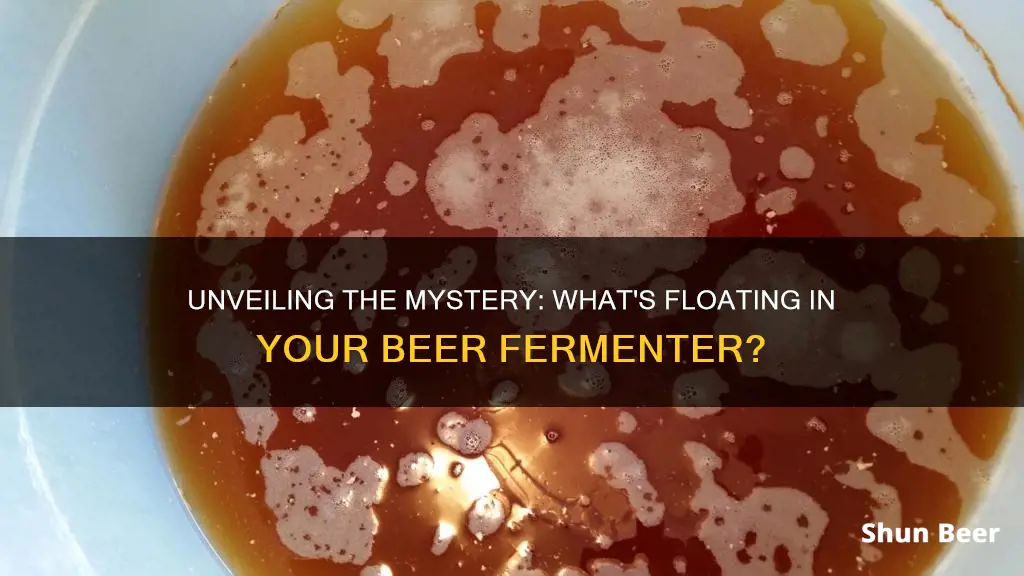

What is that floating in my beer fermenter? is a common question among homebrewers, especially those new to the art of fermentation. This query often arises when a mysterious substance, often a layer of foam or a cloud of particles, appears on the surface of the fermenter during the brewing process. Understanding the causes and implications of these floating elements is crucial for maintaining the quality and consistency of the final beer product.

What You'll Learn

- Ingredients: Yeast, hops, malt, and water are the primary components

- Fermentation Process: Yeast converts sugars into alcohol and carbon dioxide

- Cloudiness: Floating particles can be yeast, proteins, or sediment

- Odor: Aroma can indicate the type of beer and fermentation stage

- Color: Changes in color may suggest contamination or aging

Ingredients: Yeast, hops, malt, and water are the primary components

Yeast, hops, malt, and water are the fundamental ingredients that form the basis of beer fermentation and the key to understanding what might be floating in your beer fermenter. These components work in harmony to create the beverage we all know and love.

Yeast is a microorganism that plays a crucial role in fermentation. It is responsible for converting sugars derived from malt into alcohol and carbon dioxide. There are various types of yeast, each with unique characteristics, such as ale yeast and lager yeast. Ale yeasts produce a fruity and estery flavor profile, while lager yeasts result in a cleaner and crisper taste. When brewing, yeast is added to the wort (the sugary liquid extracted from malt) to initiate the fermentation process.

Hops, another essential ingredient, provide bitterness, flavor, and aroma to beer. They also act as a natural preservative, helping to prevent spoilage. Hops can be added at different stages of the brewing process, such as during the boil, just before packaging, or even dry-hopped after fermentation. The bitterness of hops is measured in International Bitterness Units (IBU), and different varieties offer distinct flavor profiles, ranging from citrusy to resiny.

Malt, derived from grains like barley, wheat, or rye, is the primary source of sugars for fermentation. It is malted, or soaked in water, to germinate and break down complex starches into simpler sugars. The malted grains are then dried and roasted, which affects the color, flavor, and body of the final beer. Different malt varieties contribute to the beer's color, from pale to dark, and influence the overall taste and mouthfeel.

Water, often overlooked, is a critical ingredient as it affects the beer's flavor, clarity, and overall quality. The mineral content and pH level of water can impact the brewing process and the final product. Brewers carefully select water profiles to complement the desired beer style, ensuring the right balance of flavors and aromas.

Understanding these primary ingredients and their roles is essential for brewers and enthusiasts alike. By mastering the art of yeast, hops, malt, and water, one can create a wide range of beer styles and appreciate the complexities that might be floating in your fermenter.

Fermentation's Gravity: Uncovering the Science of Low-Gravity Beer

You may want to see also

Fermentation Process: Yeast converts sugars into alcohol and carbon dioxide

The fermentation process is a fascinating and crucial aspect of brewing beer, and it all begins with the tiny yet mighty yeast. When you see that floating mass in your beer fermenter, it's the yeast at work, performing its magical transformation. This process is an ancient practice, dating back thousands of years, and it's the key to creating the beloved beverage we know and love.

Yeast, a single-celled microorganism, is the unsung hero of fermentation. It is responsible for breaking down the sugars present in the wort (the sugary liquid extracted from malted grains) and converting them into alcohol and carbon dioxide. This process is a delicate balance of chemistry and biology, where yeast acts as the catalyst. The sugars, primarily glucose and maltose, are abundant in the wort, providing an ideal food source for the yeast.

As the yeast feeds on these sugars, it undergoes a series of metabolic reactions. Through a process called glycolysis, yeast cells break down glucose into pyruvate, releasing a small amount of alcohol and carbon dioxide as byproducts. This is where the magic happens! The alcohol produced is what gives beer its characteristic kick, while the carbon dioxide is released into the air, forming those tiny bubbles that make beer so refreshing. The maltose, being a disaccharide, is then converted into glucose, providing a continuous supply of energy for the yeast to continue its work.

The fermentation process can be divided into two main stages. The primary fermentation occurs at a higher temperature, typically around 65-75°F (18-24°C), where the yeast rapidly consumes the available sugars, producing a significant amount of alcohol and carbon dioxide. This stage is crucial for developing the beer's flavor and character. After the primary fermentation, a secondary fermentation may take place at a cooler temperature to refine the beer's taste and clarity.

During fermentation, it's essential to maintain a clean and sterile environment to ensure the yeast's optimal performance. Any contamination can lead to off-flavors or even a failed fermentation. Brewers often use specific yeast strains, such as ale or lager yeasts, to achieve the desired beer style and flavor profile. These yeasts have unique characteristics, influencing the beer's aroma, mouthfeel, and overall quality. So, the next time you see that frothy, floating mass in your beer fermenter, remember the intricate dance of yeast and sugars, creating the essence of beer.

Brewing Creativity: A Guide to Logo-Adorned Beer Bottles

You may want to see also

Cloudiness: Floating particles can be yeast, proteins, or sediment

Cloudiness in your beer fermenter can be a result of several factors, and identifying the source of these floating particles is crucial for maintaining the quality of your brew. One common culprit is yeast, which is an essential component of the fermentation process. Yeast cells, being microscopic, can sometimes escape from the sediment and float to the surface of your beer. This is a natural occurrence and is often a sign that your yeast is actively working to convert sugars into alcohol. However, if you notice a significant amount of yeast floating, it might indicate an issue with the yeast's health or the fermentation process. In such cases, you may need to consider adding more yeast or adjusting the fermentation temperature to encourage proper yeast activity.

Proteins can also contribute to cloudiness. These are byproducts of the brewing process and can come from various sources, including the grains used for malting, enzymes, and even the yeast itself. Proteins can form clumps or aggregates, especially when the beer is exposed to certain conditions like temperature changes or the presence of specific enzymes. While some cloudiness caused by proteins is normal and can be filtered out, excessive cloudiness might suggest an imbalance in the brewing process or the presence of contaminants.

Sediment, another potential cause of cloudiness, is the solid matter that settles at the bottom of the fermenter during the brewing process. This sediment can include spent grain, hops, and other solid ingredients used in the recipe. It is normal for some sediment to remain, especially if the beer is not properly clarified. However, if you notice a significant amount of sediment floating, it could indicate that the beer has not been properly conditioned or that there is an issue with the fermentation process, leading to an improper separation of solids and liquids.

To address cloudiness, you can employ various techniques. Filtering is a common method to remove yeast, proteins, and sediment, ensuring a clear and smooth beer. This can be done using a coffee filter, cheesecloth, or a specialized brewing filter. Additionally, conditioning the beer for an extended period can help clarify it naturally. During this process, the beer is left undisturbed, allowing the sediment to settle, and the clear liquid to separate. Regularly monitoring the fermentation process and adjusting parameters like temperature and yeast health can also prevent excessive cloudiness.

Mastering the Art of Warming Up Your Fermenting Beer: A Guide

You may want to see also

Odor: Aroma can indicate the type of beer and fermentation stage

The aroma of your beer fermenter is a crucial aspect of the brewing process, offering valuable insights into the fermentation stage and the type of beer you're crafting. During fermentation, the yeast consumes sugars and produces alcohol and carbon dioxide, which can leave distinct odors that can vary depending on the beer style and the fermentation process.

For instance, a fruity or estery aroma often indicates a high-gravity beer, such as a Belgian or wheat beer, where the yeast ferments a higher percentage of the available sugars. This can result in a noticeable fruity or spicy scent, which may include notes of banana, clove, or even a hint of apple. These aromas are often associated with the yeast's consumption of esters, which are byproducts of the fermentation process.

On the other hand, a more neutral or malt-forward aroma could suggest a lager or pale ale, where the yeast's activity is more subtle. These beers often have a cleaner, crisper profile, with notes of malt, hops, or a hint of sweetness. The odor might be more subtle, with a focus on the malt's natural flavors or the presence of hops, which can contribute a floral or citrusy scent.

As the fermentation progresses, the odor can change. In the early stages, you might notice a more active yeast presence, with a strong, pungent smell. This is often due to the yeast's rapid growth and the production of carbon dioxide, which can create a frothy, bubbling environment in the fermenter. Over time, as the yeast slows down and the fermentation nears completion, the aroma may become more subtle and less intense.

Understanding the odor and aroma of your beer fermenter is essential for troubleshooting and ensuring the quality of your brew. If you notice an off-putting or unusual scent, it could indicate a problem with the yeast, the brewing process, or the ingredients used. For example, a sulfurous or "skunky" odor might suggest a problem with the yeast or the presence of sulfur compounds, while a metallic or "green" smell could indicate a contamination or an issue with the water used in brewing. By paying attention to these aromas, you can make informed decisions to optimize your brewing process and create a delicious, well-balanced beer.

Unlocking Flavor: Exploring Secondary Fermentation's Magic in Beer

You may want to see also

Color: Changes in color may suggest contamination or aging

The appearance of floating particles in your beer fermenter can be a cause for concern, especially if you notice changes in color. While some variation in color is normal during the brewing process, sudden or drastic color shifts could indicate potential issues. One common cause of color changes is contamination, which can occur at various stages of fermentation.

Contamination often results in an undesirable flavor and aroma, making the beer undrinkable. It can be caused by various factors, including wild yeast strains, bacteria, or even dust and debris in the air. For instance, if you notice a green or blue hue in your beer, it might be due to the presence of certain bacteria that can turn the liquid green or blue. This type of contamination can give the beer an off-putting flavor and appearance.

Aging is another factor that can lead to color changes. As beer ages, it undergoes a natural process of oxidation, which can cause the liquid to darken over time. This is more common in darker beers like stouts and porters, where the natural color is already quite dark. However, if you notice a significant darkening in a relatively short period, it could be a sign of aging, especially if the beer has been stored in a warm environment.

To address these color changes, it's essential to take preventive measures. Ensure that your brewing equipment is clean and sanitized to prevent any foreign particles from entering the fermentation process. Regularly clean your fermenter and use high-quality ingredients to minimize the risk of contamination. Additionally, monitor the fermentation process closely, as any deviations from the expected color can indicate potential issues.

If you do notice color changes, it's crucial to investigate the cause. Take samples for laboratory analysis to identify the specific contaminants or aging-related compounds present. This will help you take appropriate action, such as adjusting the brewing process, adding specific yeast strains, or even discarding the batch if the contamination is severe. Being proactive in addressing color changes will ensure that your beer remains of high quality and enjoyable for your taste buds.

Unraveling the Fermentable Nature of Beer: Carbohydrates and Beyond

You may want to see also

Frequently asked questions

That's likely yeast! Yeast is a crucial ingredient in beer fermentation, and it's responsible for converting sugars into alcohol and carbon dioxide. The white or cloudy appearance is normal and indicates a healthy fermentation process.

The foam is caused by the carbon dioxide being released from the yeast's activity. This is a natural and expected phenomenon. As the beer ferments, the yeast produces CO2, which gets trapped in the liquid, creating a frothy layer. This foam will typically subside as the fermentation progresses.

Absolutely! These bubbles are a sign of active fermentation. The yeast is working to break down sugars, and this process releases carbon dioxide, creating the bubbles you see. It's a good indicator that your beer is fermenting correctly.

Those particles are known as "trub" or "beer sediment." They are formed during the brewing process and consist of proteins, yeast, and other solids. This sediment is typically harmless and can be left in the fermenter or gently siphoned out after fermentation is complete.