The temperature at which yeast ferments beer is a critical factor in the brewing process. Yeast fermentation is a complex biochemical reaction that converts sugars into alcohol and carbon dioxide. The optimal temperature for this process is between 65°F and 75°F (18°C and 24°C). At this range, yeast activity is maximized, leading to efficient fermentation and the development of desired flavors and aromas. However, temperatures outside this range can significantly impact the fermentation process and the final beer quality.

What You'll Learn

- Yeast Type: Different yeast strains thrive at varying temperature ranges

- Fermentation Speed: Higher temperatures accelerate fermentation, but may reduce flavor complexity

- Flavor Development: Optimal temperatures enhance beer's flavor and aroma

- Alcohol Content: Warmer temperatures can increase alcohol by-products, affecting beer quality

- Carbonation: Temperature impacts carbonation levels, with cooler temperatures promoting higher carbonation

Yeast Type: Different yeast strains thrive at varying temperature ranges

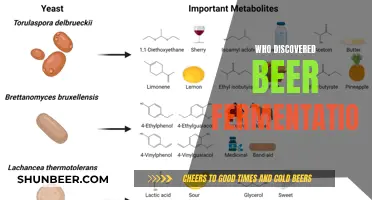

Yeast is a crucial component in the brewing process, and its performance is highly dependent on temperature. Different yeast strains have unique temperature preferences and optimal growth ranges, which can significantly impact the flavor, aroma, and overall quality of the beer. Understanding these temperature requirements is essential for brewers to achieve the desired results and create exceptional beers.

For ale yeasts, the temperature range typically falls between 65°F and 75°F (18°C and 24°C). This range is considered ideal for most ale fermentation processes. At these temperatures, the yeast is active and efficiently converts sugars into alcohol and carbon dioxide. For example, American Ale yeasts, known for their high-alcohol tolerance, perform best in this temperature range, allowing brewers to produce robust and flavorful beers like IPAs and stouts.

On the other hand, lager yeasts have different temperature preferences. These yeasts thrive in cooler environments, typically between 50°F and 65°F (10°C to 18°C). This lower temperature range is crucial for the slow and controlled fermentation of lagers, which results in a clean and crisp flavor profile. German lager yeasts, for instance, are commonly used for pilsners and lagers and require this cooler temperature to produce the desired characteristics.

It's important to note that temperature control is not just about the optimal range but also the consistency. Yeast requires a stable temperature environment to perform optimally. Fluctuations in temperature can lead to off-flavors and inconsistent fermentation. Therefore, brewers often invest in temperature-controlled fermentation vessels and monitoring systems to maintain precise control throughout the brewing process.

Additionally, some yeast strains have specific temperature requirements. For instance, some specialty yeasts used in Belgian-style beers, like Belgian Ale yeasts, thrive at slightly higher temperatures around 70°F to 75°F (21°C to 24°C). These yeasts contribute to the unique esters and fruity aromas associated with Belgian beers. Understanding these nuances allows brewers to select the right yeast for their specific beer style and temperature-controlled fermentation processes.

Why Beer Hopping Isn't the Answer: A Brew-tiful Perspective

You may want to see also

Fermentation Speed: Higher temperatures accelerate fermentation, but may reduce flavor complexity

The temperature at which yeast ferments beer is a critical factor in the brewing process, as it directly influences the speed and efficiency of fermentation, as well as the final flavor profile of the beer. While higher temperatures can accelerate the fermentation process, they may also have some drawbacks, particularly in terms of flavor development.

When it comes to fermentation speed, yeast thrives in warmer environments. As the temperature increases, the yeast's metabolic rate rises, causing it to consume sugars and produce alcohol and carbon dioxide at a faster pace. This accelerated fermentation can be advantageous for brewers who want to shorten the brewing cycle, especially in commercial settings where time is a valuable resource. For instance, a temperature of around 68-72°F (20-22°C) is often recommended for ale yeasts, which can ferment at a rapid pace, transforming the wort into beer in a matter of weeks.

However, the trade-off for this increased speed is a potential sacrifice in flavor complexity. Higher temperatures can lead to a more rapid conversion of sugars, which may result in a less nuanced flavor profile. Yeast can produce a wide array of flavors and aromas, including esters, phenols, and fruity notes, which are essential for creating unique and desirable beer styles. At elevated temperatures, these flavor compounds may not have enough time to develop fully, leading to a beer that lacks the depth and character typically associated with slower, cooler fermentations.

To strike a balance, brewers often employ various techniques. One approach is to use temperature control systems, such as yeast starters or pre-fermentation at specific temperatures, to optimize the yeast's activity without compromising flavor. Another strategy is to gradually increase the temperature during the fermentation process, allowing the yeast to adapt and produce more complex flavors. This method, known as 'temperature ramping,' can be particularly useful for achieving the desired balance between fermentation speed and flavor development.

In summary, while higher temperatures can significantly speed up the fermentation process, they may not be the best choice for every beer style. Brewers must consider the potential trade-offs and employ techniques to manage temperature and yeast activity, ensuring that the final product meets the desired quality and flavor standards. Understanding these nuances is essential for crafting exceptional beers that showcase the art of fermentation.

Beer Traps for Slugs: The Optimal Frequency

You may want to see also

Flavor Development: Optimal temperatures enhance beer's flavor and aroma

The temperature at which yeast ferments beer is a critical factor in the flavor and aroma development of the final product. Yeast fermentation is a complex process where sugars are converted into alcohol and carbon dioxide, and the optimal temperature range for this process is between 65°F and 75°F (18°C and 24°C). This temperature range is ideal for most beer styles, as it allows for a balanced and efficient fermentation.

At these temperatures, the yeast actively metabolizes the sugars, producing a wide range of flavor compounds. For example, at 68°F (20°C), the yeast will produce a more estery flavor, which is characteristic of styles like Belgian Tripels and Dubbels. This estery flavor is a result of the yeast's increased activity in converting sugars into esters, which contribute to the beer's fruity and spicy notes. On the other hand, at 72°F (22°C), the yeast will produce a more clean and crisp flavor, which is often desired in pale ales and lagers. This temperature range also encourages the development of hop-derived aromas, as the yeast's activity allows for better extraction of hop oils, resulting in a more pronounced hop character.

Lowering the fermentation temperature can lead to a slower fermentation process, which may result in a more subtle and delicate flavor profile. This is often the case with Belgian-style beers, where a cooler fermentation temperature of around 60-65°F (15-18°C) is used. This slower process allows the yeast to produce a more complex and nuanced flavor, with a focus on fruity esters and a smooth, velvety mouthfeel.

Conversely, raising the fermentation temperature above the optimal range can also have an impact on flavor. If the temperature exceeds 75°F (24°C), the yeast may become less active, leading to a slower fermentation and a potential loss of flavor compounds. Additionally, higher temperatures can cause the beer to become more alcoholic, which may mask some of the desired flavors and aromas. Therefore, maintaining the optimal temperature range is crucial to ensure the beer's flavor and aroma are well-developed and balanced.

In summary, the optimal temperature range for yeast fermentation in beer production is between 65°F and 75°F (18°C and 24°C). This temperature range encourages the development of a wide range of flavor compounds, from estery notes to clean and crisp profiles, depending on the beer style. Brewers can manipulate the fermentation temperature to achieve specific flavor goals, ensuring that the final product is well-balanced and appealing to beer enthusiasts.

Beer's Sedative Effect: Unlocking the Power of Sleep

You may want to see also

Alcohol Content: Warmer temperatures can increase alcohol by-products, affecting beer quality

The temperature of the fermentation process is a critical factor in the production of beer, especially when it comes to managing alcohol content and overall beer quality. Warmer temperatures can have a significant impact on the yeast's fermentation process and the resulting beer.

When yeast ferments beer at higher temperatures, it can lead to an increase in the production of alcohol by-products. These by-products, such as esters and higher alcohols, can negatively affect the beer's flavor profile and overall quality. Esters, for example, contribute to a fruity or spicy aroma, which may be undesirable in certain beer styles. Higher alcohols can also result in a harsher, more pungent flavor, making the beer less palatable.

The yeast's optimal temperature range for fermentation is typically between 65°F and 75°F (18°C and 24°C). Operating outside this range can lead to various issues. At temperatures above the optimal range, the yeast may struggle to perform efficiently, resulting in a slower fermentation process. This can cause the beer to remain in the fermentation vessel for an extended period, potentially leading to off-flavors and a higher alcohol content.

Conversely, temperatures below the optimal range can also be problematic. Yeast may become inactive or slow down their metabolic activities, leading to a prolonged fermentation process and the risk of infection. This can result in a beer with an off-taste or a lower alcohol content than desired.

To ensure the best beer quality, brewers should aim to maintain a consistent temperature within the optimal range. Monitoring and controlling temperature during fermentation is crucial, as it directly influences the yeast's activity and the final beer's characteristics. By understanding the relationship between temperature and alcohol by-products, brewers can make informed decisions to produce beers with the desired alcohol content and flavor profiles.

Unraveling the Mystery: Does Metabolism Occur in Beer Fermentation?

You may want to see also

Carbonation: Temperature impacts carbonation levels, with cooler temperatures promoting higher carbonation

The temperature at which you ferment your beer plays a crucial role in the carbonation levels of the final product. Yeast fermentation is a complex process where sugars are converted into alcohol and carbon dioxide. The rate and efficiency of this process are significantly influenced by temperature. When it comes to carbonation, cooler temperatures are generally preferred. This is because lower temperatures slow down the fermentation process, allowing for more controlled and precise carbonation.

In the brewing process, yeast is added to the wort (the sugary liquid extracted from malted grains) to initiate fermentation. As the yeast consumes the sugars, it produces carbon dioxide as a byproduct. This CO2 is dissolved in the liquid, contributing to the beer's carbonation. Cooler temperatures during fermentation encourage the yeast to produce more CO2, resulting in higher carbonation levels. This is particularly beneficial for styles of beer that require a crisp, refreshing mouthfeel, such as lagers and certain wheat beers.

The science behind this phenomenon lies in the yeast's metabolic rate. At lower temperatures, yeast cells slow down their metabolic activities, leading to a more gradual release of carbon dioxide. This gradual release allows for better control over the carbonation process, ensuring that the beer achieves the desired level of fizziness without excessive carbonation that might make the beer too sharp or even cause it to go flat.

It's important to note that while cooler temperatures promote higher carbonation, there is an optimal range for fermentation temperature. Yeast requires a certain temperature range to function optimally. If the temperature is too low, fermentation may stall, and if it's too high, the yeast can become stressed, leading to off-flavors and reduced carbonation. Therefore, brewers often aim for a specific temperature range, typically between 55°F and 65°F (13°C and 18°C), to balance carbonation and flavor development.

Understanding the relationship between temperature and carbonation is essential for brewers to craft beers with the desired level of fizziness and refreshment. By controlling the fermentation temperature, brewers can ensure that their beers have the perfect balance of carbonation, flavor, and mouthfeel, catering to the preferences of beer enthusiasts worldwide.

The Magic of Fermentation: Unlocking Beer's Golden Potential from Barley

You may want to see also

Frequently asked questions

The optimal temperature for yeast fermentation in beer production is typically between 65°F and 75°F (18°C and 24°C). This range is crucial for yeast health and activity, ensuring efficient fermentation and the desired flavor development.

Temperature control is essential because it directly impacts yeast performance. Yeast fermentation is a delicate process; too high a temperature can cause yeast stress and potential death, while too low a temperature may slow down fermentation or even halt it. Maintaining the optimal temperature range ensures the yeast works efficiently, producing the desired beer style and character.

Temperature plays a significant role in flavor development. Higher temperatures can lead to faster fermentation, but they may also cause the yeast to produce more esters, resulting in fruity or spicy notes. Lower temperatures can slow down fermentation, allowing for more complex flavor development, especially in styles like Belgian ales and wheat beers.

Different beer styles have varying temperature preferences during fermentation. For example, American ales often benefit from a slightly warmer fermentation temperature (around 70-72°F) to enhance hop character and bitterness. In contrast, Belgian styles typically require a cooler temperature (65-68°F) to develop their characteristic fruity esters and high alcohol content.