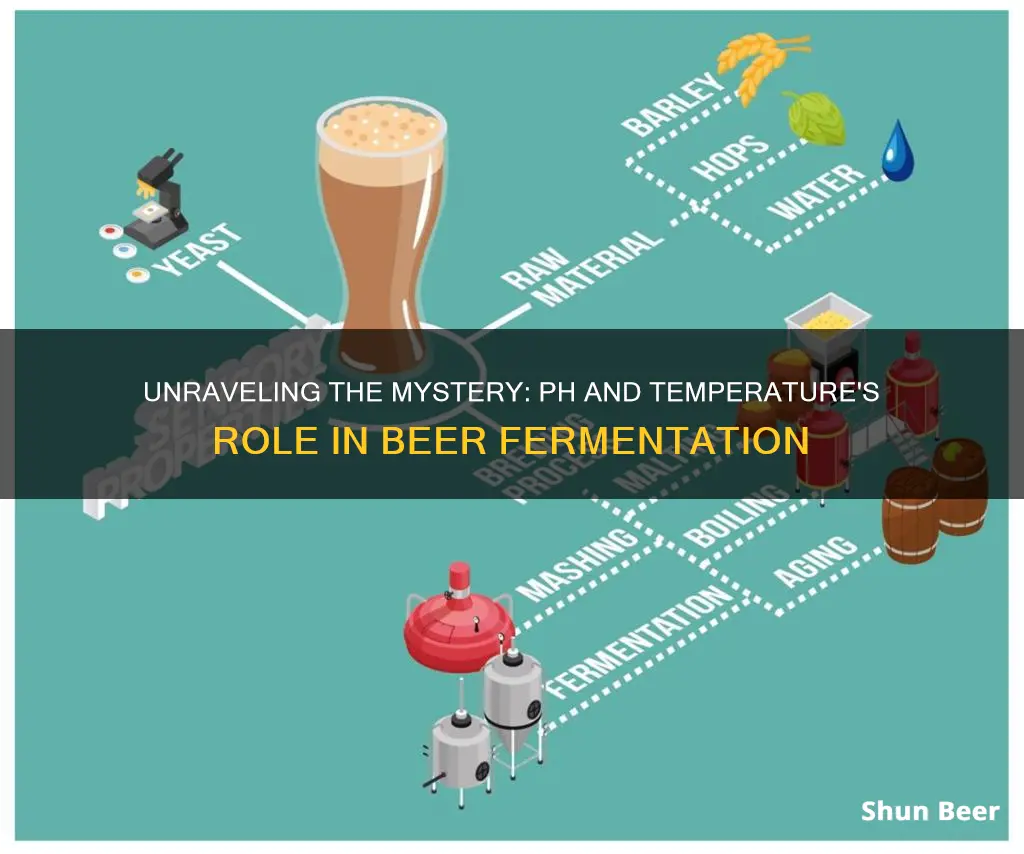

The fermentation process of beer is a complex interplay of various factors, including pH and temperature. These two variables significantly influence the fermentation process, impacting the final flavor, aroma, and overall quality of the beer. Understanding the relationship between pH, temperature, and fermentation is crucial for brewers to optimize their brewing techniques and produce consistent, high-quality beer. This paragraph will explore how these factors affect the fermentation of beer, providing insights into the science behind this fascinating process.

| Characteristics | Values |

|---|---|

| pH Level | Beer fermentation is most efficient at a pH level of around 4.5 to 5.5. Lower pH values can inhibit yeast activity, while higher pH can lead to off-flavors and slower fermentation. |

| Temperature | Fermentation temperature is a critical factor. Yeast typically works best at temperatures between 65-75°F (18-24°C). Warmer temperatures can speed up fermentation but may also lead to off-flavors and increased alcohol content. Cooler temperatures can slow down fermentation but improve flavor development. |

| Enzyme Activity | pH and temperature influence enzyme activity, which is crucial for breaking down sugars and producing alcohol. Enzymes work optimally within specific pH and temperature ranges, and deviations can affect fermentation efficiency. |

| Yeast Health | Extreme pH levels or temperatures can stress yeast, leading to reduced viability and fermentation success. Maintaining optimal conditions ensures healthy yeast activity. |

| Flavor Development | pH and temperature impact the flavor profile of the beer. Warmer temperatures can enhance ester production, while cooler temperatures may favor more neutral flavors. pH also affects the perception of bitter and sour notes. |

| Alcohol Content | Higher temperatures can increase alcohol by-products, potentially leading to higher alcohol content. However, this can be controlled by adjusting fermentation time and yeast type. |

| Carbonation | Fermentation temperature and pH can influence the carbonation level. Warmer temperatures may result in less carbonation, while specific pH adjustments can affect the solubility of carbon dioxide. |

What You'll Learn

- pH Impact: Yeast activity and fermentation rate are influenced by beer pH levels

- Temperature Regulation: Fermentation efficiency and flavor development are temperature-dependent

- Enzyme Activity: Enzymes' performance in brewing is pH and temperature-sensitive

- Flavor Profile: pH and temperature affect beer's final taste and aroma

- Carbonation: Fermentation conditions impact beer's carbonation level and mouthfeel

pH Impact: Yeast activity and fermentation rate are influenced by beer pH levels

The pH level of beer significantly impacts the fermentation process, primarily by affecting yeast activity and fermentation rate. Yeast, a crucial microorganism in beer fermentation, is highly sensitive to pH changes. Beer's pH level, which is typically around 4.0 to 4.5, is ideal for yeast growth and activity. When the pH deviates from this range, yeast activity can be significantly affected.

In general, yeast thrives in slightly acidic to neutral environments. When the pH of the beer is below 4.0, yeast activity slows down, and fermentation can become sluggish. This is because the low pH can disrupt the yeast's cellular functions, making it harder for them to metabolize sugars and produce alcohol. As a result, the beer may take longer to ferment, and the final product might have an off-flavor or lower alcohol content.

On the other hand, a pH above 4.5 can also be detrimental. At this higher pH, yeast activity may decrease, and the fermentation process can become inefficient. The yeast might struggle to maintain its metabolic functions, leading to a slower fermentation rate and potential defects in the beer's flavor and aroma.

Brewers often use pH adjustments to control the fermentation process. By monitoring and adjusting the pH, they can ensure optimal yeast activity and fermentation rates. For instance, adding specific acids or bases can help bring the pH back to the ideal range if it becomes too high or too low during the brewing process. This precision in pH control is essential for producing high-quality beer with consistent flavor profiles.

In summary, the pH of beer plays a critical role in yeast activity and fermentation rate. Brewers must carefully manage pH levels to ensure efficient fermentation and the desired beer characteristics. Understanding the relationship between pH and yeast behavior allows for better control over the brewing process, ultimately leading to the production of superior beer.

The Surprising Reason to Sift Beer: Uncovering a Hidden Secret

You may want to see also

Temperature Regulation: Fermentation efficiency and flavor development are temperature-dependent

Temperature plays a critical role in the fermentation process of beer, significantly impacting both the efficiency of fermentation and the development of flavor. The ideal temperature range for fermentation is between 65°F and 75°F (18°C and 24°C), as this range allows for optimal yeast activity and enzyme function. During this temperature range, the yeast can efficiently convert sugars into alcohol and carbon dioxide, resulting in a faster and more complete fermentation process.

Maintaining the right temperature is crucial as it directly influences the yeast's metabolic activity. Yeast is a living organism, and its performance is highly temperature-sensitive. When the temperature is too low, yeast activity slows down, leading to a longer fermentation time and potentially affecting the beer's final flavor. Conversely, if the temperature is too high, the yeast can become stressed, leading to off-flavors and potential spoilage.

The temperature also affects the development of flavor compounds in the beer. As the yeast ferments the sugars, it produces a range of flavor and aroma compounds. Warmer temperatures can enhance the production of esters, which contribute to fruity and spicy notes in the beer. However, if the temperature is too high, these esters can become overly prominent, leading to an off-putting 'banana' or 'spicy' flavor. Cooler temperatures, on the other hand, can result in a more balanced and crisp beer, with less emphasis on esters.

Additionally, temperature regulation is essential for preventing the growth of unwanted bacteria and wild yeast strains. These microorganisms can thrive in warmer conditions and produce undesirable flavors and aromas, such as sulfur or ethyl acetate. By keeping the temperature within the optimal range, brewers can minimize the risk of contamination and ensure a clean, crisp beer profile.

In summary, temperature regulation is a critical aspect of brewing, as it directly impacts fermentation efficiency and flavor development. By maintaining the ideal temperature range, brewers can optimize the yeast's performance, control the production of flavor compounds, and minimize the risk of contamination, ultimately resulting in high-quality, consistent beer.

Chilling Beer: Is Ice a Friend or Foe?

You may want to see also

Enzyme Activity: Enzymes' performance in brewing is pH and temperature-sensitive

Enzymes are essential catalysts in the brewing process, and their performance is highly sensitive to pH and temperature variations. These factors play a critical role in determining the efficiency and specificity of enzymatic reactions, which are fundamental to the fermentation of beer. Understanding the impact of pH and temperature on enzyme activity is crucial for brewers to optimize the fermentation process and achieve the desired beer characteristics.

The pH level significantly influences enzyme function. Enzymes have an optimal pH range at which they exhibit maximum activity. For example, amylase, an enzyme responsible for breaking down starches into fermentable sugars, performs optimally at a pH of around 4.5 to 5.5. When the pH deviates from this range, the enzyme's activity decreases. If the pH is too low, the enzyme may become denatured, losing its structural integrity and functionality. Conversely, a highly alkaline environment can also inactivate enzymes, affecting the overall fermentation efficiency. Brewers must carefully control the pH of the brewing water and mash to ensure optimal enzyme performance during the mashing process.

Temperature is another critical factor affecting enzyme activity. Enzymes have an optimal temperature range where they function most efficiently. For instance, the enzyme alpha-amylase, crucial for starch hydrolysis, works best at temperatures around 65-70°C (149-158°F). Operating outside this temperature range can lead to decreased enzyme activity. High temperatures may cause enzyme denaturation, while low temperatures can slow down the reaction rate. Brewers often use temperature control systems in the brewhouse to maintain the desired temperature for optimal enzyme performance during mashing and lautering.

The sensitivity of enzyme activity to pH and temperature highlights the importance of precise control in brewing. Brewers employ various techniques to manage these variables. Adjusting the pH of the brewing water and using specific enzymes with tailored optimal conditions are common practices. Additionally, temperature control during mashing and fermentation ensures that enzymes remain active and functional. By understanding and managing these factors, brewers can enhance the efficiency of the brewing process, resulting in a more consistent and high-quality beer product.

In summary, enzyme activity in brewing is highly pH and temperature-sensitive. Brewers must carefully consider these factors to optimize the fermentation process. Controlling pH and temperature allows brewers to maximize enzyme efficiency, ensuring the conversion of starches to sugars and other desired biochemical reactions. This attention to detail contributes to the art and science of brewing, ultimately shaping the character and quality of the final beer product.

The Mystery of Donny's Locker: Who Added the Beer?

You may want to see also

Flavor Profile: pH and temperature affect beer's final taste and aroma

The pH and temperature of the fermentation process significantly impact the flavor profile of beer, playing a crucial role in determining the final taste and aroma. These factors influence the activity of yeast and the chemical reactions that occur during fermentation, ultimately shaping the beer's characteristics.

PH, or the measure of acidity, is a critical factor in beer fermentation. Yeast, the microorganism responsible for fermentation, thrives in an environment with a specific pH range. Most beer yeasts prefer a slightly acidic to neutral pH, typically around 4.0 to 6.0. When the pH deviates from this range, yeast activity can be affected, leading to potential off-flavors and aromas. For instance, a highly acidic environment might inhibit yeast growth, resulting in a slower fermentation process and the possibility of a 'green' or unripe flavor in the beer. Conversely, a highly alkaline pH can also be detrimental, causing the yeast to produce unwanted esters and off-flavors.

Temperature is another essential variable that influences the flavor development during fermentation. Yeast metabolism and the rate of fermentation are highly temperature-dependent. In general, beer fermentation thrives in a warm environment, typically between 65°F and 75°F (18°C to 24°C). At these temperatures, yeast activity is optimal, leading to efficient fermentation and the production of desired flavors and aromas. Lower temperatures can slow down fermentation, resulting in a flatter flavor profile, while higher temperatures might cause the beer to become overly sweet or produce off-flavors due to the breakdown of sugars.

The interaction between pH and temperature is particularly interesting. When the pH is adjusted, the temperature can influence how the yeast responds to this change. For example, a slightly acidic pH might be beneficial at a warmer temperature, as it can enhance the yeast's ability to produce certain esters and fruity notes. However, if the temperature is too low, the yeast may struggle to adapt, leading to a less desirable flavor profile. Similarly, a highly acidic environment at a higher temperature could result in an over-fermented beer with a sharp, sour taste.

Understanding these relationships is essential for brewers to control and manipulate the flavor profile of their beers. By carefully managing pH and temperature, brewers can encourage the production of specific flavors and aromas, ensuring a unique and desirable taste in their final product. This knowledge also allows for the creation of various beer styles, from crisp and refreshing lagers to rich, complex stouts, each with its distinct flavor characteristics.

Unveiling the Light: Exploring Beer Fermentation in Darkness

You may want to see also

Carbonation: Fermentation conditions impact beer's carbonation level and mouthfeel

The carbonation level in beer is a crucial aspect of its sensory profile, and it is significantly influenced by the fermentation process. Fermentation conditions, such as pH and temperature, play a pivotal role in determining the final carbonation of the beer. Understanding these factors is essential for brewers to craft beers with the desired level of effervescence and mouthfeel.

During fermentation, yeast consumes sugars and produces alcohol and carbon dioxide (CO2) as byproducts. The amount of CO2 generated is directly related to the fermentation conditions. When the pH of the wort (the sugary liquid before fermentation) is adjusted to a specific range, typically around 4.5 to 5.5, it creates an optimal environment for yeast activity. This pH range is often referred to as the 'fermentation pH' and is crucial for efficient fermentation. Within this pH range, the yeast can effectively metabolize the sugars, resulting in a higher production of CO2.

Temperature also plays a critical role in carbonation. Yeast fermentation is temperature-sensitive, and optimal fermentation temperatures vary depending on the beer style. Generally, warmer temperatures (around 65-75°F or 18-24°C) accelerate fermentation, leading to a higher CO2 production rate. This is because the yeast enzymes become more active at these temperatures, facilitating the breakdown of sugars. However, if the temperature is too high, it can cause a rapid and uncontrolled fermentation, resulting in a lower carbonation level. Conversely, cooler temperatures (around 55-65°F or 13-18°C) slow down fermentation, producing a more controlled and gradual release of CO2, which is beneficial for achieving higher carbonation.

The impact of pH and temperature on carbonation is further influenced by the type of yeast used. Different yeast strains have varying preferences for pH and temperature, which can affect their fermentation performance. For instance, some yeast strains thrive at slightly acidic pH levels, while others prefer a more neutral environment. Brewers often select yeast strains based on their desired carbonation level and beer style.

In summary, controlling the pH and temperature during fermentation is essential for achieving the desired carbonation in beer. Brewers can manipulate these conditions to influence the yeast's activity, resulting in beers with varying levels of effervescence and mouthfeel. Achieving the right balance between pH and temperature is a delicate art, and mastering it allows brewers to create beers that tantalize the taste buds of beer enthusiasts.

The Beer Bag Conundrum: Uncovering the Mystery

You may want to see also

Frequently asked questions

pH plays a crucial role in the fermentation process. Beer yeast is sensitive to pH changes, and a slight increase or decrease can impact fermentation efficiency. Generally, a pH range of 4.0 to 5.0 is ideal for most beer styles. If the pH is too low (acidic), it can slow down fermentation and even inhibit yeast activity. Conversely, a highly alkaline environment (high pH) can also be detrimental, as it may lead to off-flavors and reduced fermentation rates.

Temperature is a critical factor in beer fermentation. Yeast, the microorganism responsible for fermentation, has an optimal temperature range. Most beer yeasts thrive and ferment efficiently between 65°F and 75°F (18°C and 24°C). If the temperature is too low, fermentation slows down, and if it's too high, it can lead to a rapid and uncontrolled fermentation, resulting in a harsh, acidic flavor. Controlling temperature is essential to ensure the desired beer character and quality.

Absolutely! pH and temperature fluctuations during fermentation can significantly impact the final beer's taste and quality. For instance, if the pH drops too low, it can lead to a sharp, acidic beer, while a high pH might result in a flat, dull flavor. Temperature variations can also cause off-flavors. High temperatures can produce esters, which contribute to fruity notes, but too much can lead to a 'green' or 'banana' flavor. Low temperatures may result in a slow fermentation, allowing more undesirable compounds to accumulate.

Maintaining consistent pH and temperature is essential for successful beer fermentation. Brewers often use various techniques, such as temperature control systems, pH meters, and specific yeast strains, to manage these factors. Pre-fermentation processes like mashing and boiling can also influence pH. After fermentation, proper packaging and storage at the right temperature ensure the beer's quality. Regular monitoring and adjustments are key to achieving the desired beer profile.