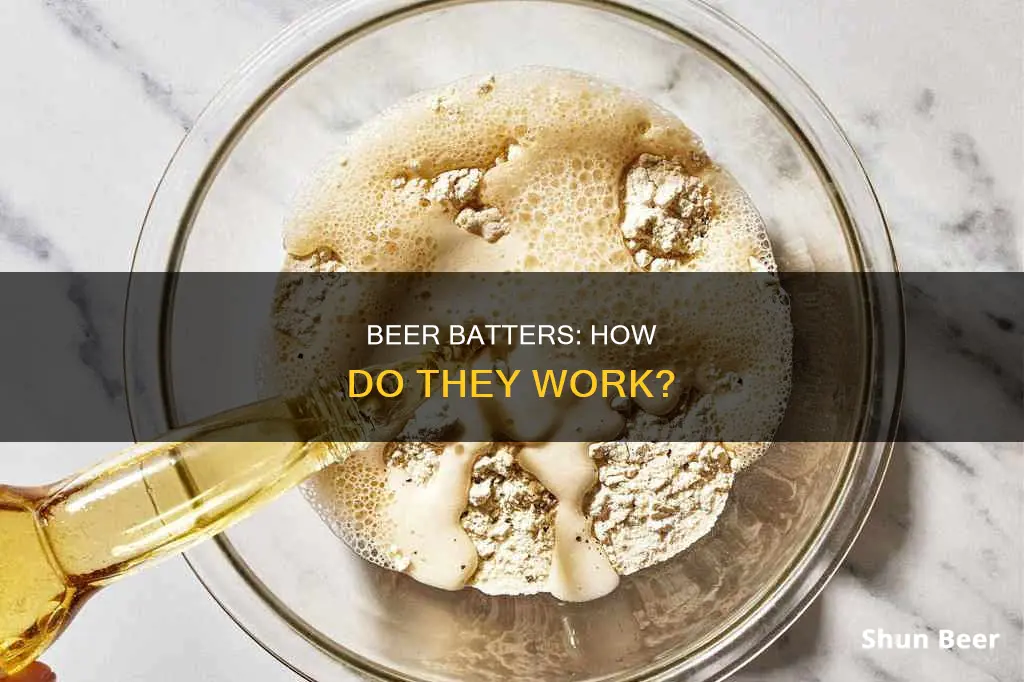

Beer batter is a popular choice for coating fried foods, such as fish and onion rings. The batter is made by combining beer, flour, and sometimes eggs to create a thick, pancake-like consistency. This batter adds flavour and texture to the food, resulting in a light, crispy, and golden brown crust. The unique properties of beer, including its carbonation, foaming agents, and alcohol content, contribute to these desirable effects. The carbonation and foaming agents create a light and airy texture, while the alcohol evaporates quickly, preventing the food from becoming soggy and overcooked.

| Characteristics | Values |

|---|---|

| Main ingredients | Beer, egg, flour |

| Beer type | Lighter style (e.g. lager) |

| Alcohol content | Low (around 5%) |

| Carbonation | High |

| pH | 4 |

| Effect on gluten formation | Prevents tough batter by limiting gluten formation |

| Texture | Light, tender, airy, crispy |

| Browning | Encourages browning |

| Taste | Adds flavour |

| Protection | Protects softer, more fragile foods during frying |

| Foaming agents | Insulate and slow bursting of bubbles |

| Thermal properties | Heats up quickly, cooking food inside without overcooking |

What You'll Learn

Carbonation

The amount of carbonation in beer is typically measured in volumes of carbon dioxide (CO2). The colder the beer, the more CO2 it can hold, which is why beers are often served chilled to maintain their carbonation. When the beer batter hits the hot oil, the solubility of the CO2 decreases, and bubbles froth up, expanding the batter and giving it a lacy, crisp texture. This expansion of the batter mix is what creates the characteristic lightness and crispiness of beer-battered foods.

The carbonation level of beer can vary depending on the style and brewing method. For example, English cask beer typically has around 1.5 volumes of CO2, while champagne can have up to 7.0 volumes. The desired level of carbonation can be achieved through natural or forced carbonation methods. Natural carbonation occurs during the fermentation process, where the brewer seals the beer in a container to trap the CO2. Forced carbonation, on the other hand, involves pumping CO2 into a sealed container with the beer, which is commonly done for kegs.

The type of beer used in the batter also matters. Carbonated beers like lager or ale are recommended because their carbon dioxide bubbles create a lighter and airier texture in the fried food. Additionally, using cold beer and other cold ingredients in the batter promotes the formation of steam and air pockets during frying, resulting in an even crispier texture.

In summary, the carbonation in beer batter plays a crucial role in achieving the desired texture and flavour of fried dishes. The release of carbon dioxide during frying creates a light and airy coating, while the carbonation level and type of beer used can be adjusted to influence the final texture and crispiness of the dish.

Beer Chillers: How Do They Work?

You may want to see also

Gluten formation

Gluten is a complex mixture of protein, prolamins, and glutenins. It is formed when flour containing proteins like glutenin and gliadin come into contact with liquid. In the case of beer batter, this liquid is the beer. The gluten gives structure and elasticity to the batter, helping to hold the ingredients together and trap air during frying. This is what gives beer-battered food its characteristic lightness and crispiness.

To ensure the formation of gluten, it is important to use the right type of flour. All-purpose flour or a combination of all-purpose and cornstarch is often recommended for beer batter. It is also crucial to avoid over-mixing the batter, as this can lead to the development of too much gluten, resulting in a dense and tough batter. Allowing the batter to rest for a short period can also help relax the gluten and improve the texture and taste of the final product.

Additionally, maintaining the right temperature is essential for gluten formation. Beer batter should be fried at temperatures between 350-375°F (175-190°C). Using a cooking thermometer can help maintain precise frying temperatures and prevent undercooking or burning.

By understanding the role of gluten in beer batter and following these tips, cooks can create light, crispy, and flavourful fried dishes.

Beer as Petrol: Can You Really Run on Hops?

You may want to see also

Foaming agents

The foaming agents in beer are what make beer-battered foods so light and crispy. When the batter hits the hot oil, the solubility of the CO2 in the beer plummets, and bubbles froth up, expanding the batter mix and lending it a lacy, crisp texture.

Some foaming agents are proteins that occur naturally in the beer, and some are ingredients that brewers add to produce a creamy, long-lasting head. These compounds form thin films that surround the bubbles and slow the rate at which they burst.

Foams also make good thermal insulators. When you dunk a piece of beer-battered fish into a deep fryer, most of the heat goes into the batter rather than the delicate food it encloses. The bubbly batter can heat up to well over 130 degrees Celsius, while the fish gently simmers inside.

The foaming agents in beer come from the beer's carbonation. Non-alcoholic beer can be used to achieve a similar effect, but additional foaming agents may be needed. These include egg whites, baking powder, and club soda.

Brewers sometimes add anti-foaming agents to beer to reduce the size of the foam cap on top of the wort and to prevent dangerous boilovers. These anti-foaming agents take the form of liquid silicone or vegetable oil-based materials that work by reducing the surface tension of the wort.

Mouthwash and Beer: Effective Mosquito Repellents or Old Wives' Tales?

You may want to see also

Alcohol

Beer batter is a popular cooking technique, especially for fried foods. The process involves coating food with a mixture of beer and flour, and sometimes other ingredients like eggs, salt, or water. Beer batter is commonly used for fish, onion rings, and other types of pub-style fare.

The alcohol in beer batter plays a significant role in the cooking process and the final texture and taste of the food. Firstly, alcohol evaporates faster than water. This means that a beer batter cooks more quickly than a batter made with only water or milk, reducing the risk of overcooking the food inside. The rapid evaporation of alcohol also contributes to the formation of a light and crispy crust on the outside.

Additionally, the presence of alcohol affects the gluten formation in the batter. Gluten is a protein that forms when flour mixes with water, and it can make the batter tough and dense. However, alcohol does not mix with flour to produce gluten, resulting in a lighter and more tender texture. This is why batters made with wheat flour are often mixed with alcohol to prevent them from becoming too thick and heavy.

The amount of alcohol in beer batter can vary depending on the recipe and the type of beer used. Some recipes use beer as the only liquid component, while others combine it with water or other liquids. The alcohol content in beer typically ranges from 3% to 8%, but it can go up to 11.5 ounces for certain beers. When cooking with high temperatures, some of the alcohol burns off, but due to the short frying times, not all of it evaporates. It is estimated that up to 85% of the original alcohol content can remain in the food after cooking.

Understanding Three-Burner Brewing: An Efficient Beer System

You may want to see also

Browning

The Maillard Reaction:

When frying beer-battered food, the high heat triggers the Maillard reaction, a chemical reaction between amino acids and reducing sugars in the batter. This reaction is responsible for the browning of the outer layer of the batter, giving it that desirable golden-brown colour. The Maillard reaction not only contributes to the visual appeal of the dish but also adds flavour and aroma, enhancing the overall taste experience.

Role of Carbonation:

The carbonation in beer plays a crucial role in achieving the perfect browning. When the beer is mixed with the dry ingredients, the dissolved carbon dioxide gas is released, creating bubbles in the batter. These bubbles then expand during frying, contributing to the airy texture and ensuring that the batter becomes golden and crispy. The carbonation also helps to lighten the batter, preventing it from becoming too dense or heavy.

Heat Application:

Applying heat during the frying process is essential to achieving the desired browning. The high temperature causes the batter to cook rapidly, encouraging the Maillard reaction and promoting the formation of a crispy, golden-brown exterior. The heat needs to be carefully controlled to prevent burning or undercooking the batter. Maintaining the ideal temperature range of 350-375°F (175-190°C) is crucial for the best results.

By understanding and harnessing the interactions between carbonation, gluten formation, moisture, high heat, and the Maillard reaction, cooks can consistently create light, crispy, and flavourful beer-battered dishes with that perfect golden-brown exterior.

Beer Growlers: How Do They Work?

You may want to see also

Frequently asked questions

Beer adds three ingredients to the batter: carbon dioxide, foaming agents, and alcohol. The carbonation from the carbon dioxide creates a light and airy texture, while the foaming agents act as insulators, allowing the food to cook without overcooking. The alcohol evaporates quickly, helping to create a crispy texture.

Lighter beers, such as lager and wheat beer, are typically used for batter. These beers have a low alcohol content (around 5%) and are carbonated, which is ideal for creating a light and crispy texture when frying.

Yes, any carbonated drink with a neutral or complementary flavor profile can be used as a substitute for beer in batter. Non-alcoholic beer and seltzer water are good alternatives, as they will still create a light and tender crust.