Wheat beers are brewed with a blend of wheat and barley, with the wheat portion making up anywhere from 30% to 70% of the total. Wheat beers have a lighter colour and contribute less flavour than barley, making them a great summer brew and a smooth transition to craft beers. When it comes to racking wheat beer, some brewers choose to rack the beer to a secondary fermenter, while others believe that a secondary fermentation is unnecessary and may even introduce an unnecessary risk of infection and oxidation. The optimal time to rack wheat beer depends on various factors, including the desired flavour profile and clarity, as well as the specific brewing process and ingredients used.

What You'll Learn

- Wheat beer is best when young, so it's best to rack it soon after fermentation

- Racking to a secondary fermenter is unnecessary for wheat beer, which is best drunk fresh

- Wheat beers ferment relatively fast, so they don't need a long time in the fermenter

- Wheat beers are cloudy, so clarity isn't an issue and a secondary fermenter is not needed

- Wheat beers have a dense, hard-to-crack kernel, so a finer mill setting is required

Wheat beer is best when young, so it's best to rack it soon after fermentation

Wheat beer is best consumed young, so it's generally recommended to rack it soon after fermentation. Racking is the process of transferring beer from one fermenter to another, leaving the trub (dead yeast and other undesirable components) behind. While some brewers choose to rack their wheat beer into a secondary fermenter, others argue that this step is unnecessary and introduces an unnecessary risk of infection and oxidation.

The consensus among wheat beer enthusiasts is that these beers are best enjoyed fresh, and the secondary fermentation process can slow down the brewing process. By racking the beer soon after primary fermentation, brewers can get their product ready for drinking sooner. This is especially important for wheat beers, which are known for their fruity and aromatic qualities that are best appreciated when the beer is young.

Wheat beers typically contain 30-70% wheat, with the rest being barley. The wheat provides more protein, resulting in a longer-lasting head. Wheat also contributes to haze and a lighter colour, making wheat beers ideal for summer consumption. The type of yeast used also significantly impacts the flavour and aroma of wheat beer. For example, German Hefeweizens use special yeasts that produce clove, bubble gum, banana, or vanilla flavours, while American wheat beers use a neutral yeast that doesn't impart these flavours.

To ensure a successful wheat beer brew, it's crucial to follow specific milling, lautering, and yeast management practices. Milling wheat requires a finer setting than barley, but it's important not to make it too fine to avoid sticking the mash. Lautering with wheat can be slower due to its higher protein content, so brewers must be prepared to cut the grain bed delicately. Additionally, a healthy and vibrant yeast strain is essential for a good wheat beer.

In summary, wheat beer is best enjoyed when young, so it's advisable to rack it soon after primary fermentation to preserve its fresh, fruity qualities and avoid the potential drawbacks of secondary fermentation.

Michelob Ultra: Wheat Beer or Not?

You may want to see also

Racking to a secondary fermenter is unnecessary for wheat beer, which is best drunk fresh

Wheat beer is unique in that it is brewed with a blend of wheat and barley, with the wheat portion comprising anywhere from 30% to 70% of the total. This higher wheat content gives wheat beers a lighter colour and contributes to a longer-lasting head, haze, and a smoother taste. Wheat beers are typically unfiltered, which increases their stability as the yeast remains in the beer, consuming oxygen and acting as a natural barrier against bacteria.

When it comes to racking wheat beer to a secondary fermenter, some brewers argue that it is unnecessary. Wheat beers are best enjoyed fresh, and the secondary fermentation process is primarily for clarification, which is not as crucial for wheat beers since they are naturally cloudier due to the higher wheat content. Additionally, transferring the beer to a secondary fermenter introduces an unnecessary risk of infection and oxidation without providing a significant benefit.

Instead of racking to a secondary fermenter, some brewers choose to dry hop and add fruits or other ingredients directly to the primary fermenter or keg. This approach simplifies the brewing process and reduces the risk of contamination. It is worth noting that the decision to rack to a secondary fermenter may also depend on the specific style of wheat beer being brewed and the desired level of clarity.

For homebrewers, it is essential to manage the yeast strain properly. A healthy yeast strain, pitched at high kraeusen, is crucial for consistency and flavour development. Proper oxygenation of the wort and maintaining the ideal fermentation temperature range of 68°F to 72°F are also important factors in brewing wheat beer.

In summary, racking wheat beer to a secondary fermenter is generally unnecessary, especially considering that wheat beers are best enjoyed fresh. The secondary fermentation process adds time and potential risks of infection and oxidation without significantly enhancing the final product. By avoiding this step, brewers can streamline the brewing process and focus on other critical factors that contribute to the unique characteristics of wheat beer.

Wheat vs Wit: Understanding the Grainy Truth

You may want to see also

Wheat beers ferment relatively fast, so they don't need a long time in the fermenter

Wheat beers are unique in that they typically consist of 50% wheat and 50% barley, whereas American wheat beers usually contain 20-30% wheat. The difference in texture between barley and wheat affects the lautering process. The more wheat in a recipe, the slower the lautering will be.

Wheat beers also ferment relatively quickly, typically within three to ten days. The first three days will be a vigorous fermentation, and then it will slow down significantly. Wheat beers are cloudy, and they are often consumed young, after just two to three weeks in the bottle straight from the primary fermenter. This is because they are better to drink when they are young and cloudy.

The fermentation duration for beer depends on the style of beer being brewed. Ales typically ferment in two to five days, whereas lagers ferment in two to three weeks, followed by several weeks or months of conditioning.

The fermentation process for wheat beer is relatively fast, and it is important to rack the beer at the right time. Racking too early can disrupt the conditioning phase, where yeast finishes its job and cleans up undesirable byproducts from primary fermentation.

Shipping Boulevard Wheat Beer to California: A Guide

You may want to see also

Wheat beers are cloudy, so clarity isn't an issue and a secondary fermenter is not needed

Wheat beers are unique in that they are cloudy in appearance, and this cloudiness is a defining feature of the style. This cloudiness is caused by the use of a particular strain of yeast, which also gives the beer its rich flavour and aroma. Because cloudiness is desirable in wheat beers, clarity is not a concern, and brewers do not need to worry about removing the yeast or sediment from the beer.

In other styles of beer, a secondary fermenter is used to achieve a clear, bright beer. This is done by racking the beer away from the yeast and trub (the sediment that forms during fermentation) into a secondary vessel, such as a glass carboy. However, this step is not necessary for wheat beers, as the yeast and sediment contribute to the desired cloudy appearance.

In addition, transferring the beer to a secondary fermenter can introduce oxygen, which can affect the flavour of the beer. Wheat beers are meant to be consumed early, so there is no need to condition or age the beer for an extended period. By leaving the beer in the primary fermenter, brewers can avoid the risk of oxidation and off-flavours that can occur during the transfer process.

Furthermore, leaving the beer on the yeast for an extended period allows the yeast to re-absorb unwanted compounds, which can improve the flavour of the beer. This is especially important for wheat beers, as the yeast strain used can produce a significant amount of cloudiness. By avoiding a secondary fermenter, brewers can achieve the desired cloudiness and flavour profile without the need for additional equipment or processes.

Overall, wheat beers are meant to be cloudy and consumed fresh, so a secondary fermenter is not necessary. Brewers can achieve the desired appearance and flavour by leaving the beer in the primary fermenter, which also reduces the risk of oxidation and off-flavours that can occur during transfer.

Cherry Wheat Beer: Sam Adams' Seasonal Surprise?

You may want to see also

Wheat beers have a dense, hard-to-crack kernel, so a finer mill setting is required

Wheat beers have unique qualities that set them apart from other beers. One key difference is that wheat beers use wheat malt, which has a softer, crisper flavour that serves as an excellent base for fruit additions. Wheat beers are often hazy with proteins and offer a distinct contrast to the bright, filtered "industrial" brews. They also tend to have higher protein levels, which enhance foam stability and create a fuller mouthfeel.

When it comes to brewing wheat beer, one important consideration is the milling process. Wheat beers have denser and harder-to-crack kernels compared to other grains like barley. This is because wheat kernels are generally smaller and lack the thick husk that barley possesses. As a result, a finer mill setting is required to crack the wheat kernels effectively. The mill setting should be tighter than what would be used for barley to ensure that the wheat kernels are cracked without being too finely ground.

It is important to strike a balance when milling wheat for beer. While a finer setting is necessary, the milled wheat should not be too fine or powder-like. This is to avoid a stuck mash, where the finely ground wheat can cause issues during the brewing process. Therefore, the goal is to achieve a good balance of grits and flour when milling the wheat.

Additionally, the shape of the wheat kernel also plays a role in the milling process. Wheat kernels are more rounded than barley kernels and have a pronounced groove. This unique shape contributes to the difficulty in cracking them effectively. As a result, brewers need to pay close attention to the mill setting and make adjustments as needed to ensure optimal results.

In summary, brewing wheat beer requires a finer mill setting due to the dense and hard-to-crack nature of wheat kernels. By using a tighter setting than what is typically used for barley, brewers can effectively crack the wheat while also avoiding issues like stuck mash. Finding the right balance in the milling process is crucial to achieving the desired flavour, texture, and clarity in wheat beers.

Wheat Beer Allergies: Understanding the Connection and Symptoms

You may want to see also

Frequently asked questions

It is recommended to rack wheat beer about 12 to 15 hours after brewing, once you've added yeast.

The ideal temperature range for fermenting wheat beer is between 68°F and 72°F.

The mill setting for wheat beer should be finer than for barley, but not too fine to avoid a stuck mash.

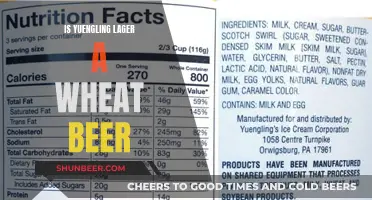

Wheat has more protein than barley, which contributes to a great long-lasting head and a nice head when poured. Wheat also gives more haze and contributes to a lighter colour and smoother taste.