Beer is an alcoholic beverage produced through the brewing process. Brewing involves steeping a starch source, commonly cereal grains, in water and then leaving the mixture to ferment. The most popular starch source is barley, and the process of converting barley to fermentable sugars is complex and involves a series of biochemical reactions. Brewers must regulate the process to ensure they get the desired results. In addition to barley, brewers also use hops and yeast to make beer.

| Characteristics | Values |

|---|---|

| Brewing Process | Soaking barley in water, fermentation, boiling, conditioning, filtering, packaging |

| Basic Ingredients | Water, barley, hops, yeast |

| Other Ingredients | Millet, sorghum, cassava, maize, rice, sugar, wheat |

| Fermentation Methods | Warm, cool, spontaneous |

| Fermentation Vessels | Cylindroconical vessels, open stone vessels, wooden vats |

| Yeast Types | Saccharomyces cerevisiae, Saccharomyces pastorianus, Brettanomyces, Torulaspora delbrueckii |

| Conditioning Method | Kräusening |

| Filtration Methods | Sheet filters, powder filters (e.g. diatomaceous earth) |

| By-Products | Spent grain, yeast sediment |

What You'll Learn

- The ingredients: barley, water, hops, and yeast

- The process: malting, milling, mashing, lautering, boiling, fermenting, conditioning, filtering, and packaging

- The history: ancient Egypt, China, and Mesopotamia

- The science: biochemical reactions, enzymes, and fermentation

- The business: breweries, regional variations, and global sales

The ingredients: barley, water, hops, and yeast

Brewing is the production of beer by steeping a starch source in water and fermenting the resulting sweet liquid with yeast. The basic ingredients of beer are water, a starch source, yeast, and a flavouring agent. The most popular starch source is barley, which is soaked in water, germinated, and then dried in a kiln. This process of malting barley produces enzymes that convert the starches in the grain into fermentable sugars. The malted barley is then crushed and mixed with hot water, activating the enzymes that convert starch into sugar.

The other key ingredient in beer is water. The mineral composition of water varies by region, which influenced the types of beer that different regions were suited to brewing. For example, Dublin's hard water is well-suited for brewing stout, while Pilsen's soft water is ideal for making pale lager.

Yeast is added to the mixture to initiate the fermentation process, converting the sugars into alcohol and carbon dioxide. The two dominant types of yeast used in brewing are Saccharomyces cerevisiae, or ale yeast, and Saccharomyces pastorianus, or lager yeast.

Hops are the female flower clusters of the hop vine Humulus lupulus, and they are used as a flavouring and preservative agent in beer. Hops contribute bitterness, floral and citrus aromas, and antibiotic effects that favour the activity of brewer's yeast. They also aid in "head retention," or the length of time that the foam on top of the beer lasts.

Energy and Alcohol: Do Beer and Red Bull Work?

You may want to see also

The process: malting, milling, mashing, lautering, boiling, fermenting, conditioning, filtering, and packaging

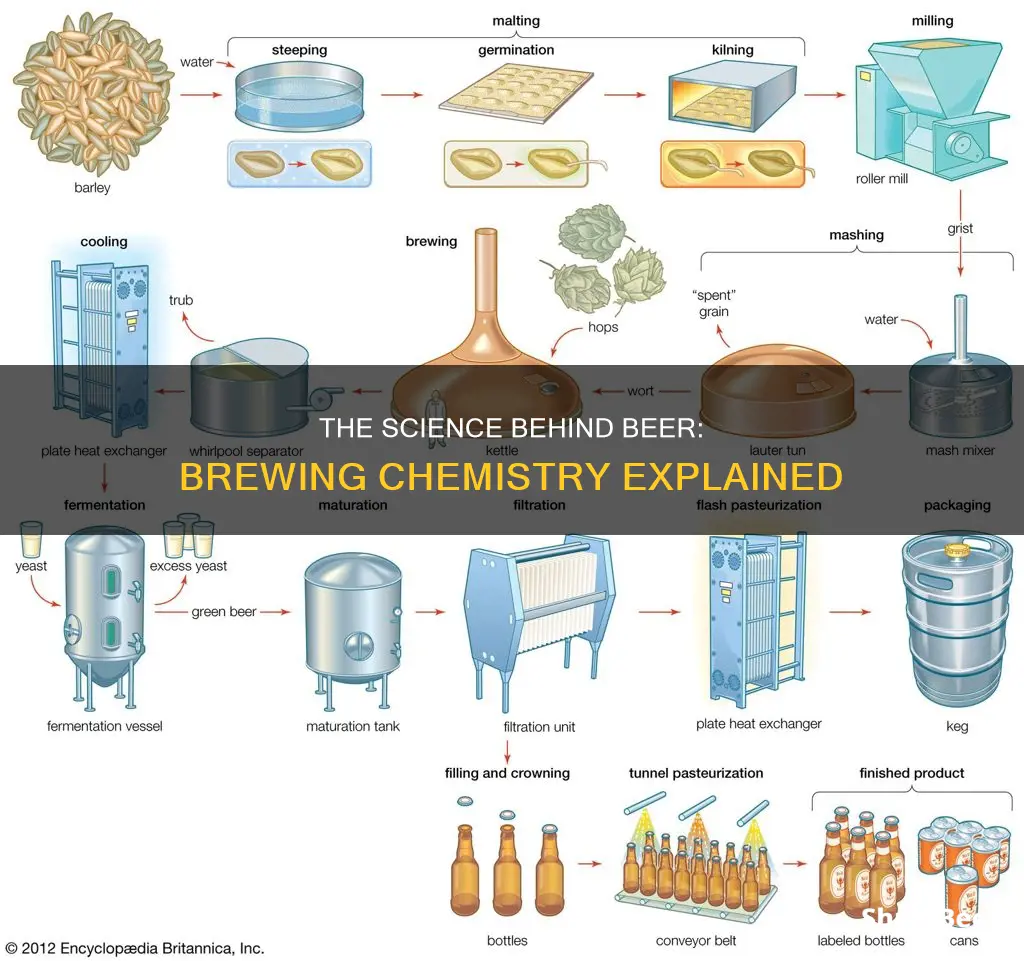

The process of making beer can be broken down into nine steps: malting, milling, mashing, lautering, boiling, fermenting, conditioning, filtering, and packaging.

Malting is the process of preparing barley grain for brewing. It involves three steps: steeping, germination, and kilning. During steeping, the barley grain is soaked in water for around 40 hours. Next, during germination, the grain is spread out on the floor of the germination room for about five days. Finally, kilning involves drying the grain in a kiln, with a gradual increase in temperature over several hours. Once kilning is complete, the grains are now called malt and are ready for the milling stage.

Milling involves crushing the malted barley to expose the starchy part of the grain, which will be converted into fermentable sugars. The grain must not be crushed too much, as this can destroy the husk, which serves as a natural filter bed. On the other hand, if the crush is too coarse, not enough starch will be exposed.

Mashing is the process of mixing the milled grain with hot water in a large vessel called a mash tun. The temperature of the water activates enzymes in the barley, which convert starch into sugar. The different enzymes that bring about this conversion function at different temperatures, so the brewer must regulate the temperature to achieve the desired result. The mashing process lasts for about an hour, after which the brewer stops the process by raising the temperature above 200°F.

Lautering is the process of separating the solid mash from the sweet liquid, now called wort. The mash is drained into a Lauter tun, a vessel with a false bottom, and the liquid is drained away from the solid mash. Hot water may be added to extract any remaining sugars.

The boiling process involves placing the wort into a large brew kettle, where it is boiled for one to two hours. During this stage, hops are added to the wort, giving it a bitter taste and adding flavour and aroma. The boiling process also sterilizes the mixture.

After boiling, the brew is drained into a whirlpool chamber, where any remaining hop matter, coagulated matter, and other liquids are filtered off. The brew is then quickly cooled and drained into a fermentation chamber, where yeast is added. The brew is left to ferment for about two weeks, during which yeast converts the sugars into alcohol and carbon dioxide.

During the conditioning stage, the beer is pumped into a bright beer tank, where it is mechanically filtered and carbonated. The brewer may also add carbon dioxide at this stage. The beer is then packaged into sealed bottles, cans, or kegs, ready for the market.

Beer Enemas: Do They Work or Are They Dangerous?

You may want to see also

The history: ancient Egypt, China, and Mesopotamia

The history of beer can be traced back to the 6th millennium BCE, with archaeological evidence suggesting that ancient civilisations in Egypt, China, and Mesopotamia brewed beer.

The first beer in the world was brewed by the ancient Chinese around 7000 BCE, known as "kui". However, the process now recognised as beer brewing began in Mesopotamia (modern-day Iraq) at the Godin Tepe settlement in Iran between 3500 and 3100 BCE. The Sumerians of Mesopotamia are credited with creating the product that became the most popular, likely beginning over 10,000 years ago.

Beer was also an important drink in ancient Egypt, where it was considered a type of food and consumed daily. It was a staple for labourers, who were provided with a daily ration of 1⅓ gallons (over 10 pints). Beer was also used in religious practices and had divine status, with several gods and goddesses associated with it, including Tenenit, closely associated with Meskhenet, the goddess of childbirth. Hathor, the goddess of love, dance, and beauty, was also known as "The Lady of Drunkenness".

In ancient Mesopotamia, beer was enjoyed by both humans and their gods, as depicted in paintings, poems, and myths. It was consumed through a straw to filter out pieces of bread or herbs, and it had a thick, porridge-like consistency. The Sumerian poem "Hymn to Ninkasi", written around 1800 BCE, is both a song of praise to the goddess of beer, Ninkasi, and the oldest surviving beer recipe.

Beer in ancient China dates back to around 5,000 years ago, with residue on pottery showing that beer was brewed using barley and other grains. Archaeological findings indicate that Chinese villagers brewed fermented alcoholic drinks as far back as 7000 BCE on a small, individual scale, with production processes and methods similar to those of ancient Egypt and Mesopotamia.

Beer as a Hair Conditioner: Does it Work?

You may want to see also

The science: biochemical reactions, enzymes, and fermentation

The process of making beer involves a series of complex biochemical reactions, which convert barley to fermentable sugars, and allow yeast to multiply and turn those sugars into alcohol.

The first step in this process is milling, where the malted barley or other brewing grain is crushed. This exposes the starchy part of the grain, which will eventually be converted into sugar. The grain must not be crushed too finely, as this can destroy the husk, which acts as a natural filter bed.

The crushed grain is then placed into a mash tun, an insulated vessel, and mixed with hot water. The temperature of the water activates the enzymes in the barley, which convert starch into sugar. The enzymes in malted barley are typically alpha-amylase and beta-amylase. These enzymes function at different temperatures, so the brewer must carefully regulate the temperature to ensure the desired conversion takes place. If the temperature is too high, the enzymes may denature, while too low a temperature may deactivate them.

The mashing process lasts for about an hour, after which the brewer stops the process by raising the temperature above 200 degrees Fahrenheit. The next step is lautering, where the solid mash is separated from the sweet liquid, known as wort. The mash is drained into a Lauter tun with a false bottom, and the liquid is drained away from the solid mash. Hot water may be added at this stage to extract any remaining sugars.

The wort is then boiled for one to two hours. During this stage, hops are added to give the beer a bitter taste and add flavour and aroma. The boiling process also sterilises the mixture. After boiling, the brew is drained into a whirlpool chamber, where any remaining hop matter and coagulated material are filtered out, and the brew is cooled.

Finally, the brew is drained into a fermentation chamber, and yeast is added. The yeast converts the sugars into ethyl alcohol and carbon dioxide gas. The brew is left to ferment for about two weeks, at a constant temperature of 68 degrees Fahrenheit. If a lager is being made, the temperature is maintained at 48 degrees Fahrenheit, and fermentation lasts for more than six weeks.

Buttermilk Beer Batter: Does Druesteaz Mix Work?

You may want to see also

The business: breweries, regional variations, and global sales

The global beer market was valued at USD 821.39 billion in 2023, with Europe dominating the market, followed by Asia Pacific and North America. The market is projected to grow to USD 1,167.47 billion by 2032, exhibiting a steady CAGR of around 4%.

The beer market has traditionally been dominated by a few large, global players, such as Anheuser-Busch InBev, Heineken, and China Resources Snow Breweries, who hold significant market share in their respective regions. However, in recent years, there has been a rapid concentration of breweries within mature markets, and an expansion into emerging markets through strategic partnerships or acquisitions. This has led to an increase in industry consolidation and globalization.

The industry's main markets are Western Europe, Eastern Europe, North and South America, Africa, and Asia, including China and India. Each region is in a different stage of the industry lifecycle, with stable or declining consumption in developed countries and growing demand in underdeveloped countries. Per capita consumption and population growth indicate opportunities for the industry, particularly in emerging markets with increasing disposable incomes.

The COVID-19 pandemic significantly impacted the beer industry, with a disproportionate effect on bars and restaurants, leading to a decline in beer sales. However, the pandemic also accelerated the growth of e-commerce channels, with consumers buying more groceries and beer online. Off-trade sales channels, such as supermarkets and specialty stores, have become more important for beer manufacturers, while retail stores are becoming a significant distribution channel.

The beer market is segmented by type, distribution channel, production, and category. Lager is the most popular type of beer globally, followed by ale and stouts. The off-trade distribution channel leads the market due to price-conscious consumers. Macro breweries are the most common production method, but microbreweries have gained popularity, offering a wide variety of drinks. The premium category is expected to dominate the market during the forecast period due to increasing demand for high-quality, innovative products.

The Science of Beer: Understanding Silos

You may want to see also

Frequently asked questions

The basic ingredients of beer are water, barley (a source of starch), hops and yeast.

The process of making beer involves steeping barley in water and then leaving the mixture to ferment. Yeast is added to the mixture to speed up the fermentation process and convert sugar into alcohol.

Brewing has taken place since around the 6th millennium BCE. Archaeological evidence suggests that ancient civilisations, including Egypt, China and Mesopotamia, brewed beer. Beer became a staple in the Middle Ages when it was safer to drink than water due to poor sanitation.