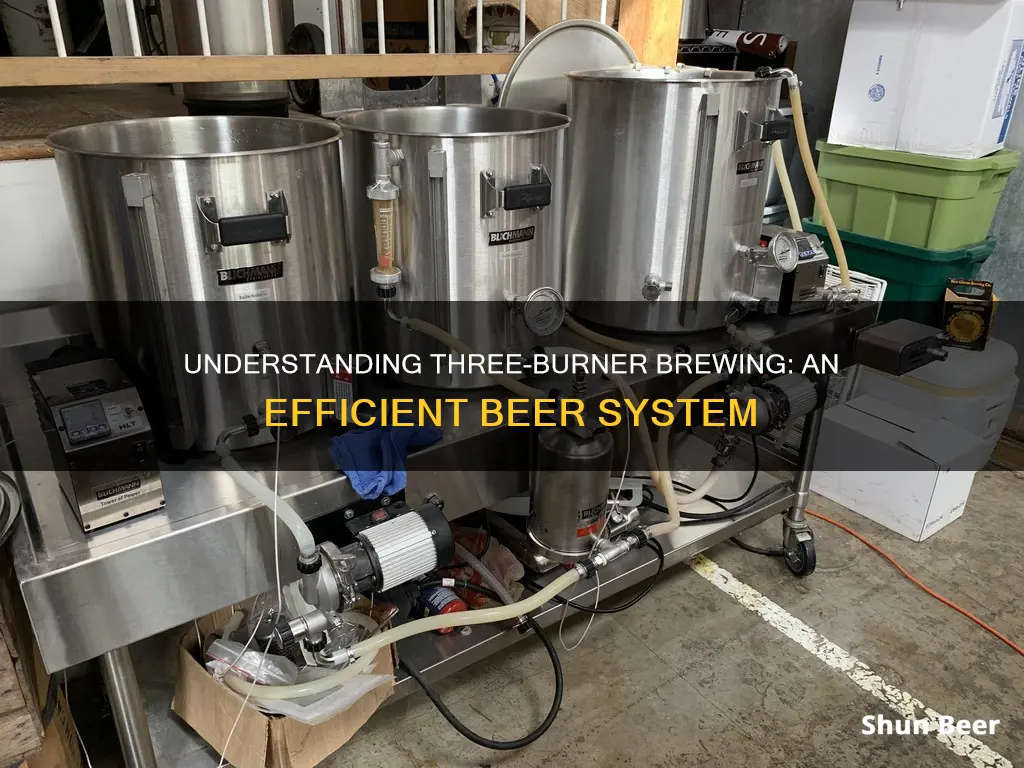

Brewing your own beer at home is an exciting and rewarding hobby, and a three-vessel brewing system is a popular setup for both beginners and experienced homebrewers. This system optimises the beer-making process by allowing different steps to be conducted simultaneously, streamlining production time. The three vessels used are the mash tun, the lauter tun, and the boil kettle, each serving a unique purpose in the beer-making process.

| Characteristics | Values |

|---|---|

| Purpose | Home brewing |

| System type | Three-tier, three-vessel |

| Brewing process | Mash tun, lauter tun, boil kettle |

| Mash tun function | Starch conversion, temperature stepping |

| Lauter tun function | Separation of wort from grains, sparging |

| Boil kettle function | Boiling & hop addition, sterilisation, whirlpool formation |

| Burners | Liquid propane gas (LPG) with electronic ignition |

| Pump | 110-V magnetic drive sealless pump |

| Control panel | Wiring terminations, motor capacitor, gauges, fuses, switches |

| Cost | $450 |

What You'll Learn

- Mash Tun: crushed malt mixed with hot water to create fermentable sugars

- Lauter Tun: spent grains separated from the wort

- Boil Kettle: hops added to the wort for bitterness, aroma and flavour

- Temperature controls, automated stirring and efficient cooling

- Pros and cons: cost, portability, repeatability, ease of use

Mash Tun: crushed malt mixed with hot water to create fermentable sugars

The mash tun is an essential component of the brewing process, especially when advancing to all-grain brewing. It is a vessel where the mashing process takes place, allowing for the easy lautering or separation of the liquid wort from the grain solids. The mash tun plays a crucial role in creating the fermentable sugars that are necessary for beer production.

In a three-vessel brewing system, the mash tun is one of the key components, alongside the hot liquor tank and the kettle burner. The process begins by filling the hot liquor tank with water and heating it to the desired temperature. The water is then carefully added to the mash tun, ensuring that it covers the false bottom, which is typically made of perforated stainless steel. With the mash mixer running, the crushed malt or grist is added to the hot water, creating a mixture known as the mash.

The mash mixer, consisting of rakes and plows powered by a geared motor, plays a vital role in maintaining an even temperature within the mash tun. It carefully stirs the mash to prevent dough balls from forming and ensures a consistent temperature throughout the mixture. This temperature control is essential for activating enzymes and converting starches into fermentable sugars.

During the mashing process, the mash tun's false bottom allows the liquid wort to be separated from the grain solids. The wort is carefully drained or circulated through a filter, leaving the grains and sediment behind in the mash tun. This clear wort is then transferred to the kettle burner, where it is boiled and hops are added, continuing the beer-making process.

The design of the mash tun can vary, with homebrewers opting for different shapes, sizes, and materials based on their specific needs and goals. Some brewers may choose to build their own mash tuns, while others purchase them from homebrew shops. The mash tun is a crucial component in the three-vessel brewing system, facilitating the mashing process and enabling the creation of fermentable sugars that are essential for producing beer.

Beer Aids: Fact or Fiction?

You may want to see also

Lauter Tun: spent grains separated from the wort

The Lauter Tun is a vessel used to separate the wort from the solids of the mash. It works like a large sieve, with a slotted, perforated floor, also known as a false bottom. This false bottom holds the spent milled grains, allowing the wort to filter through the grain bed and collect underneath, before running into the brew kettle.

The Lauter Tun is designed similarly to an infusion mash tun, but it is wider and shallower. This design improves filter performance and allows for the use of finer grist, resulting in higher extract rates. The wider tun also reduces the thickness of the grain bed, allowing for a faster sparging process with a higher flow rate. The true bottom of the Lauter Tun can be flat, sloped, or constructed with several concentric valleys and intervening ridges.

Before receiving the mash, the Lauter Tun is thoroughly rinsed and filled with hot water (typically 75–78°C or 167–172°F). The plates of the false bottom are also covered with hot water to aid in spreading the mash. The mash is then pumped from the mash mixer or mash tun into the Lauter Tun. It is important to ensure that the mash is well-mixed before this step to create an even grain bed, and a low-shear pump should be used to avoid breaking up the mash particles.

The bed depth in the Lauter Tun typically ranges from 25 to 50 centimetres (10–20 inches), but some tuns can have depths of up to 55 centimetres or as shallow as 20 centimetres. To establish a uniform grain filter bed, two methods can be used. The first method involves operating the lautering machine in a raised position at moderate speed with the blades in the "grains out" position until all the mash is transferred.

After the mash has been transferred, it is common to allow for a rest period of 15 to 30 minutes (mash rest) to let the mash settle before recirculation, preventing cloudy wort. The wort is then recirculated through the grain bed to assist in establishing the filter bed and clarifying the wort. If the pumping is too fast, it can cause turbulence and affect the clarity of the wort.

Once the filter bed is established and the wort has reached the desired clarity, the circulation is stopped, and the "first wort" is diverted to the brew kettle or underback. The brewer may choose to transfer the wort with some fine solids present, knowing that it will clarify further during the transfer. During this first wort transfer, the grain is sprayed with hot water (71–78°C or 160–172°F) in a process called sparging, which washes additional sugar from the grain. Sparging can be done continuously or intermittently, but the water temperature should not exceed 79°C (175°F) to avoid extracting harsh polyphenolic compounds from the malt husk.

How Well Do Beer Thermoses Work?

You may want to see also

Boil Kettle: hops added to the wort for bitterness, aroma and flavour

The boil kettle is where hops are added to the wort for bitterness, aroma and flavour. The boil kettle sits on a burner, which is raised on bricks to allow the wort to be gravity-fed through a chiller at the end of the boil. The burner is usually a liquid propane gas (LPG) burner with electronic ignition. The boil is typically between 60 minutes and a few hours. The first hops are added with 60 minutes left in the boil, and these hops add bitterness to the beer. Flavour hops are added between 30 and 15 minutes before the boil ends, and aroma hops are added at flameout or shortly after.

For simplicity, hops can be added at 60, 20 and 0 minutes (flameout). Once the boil is finished, the wort is stirred (whirlpooled) to make collecting the clear wort easier. This is done rapidly for 1 to 2 minutes to create a good whirlpool. It is then left for about 5 minutes to allow the wort to cool and stop the convection currents. The wort is then chilled or no-chilled. No-chilling involves running hot wort into a sanitised cube, removing as much air as possible and sealing the cube. The wort will then cool down to room temperature and can then be tipped into a fermenter and pitched with yeast.

Beer Enemas: Do They Work or Are They Dangerous?

You may want to see also

Temperature controls, automated stirring and efficient cooling

Temperature control is a critical aspect of brewing, as it ensures consistency and quality in the final product. In a three-burner beer system, temperature control can be achieved through various methods, such as digital temperature switches, PID temperature controllers, and insulated vessels. For example, the Blichmann Engineering Pro Pilot Series, a top-of-the-line electric three-vessel brewing system, likely features precise temperature control through its digital interface. Additionally, the Brewmation Electric Systems offer remote access to control temperatures via PC, laptop, tablet, or smartphone.

Automated stirring is another important feature in a three-burner beer system, ensuring even heating and maintaining a consistent temperature. This can be achieved through a mash mixer or a recirculation pump, which helps distribute heat evenly and prevent scorching. The mash mixer consists of rakes and plows powered by a geared motor, which carefully stirs the mash.

Efficient cooling is a crucial aspect of the brewing process, especially during the chilling phase. Most three-burner beer systems incorporate some form of cooling mechanism, such as a chiller or cooling jacket. For instance, the Brew-Boss Deluxe 240 Volt Electric Brewery includes a unique cooling feature: an automated pellet hop feeder. This system fills each chamber with hops, and the brewer can set the time for the hop addition, allowing for a hands-off, automated process. Another example is the Brew-in-a-Conical (BIAC) system, which chills the wort by passing cold water through a cooling jacket, efficiently reducing the temperature.

Beer Fast: Does It Work Quickly?

You may want to see also

Pros and cons: cost, portability, repeatability, ease of use

A three-vessel brewing system can be an exciting prospect for any home brewer, but it's important to consider the pros and cons before investing. Here is a detailed breakdown of the advantages and disadvantages in terms of cost, portability, repeatability, and ease of use:

Cost

One of the biggest drawbacks of a three-vessel brewing system is the cost. This type of equipment is top-of-the-line for home brewers and is priced accordingly. The high cost is due to the system's complexity, all-electric setup, and stainless steel construction. However, it is possible to build a more affordable setup with salvaged parts, as described by Jeffrey Pugh in "Brewing Techniques".

Portability

The three-vessel brewing system is not designed to be portable. Its bulk and weight make it difficult to move around, and it requires a dedicated space, preferably with 240V outlets. This lack of portability means that brewers cannot easily take advantage of nice weather by brewing outdoors or in different locations.

Repeatability

One of the biggest advantages of the three-vessel system is the level of control it offers brewers. The ability to precisely control temperatures and other variables means that brewers can produce the same beer time after time. This repeatability is a significant benefit, as it helps brewers improve their craft by reducing variables in the brewing process.

Ease of Use

The three-vessel brewing system is designed to be easy to use, allowing brewers to focus on creating their desired beer rather than troubleshooting equipment issues. The purpose-built nature of the system eliminates the need for makeshift solutions, and the electric setup offers more precise control than traditional direct-fire methods. Additionally, the recirculating infusion mash (RIMS) system ensures clear wort and simplifies the mashing process.

Lovastatin and Beer: A Safe Mix?

You may want to see also

Frequently asked questions

A three-vessel brewing system is a setup that uses three separate vessels for different stages of the beer-making process: the mash tun, the lauter tun, and the boil kettle.

The mash tun is where the crushed malt (grist) is mixed with hot water to activate enzymes, which then convert starches into fermentable sugars. The lauter tun is where the spent grains are separated from the wort (liquid), a vital process for the clarity and quality of the beer. The boil kettle is where the clear wort is boiled with hops to add bitterness, aroma, and flavor, and to sterilize the wort.

A three-vessel system streamlines the brewing process, allowing different steps to be conducted simultaneously and optimizing production time. It also offers greater control over each step, helping brewers achieve consistency and high-quality beer batches. Additionally, by dedicating vessels to specific tasks, the risk of cross-contamination or process interruption is reduced.

Modern three-vessel brewing systems often include features such as temperature controls, automated stirring mechanisms, and efficient cooling systems. These features simplify the brewing process and improve the final product.

A three-burner beer system typically involves heating water in one vessel (the hot liquor tank), transferring it to the mash tun to mix with the crushed malt, and then transferring the resulting wort to the lauter tun for separation. Finally, the clear wort is boiled in the boil kettle, with hops and other ingredients added at various stages.