops can be easily dispersed into the beer during the brewing process.

Quality Control and Analysis

Throughout the harvesting and processing stages, quality control measures are implemented to ensure the hops meet the desired standards. This includes inspecting the hops for moisture content, temperature, and stem and leaf content. Additionally, every lot of pellets is tested and analysed to provide brewers with detailed information about the product they are receiving.

By following these steps and maintaining a high level of attention to detail, hop farmers can produce high-quality hops that meet the demands of craft brewers and contribute to the growing craft beer industry.

Growing Beer Hops Indoors: A Step-by-Step Guide

You may want to see also