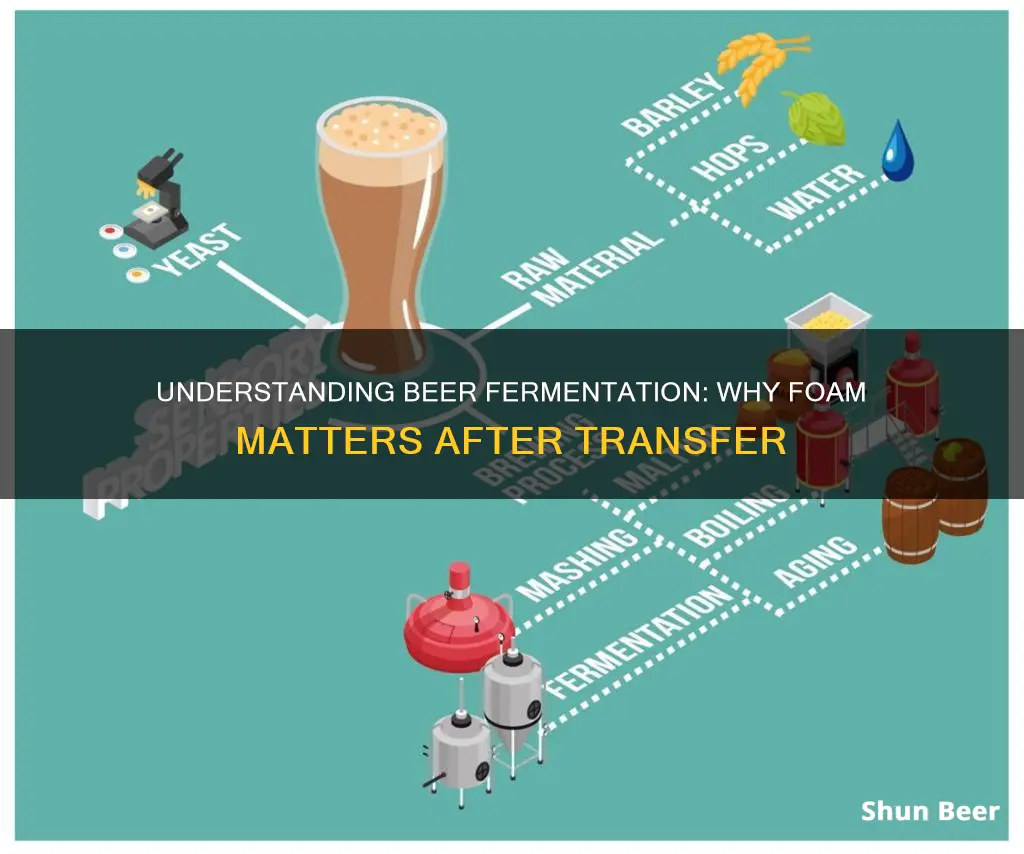

When it comes to the process of brewing beer, the fermentation stage is a crucial step that can significantly impact the final product's quality and characteristics. One common question that arises among homebrewers and beer enthusiasts is whether fermenting beer should be foamy after the transfer process. This paragraph aims to shed light on this topic, exploring the reasons behind the appearance of foam during fermentation and its implications for the beer's overall health and flavor development. By understanding the science behind fermentation foam, brewers can make informed decisions to ensure a successful and flavorful beer-making journey.

| Characteristics | Values |

|---|---|

| Appearance | Yes, it is common for beer to be slightly foamy or cloudy after transferring from the primary to the secondary fermenter. This is due to the yeast activity and the release of carbon dioxide. |

| Fermentation Process | The foaming is a natural part of the fermentation process, especially during the initial stages. It indicates that the yeast is active and metabolizing sugars. |

| Yeast Type | Different yeast strains can produce varying levels of foam. Some yeasts are known for their high foam potential, while others may produce less. |

| Temperature | Lower temperatures can sometimes lead to more pronounced foaming as the yeast activity slows down. |

| Gravity | Higher gravity beers (more sugar content) may exhibit more foam due to the increased yeast activity and sugar availability. |

| Time | The foaming might subside over time as the beer stabilizes and the yeast activity slows down. |

| Carbonation | Fermentation produces carbon dioxide, which can cause the beer to be slightly carbonated and foamy. |

| Flavor Impact | In most cases, the foaming is not a cause for concern and does not significantly affect the final beer flavor. |

What You'll Learn

- Fermentation Dynamics: Understanding how yeast activity affects beer foam

- Temperature Impact: Higher temperatures can increase foaminess during fermentation

- Oxygen Levels: Controlled oxygen can promote desired foam characteristics

- Nutrient Availability: Adequate nutrients support yeast growth and foam formation

- Fermentation Vessel: Type of vessel influences foam stability post-transfer

Fermentation Dynamics: Understanding how yeast activity affects beer foam

The process of fermentation in beer production is a fascinating interplay of yeast and sugars, and one of the key outcomes is the formation of beer foam. This phenomenon is not just a visual delight but also an indicator of the yeast's activity and the overall health of the fermentation process. When you transfer the beer from the primary fermentation vessel to the secondary one, the yeast's role becomes even more crucial in determining the final product's characteristics, including foam stability.

Yeast, a microscopic organism, is responsible for converting sugars derived from malted grains into alcohol and carbon dioxide. During fermentation, yeast activity creates a complex network of bubbles within the beer, which contributes to the foam. The intensity and longevity of this foam can vary significantly depending on the type of yeast used and the fermentation conditions. For instance, ale yeasts tend to produce more robust, longer-lasting foam due to their higher esterase activity, which breaks down sugars and contributes to the beer's carbonation. In contrast, lager yeasts are known for their slower fermentation process, resulting in a more subtle foam.

The transfer process itself can impact yeast activity and, consequently, the beer's foam. When transferring, it's essential to handle the beer gently to avoid excessive oxygen exposure, as this can stimulate yeast activity and lead to a more vigorous fermentation. However, if the transfer is too rough, it might disrupt the yeast's environment, causing a temporary slowdown in fermentation. This slowdown can result in a less foamy beer initially but may lead to a more stable and persistent foam over time as the yeast readjusts.

Understanding the dynamics of yeast activity is crucial for brewers aiming to control the beer's final attributes. By manipulating fermentation conditions, such as temperature and nutrient availability, brewers can influence the yeast's behavior. For example, warmer temperatures can accelerate fermentation, potentially leading to a more active yeast and a more pronounced foam. Conversely, cooler temperatures might slow down fermentation, resulting in a more subtle foam character.

In summary, the foam in beer is a direct reflection of the yeast's fermentation process and the conditions it experiences. The transfer process and overall fermentation management play a significant role in shaping the beer's foam characteristics. Brewers can create beers with varying foam profiles by carefully selecting yeasts and controlling fermentation parameters, ensuring a diverse and satisfying range of beer styles.

The Ultimate Guide to Filling Your Beer Advent Calendar

You may want to see also

Temperature Impact: Higher temperatures can increase foaminess during fermentation

The temperature of the fermentation environment plays a significant role in the beer-making process, particularly when it comes to foaminess. Higher temperatures can indeed contribute to increased foaminess during fermentation, and understanding this relationship is crucial for brewers aiming to produce a smooth and consistent beer.

When yeast ferments beer, it undergoes a complex process of breaking down sugars and producing alcohol and carbon dioxide. This process is highly sensitive to temperature changes. As the temperature rises, the yeast's activity intensifies, leading to a faster fermentation rate. While this might seem beneficial, it can have an unintended consequence: increased foam formation. The higher temperature accelerates the yeast's work, causing it to release more carbon dioxide gas. This excess gas can lead to a more vigorous bubbling and foaming action in the fermenter.

Brewers often aim for a controlled fermentation process, and temperature management is a critical tool in their arsenal. By maintaining a slightly warmer environment, they can encourage a faster fermentation, which can help reduce the time spent in the fermenter. However, this increased temperature must be carefully monitored to prevent the beer from becoming too foamy. Excessive foam can make the beer appear unappealing and may even lead to issues during the bottling or canning process.

To manage this, brewers employ various techniques. One approach is to gradually ramp up the temperature during the early stages of fermentation, allowing the yeast to adapt and then stabilize the temperature. This controlled temperature increase helps the yeast work efficiently without causing an overproduction of foam. Additionally, using specific yeast strains that are more tolerant of higher temperatures can also contribute to better foam control.

In summary, while higher temperatures can speed up the fermentation process, they also have the potential to increase foaminess. Brewers must carefully consider temperature management to strike a balance between a rapid fermentation and a beer that meets the desired quality standards. Understanding this temperature-foam relationship is essential for producing consistently excellent beer.

Master the Art of Beer in Your Margarita: A Guide to the Perfect Blend

You may want to see also

Oxygen Levels: Controlled oxygen can promote desired foam characteristics

The role of oxygen in beer fermentation is often overlooked, but it can significantly impact the final product, especially when it comes to foam stability. Controlled oxygen levels during the fermentation process can be a powerful tool for brewers to achieve the desired foam characteristics in their beer. This technique is particularly useful for styles that require a robust and long-lasting head, such as stouts, porters, and certain wheat beers.

When transferring the beer from the fermentation vessel to the conditioning tank, the process of aeration can be utilized to introduce a precise amount of oxygen. This controlled introduction of oxygen can have a profound effect on the beer's foam stability. By carefully managing the oxygen levels, brewers can encourage the growth of specific yeast strains that produce more stable foam. These yeast strains often have the ability to create a thicker, creamier head, which can persist for a longer duration.

The science behind this phenomenon lies in the yeast's metabolism. Yeast consumes sugars and, in the process, produces carbon dioxide and ethanol. When oxygen is present, the yeast's metabolism shifts, leading to the production of more complex compounds. These compounds contribute to the formation of a more stable foam layer on the beer's surface. For instance, certain yeast strains can produce higher levels of esters and other volatile compounds when exposed to controlled oxygen, resulting in a richer, more persistent foam.

To implement this technique, brewers can employ various methods. One approach is to use a small, dedicated aeration system that introduces a measured amount of oxygen into the beer during the transfer process. This ensures that the beer receives the right amount of oxygen without causing excessive bubbling or agitation, which can lead to unwanted off-flavors. Additionally, the type of yeast used can be a critical factor. Some yeast strains are naturally more foam-friendly and can benefit from controlled oxygen exposure, while others may require different fermentation conditions.

In summary, by carefully controlling oxygen levels during the fermentation process, especially when transferring the beer, brewers can significantly influence the foam characteristics of their creations. This technique allows for the manipulation of yeast behavior, leading to the production of beers with desirable foam stability and consistency. Achieving the perfect head on a beer is an art that can be mastered through the understanding and application of these scientific principles.

Fermenting Beer in Florida Heat: Tips for Success at 72°F

You may want to see also

Nutrient Availability: Adequate nutrients support yeast growth and foam formation

When transferring beer to a secondary fermenter, ensuring that the yeast has access to sufficient nutrients is crucial for a successful fermentation process. Adequate nutrient availability directly impacts yeast growth and, consequently, the formation of foam. Yeast, like any living organism, requires a steady supply of essential nutrients to thrive and perform its functions optimally. These nutrients include amino acids, sugars, and various vitamins and minerals.

During the fermentation process, yeast consumes sugars and converts them into alcohol and carbon dioxide, a process that also generates byproducts. These byproducts, such as organic acids and esters, contribute to the overall flavor and aroma of the beer. However, for optimal yeast performance, it is essential to provide a rich and diverse nutrient environment. This can be achieved by using a high-quality yeast nutrient mix or by adding specific ingredients to the beer before fermentation.

The availability of nutrients can significantly influence yeast activity and the resulting foam. When yeast has ample nutrients, it can actively metabolize and reproduce, leading to a robust and healthy fermentation. This, in turn, promotes the production of proteins and other compounds that contribute to the formation of foam. Foam is essentially a result of the yeast's metabolic activities, where proteins and sugars interact with each other, creating a stable and persistent head.

In practice, brewers often use yeast-specific nutrients, such as yeast-food or yeast-extract, to enhance yeast performance. These nutrients provide a concentrated source of essential amino acids and vitamins, ensuring the yeast has the building blocks it needs to grow and function optimally. Additionally, maintaining a balanced pH level in the beer is vital, as it affects the availability of nutrients and the overall yeast health.

By ensuring a well-nourished yeast population, brewers can encourage vigorous fermentation and the development of a desirable foam profile. This is particularly important when transferring beer to a secondary fermenter, as the yeast's activity and health can significantly impact the final beer's characteristics. Proper nutrient management is a key factor in achieving the desired foam stability and quality.

Mastering Secondary Fermentation: Tips for Beer Enthusiasts

You may want to see also

Fermentation Vessel: Type of vessel influences foam stability post-transfer

The type of fermentation vessel you choose can significantly impact the stability of foam in your beer after the transfer process. This is particularly important for homebrewers and small-scale producers who aim to achieve a clear and well-presented final product. When transferring beer from the primary fermentation vessel to the secondary one, the goal is to minimize the formation of excessive foam, as it can lead to a cloudy appearance and affect the overall quality of the beer.

One key factor is the material and design of the fermentation vessel. Glass carboys are popular among homebrewers due to their transparency, which allows for easy monitoring of the fermentation process. However, glass can be prone to generating foam, especially when the beer is agitated during the transfer. This is because glass surfaces can promote the formation of bubbles, leading to a foamy appearance. To mitigate this, some brewers opt for using a glass carboy with a wider neck, which reduces the agitation during transfers. Alternatively, using a glass vessel with a smooth interior surface can help minimize foam formation.

On the other hand, plastic fermentation vessels are often preferred for their foam-reducing properties. Plastic is generally less reactive with beer components, and it tends to produce less foam compared to glass. This makes plastic vessels an excellent choice for brewers who want to minimize foam during the transfer process. Additionally, some plastic vessels are designed with a non-stick interior, further reducing the likelihood of foam formation.

Another crucial aspect is the size and shape of the fermentation vessel. Larger vessels provide more surface area for the beer, which can lead to increased foam generation during transfers. This is especially true for beer styles that are naturally more foamy, such as wheat beers or those with high levels of carbon dioxide. To combat this, some brewers opt for smaller, more compact vessels or use techniques like partial transfers, where only a portion of the beer is moved at a time, reducing the overall agitation.

Furthermore, the temperature and agitation during the transfer process play a vital role in foam stability. Colder temperatures can help reduce foam, as lower temperatures slow down the formation of bubbles. It is recommended to keep the transfer process as gentle as possible, using a slow and controlled approach to minimize foam. Some brewers even use a siphoning technique, which allows for a more graceful transfer without excessive agitation.

In summary, the choice of fermentation vessel is crucial for managing foam stability during the beer transfer process. Glass vessels, while offering transparency, may require careful consideration to minimize foam. Plastic vessels, with their non-reactive nature, are often preferred for their foam-reducing properties. Additionally, the size and shape of the vessel, along with temperature and agitation control, contribute to achieving a clear and well-presented beer after the transfer.

Mastering Beer Fermentation: Tips for Accurate Temperature Control

You may want to see also

Frequently asked questions

Yes, it is normal for beer to be slightly foamy or bubbly during the fermentation process. This is due to the yeast's activity, which produces carbon dioxide as a byproduct. The foam can vary in intensity depending on the yeast strain, fermentation temperature, and other brewing factors.

Fermentation is a biological process where yeast consumes sugars and produces alcohol and carbon dioxide. This carbon dioxide gas gets trapped in the liquid, creating bubbles and foam. It's a natural part of the brewing process and indicates that the yeast is actively working.

While some foam is expected, excessive foam can be a sign of potential issues. If the foam is unusually persistent or overwhelming, it might indicate a problem with the yeast, such as a faulty yeast strain or improper activation. Monitoring the foam level during fermentation can help identify any brewing anomalies.

Managing foam during fermentation can be challenging, but there are a few techniques to consider. You can try using a blow-off tube to release excess gas, which helps reduce foam. Additionally, ensuring proper yeast nutrition and maintaining a stable fermentation temperature can contribute to a healthier fermentation process with more controlled foam levels.