Fermentation is a fundamental process in the art of brewing beer, but is it the most important? This question delves into the heart of brewing, where the transformation of simple ingredients into a complex beverage is a delicate dance of science and tradition. The fermentation process, where yeast converts sugars into alcohol and carbon dioxide, is indeed crucial, as it determines the beer's flavor, aroma, and overall character. However, other processes, such as mashing and hopping, also play significant roles in shaping the final product. This exploration aims to unravel the significance of fermentation while considering the intricate interplay of various brewing techniques.

What You'll Learn

- Fermentation Basics: Yeast converts sugars into alcohol and carbon dioxide, a key process in beer production

- Flavor and Aroma: Fermentation influences the unique flavors and aromas found in different beer styles

- Alcohol Content: The fermentation process determines the beer's alcohol by volume (ABV) level

- Yeast Strains: Different yeast strains produce distinct beer characteristics, impacting flavor and fermentation efficiency

- Fermentation Time: Longer fermentation periods can enhance beer complexity, but shorter times may preserve freshness

Fermentation Basics: Yeast converts sugars into alcohol and carbon dioxide, a key process in beer production

Fermentation is indeed a fundamental and transformative process in the art of brewing beer. At its core, fermentation is the magical process by which yeast, a microscopic organism, transforms simple sugars into alcohol and carbon dioxide. This seemingly simple conversion is the very essence of beer's character and flavor profile.

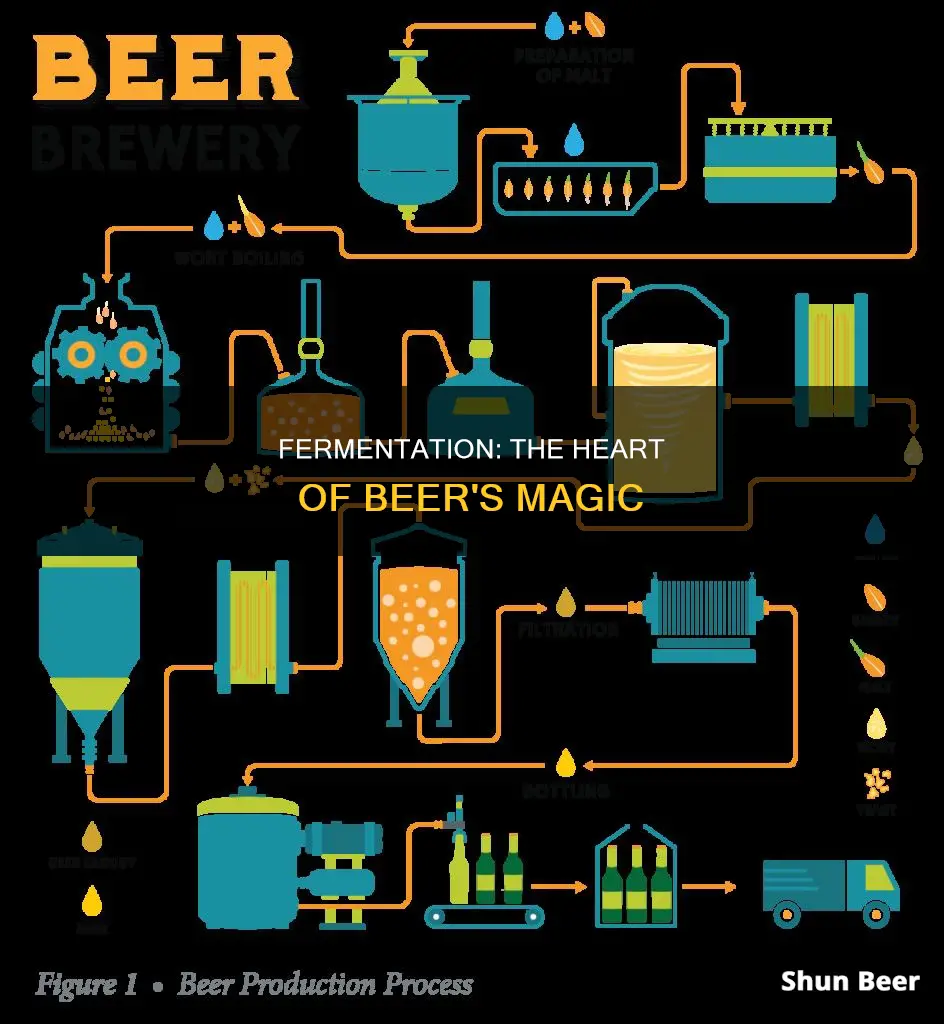

In the context of beer production, the process begins with the malting of grains, primarily barley. Through a series of steps, including soaking, germination, and drying, the grains are prepared to extract their starches. These starches, primarily in the form of maltose, are the primary food source for the yeast. When the malted grains are crushed and mixed with hot water in a process called mashing, the enzymes in the malt break down the starches into simpler sugars, primarily maltose. This sugary liquid, known as wort, is then separated from the grain and is where the yeast comes into play.

Yeast, a single-celled microorganism, is added to the wort in a carefully controlled environment. There are various types of yeast used in brewing, each contributing unique characteristics to the final beer. Ale yeasts, for instance, are commonly used for their ability to ferment at warmer temperatures, producing beers with fruity and estery notes. Lager yeasts, on the other hand, are used for their efficiency in cooler temperatures, resulting in crisp and clean lagers. The yeast's role is to consume the maltose and other sugars in the wort, producing alcohol and carbon dioxide as byproducts. This fermentation process can take anywhere from a few days to several weeks, depending on the style of beer and the yeast strain used.

As the yeast works its magic, the alcohol content in the beer gradually increases, while the carbon dioxide is released as a gas. This carbon dioxide is what gives beer its characteristic fizz and is a crucial aspect of the beverage's appeal. The fermentation process also contributes to the development of the beer's flavor and aroma, as the yeast metabolizes various compounds in the wort, creating unique esters, phenols, and other flavor compounds.

In summary, fermentation is the cornerstone of beer production, where yeast's metabolic activities transform sugars into alcohol and carbon dioxide, shaping the beer's character and quality. It is a delicate and intricate process that brewers carefully manage to create the diverse range of beers we enjoy today. Understanding this basic yet vital process is key to appreciating the complexity and artistry of the beer-making craft.

Unraveling the Fermentation Timeline: From Brew to Beer

You may want to see also

Flavor and Aroma: Fermentation influences the unique flavors and aromas found in different beer styles

Fermentation is indeed a pivotal process in the art of brewing, and it significantly contributes to the diverse range of flavors and aromas that define various beer styles. This intricate biochemical transformation involves yeast metabolizing sugars derived from malted grains, primarily barley, and producing alcohol and carbon dioxide as byproducts. The specific yeast strains and fermentation techniques employed play a crucial role in shaping the sensory characteristics of the final product.

During fermentation, yeast interacts with the malt's natural sugars, primarily maltose, and converts them into simpler sugars like glucose and fructose. This process is facilitated by enzymes present in the malt, which break down complex carbohydrates. The yeast then ferments these sugars, releasing carbon dioxide and producing ethanol, the alcohol responsible for the beer's intoxicating effect. The type of yeast and the fermentation conditions can lead to vastly different flavor and aroma profiles.

For instance, top-fermenting yeast strains, such as those used in ale brewing, tend to produce fruity and estery flavors. These yeasts can create a range of aromas, from the refreshing citrus notes of a wheat beer to the tropical fruitiness of a tropical ale. On the other hand, bottom-fermenting yeasts, commonly used in lager brewing, often result in cleaner, crisper flavors with less estery character. They contribute to the crisp, refreshing qualities often associated with lagers.

The fermentation process also influences the beer's color and body. For example, the presence of certain yeast strains can lead to a more pronounced hop character, as they may enhance the perception of hop bitterness or create unique, spicy notes. Additionally, the fermentation temperature can impact the beer's flavor and aroma. Higher fermentation temperatures might encourage the development of fruity esters, while cooler temperatures can result in a more neutral, crisp profile.

Mastering fermentation is an art that brewers refine over years of experience. By carefully selecting yeast strains and controlling fermentation parameters, brewers can craft beers with distinct flavor and aroma profiles. This attention to detail allows for the creation of a vast array of beer styles, each with its unique sensory characteristics, making fermentation an indispensable process in the world of beer.

Unraveling the Mystery: Why Beer Needs a Yolk

You may want to see also

Alcohol Content: The fermentation process determines the beer's alcohol by volume (ABV) level

The fermentation process is indeed a critical and intricate phase in the art of brewing beer, and it plays a pivotal role in determining the alcohol content of the final product. This process involves the transformation of sugars present in the wort (the sugary liquid extracted from malted grains) into alcohol and carbon dioxide by yeast. The alcohol by volume (ABV) level, a measure of the beer's strength, is directly influenced by the efficiency and duration of this fermentation.

During fermentation, yeast consumes the fermentable sugars, primarily maltose, and produces ethanol and CO2. The amount of sugar available and the type of yeast used significantly impact the ABV. For instance, a higher initial sugar concentration in the wort will result in a more robust fermentation, leading to a beer with a higher alcohol content. Brewers carefully manage the sugar-to-water ratio and select specific yeast strains to achieve their desired ABV.

The duration of fermentation also plays a crucial role. Longer fermentation periods often result in a more robust flavor development and a higher alcohol level. This is because the yeast continues to metabolize sugars, producing more alcohol and complexing the beer's flavor profile. However, extended fermentation can also lead to off-flavors if not carefully monitored. Brewers often use temperature control and specific yeast strains to manage fermentation duration and intensity.

Additionally, the type of yeast used is essential. Different yeast strains have varying fermentation capabilities and alcohol tolerances. For example, ale yeasts typically produce higher alcohol levels compared to lager yeasts. Brewers might choose specific yeast strains to target a particular ABV range, ensuring the beer meets the desired style and strength guidelines.

In summary, the fermentation process is a key determinant of a beer's alcohol content. Brewers have a wide range of techniques and tools at their disposal to manipulate this process, allowing them to craft beers with diverse ABV levels and flavor profiles. Understanding and controlling fermentation is an art that brewers refine over years of experience, resulting in the diverse and captivating world of beer we enjoy today.

Fermentation Timeline: Unlocking the Secrets of Beer's Magic Brew

You may want to see also

Yeast Strains: Different yeast strains produce distinct beer characteristics, impacting flavor and fermentation efficiency

Yeast strains play a pivotal role in the art of brewing, significantly influencing the final beer's character and quality. Different yeast strains possess unique characteristics that can either enhance or detract from the desired flavor profile. For instance, the widely used *Saccharomyces cerevisiae* yeast strain is renowned for its efficiency in alcohol production and its ability to ferment a broad range of sugars. This strain is often employed in lager brewing, contributing to the crisp, clean taste associated with pale lagers. However, when it comes to more complex beer styles like Belgian ales or wheat beers, brewers might opt for *Lactobacillus* or *Brevethella* strains, which introduce fruity esters and a distinct sour note, adding complexity to the beer's flavor profile.

The impact of yeast strains extends beyond flavor; it also affects fermentation efficiency. Some yeast strains are more robust and can handle higher alcohol levels, making them ideal for producing stronger, more robust beers. For instance, *Saccharomyces bayanus* is known for its high-temperature fermentation capabilities, allowing brewers to create beers with higher alcohol content without compromising fermentation success. Conversely, *Saccharomyces cerevisiae* strains may struggle with high-gravity wort, often requiring specific techniques like yeast propagation and nutrient management to ensure a successful fermentation.

Understanding the nuances of different yeast strains is crucial for brewers aiming to create beers with specific characteristics. For instance, the use of *Wyeast 3522* yeast is popular in homebrewing circles for its ability to produce a clean, crisp ale with a well-balanced flavor. In contrast, *White Labs WLP099* is favored for its ability to produce fruity, estery notes, making it a go-to choice for Belgian-style ales. These yeast strains not only influence the beer's flavor but also contribute to the overall fermentation process, affecting the beer's clarity, color, and overall quality.

The art of yeast selection is a delicate balance between flavor and fermentation efficiency. Brewers must consider the unique attributes of each yeast strain to ensure the beer's character aligns with their vision. For instance, while *Saccharomyces pastorianus* is known for its ability to produce rich, fruity flavors, it may require specific fermentation conditions, such as a cool, controlled environment, to prevent off-flavors. Similarly, *Lactobacillus* strains, often used for sour beers, can introduce a range of flavors, from tart and acidic to fruity and complex, but they may also require careful management to avoid over-fermentation.

In conclusion, yeast strains are a critical component in the brewing process, offering brewers a means to control and manipulate the beer's flavor and fermentation characteristics. The choice of yeast can significantly impact the final product, from the beer's taste and aroma to its overall quality and drinkability. Understanding the unique attributes of different yeast strains empowers brewers to create beers that meet specific style guidelines and cater to a wide range of consumer preferences.

Crafting a Beer Cap Map: A Guide to Organizing Your Collection

You may want to see also

Fermentation Time: Longer fermentation periods can enhance beer complexity, but shorter times may preserve freshness

Fermentation is indeed a pivotal process in the art of brewing, and the duration of this process significantly influences the character and quality of the final beer. While longer fermentation periods are often associated with more complex and nuanced flavors, shorter fermentation times can offer a different set of advantages, particularly in terms of preserving the beer's freshness and vibrancy.

In the realm of brewing, fermentation is the transformation of sugars into alcohol and carbon dioxide, primarily carried out by yeast. This process is not merely a chemical reaction but a delicate dance of flavors and aromas. Longer fermentation periods, typically ranging from 7 to 14 days or more, allow for a more extensive development of flavors and aromas. During this extended time, yeast continues to metabolize sugars, producing a broader spectrum of compounds that contribute to the beer's complexity. For instance, longer fermentation can enhance the development of fruity esters, which add a delightful fruitiness to the beer, and also intensify the formation of hop-derived bittering compounds, resulting in a more robust and flavorful beer.

However, shorter fermentation times, often ranging from 3 to 7 days, have their own merits. One of the primary benefits is the preservation of the beer's freshness and natural vibrancy. When fermentation is completed swiftly, the beer retains more of its original character, including the subtle nuances of the malt, hops, and water used in the brewing process. This approach is particularly favored in styles like American lagers and certain wheat beers, where a crisp, clean taste is desired. By minimizing the time yeast interacts with the beer, brewers can ensure that the beer's natural flavors and aromas are not overly altered, resulting in a more authentic and refreshing drinking experience.

The choice between longer and shorter fermentation periods ultimately depends on the beer style and the brewer's objectives. For instance, Belgian ales and some stouts benefit from extended fermentation, which contributes to their rich, complex flavors. In contrast, pale lagers and certain IPAs may be fermented for shorter durations to maintain a crisp, hop-forward profile. Additionally, brewers can employ techniques like temperature control and the use of specific yeast strains to further influence the fermentation process and achieve the desired outcome.

In summary, fermentation time is a critical factor in the brewing process, offering brewers a spectrum of options to craft beers with distinct characteristics. Longer fermentation periods unlock a beer's full potential for complexity, while shorter times preserve freshness and authenticity. Understanding and manipulating fermentation duration allows brewers to cater to diverse tastes and preferences, making fermentation a truly essential and versatile process in the world of beer.

Blue Moon's Secret: Lactose or Not? Unveiling the Truth

You may want to see also

Frequently asked questions

Fermentation is a natural process where yeast microbes convert sugars derived from malted grains into alcohol and carbon dioxide. This step is crucial in beer production as it determines the final flavor, alcohol content, and overall character of the beverage.

Fermentation is the key to transforming the sugary liquid known as wort into beer. It allows brewers to control the alcohol level, create unique flavors, and develop the desired aroma and mouthfeel. Without fermentation, beer would lack the characteristic fizz and taste we associate with it.

Absolutely! There are primarily two types: top-fermentation and bottom-fermentation. Top-fermentation occurs at warmer temperatures and is common in ale production, resulting in fruity and spicy notes. Bottom-fermentation, used for lagers, happens at cooler temperatures, leading to cleaner and crisper flavors.

While fermentation is undoubtedly vital, other processes play equally important roles. Mashing, for instance, involves heating malted grains to extract sugars, providing the raw material for fermentation. Hop addition during boiling contributes bitterness, flavor, and aroma. Additionally, aging and conditioning processes further refine the beer's character, making each step essential to the final product.