Determining when fermentation is complete in beer brewing can be a tricky process, especially when you don't have a hydrometer. However, there are several methods you can use to estimate when fermentation is finished. These include monitoring the beer's temperature, color, and carbonation levels, as well as using sensory cues like smell and taste. By paying close attention to these factors, you can make an educated guess about when fermentation is complete, ensuring your beer reaches the desired flavor and alcohol content.

| Characteristics | Values |

|---|---|

| Temperature Check | Fermentation is complete when the temperature of the beer stabilizes and remains consistent. You can take temperature readings at different points during fermentation and observe if there's a significant drop or rise. |

| Visual Inspection | Look for a clear, stable beer with no visible signs of bubbling or agitation. The color should remain consistent, and there should be no visible signs of yeast activity. |

| Time Duration | Fermentation typically takes 1-2 weeks for most beer styles. However, this can vary depending on the recipe, yeast type, and desired alcohol content. |

| Carbonation Level | As fermentation progresses, the beer will become carbonated. When fermentation is complete, the carbonation level should be stable and not increase further. |

| Odor and Flavor | The beer's odor and flavor should be stable and not show any signs of off-flavors or esters. A well-fermented beer will have a clean, crisp taste. |

| Yeast Activity | When fermentation is complete, yeast activity should be minimal. You might notice a slight increase in yeast activity during the 'lag phase' at the beginning of fermentation, but it should subside as the process continues. |

| Gravity Reading (Optional) | While a hydrometer is not always necessary, you can measure the specific gravity of the beer at the start and end of fermentation. A stable reading indicates completion. |

| Sugar Consumption | Monitor the sugar consumption during fermentation. When the sugar is completely consumed, fermentation is likely complete. |

| Oxygen Exposure | Ensure the beer has adequate oxygen exposure during fermentation, as this can affect the completion time and quality. |

What You'll Learn

- Visual Cues: Cloudiness, color change, and sediment settling indicate fermentation's end

- Odor: Alcohol and esters become dominant, while sulfur odors fade

- Time: Fermentation typically takes 1-2 weeks, but can vary

- Temperature: Fermentation slows at room temperature, stops at cold temperatures

- Carbonation: Carbon dioxide release decreases, and beer becomes carbonated

Visual Cues: Cloudiness, color change, and sediment settling indicate fermentation's end

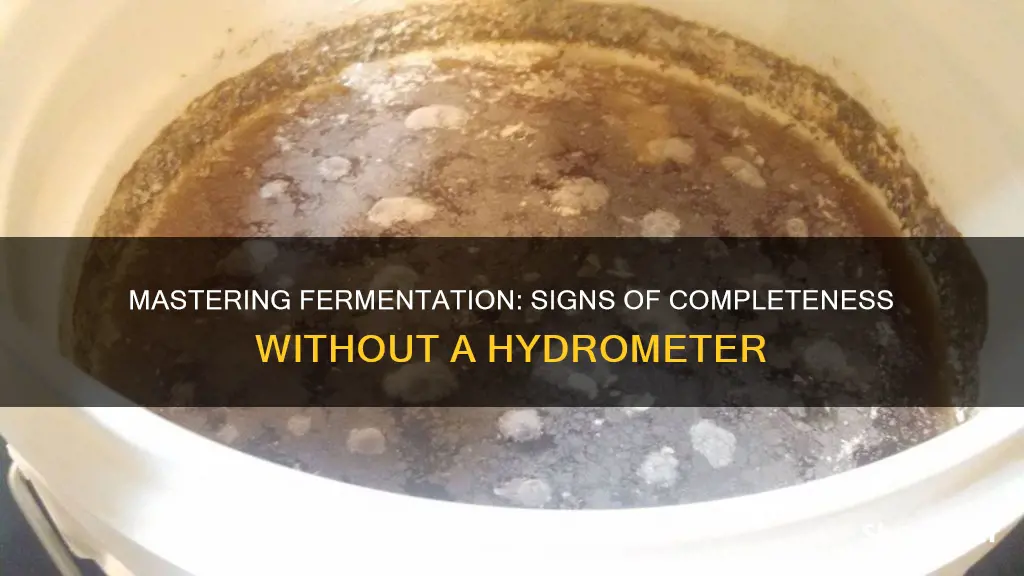

When it comes to homebrewing, determining the end of fermentation without a hydrometer can be an art, but visual cues can be your trusted allies. Here's a breakdown of how to read the signs:

Cloudiness: One of the most noticeable changes is the appearance of cloudiness in your brew. During fermentation, yeast consumes sugars and produces alcohol and carbon dioxide. This process leaves behind yeast particles and other solids, causing the liquid to become cloudy. As fermentation progresses, you'll likely notice a gradual increase in cloudiness. Once fermentation is complete, the yeast activity slows down, and the beer becomes clearer. If you notice a sudden clearing or a significant reduction in cloudiness, it might indicate that the yeast has finished its work.

Color Change: Keep an eye on the color transformation of your beer. Initially, the wort (the sugary liquid before fermentation) will have a pale, golden hue. As fermentation begins, the color might darken slightly due to the yeast's activity. However, towards the end of fermentation, you might observe a stabilization or even a slight lightening of the color. This color change is often subtle but can be a valuable indicator of the fermentation's progress.

Sediment Settling: Another visual sign is the appearance of sediment at the bottom of the fermenter. As fermentation progresses, yeast and other solids will settle, creating a layer at the bottom. When fermentation is complete, this sediment will remain relatively undisturbed. If you notice a significant amount of sediment moving around or rising to the surface, it could suggest that fermentation is still active. Allowing the beer to rest for a few days can help confirm if the sediment has settled, providing a clear indication of fermentation's end.

It's important to remember that these visual cues are more art than science, and individual batches may vary. Patience is key; observing your beer regularly will help you develop a keen eye for these fermentation signs. Additionally, keeping notes on the appearance of your brew at different stages can be incredibly helpful for future brews, allowing you to refine your techniques and become a master of the fermentation process.

The Art of Aging Beer: Post-Fermentation Waiting Game

You may want to see also

Odor: Alcohol and esters become dominant, while sulfur odors fade

The process of fermentation is a fascinating transformation of sugars into alcohol and carbon dioxide, and it's crucial to understand the signs that indicate when this process is nearing its end. When you're brewing beer without using a hydrometer, relying on sensory cues becomes essential. One of the key indicators of a successful fermentation is the shift in the beer's aroma. Initially, during the early stages of fermentation, you might notice a distinct sulfur odor, often described as "eggy" or "skunky." This sulfurous smell is a result of the production of sulfur dioxide, which is a byproduct of yeast activity. However, as the fermentation progresses, this sulfurous note begins to diminish.

As the yeast continues its work, the beer's aroma undergoes a transformation. The alcohol content in the beer becomes more pronounced, giving it a sharper, more alcoholic scent. Simultaneously, the esters, which are compounds responsible for fruity and spicy notes, start to dominate the beer's fragrance. These esters can contribute to the beer's overall flavor profile, adding complexity and depth. The transition from the sulfurous early stages to the more aromatic and alcoholic later stages is a clear sign that fermentation is nearing completion.

The fading of sulfur odors and the emergence of alcohol and ester aromas are critical markers for brewers. These changes indicate that the yeast has efficiently converted the available sugars, and the beer is no longer in a state of active fermentation. It's a subtle yet powerful indication that the beer is ready for the next step in the brewing process, such as conditioning or packaging.

For homebrewers and enthusiasts, paying close attention to these olfactory cues can be a valuable skill. It allows you to time your brewing process precisely, ensuring that your beer reaches its full potential in terms of flavor and quality. The absence of sulfur odors and the presence of distinct alcohol and ester aromas are strong indicators that your beer is ready to be enjoyed.

In summary, the evolution of a beer's aroma during fermentation is a critical aspect of brewing. The shift from sulfurous notes to the dominance of alcohol and ester aromas signifies a well-progressed fermentation process. This knowledge empowers brewers to make informed decisions, ensuring their beer reaches the desired state of maturity and flavor complexity.

Mastering Beer Fermentation: When to Stop with a Conical Refractometer

You may want to see also

Time: Fermentation typically takes 1-2 weeks, but can vary

Fermentation is a fascinating process that transforms simple ingredients into delicious beverages, and knowing when it's complete is crucial for achieving the desired outcome. While using a hydrometer is a common method, there are alternative ways to determine if your beer fermentation is finished, especially if you don't have access to this tool.

The duration of fermentation can vary depending on several factors. Typically, it takes around 1 to 2 weeks for the primary fermentation process to occur. However, this timeframe is just an estimate, and the actual completion time can differ. Factors such as yeast type, starting gravity, temperature, and the specific recipe can all influence the fermentation duration. For instance, a higher starting gravity might result in a longer fermentation period, as the yeast has more sugar to consume.

During the fermentation process, the yeast works tirelessly to convert sugars into alcohol and carbon dioxide. As the yeast population grows, it creates a visible sign of fermentation—a frothy, bubbling liquid. This activity gradually slows down as the yeast consumes the available sugars, and the fermentation nears its end. At this stage, the yeast becomes less active, and the bubbling subsides.

Another indicator of fermentation completion is the stability of the beer's characteristics. As fermentation progresses, the beer's taste, aroma, and appearance should become consistent and balanced. If you notice any significant changes in these aspects towards the end of the fermentation period, it might indicate that the process is not yet complete. For example, if the beer starts to develop off-flavors or becomes overly sweet, it could mean that the yeast is still active and needs more time to finish the job.

It's important to remember that patience is key during this stage. Allowing the beer to ferment for the appropriate duration ensures that the flavors develop fully and the yeast has a chance to work its magic. While it can be tempting to rush the process, taking the time to let the fermentation complete will result in a more satisfying and well-rounded beverage.

Mastering Beer's Balance: Stopping Yeast Fermentation

You may want to see also

Temperature: Fermentation slows at room temperature, stops at cold temperatures

Fermentation is a complex process that is highly sensitive to temperature changes. When brewing beer, understanding the relationship between temperature and fermentation is crucial to knowing when your beer has reached completion. The temperature of your fermentation environment plays a significant role in the rate and progress of the fermentation process.

As the name suggests, fermentation is a biological process where yeast converts sugars into alcohol and carbon dioxide. This process is exothermic, meaning it releases heat. Initially, when you start the fermentation, the temperature of the wort (the sugary liquid extracted from the grains) will rise due to the yeast's metabolic activities. However, as the fermentation progresses, the temperature will naturally stabilize and then gradually decrease. This temperature drop indicates that the yeast is becoming less active and the fermentation is nearing its end.

Room temperature, typically around 20-25°C (68-77°F), is often considered an ideal range for fermentation. At this temperature, the yeast remains active and continues to work efficiently. However, as fermentation progresses, the temperature will naturally drop as the yeast consumes the available sugars and the process slows down. This temperature reduction is a good indicator that the fermentation is complete, especially if you've maintained a consistent temperature throughout the process.

The critical aspect of temperature control becomes evident when you consider cold temperatures. When the fermentation vessel is placed in a cold environment, the yeast's activity significantly decreases. This is because yeast is a living organism, and like all living things, it has an optimal temperature range for growth and reproduction. Cold temperatures can slow down or even halt the fermentation process. If you notice that the fermentation has stopped or is progressing very slowly, moving the fermentation vessel to a warmer area might help resume the process.

In summary, monitoring the temperature of your fermentation is essential to determining when your beer is fully fermented. Room temperature allows for a healthy and active yeast population, while the subsequent temperature drop as fermentation progresses is a natural and expected phenomenon. Understanding these temperature-related cues will help you make informed decisions during the brewing process and ensure a successful beer fermentation.

Beer Stickers: 5 Creative Places to Display Your Favorite Brews

You may want to see also

Carbonation: Carbon dioxide release decreases, and beer becomes carbonated

When it comes to brewing beer, achieving the perfect level of carbonation is essential for a refreshing and enjoyable drinking experience. One of the key indicators of a successful fermentation process is the gradual decrease in carbon dioxide (CO2) release. Here's a detailed guide on how to monitor and understand the carbonation process without using a hydrometer:

During the fermentation process, yeast consumes sugars and produces alcohol and CO2 as byproducts. Initially, you'll notice a steady increase in CO2 release, which is a sign of active yeast activity. However, as the fermentation progresses, the rate of CO2 production will start to slow down. This reduction in CO2 release is a clear sign that the yeast is nearly finished with the fermentation process. The beer will begin to take on a slightly more stable character, and the bubbling action will become less vigorous.

The decrease in CO2 release is a result of the yeast depleting the available sugars and reaching the end of its fermentation cycle. At this stage, the beer has reached a state of equilibrium, and the yeast's activity slows down significantly. It's important to note that the fermentation process doesn't suddenly stop; instead, it gradually tapers off, allowing the beer to mature and develop its flavors.

To monitor this change, you can observe the fermentation vessel regularly. Initially, you might see a constant stream of bubbles rising to the surface. As the fermentation progresses, the frequency of these bubbles will decrease, and the bubbles themselves may become smaller. Eventually, the bubbling will become intermittent, and the beer will start to feel 'flat' to the touch. This is a natural part of the fermentation process and indicates that the beer is ready for packaging or aging.

Additionally, you can perform a simple test to estimate the level of carbonation. After the fermentation has slowed down, carefully pour a small sample of the beer into a glass and observe the head formation. If the beer forms a tight, persistent head with good retention, it suggests that the carbonation is at a desirable level. If the head is weak and dissipates quickly, it may indicate that the fermentation is not yet complete, and more time is needed.

Remember, achieving the right level of carbonation is an art, and practice makes perfect. By closely monitoring the CO2 release and observing the beer's characteristics, you can develop a keen sense of when the fermentation is complete, resulting in a well-carbonated and delicious beer.

The Art of Flavoring Beer: When and Why

You may want to see also

Frequently asked questions

One of the most common methods to assess fermentation completion is by observing the beer's clarity. If the beer has become clear and no longer shows signs of active fermentation, such as bubbling or a rising alcohol content, it's a good indicator that the process is complete.

Yes, you can check the temperature of the beer. During fermentation, the temperature should drop as the yeast consumes sugars and produces alcohol. When the temperature stabilizes and remains consistent, it suggests that fermentation is nearing its end.

Absolutely! The aroma of the beer can provide valuable insights. When fermentation is complete, the beer should have a distinct, stable smell that is characteristic of the style you're brewing. For example, a dry beer might have a crisp, clean aroma, while a fruity ale could exhibit notes of ripe fruit.

Examining the yeast can also help. When fermentation is complete, the yeast will typically settle at the bottom of the fermenter, forming a sediment layer. If you notice a clear separation of yeast and beer, it's a strong sign that fermentation is finished.