Carbonation is an essential part of the beer-making process, giving beer its distinctive fizz and mouthfeel. It is achieved by dissolving carbon dioxide into the beer under pressure, which is then released when the bottle is opened. The amount of carbonation in a beer can vary depending on the style and desired mouthfeel, with higher carbonation levels used in beers like IPAs to enhance their hop aromas and lower levels used in stouts to achieve a smoother, velvety mouthfeel. While carbonation does not directly increase hop aroma, it plays a crucial role in the overall flavour and aroma profile of the beer.

| Characteristics | Values |

|---|---|

| Beer carbonation | Beer is carbonated using either natural or forced carbonation |

| Natural carbonation | Results from the fermentation process, where yeast digests the sugar in the wort and produces alcohol and carbon dioxide |

| Forced carbonation | Carbon dioxide is pumped into a sealed container with the beer and absorbed into the liquid |

| Beer mouthfeel | Higher carbonation in IPAs helps carry the hop aromas, while lower carbonation in stouts helps achieve a smoother, velvety mouthfeel |

| Dry hopping | Adding hops after the wort has been cooled; can be done in the primary or secondary fermenter, or by adding hops directly to a keg |

| Hop aroma | Aroma hops have relatively low alpha acid ratings, often around 6% or less; common aroma hops include Cascade, Crystal, Willamette, East Kent Golding, Fuggle, Saaz, Hallertau and Tettnanger |

What You'll Learn

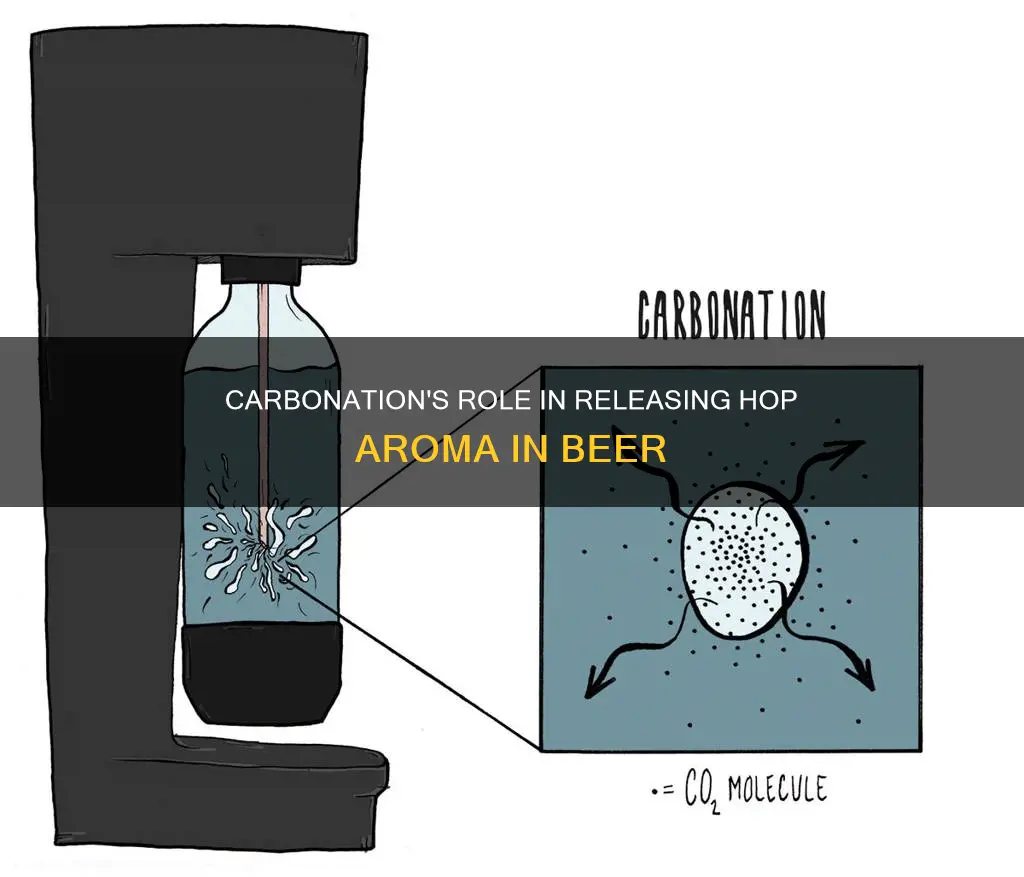

Carbonation and hop aroma

Carbonation is the process of dissolving carbon dioxide (CO2) gas into a liquid, in this case, beer. It gives beer its distinctive fizziness and contributes to its mouthfeel and overall refreshing quality. Beer can be carbonated through natural or forced carbonation. In both methods, beer and carbon dioxide are sealed in a container under pressure, allowing the beer to absorb the gas.

Natural carbonation occurs during the fermentation process when yeast digests sugar in the wort, producing alcohol and carbon dioxide. During fermentation, most of the carbon dioxide is released, but towards the end, the brewer seals the beer in a container, allowing it to become naturally carbonated. This method is used for carbonating beer in holding vessels, casks, and bottles. For bottle conditioning, a small amount of sugar is added to the beer before bottling, triggering a "re-fermentation" process. The carbon dioxide released during this process is absorbed by the beer, creating carbonation.

Forced carbonation, on the other hand, involves pumping carbon dioxide into a sealed container with the beer. This method is commonly used for kegs. The beer is refrigerated, and after a few days, the carbon dioxide is fully absorbed, resulting in a carbonated beverage.

Now, let's delve into the relationship between carbonation and hop aroma. Hop aroma is an essential aspect of the brewing process, and it is influenced by carbonation levels. Different beer styles require varying levels of carbonation to enhance their characteristics, including hop aroma. For example, IPAs typically have higher carbonation levels compared to stouts. The carbonation in IPAs helps lift the hop aromas out of the glass and towards your nose, providing an intense and desirable hoppy character.

While carbonation can enhance hop aroma, it is important to note that very high levels of carbonation can interfere with flavour perception. An excessive amount of bubbles on the tongue can reduce the ability to taste the beer's nuances. Additionally, the escaping carbon dioxide from the beer can carry away some of the hop aroma, impacting the overall aroma profile.

To maximise hop aroma, brewers often employ techniques such as dry hopping, where hops are added after the wort has been cooled or towards the end of the boil. This helps preserve the volatile oils in the hops, which are responsible for the flavour and aroma.

In summary, carbonation plays a crucial role in enhancing hop aroma in beer, particularly in styles like IPAs. However, a delicate balance must be maintained to avoid overpowering the aroma and flavour with excessive carbonation. Brewers must carefully select the appropriate carbonation level for their desired beer style to achieve the perfect harmony between carbonation and hop aroma.

Dry Hopping Mr. Beer: A Step-by-Step Guide to Success

You may want to see also

Natural vs forced carbonation

Carbonation is an essential aspect of the beer-brewing process, as it significantly influences the character and flavour profile of the final product. While there are various methods for carbonating beer, the two primary techniques are natural carbonation and forced carbonation. Each method has its advantages and disadvantages, and brewers must choose the most suitable approach based on their desired outcomes and beer style.

Natural carbonation, also known as priming, is the traditional way of carbonating beer. It involves adding a small amount of fermentable sugar, typically dextrose or priming sugar, to the beer before bottling or kegging. This additional sugar serves as food for the remaining yeast, which consumes it and produces carbon dioxide as a byproduct. The carbon dioxide then dissolves into the beer, resulting in natural carbonation. One of the key advantages of natural carbonation is that it often leads to a softer and more complex mouthfeel, with finer bubbles that contribute to the overall flavour and aroma profile of the beer. It is also considered more authentic and traditional by some beer enthusiasts. However, natural carbonation can be challenging to control precisely, and it requires additional time for conditioning, typically taking weeks or even months.

On the other hand, forced carbonation is a more modern and controlled approach that involves artificially carbonating the beer using pressure and carbonation equipment. This method skips the sugar and yeast conversion step and instead directly injects carbon dioxide into the liquid under pressure. Forced carbonation is commonly used in commercial breweries and by home brewers who prefer a faster turnaround time. One of its main advantages is the ability to achieve desired carbonation levels in a matter of hours or days, ensuring consistency across batches. It also eliminates the risk of over-carbonation or potential bottle explosions associated with natural carbonation.

Comparing the two methods, natural carbonation tends to produce a smoother and more well-integrated carbonation profile with finer bubbles, resulting in a creamy mouthfeel. It is particularly suitable for traditional beer styles such as Belgian ales, English bitters, and German wheat beers, as the slower carbonation process allows these beers to develop complex flavours and delicate effervescence over time. Forced carbonation, on the other hand, may result in larger bubbles and a more aggressive carbonation sensation. However, it offers precise control over carbonation levels and is ideal for modern beer styles like American IPAs, lagers, and stouts, where consistent and precise carbonation is crucial for showcasing intended hop aromas, malt sweetness, or smooth mouthfeel.

While natural carbonation enhances the complexity and subtleties of the beer, forced carbonation provides brewers with greater control and efficiency. The choice between natural and forced carbonation ultimately depends on the specific requirements of the beer style and the brewer's desired outcomes.

Stout Beers: Hops, Their Presence and Purpose

You may want to see also

Carbonation levels and beer styles

Carbonation is the process of dissolving carbon dioxide gas in a liquid, in this case, beer. The amount of carbonation in a beer depends on the residual carbon dioxide level after fermentation and the amount of carbonation from priming sugar. The more volumes of gas, the more carbonated the beer will be. For example, English cask beer typically has around 1.5 volumes of carbonation, while champagne can have up to 7.0 volumes.

Different beer styles will have different optimal carbonation levels. While there isn't a direct relationship between carbonation levels and perceived hop aroma, very high levels of carbonation can interfere with flavour perception. The escaping carbon dioxide gas from the beer will also carry some hop aroma, which will be noticeable to the drinker.

The carbonation level of a beer can be controlled by adjusting the amount of priming sugar in the priming solution. The type of sugar used, the temperature of the beer, and the volume of beer will all impact the final carbonation level.

Bottle conditioning is a natural carbonation method where a priming solution of water and sugar is added to flat beer before bottling, initiating a "re-fermentation" process. The carbon dioxide produced during this process is absorbed by the beer, creating carbonation. Bottle conditioning can also impact the flavour and aroma of the beer due to the presence of active yeast in the bottle, which can round out flavours and delay the effects of oxidation.

Forced carbonation, on the other hand, involves pumping carbon dioxide into a sealed container with the beer, which is commonly used for kegs. This method also allows for faster carbonation, with carbon dioxide being pumped into a chilled keg of beer and agitated to diffuse the gas more quickly.

Hops in Beer: What Else Contains This Ingredient?

You may want to see also

Beer head and aroma

Carbonation is an essential part of the beer-brewing process, and it plays a role in the aroma and flavour of the final product. Beer can be carbonated in two ways: natural and forced carbonation. In both methods, beer and carbon dioxide are sealed in a container under pressure, with the beer absorbing the carbon dioxide to create its distinctive fizz.

Natural Carbonation

Natural carbonation occurs during the fermentation process, where yeast digests the sugar in the wort to produce alcohol and carbon dioxide. Brewers seal the beer in a container towards the end of fermentation, trapping the carbon dioxide and creating natural carbonation. This method is used for carbonating beer in holding vessels, casks, and bottles. For bottle conditioning, brewers add a small amount of sugar to the beer before bottling, allowing the yeast to act on the sugar and release carbon dioxide, which is then absorbed by the beer.

Forced Carbonation

Forced carbonation involves pumping carbon dioxide into a sealed container with the beer. This method is commonly used for kegs, where carbon dioxide is pumped into a keg of refrigerated beer. After a few days, the carbon dioxide is fully absorbed, resulting in a carbonated beer.

The Role of Carbonation in Aroma

While carbonation itself does not have a direct impact on the hop aroma, it helps carry the hop aromas out of the glass and towards the drinker's nose. Different beer styles require varying levels of carbonation to enhance their distinctive mouthfeel and aroma. For example, IPAs have higher carbonation levels compared to stouts to accentuate their hoppy characteristics. On the other hand, stouts depend on lower carbonation levels to achieve a smoother, velvety mouthfeel.

Dry Hopping for Aroma

Dry hopping is a technique used by brewers to maximise the flavour and aroma of hops in the final beer. It involves adding hops after the wort has been cooled, either in the primary or secondary fermenter, or directly to a keg. Since the hops are not boiled, their volatile oils are preserved, resulting in a floral hop essence and intense flavour desirable in hoppy beer styles like pale ales and IPAs.

The Perfect Blend: Hops and Grains in Beers

You may want to see also

Dry hopping carbonated beer

Carbonation is the process of dissolving carbon dioxide gas in a liquid, in this case, beer. The gas is kept in the liquid under pressure, which is why beer bottles and cans are sealed. When the pressure is released by opening the container, the carbon dioxide rises and escapes in the form of bubbles.

Carbonation is important for hop aroma because it helps to carry the aroma to the nose. However, very high levels of carbonation can interfere with flavour perception.

Dry hopping is a process where hops are added to beer after it has been carbonated. This can be done to improve the aroma and flavour of the beer. It is possible to dry hop a beer that has already been carbonated and kegged, but there are a few things to keep in mind.

Firstly, it is important to release the pressure in the keg and bleed the gas for a few days before opening the keg to add the hops. This will help to prevent the beer from foaming and overflowing. It is also important to sanitise the hops and any equipment that will come into contact with the beer to prevent contamination.

When adding the hops to the keg, it is important to do so gently and quickly to minimise foaming. The hops can be placed in a sanitised nylon bag and lowered into the keg, taking care not to clog the dip tube. The bag can be tied to the outside of the keg using string or dental floss so that it can be removed when the desired intensity of flavour and aroma is reached.

Overall, dry hopping a carbonated beer is an effective way to boost the hop aroma and flavour, but it is important to take the necessary precautions to ensure the process is safe and sanitary.

The Historical Addition of Hops to Beer

You may want to see also

Frequently asked questions

Carbonation is necessary to give beer its distinct refreshing aspect and mouthfeel. Different styles of beer use different levels of carbonation to achieve their distinctive mouthfeel. For example, IPAs have higher carbonation than stouts to help carry the hop aromas up out of the glass and to your nose.

Carbonation is the carbon dioxide gas in a liquid. Beer can be carbonated in one of two ways: natural and forced carbonation. In both cases, beer and carbon dioxide are sealed in a container under pressure. The beer absorbs the carbon dioxide, giving the beer its fizz.

Natural carbonation results from the fermentation process. Fermentation produces alcohol and carbon dioxide as yeast digests the sugar in the wort. Although most of the carbon dioxide is allowed to escape during fermentation, the brewer will seal the beer in a container when it is almost complete.

When beer is force carbonated, it is allowed to fully ferment. Then, carbon dioxide is pumped into a sealed container with the beer and absorbed into the liquid. Forced carbonation is commonly used for kegs.

While carbonation is necessary to create the conditions for hop aroma, there is no direct relationship between carbonation levels and perceived hop aroma. However, very high levels of carbonation can interfere with flavour perception, as the bubbles on the tongue reduce the ability to taste.