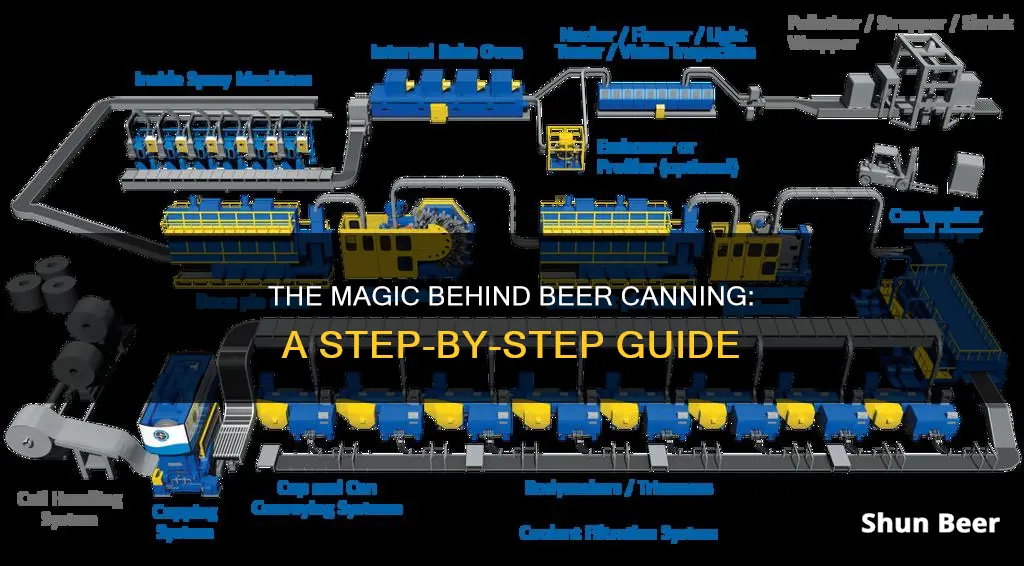

A beer canning line is a series of machines that automate the process of filling cans with beer, sealing them, and preparing them for distribution. The process begins with loading empty cans into the machine, either manually or through a depalletizer that removes them from pallets and places them on a conveyor belt. The cans are then rinsed, purged of oxygen with carbon dioxide, and filled with beer. After filling, the cans are sealed, rinsed and dried again, inspected for quality, labelled, and finally packaged for distribution.

Beer Canning Line Characteristics and Values

| Characteristics | Values |

|---|---|

| Purpose | Filling cans with beer, sealing them, and preparing them for distribution |

| Key Components | Depalletizer, filler, seamer, and labeler |

| Depalletizer Function | Removes empty cans from pallets and feeds them into the canning line |

| Filler Function | Injects beer into cans with precision and minimal waste |

| Seamer Function | Seals filled cans, making them airtight and ready for packaging |

| Labeler Function | Applies labels and date coding for traceability |

| Types of Systems | Manual, semi-automatic, and fully automatic |

| Manual System Characteristics | Suitable for small-scale operations, labor-intensive, customizable |

| Semi-Automatic System Characteristics | Balances manual and automated processes, ideal for medium-sized breweries |

| Fully Automatic System Characteristics | Fully automated with minimal human intervention, best for large-scale operations |

| Benefits of Canning | Cost-effective, consistent quality, unique labels, efficient for craft beer |

What You'll Learn

Empty cans are loaded into the machine

For automatic machines with high production capacities, a depalletizer is used to supply bulk amounts of empty cans. A depalletizer removes empty cans from their pallets and feeds them onto a conveyor belt in groups. The conveyor belt then directs the cans to each station of the production line, such as the rinsing, filling, sealing, and labelling stations. This automatic process requires minimal human intervention and is suitable for large-scale beer canning operations.

The choice between manual and automatic can loading depends on the specific needs and production goals of the brewery. Manual loading may be preferred for small-scale operations or those with limited space, while automatic loading is ideal for high-volume productions and larger enterprises.

Wet Paper Towel on Beer: Does This Method Work?

You may want to see also

Cans are rinsed

There are several methods and machinery setups that can be used to rinse cans. One common method is the "twist rinse", which involves flipping the can upside down, rinsing its interior with sanitizing water or another liquid solution, and then returning it to its upright position. This can be done manually or through an automated process. Automated twist rinsers are often used in conjunction with a depalletizer, which removes the empty cans from their pallets and feeds them onto a conveyor belt. The cans are then flipped and rinsed before being placed into the canning system.

Another method is to use a pre-rinse rinser attachment, which can be hooked up to a water supply or a keg of rinse liquid. The attachment is triggered by a sensor when the can is placed upside down into the rinser, and the rinse time can be set accordingly.

A more traditional approach is the "dunk and shake" method, where the can is manually dipped into a container of rinse liquid and then shaken to remove excess fluid.

The choice of rinsing liquid is also important. Filtered or sterilized water is commonly used, as it effectively cleans the cans without leaving behind significant residues. However, some breweries may opt for a light sanitizer, such as PAA, Iodophor, or Chlorine Dioxide, to ensure a higher level of sanitation. When using sanitizers, it is crucial to use the lowest effective concentration to avoid impacting the taste and shelf life of the beverage.

Overall, the can rinsing process is a critical step in the beer canning line, ensuring the cleanliness and quality of the final product.

Mouthwash and Beer: Effective Mosquito Repellents or Old Wives' Tales?

You may want to see also

Oxygen is purged from the cans

Purging oxygen from cans is a critical step in the beer canning process, as oxygen can shorten shelf life and negatively impact the beer's flavour. The more time beer spends exposed to oxygen, the higher the chance it will taste stale or muted.

After the cans have been rinsed, they are cleared of oxygen. This is done by filling the cans with carbon dioxide (CO2) through tubes. This process displaces the air in the can, which contains oxygen, and replaces it with CO2. The CO2 is pumped in from above, forcing all of the oxygen out of the empty cans.

Some canning lines will use nitrogen filling vacuum sealing machines. These machines push out the remaining oxygen from the filled cans by spraying nitrogen inside them as the lid is placed on top.

To ensure that the purging is effective, the speed and pressure of the CO2 must be meticulously regulated. The purging system should be able to consistently provide enough CO2 to create a stable CO2 blanket inside the can, preventing oxygen from entering during filling.

After purging the cans with CO2, the bottom filling system introduces the beer from the bottom of the can, pushing the CO2 upwards and forcing out any remaining oxygen. This process minimises the amount of oxygen that comes into contact with the beer.

To further reduce oxygen levels, it is recommended to use de-gassed water or ionized air for rinsing to eliminate the possibility of leaving water droplets that may contain oxygen.

Centrifugal Force: Spinning Beer to Perfection

You may want to see also

Cans are filled with beer

The process of filling cans with beer is a complex one, with many steps and a lot of room for error. It is also a process that has been refined over the years, with new innovations in machinery and automation.

The first step in the filling process is to load the machine with empty cans. This can be done manually or through a depalletizer, which removes the empty cans from their pallets and feeds them onto a conveyor belt. The cans are then transported to the filling station, where they are filled with beer from a tank. The number of cans filled at one time depends on the number of filler heads the machine has. After filling, the cans move under the can sealer's cap chute, which deposits a lid on top of each can. Some lines use nitrogen filling vacuum sealing machines, which push out any remaining oxygen in the can by spraying nitrogen inside as the lid is placed.

The next step is to seal the cans. A pneumatic arm pushes each can-lid combination onto the seaming station, where a seamer spins the can and crimps the lid to create an airtight double seam. This process is known as seaming and is an important step in ensuring the beer stays fresh and doesn't become stale.

Once the cans are filled and sealed, they are inspected to ensure they have been filled to the correct level. Under-filled cans are removed from the conveyor belt, while properly filled cans continue to the labelling stage.

Beer Science: Brewing Basics and Beyond

You may want to see also

Cans are sealed

Once the cans are filled, the next step is to seal them. This is done using a seamer machine, which creates an airtight double seam through the double seaming process. This process involves two "seaming rollers" that rotate around the can, one after the other, crimping the lid's rim and the can together. This type of seal is more reliable than traditional seaming methods, which can be susceptible to leakage over time. The sealed cans are then ready for the next steps in the canning process, which may include inspection, post-rinsing, drying, printing, labelling, and final packaging.

The seamer machine plays a crucial role in ensuring the integrity and freshness of the product. It helps to prevent leaks and maintain the carbonation of the beverage. The quality of the seal can also impact the shelf life of the product, as oxygen can shorten shelf life and negatively impact the flavour of the beer. A proper seal contributes to maintaining the desired taste and quality of the beer.

In addition to the seamer machine, some canning lines may also utilise an induction sealing machine. This machine uses electromagnetic induction to heat the lid and create a hermetic seal. This type of seal is also more reliable than traditional seaming methods and provides an additional layer of protection against leakage.

The specific seaming process can vary depending on the type of canning line and equipment used. For example, some seamers may use a pneumatic arm to push each lid-can combination onto the seaming station, while others may have different mechanisms to achieve the same result. The goal is always to create a secure seal that will protect the product during storage and transportation.

Overall, the sealing process is a critical step in the beer canning line. It ensures that the beer remains fresh, carbonated, and safe for consumption until it reaches the consumer. A well-sealed can also contributes to a positive customer experience, as it ensures that the beer can be enjoyed as intended, without any leaks or quality issues.

The Chemistry of Beer: How It Works and Why It Matters

You may want to see also

Frequently asked questions

A beer canning line is a series of machines that automate the process of filling cans with beer, sealing them, and preparing them for distribution.

The key components of a beer canning line include the depalletizer, filler, seamer, and labeler.

The depalletizer removes empty cans from pallets and feeds them into the canning line. The filler injects the beer into the cans, ensuring precise volumes and minimal wastage. The seamer seals the filled cans, making them airtight and ready for packaging. The labeler applies labels to the cans, often integrating date coding for traceability.

There are three main types of beer canning line equipment: manual systems, semi-automatic systems, and fully automatic systems. Manual systems are suitable for small-scale operations but require significant human intervention. Semi-automatic systems combine manual and automated processes, making them ideal for medium-sized breweries. Fully automatic systems are fully automated with minimal human intervention, making them best for large-scale operations.

The cost of a beer canning line varies depending on the system type and capacity, typically ranging from $50,000 to $150,000.