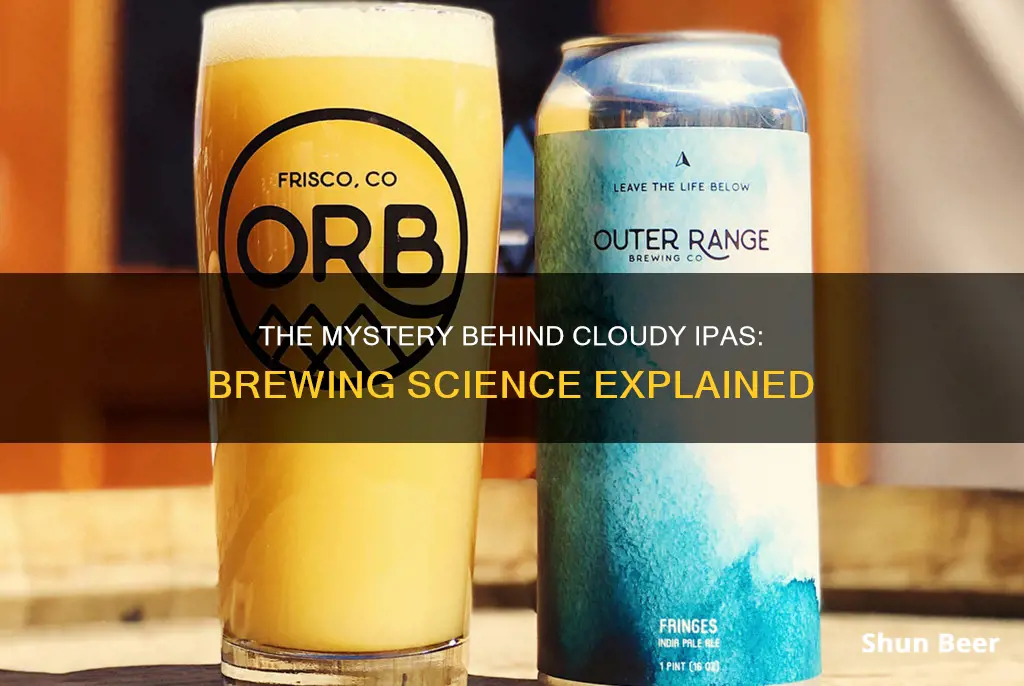

Cloudy or hazy beers are often the result of a high protein content from grains such as oats and wheat used in the brewing process. Haze can also be caused by an incomplete starch conversion, where the mash temperature was not high enough or did not last long enough, resulting in unconverted starches remaining in the wort. Additionally, haze can be developed by adding hops during the peak of fermentation, starting a process of biotransformation that increases haze and unlocks aromatic compounds. While haze in beer may be undesirable for some, the popularity of Hazy IPAs, a style of craft beer originating from New England, has challenged this perception. Hazy IPAs are characterised by their cloudy appearance and tropical aroma, with lower bitterness and fruity flavours.

| Characteristics | Values |

|---|---|

| Appearance | Cloudy or hazy |

| Opacity | Affected by the suspension of particles |

| Taste | Less bitter than other IPAs, fruity, juicy |

| Flavors | Orange, pineapple, tropical fruits |

| Cause of cloudiness | High protein content from grains like oats and wheat, biotransformation, bacterial infection, starch haze, chill haze, incomplete starch conversion |

What You'll Learn

Haze from proteins and tannins, and suspended yeast

Haze in beer is caused by suspended insoluble particles of colloidal or larger size that can be visually perceived. Haze formation is mainly associated with specific chemical components in malt barley grains, such as proteins. Haze in beer can be biological or non-biological. Biological haze is caused by wild bacteria or yeast due to poor hygiene during beer processing and storage. On the other hand, non-biological haze is caused by large molecular substances in beer, such as dextrin, β-glucan, proteins, and polyphenols.

The non-biological haze can be further divided into two types: chill haze and permanent haze. Chill haze forms when the beer is chilled to 0 °C and re-dissolves when warmed to 20 °C or higher. The particle sizes in beer with chill haze range from 0.1 to 1.0 μm in diameter. Permanent haze, on the other hand, is present in beer even at temperatures of 20 °C or higher, with particles ranging from 1 to 10 μm in diameter.

The haze formation in beer is primarily caused by the cross-linking of haze-active (HA) proteins and HA polyphenols. HA proteins have multiple binding sites with HA polyphenols, while HA polyphenols have relatively fewer binding sites. When these proteins and polyphenols bind together, they form molecules that are not very water-soluble and are large enough to scatter transmitted light, creating a hazy appearance.

Barley, wheat, oats, and rye are all rich in protein and typically contain between 8-15% protein. The malting process reduces the protein content in grains, but the composition by weight is not significantly affected. However, the nature of these proteins is significantly changed during malting by proteolytic enzymes. Grains with higher protein content, such as oats and wheat, are commonly used in hazy IPAs to contribute haze-active proteins.

Hops are another critical ingredient in hazy IPAs, as they are a significant source of polyphenols. Adding hops during fermentation can help cultivate haze and is crucial in the process of making a hazy IPA. Hops contain polyphenols, which are plant-derived flavonoid compounds like tannins. When proteins from grains react with polyphenols from grains and hops, they form a protein-polyphenol complex that scatters light and makes the beer appear hazy.

While haze in beer is often desired in styles like hazy IPAs, it can also be a sign of poor quality. Haze formation shortens the shelf life and affects the flavor of the beer. Therefore, understanding the factors contributing to haze formation is essential for brewers to create the desired haze level and maintain beer quality.

The Irish Heritage of Guinness Beer

You may want to see also

Starch haze from incomplete conversion

Starch haze is a common issue in homebrewing and can occur due to incomplete starch conversion during the mashing process. Mashing is the step in the brewing process where grains are soaked in hot water to convert starches into sugars, which are then fermented into alcohol. If the starch conversion is incomplete, some starch particles may remain in the wort, causing a haze in the final beer.

There are several factors that can contribute to incomplete starch conversion and, consequently, starch haze in beer:

- Mash duration: If the mash doesn't last long enough, the enzymes may not have sufficient time to break down all the starches.

- Lack of agitation: Stirring the mash helps ensure even temperature distribution and can facilitate the starch conversion process. Inadequate agitation can lead to incomplete starch conversion.

- Water-to-grain ratio: If the ratio of water to grain is too low, it can hinder the effectiveness of the enzymes in breaking down the starches.

- Grain bill and modification: The type of grains used and their degree of modification can impact starch conversion. For example, continental Pilsner malts may benefit from a protein rest, while US and UK malts may not require it.

- Milling: Finely milled grains increase the surface area available for enzyme action, leading to better starch conversion. A finer grist can result in higher mash efficiency.

- Mash technique: Different mash techniques, such as thin stirred mashes, tend to yield better efficiency compared to thick infusion mashes.

- Equipment and process design: The design of the lauter tun or mash tun, as well as the brewing process, can impact mash efficiency. Commercial brewers often aim for high efficiencies to minimise raw material loss, but excessively high efficiencies can negatively affect beer quality.

To troubleshoot starch haze due to incomplete starch conversion, brewers can consider the following:

- Iodine test: Performing an iodine test on a white dish during the mashing process can help determine if starch conversion is complete. A positive result indicates the presence of starch, while a negative result suggests that all starches have been converted. However, some brewers have reported false positives with this test.

- PH: Checking the pH during mashing can provide valuable information. Deviations from the optimal pH range may hinder enzyme activity and impact starch conversion.

- Grain bill adjustments: Modifying the grain bill or incorporating a protein rest, especially when using continental Pilsner malts, may improve starch conversion.

- Milling adjustments: Ensuring a finer grist can increase the surface area for enzyme action, leading to more effective starch conversion.

- Mash technique and duration: Opting for a thin stirred mash and extending the mash duration can enhance starch conversion by providing a more favourable environment for enzyme activity.

Guinness Beer: Kosher Certification and Jewish Drinking Traditions

You may want to see also

Bacterial infection

One of the most common bacterial infections in breweries is Pediococcus damnosus, which generates large amounts of diacetyl, resulting in an unwelcome buttery taste. Lactobacillus is another common bacteria that can produce an array of flavors, often characterized by its lactic tartness. Additionally, coliform bacteria can cause haze in beer, resulting in vegetal off-flavors that may remind drinkers of parsnips and old celery.

These bacterial infections often develop in the bottle after fermentation, and there are limited options for rectifying the issue. The beer can either be consumed as is, discarded, or used for painting, as haze caused by bacteria cannot be removed.

To prevent bacterial infections, it is crucial to prioritize cleanliness and sanitation during the brewing process. Plastic gear, such as hoses and buckets, should be replaced regularly, and sanitation practices should be improved to minimize the risk of contamination.

Guinness Beer's IBUs: The Bitter Truth Unveiled

You may want to see also

Chill haze from insufficient or slow cold break

Chill haze is a common issue in IPAs and other craft beers. It occurs when the beer is chilled below 35°F (1.6°C) and polyphenols, such as tannins, form larger particles through weak interactions, such as hydrogen bonds. These polyphenols are derived primarily from the grain bill but also from the hops used in brewing. While chill haze does not affect the flavour of the beer, it can impact its shelf life, causing it to go stale faster than regular beers.

To prevent chill haze, it is crucial to rapidly chill the wort after boiling. A rapid decrease in temperature causes haze-forming compounds to precipitate out of solution, resulting in a clear beer. This process is known as a "cold break". A slow cooling process will result in haze-forming compounds remaining in the solution, leading to chill haze.

To achieve a successful cold break, it is recommended to use a wort chiller or other rapid cooling methods to bring the wort temperature below 80°F (26.7°C) within 15 minutes. This quick chilling step ensures that the haze-forming compounds are removed, resulting in a clear beer.

In addition to rapid chilling, other techniques such as using finings like Irish moss or whirlfloc can help precipitate hot and cold break from the wort. These finings aid in removing proteins and haze-inducing particles, further enhancing the clarity of the beer.

By implementing these practices, brewers can effectively prevent chill haze and produce clear, aesthetically pleasing beers that are inviting to consumers.

Exploring IPAs: Beer Styles and Tasting Notes

You may want to see also

Incomplete starch conversion

An IPA beer can turn cloudy due to several reasons, one of them being an incomplete starch conversion. This issue is more common in all-grain brewing but can also occur during the steeping process in extract brewing.

To rectify this issue, brewers can try mashing for a longer duration and closely monitoring their mashing temperatures. It is important to note that different malts have specific temperature and time requirements for effective starch conversion, so brewers should pay close attention to the malts they are using.

In extract brewing, some malts require a mash or a longer steeping time to complete the starch conversion process. Failing to do so can result in a cloudy beer.

To test for incomplete starch conversion, brewers can perform an iodine test. This involves adding a drop of iodine to a sample of the wort. If the colour changes to amber/yellow, the conversion is complete. If it turns black/purple, the conversion is incomplete, and further mashing is required.

Skull IPA Beer: Registered in New York?

You may want to see also

Frequently asked questions

The cloudiness of an IPA beer could be due to chill haze, which occurs when the cold break is insufficient or too slow.

The cold break is when you finish boiling and start cooling your beer down to your yeast pitching temperature.

You can upgrade to an immersion wort chiller to cool the beer faster. If you are already using one, try using water that is colder than your house tap water to cool the wort more effectively.

Yes, another cause could be an incomplete starch conversion, which is more prevalent in all-grain brewing but can also happen during the steeping process in extract brewing.

Ensure that your mash temperature is high enough and that you mash for a sufficient period of time to allow for complete starch conversion. Pay attention to the specific requirements of the malts you are using, as some may require a longer mashing or steeping time.