When it comes to brewing beer, the fermentation process is a crucial step that can make or break the final product. While some level of fermentation is expected and desired, there are certain signs that may indicate a brewing issue or an over-fermentation problem. Understanding when to worry about beer fermenting is essential for any homebrewer or professional brewer, as it can help prevent off-flavors, cloudiness, and other undesirable outcomes. This paragraph will explore the key indicators that suggest a brewing concern and provide insights into what brewers should look out for during the fermentation stage.

What You'll Learn

Temperature: Fermentation slows below 55°F or above 75°F

Temperature plays a critical role in the fermentation process of beer, and understanding its impact is essential for any homebrewer or beer enthusiast. When it comes to fermentation, temperature is a key factor that can significantly affect the outcome of your brew. Here's a detailed look at how temperature, specifically when it falls below 55°F or rises above 75°F, can influence the fermentation process:

Slowing Fermentation Below 55°F:

Fermentation is a biological process where yeast converts sugars into alcohol and carbon dioxide. This process is highly sensitive to temperature. When the temperature drops below 55°F (12.8°C), the yeast's activity slows down significantly. Yeast is a living organism, and like all living things, it has an optimal temperature range for growth and reproduction. At lower temperatures, the yeast's metabolic rate decreases, leading to a slower fermentation process. This can result in a longer fermentation time, which may be desirable for some beer styles, but it can also lead to off-flavors and a less-than-ideal beer if not managed properly. Homebrewers often use specialized fermentation chambers or cold baths to maintain a consistent temperature in this range, especially when brewing high-gravity beers or those with unique yeast strains.

Challenges at Higher Temperatures:

On the other hand, when the fermentation temperature rises above 75°F (23.9°C), the yeast's activity can also be negatively impacted. Yeast fermentation is an exothermic process, meaning it releases heat as a byproduct. At higher temperatures, the yeast may become less active, and the fermentation process can slow down or even stall. This can lead to a range of issues, including a lack of carbonation, off-flavors, and a decrease in the beer's overall quality. Some beer styles, like wheat beers and certain fruit-infused beers, may benefit from slightly warmer fermentation temperatures, but for most traditional ales and lagers, keeping the temperature within a narrow range is crucial.

Managing Temperature for Optimal Results:

To ensure a successful fermentation, it's essential to maintain a consistent temperature within the ideal range for your specific beer style. Most homebrewers use a combination of techniques, such as using a fermentation chamber, a cooling system, or a simple temperature-controlled water bath, to keep the beer at the desired temperature. Monitoring the temperature regularly and making adjustments as needed is key to achieving the best results. Additionally, understanding the specific temperature requirements of different yeast strains can further refine your brewing process.

In summary, temperature control is a critical aspect of brewing beer, and being mindful of how temperature affects fermentation can lead to better-quality beers. Whether it's keeping the temperature cool to slow down fermentation or managing heat to prevent stalling, temperature management is an art and a science that every brewer should master.

Mastering Oktoberfest: Your Guide to Fermenting Lager Beer

You may want to see also

Cloudiness: Hazy beer may indicate yeast or sediment

Cloudiness in beer can be a sign of several things, and it's important to understand what might be causing it to ensure you're enjoying a well-fermented beverage. One common cause of cloudiness is the presence of yeast or sediment. Yeast is a crucial component in the fermentation process, converting sugars into alcohol and carbon dioxide. However, if yeast is not properly managed, it can lead to an over-fermentation, resulting in a hazy appearance. This often occurs when the yeast is not given enough time to settle and clarify the beer after fermentation.

When yeast is active during the bottling or canning process, it can leave behind small particles that remain suspended in the beer, causing cloudiness. This is more common in homebrewing scenarios where the beer might not be filtered or clarified properly. To address this, brewers often use fining agents or cold stabilization techniques to encourage the yeast to settle. If you notice cloudiness in your beer, it's a good idea to let it sit for a while, allowing the yeast to drop to the bottom. This process is known as "aging" and can help clarify the beer over time.

Sediment, on the other hand, is typically a result of the beer's ingredients or the brewing process. For example, if the water used in brewing has a high mineral content, it can lead to a cloudy appearance. Additionally, if the brewing process involves the use of grains that are not properly milled or if the wort is not adequately clarified, sediment can form. This type of cloudiness is usually harmless and can be filtered out during the brewing process or by aging the beer.

In some cases, cloudiness might indicate a problem with the fermentation process itself. If the beer is overly cloudy, it could suggest that the yeast was not active enough during fermentation, leaving behind unfermented sugars. This can happen if the yeast is not properly fed or if the fermentation temperature is too low. In such cases, the beer might require a re-fermentation or a touch-up to ensure complete fermentation and clarity.

Understanding the cause of cloudiness in beer is essential for brewers and beer enthusiasts alike. While some cloudiness is normal and can be managed through proper brewing techniques and aging, excessive cloudiness might indicate a need for intervention or a re-evaluation of the brewing process. By paying attention to these details, you can ensure that your beer is not only well-fermented but also clear and enjoyable.

Unraveling the Mystery: Why Raw Eggs in Beer?

You may want to see also

Sulfur: A skunky smell suggests sulfur compounds

Sulfur compounds in beer can be a cause for concern for brewers and enthusiasts alike, as they often result in an unpleasant "skunky" odor. This characteristic smell is a common indicator of sulfur issues in the brewing process, and it can significantly impact the overall quality and appeal of the final product. When sulfur compounds are present in excess, they can create a strong, pungent aroma that is often described as similar to that of a skunk or rotten eggs.

The presence of sulfur in beer is not inherently harmful, but its concentration and the way it affects the flavor and aroma are crucial factors. Sulfur is a natural component of water and can be introduced during the brewing process through various means. One common source is the use of sulfur dioxide (SO2) as a preservative and disinfectant, which is often added to prevent microbial contamination. However, if not carefully controlled, sulfur dioxide can lead to the formation of sulfur compounds, particularly dimethyl sulfide (DMS), which is responsible for the skunky odor.

Brewers aim to achieve a delicate balance when working with sulfur. A slight sulfur character can sometimes enhance the flavor profile of a beer, especially in styles like wheat beers or certain pale ales. However, excessive sulfur can quickly become a problem. When the skunky smell becomes dominant, it can mask other desirable aromas and flavors, making the beer less appealing to consumers. This is why it is essential to monitor and control sulfur levels throughout the brewing process.

To manage sulfur levels, brewers employ several techniques. One approach is to adjust the water chemistry by adding specific minerals or ions that can bind with sulfur compounds, preventing their formation. Another strategy is to use yeast strains that are more tolerant of sulfur, allowing for better control during fermentation. Additionally, some brewers opt for sulfur-free brewing methods or utilize specialized yeast cultures that produce less DMS.

In summary, while a subtle sulfur character can be desirable in certain beers, a strong skunky smell indicates an overabundance of sulfur compounds. Brewers must carefully manage sulfur levels to ensure the beer's quality and appeal. By employing various techniques and monitoring the brewing process, they can strike the right balance, creating beers with the desired aroma and flavor profiles.

The Strange Practice of Adding Fruit to Beer: Who Does This?

You may want to see also

Color Change: Rapid color darkening can indicate contamination

When brewing beer, one of the most critical aspects to monitor is the color of the final product. While some color variation is expected and can be a sign of a well-fermented beer, a rapid and significant color darkening can be a cause for concern. This change in color can often be an early indicator of contamination, which can have detrimental effects on the beer's flavor, aroma, and overall quality.

Contamination in beer can occur at various stages of the brewing process, from the initial ingredients to the fermentation stage. One common source of contamination is the presence of wild yeast or bacteria, which can be introduced through poor sanitation practices or the use of contaminated equipment. These microorganisms can rapidly multiply, leading to an off-flavor and an undesirable color change. For example, a sudden darkening of the beer might indicate the presence of Brettanomyces, a wild yeast that can produce fruity and spicy notes, but if it becomes excessive, it can result in an overly complex and off-putting flavor profile.

The rapid color darkening is often a result of the yeast's activity or the introduction of certain bacteria. As the yeast or bacteria feed on the sugars in the beer, they produce byproducts, including pigments that can color the beer. This can lead to a range of issues, from a slight darkening that might be acceptable to a rapid transformation that indicates a brewing disaster. In some cases, the color change might be accompanied by a change in the beer's clarity, becoming hazy or cloudy, which can further suggest contamination.

To address this issue, brewers should pay close attention to the fermentation process and take preventive measures. Maintaining a clean and sterile brewing environment is crucial, including proper sanitization of equipment and ingredients. Regularly monitoring the fermentation vessel's temperature and pH levels can also help detect any deviations that might indicate contamination. Additionally, using yeast strains known for their purity and stability can reduce the risk of unwanted color changes and off-flavors.

In summary, a rapid and significant color darkening during the brewing process should be a red flag for brewers. It often signals contamination, which can have a negative impact on the beer's quality. By being vigilant and implementing good brewing practices, brewers can minimize the risk of contamination and ensure that their beer meets the desired standards of color, flavor, and aroma.

The Magic of Fermentation: Unlocking Beer's Golden Potential from Barley

You may want to see also

Carbonation: Low or no carbonation may indicate a problem

Low or no carbonation in beer can be a cause for concern and may indicate an issue with the fermentation process. Carbonation is a crucial aspect of beer, contributing to its refreshing character and overall quality. When brewing beer, carbon dioxide (CO2) is produced during fermentation, and this CO2 is what gives the beer its fizz and effervescence. If the carbonation levels are significantly lower than expected, it could suggest a problem with the fermentation or the yeast's activity.

One possible reason for low carbonation is an insufficient amount of yeast or an imbalance in the yeast strain. Yeast plays a vital role in fermentation, converting sugars into alcohol and CO2. If there isn't enough yeast or if the yeast is not active enough, the fermentation process may be incomplete, resulting in minimal CO2 production. Brewers should ensure they use an appropriate amount of yeast and consider the specific requirements of the beer style they are brewing.

Another factor to consider is the temperature during fermentation. Yeast activity is highly temperature-dependent. If the fermentation temperature is too low, the yeast may become inactive, slowing down the fermentation process and reducing CO2 production. On the other hand, if the temperature is too high, it can also inhibit yeast activity and lead to off-flavors. Maintaining the optimal temperature range for the chosen yeast strain is essential to ensure proper fermentation and adequate carbonation.

Additionally, the brewing process itself can impact carbonation. If the wort (the sugary liquid before fermentation) is not boiled correctly or if there are any issues with sanitization, it can introduce contaminants that may affect yeast performance and carbonation levels. Brewers should pay close attention to these steps to ensure a clean and controlled environment for fermentation.

In summary, low or no carbonation in beer could be a sign of a fermentation issue, such as insufficient yeast, improper temperature control, or brewing process problems. Brewers should monitor carbonation levels throughout the brewing process and take corrective actions if needed to ensure a well-fermented and properly carbonated beer. Regular testing and an understanding of the yeast's requirements are key to achieving the desired carbonation levels.

Uncovering the Essential Minerals: Yeast's Role in Beer Fermentation

You may want to see also

Frequently asked questions

Beer fermentation is a natural process, but it's important to monitor it to ensure the quality and safety of your brew. You should start paying attention if the fermentation process takes significantly longer than expected, typically around 1-2 weeks for most styles. If the yeast is not active or the beer shows signs of stalling, it might indicate an issue with the ingredients, temperature, or yeast health.

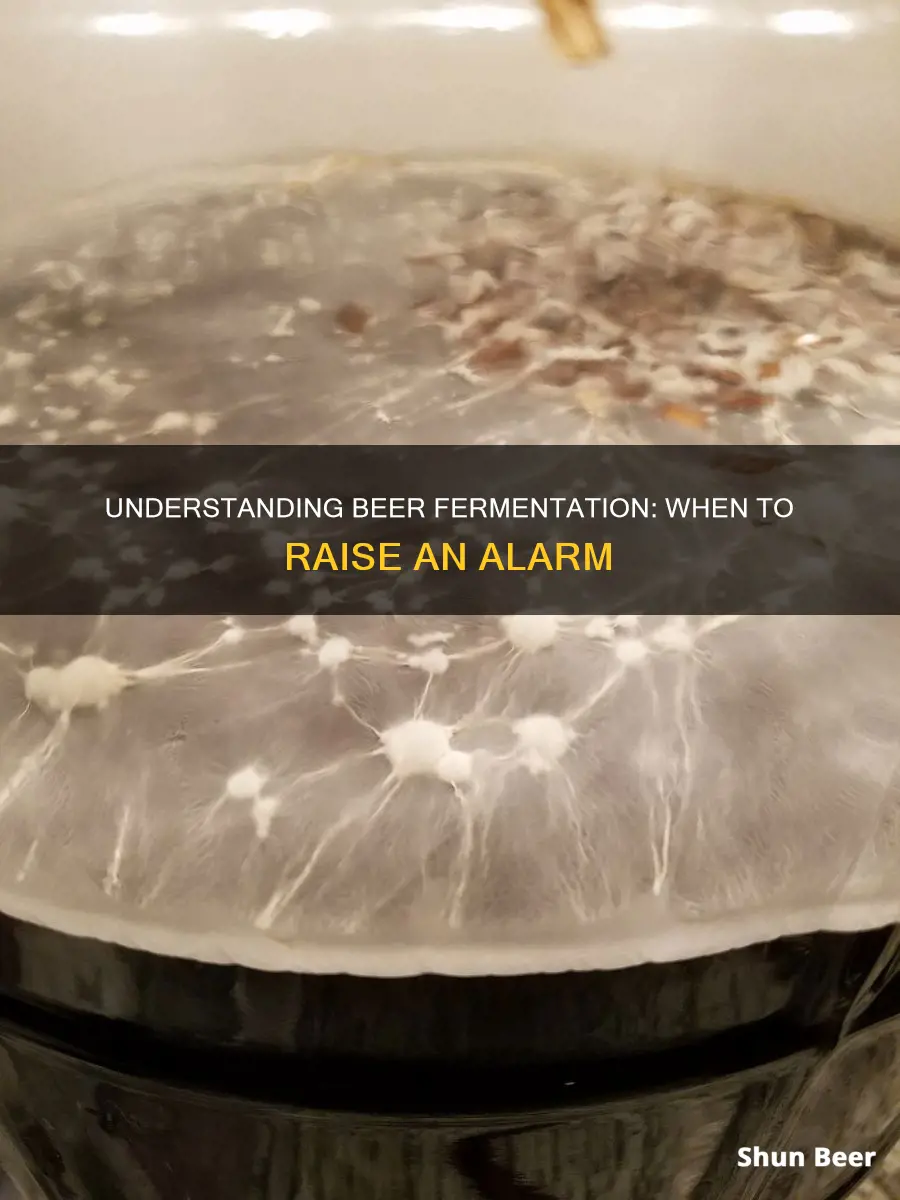

A successful fermentation is often indicated by a clear, bubbly liquid with a slight carbonation. You can use a hydrometer to measure the specific gravity of the beer before and after fermentation. If the reading drops by around 0.010-0.015, it suggests successful fermentation. Additionally, keep an eye on the yeast activity; active yeast will produce a visible foam or 'cap' on the beer, which can be observed through the airlock.

If fermentation is not proceeding as expected, you might notice a few red flags. One sign is a lack of carbonation, where the beer remains flat despite the expected bubbling. Another indicator is a stuck fermentation, where the yeast activity slows down or stops, often due to high alcohol content or nutrient depletion. This can be identified by a flat beer or one with an off-flavor.

While you can't instantly accelerate fermentation, there are a few strategies to encourage a faster process. Ensure your yeast is fresh and properly rehydrated. Maintain a consistent temperature, ideally around 68-72°F (20-22°C), and keep an eye on the fermentation vessel's cleanliness. Adding nutrients like vitamin B or yeast food can also stimulate yeast activity. However, be cautious not to over-ferment, as this can lead to off-flavors and potential spoilage.