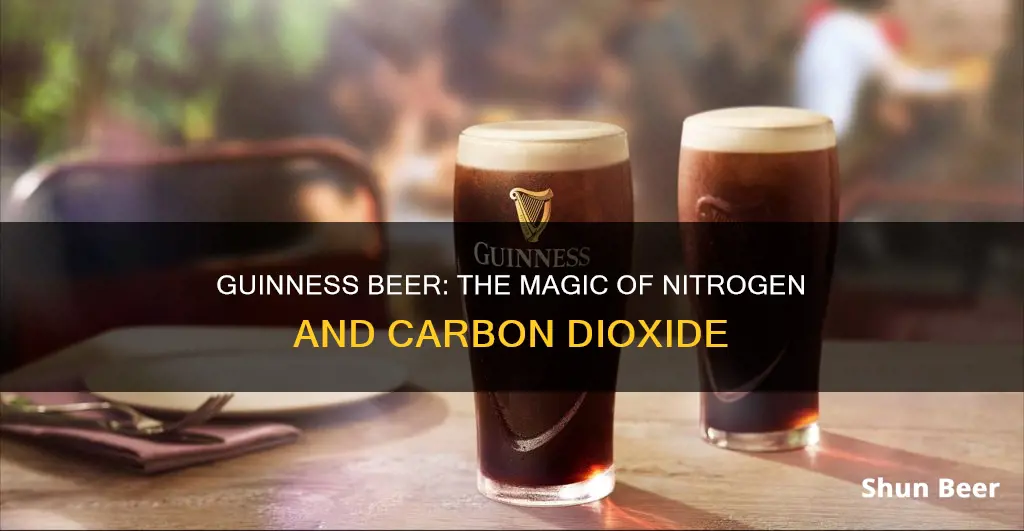

Guinness is a stout beer with a distinct creamy, rich taste and a dark ruby colour. Unlike most beers, it uses a blend of 75% nitrogen and 25% carbon dioxide gas, often referred to as Guinness Gas, to push the beer through the lines. This gas mixture, along with a specific pouring technique, is what gives Guinness its signature creamy, white foam and smooth texture.

| Characteristics | Values |

|---|---|

| Gas Composition | 75% Nitrogen and 25% Carbon Dioxide |

| Gas Name | Guinness Gas, Mixed Gas, Alley Gas, G-Mix |

| Gas Cylinder | Nitrogen gas tank |

| Gas Cylinder Composition | 75% nitrogen and 25% CO2 |

| Dispense Pressure | 38 lbs |

| Serving Temperature | 42°F |

What You'll Learn

Guinness uses a blend of nitrogen and carbon dioxide gas

The use of nitrogen in Guinness can be traced back to 1951 when Michael Ash joined the Guinness team. Ash, a master mathematician turned master brewer, became fascinated by the idea of serving Guinness on draught and believed that adding nitrogen to the beer would not only be the most effective way to do so but also transform the beer itself. He created the "Easy Serve" system, which produced the "surge and settle" effect that draught Guinness is now famous for.

To serve Guinness on tap, a Nitro stout system is required. This system includes a stout faucet, a Nitrogen regulator, a U-system keg coupler, and adapters for a proper connection. The stout faucet, also known as a European Specialty Faucet, has a unique handle that pulls forward and down and a tiny restrictor disc inside the faucet head. When Guinness is forced through the disc, it forms the distinctive head that is synonymous with the brand.

It is important to note that the gas blend used in Guinness is not suitable for ales and lagers as it will alter the CO2 content and, consequently, the flavour of these beers. Additionally, the recommended serving temperature for Guinness is 42°F, which is slightly warmer than the typical serving temperature for most beers. This temperature is said to unlock all the unique tastes and flavours of Guinness, providing the optimal drinking experience.

In conclusion, the blend of nitrogen and carbon dioxide gas used in Guinness plays a crucial role in delivering the brand's signature taste, texture, and overall drinking experience. From its innovation in the 1950s to its continued use today, this gas blend has become an integral part of what makes Guinness one of the world's most recognisable and beloved beers.

Guinness: Exploring the Dark Beer Connoisseur's Favorite Brew

You may want to see also

The gas blend is 75% nitrogen and 25% carbon dioxide

Nitrogen and carbon dioxide are the two gases that make up the gas blend in Guinness beer, with a ratio of 75% nitrogen to 25% carbon dioxide. This blend is essential to achieving the ideal pour and taste of Guinness.

The gas blend plays a crucial role in delivering the distinctive creamy, tight head that Guinness is known for. The nitrogen and carbon dioxide mixture is pushed through the beer lines, resulting in a smooth, velvety texture and a unique dark ruby colour. This combination of gases is specifically formulated for nitrogen-infused beers like Guinness Stout, contributing to its iconic appearance and flavour.

Michael Ash, a master mathematician turned master brewer, is credited with innovating the use of nitrogen in beer, specifically in the creation of Guinness draught. Ash's 'Easy Serve' system introduced the ''surge and settle' effect, now synonymous with Guinness. His method revolutionised the way Guinness is enjoyed worldwide and marked the introduction of nitro beer.

To achieve the perfect pour of Guinness, it's important to follow specific steps. Firstly, a clean, dry glass is tilted at a 45-degree angle, and three-quarters of the glass is filled. Then, the bartender waits for the nitrogen to react and the white head to form before filling the glass completely. The final step is to allow the foam to settle into a thick, white layer, resulting in the perfect pint of Guinness.

The gas blend in Guinness, with its specific ratio of nitrogen and carbon dioxide, is integral to the unique characteristics of this beloved beer. It contributes to the smooth taste, creamy head, and overall sensory experience that has made Guinness a favourite among beer enthusiasts worldwide.

Guinness Beer: Heartworm Killer or Old Wives' Tale?

You may want to see also

This gas blend is known as Guinness Gas

Guinness Beer is a stout beer with very specific requirements. It is dispensed using a blend of 75% nitrogen and 25% carbon dioxide gas, commonly known as "Guinness Gas". This gas blend is essential to achieving the optimal taste and pour associated with Guinness. The use of nitrogen in beer was first introduced by mathematician-turned-brewer Michael Ash, who joined the Guinness team in 1951. Ash's "Easy Serve" system created the "surge and settle" effect that draught Guinness is now famous for, and it marked the world's first nitro beer.

The "Guinness Gas" blend is used in conjunction with a stout faucet and a dispense pressure of 38 lbs to retain the taste intended by the brewery. The stout faucet includes an integrated restrictor disc, which the beer is forced through. This disc breaks down the nitrogen in the beer, creating the distinctive cascading head characteristic of stout beers. Proper maintenance of the disc is crucial, as any buildup that clogs its tiny holes can impact the beer's signature cascading effect.

To achieve the perfect pour, Guinness recommends starting with a clean, dry glass tilted at a 45-degree angle. The glass is then filled to three-quarters, allowing the bubbles to rise and the nitrogen to react. Once the white head begins to form, the glass is filled completely, and the foam is allowed to settle into a thick white layer.

The gas blend plays a critical role in the overall experience of drinking Guinness. The nitrogen and carbon dioxide mixture is key to producing the beer's signature creamy, tight head and smooth, velvety texture. This blend is also referred to as Mixed Gas, Alley Gas, G-Mix, or Guinness Gas and is specifically formulated for dispensing nitrogen-infused beers like Guinness Stout.

Guinness Book and Beer: Any Connection?

You may want to see also

The gas is pushed through the lines to dispense the beer

Dispensing beer from a keg requires a blend of pressurised gas to push the beer through the lines from the keg to the tap. This blend of gas is usually a mix of nitrogen and carbon dioxide, known as beer gas or G-mix. The gas blend is necessary for nitrogenated beers like Guinness, as dispensing with pure CO2 would cause the nitrogen in the beer to diffuse out of the beer and into the headspace of the keg.

The blend of gas is pushed into the keg through the coupler, which forces the beer out into the beer line, where it eventually travels up to the tap. The coupler has two ports: one for the air line to attach (so the gas gets pushed into the keg) and one for the beer line to attach (so the beer gets pushed out). The beer line is typically made from food-grade vinyl and is purchased by the foot. It is attached to the coupler and the shank or faucet using a hose barb and a hex nut wrench to ensure a tight seal.

The shank is a chrome-plated brass tube that runs through the hole in a draft tower or the side of a fridge, where the faucet is attached. The draft tower is where all the beer lines are housed and attach to the draft shank, which carries the beer to the final leg of its journey to the draft faucet. The faucet is the tap that the beer is dispensed from, and different quality levels and features are available depending on your requirements and budget.

The gas blend is stored in a gas cylinder, which can be a pre-mixed blend of CO2 and nitrogen, or a blend can be achieved on-site using a gas blender. The gas is pushed through the lines using a regulator, which controls the pressure and ensures the gas does its job. The regulator has both a high-pressure and low-pressure gauge to allow for quick identification and troubleshooting of any issues.

Guinness Beer: A Union Brew?

You may want to see also

The gas blend contributes to the creamy, tight head of Guinness

The gas blend in Guinness beer is a mix of 75% nitrogen and 25% carbon dioxide, also known as "Guinness Gas". This blend is essential to achieving the iconic creamy, tight head that Guinness is known for.

The use of nitrogen in Guinness dates back to 1951 when mathematician-turned-brewer Michael Ash joined the company. Ash was fascinated by the idea of serving Guinness on draught and believed that adding nitrogen to the beer would be the most effective way to do so. He created the "Easy Serve" system, which produced the "surge and settle" effect that is now synonymous with Guinness.

The nitrogen/CO2 blend is used to push the beer through the lines, creating a rich and creamy texture. This blend is different from traditional draft beer systems that use only CO2. The specific gas mixture and the unique stout faucet work together to create the distinctive head on a pint of Guinness.

The stout faucet, also known as a European Specialty Faucet, has a distinct handle that pulls forward and down. It also contains a tiny restrictor disc inside the faucet head. When the beer is forced through this disc, it forms the tight, creamy head. Regular cleaning of the restrictor disc is important to remove any buildup that may clog its tiny holes.

To achieve the perfect pint of Guinness, a two-pour technique is required. According to the experts at Guinness, the glass should be clean and dry, tilted at a 45-degree angle, and initially filled to three-quarters full. After the initial pour, the bartender allows the bubbles to rise and the nitrogen to react, creating the distinctive white head. Once the head starts to form, the glass is filled to the top, and the foam is allowed to settle into a thick, white layer.

Daphne Guinness: Beer Heiress or Just a Coincidence?

You may want to see also

Frequently asked questions

Guinness beer uses a blend of 75% nitrogen and 25% carbon dioxide.

Guinness is a stout beer, which requires the right kind of gas to keep the keg operating correctly. The blend of nitrogen and carbon dioxide also helps achieve the signature creamy white foam at the top of a glass of Guinness.

Guinness beer should be dispensed at exactly 38 pounds of pressure.