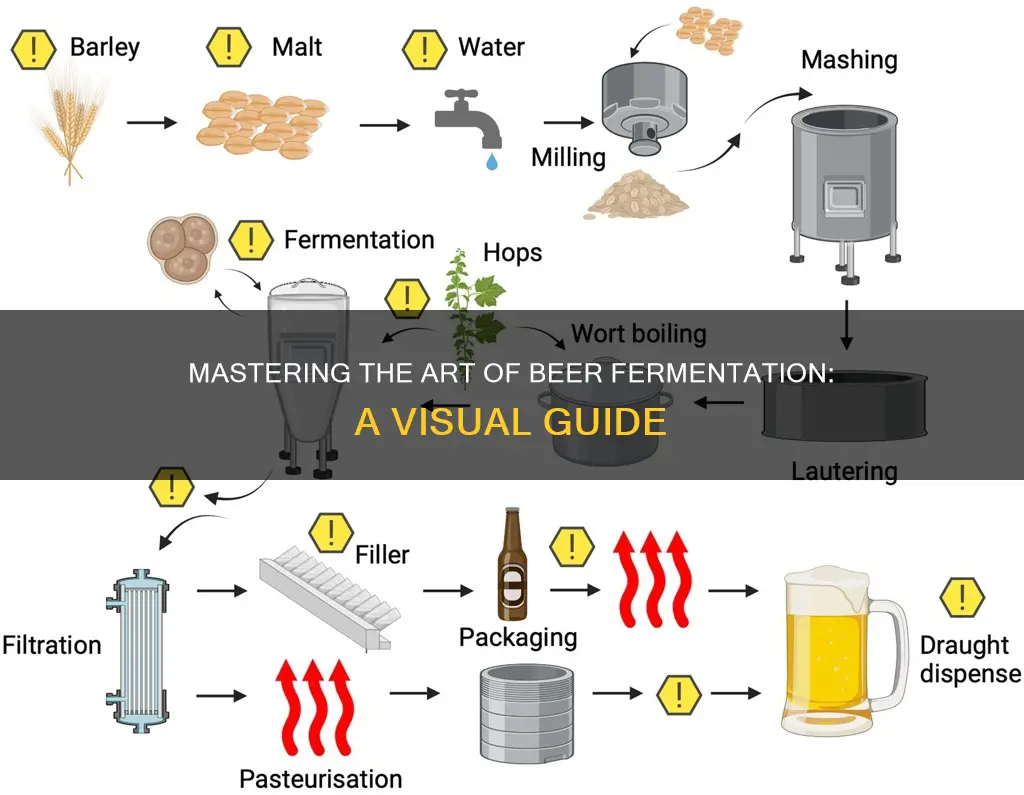

Beer fermentation is a crucial step in the brewing process, transforming the sugary wort into a delicious beverage. It involves the conversion of sugars into alcohol and carbon dioxide by yeast, and the quality of this process can significantly impact the final product's flavor, aroma, and overall character. Understanding the ideal fermentation process is essential for brewers to achieve consistent and desirable results. This introduction will explore the key factors and techniques that contribute to a successful fermentation, ensuring a well-balanced and flavorful beer.

What You'll Learn

- Yeast Selection: Choose yeast strain for desired flavor profile and fermentation efficiency

- Temperature Control: Maintain optimal temperature range for yeast activity and fermentation rate

- Oxygen Management: Avoid oxygen exposure to prevent off-flavors and ensure clean fermentation

- Sugar Addition: Add sugars gradually to support yeast and enhance fermentation

- Fermentation Time: Monitor fermentation duration for desired alcohol content and flavor development

Yeast Selection: Choose yeast strain for desired flavor profile and fermentation efficiency

When it comes to brewing beer, yeast selection is a critical step that can significantly impact the final product's flavor, aroma, and overall quality. Different yeast strains offer unique characteristics and contribute to the beer's fermentation process in various ways. Understanding the role of yeast and its influence on flavor profiles is essential for brewers to create the desired beer style.

The primary function of yeast in fermentation is to convert sugars present in the wort (the sugary liquid extracted from malted grains) into alcohol and carbon dioxide. This process not only reduces the overall sugar content but also plays a pivotal role in developing the beer's flavor and aroma. Yeast strains can be categorized into two main types: ale yeasts and lager yeasts, each with distinct characteristics. Ale yeasts, such as Saccharomyces cerevisiae, are known for their high-temperature fermentation capabilities, resulting in fruity and estery flavors. These yeasts are commonly used in styles like IPAs, stouts, and wheat beers, where a vibrant, complex flavor profile is desired. On the other hand, lager yeasts, including Saccharomyces pastorianus, ferment at lower temperatures, producing a cleaner and crisper beer with less esters. Lagers, pilsners, and certain types of wheat beers often utilize these yeasts for their smooth and balanced nature.

Selecting the appropriate yeast strain is crucial to achieving the desired flavor profile. For instance, if you aim to create a robust, hop-forward IPA, a high-alcohol ale yeast like Wyeast 3522 or White Labs WLP099 would be an excellent choice. These yeasts can handle higher alcohol levels and contribute to the beer's hoppy character, resulting in a more pronounced bitterness and aroma. In contrast, for a classic, crisp lager, a lager yeast like White Labs WLP614 or Wyeast 2278 would be ideal, as they produce a clean, neutral flavor that allows the malt character to shine.

Additionally, yeast selection impacts fermentation efficiency. Some yeasts are known for their high fermentation rates, ensuring a quicker and more efficient process. For example, ale yeasts like Wyeast 3787 or White Labs WLP028 are highly regarded for their rapid fermentation, making them suitable for homebrewers who want to minimize the time between brewing and enjoying their beer. Lager yeasts, while generally slower, provide a more controlled fermentation, resulting in a consistent and predictable outcome.

In summary, yeast selection is a critical aspect of beer fermentation, offering brewers the ability to tailor the flavor profile and fermentation efficiency to their specific needs. By understanding the characteristics of different yeast strains, brewers can make informed decisions to create beers that meet their desired style and quality standards. Whether it's the fruity notes of an ale yeast or the crispness of a lager yeast, the right choice can elevate a beer from good to exceptional.

Uncorking the Mystery: Why Beer Fizzed with Salt

You may want to see also

Temperature Control: Maintain optimal temperature range for yeast activity and fermentation rate

Temperature control is a critical aspect of the beer fermentation process, as it directly influences the activity of yeast and the overall fermentation rate. Yeast, the microorganism responsible for converting sugars into alcohol and carbon dioxide, is highly sensitive to temperature variations. Maintaining the optimal temperature range is essential to ensure a successful fermentation and the desired beer characteristics.

The ideal temperature range for yeast activity in beer fermentation typically falls between 65°F and 75°F (18°C and 24°C). Within this range, yeast exhibits optimal metabolic activity, efficiently converting sugars present in the wort (the sugary liquid extracted from malted grains) into alcohol and carbon dioxide. At these temperatures, the yeast population remains healthy and active, promoting a robust fermentation process.

During the early stages of fermentation, a slightly warmer temperature of around 70°F (21°C) is often recommended. This slightly elevated temperature can stimulate yeast activity and enhance the initial fermentation rate. However, it is crucial to monitor the temperature closely and make adjustments as needed to prevent overheating, which can lead to off-flavors and potential yeast stress. As fermentation progresses, a gradual temperature drop to the optimal range is ideal to maintain yeast health and ensure a clean fermentation profile.

For homebrewers and small-scale operations, precise temperature control can be achieved through various methods. One common approach is to use a fermentation chamber or a dedicated brewing refrigerator, which allows for accurate temperature regulation. These devices can maintain a consistent temperature throughout the fermentation process, ensuring optimal yeast performance. Additionally, monitoring the temperature regularly and making small adjustments with a heating or cooling element can help keep the fermentation within the desired range.

In larger-scale brewing operations, temperature control is often automated and integrated into the brewing system. Breweries employ sophisticated equipment, such as fermenters with built-in temperature control systems, to maintain precise temperature conditions. This level of control is crucial for consistency and quality, especially when producing large batches of beer. By carefully managing temperature, brewers can optimize yeast activity, control fermentation rates, and ultimately produce beers with the desired flavor profiles and characteristics.

The Perfect Pour: Can You Chill Beer in a Hydro Flask?

You may want to see also

Oxygen Management: Avoid oxygen exposure to prevent off-flavors and ensure clean fermentation

Oxygen management is a critical aspect of the brewing process, especially when it comes to fermentation. While oxygen is essential for the initial stages of brewing, its presence during fermentation can lead to undesirable outcomes. The goal is to ensure a clean and controlled fermentation process that avoids any off-flavors or unwanted microbial activity. Here's a detailed guide on how to manage oxygen exposure during beer fermentation:

Understanding the Risks of Oxygen Exposure:

During fermentation, yeast consumes sugars and produces alcohol and carbon dioxide. This process is highly sensitive to oxygen levels. When oxygen is present in the fermentation vessel, it can stimulate the growth of aerobic bacteria, leading to off-flavors and odors. These bacteria can also compete with the yeast, slowing down the fermentation process. Additionally, oxygen can cause the formation of volatile compounds, resulting in harsh or metallic tastes in the beer.

Pre-Fermentation Preparation:

Before transferring the wort to the fermentation vessel, it's crucial to minimize oxygen contact. Use oxygen-free water and ensure all equipment is properly sanitized. Consider using a degassing system to remove dissolved oxygen from the wort. This can be achieved by passing the wort through a carbon filter or using a vacuum-degassing system.

Fermentation Vessel and Technique:

- Closed System: Employ a closed fermentation system where the beer is sealed in the vessel. This prevents external oxygen from entering and minimizes the risk of contamination.

- Fermentation Temperature: Maintain a consistent fermentation temperature. Warmer temperatures can increase the risk of oxygen absorption, so keeping the beer cool is essential.

- Use of Yeast Camp: When transferring the wort to the fermentation vessel, quickly and gently pour it in to avoid excessive aeration.

Yeast Selection and Pitching:

Choose yeast strains specifically suited for beer fermentation. Different yeasts have varying oxygen requirements and tolerance levels. Some yeasts, like ale yeasts, are more oxygen-sensitive and may require additional precautions. When pitching the yeast, ensure a healthy starter culture to promote efficient fermentation without the need for excessive oxygen.

Monitoring and Adjustments:

- Oxygen Sensors: Consider investing in oxygen sensors for the fermentation vessel. These sensors can provide real-time data on oxygen levels, allowing you to make adjustments as needed.

- Regular Sampling: Take regular samples of the beer during fermentation to check for off-flavors or signs of bacterial contamination.

- Adjusting Fermentation Conditions: If oxygen levels are a concern, you can adjust the fermentation conditions by adding nutrients or adjusting the temperature to promote a healthier yeast environment.

By implementing these oxygen management techniques, brewers can ensure a clean and consistent fermentation process, resulting in high-quality beers with desirable flavors and aromas. It's an art that requires precision and attention to detail, but the rewards are a well-crafted, delicious beer.

Brewed Adventure: A Guide to Stuffing Beer in Turkey

You may want to see also

Sugar Addition: Add sugars gradually to support yeast and enhance fermentation

When it comes to the art of brewing beer, fermentation is a crucial step that transforms the sweet wort into a delightful beverage. One essential technique to master is the gradual addition of sugars, a practice that significantly impacts the fermentation process and the final beer's character. This methodical approach ensures the yeast has a steady supply of nutrients, promoting a healthy and efficient fermentation.

The primary reason for adding sugars during fermentation is to provide the yeast with energy. Yeast, the microscopic workhorses of brewing, require a constant source of food to sustain their activity. By gradually introducing sugars, you create a controlled environment where the yeast can feed and multiply, resulting in a robust and active population. This is particularly important in the early stages of fermentation, where the yeast's activity is vital for the process's success.

Gradual sugar addition also allows for better control over the fermentation temperature. Yeast thrives within a specific temperature range, and maintaining this optimal range is essential for efficient fermentation. By adding sugars slowly, you can monitor the yeast's activity and adjust the temperature accordingly. This precision ensures that the yeast remains active and healthy, contributing to a clean and consistent fermentation process.

Furthermore, this technique enhances the beer's overall quality and flavor profile. The yeast, with a steady supply of sugars, can produce a more complex and nuanced beer. It encourages the development of desirable esters and other flavor compounds, resulting in a beer with a more interesting and appealing taste. This method is especially beneficial for styles like Belgian ales and certain wheat beers, where a rich, fruity character is desired.

In practice, the sugar addition process involves carefully measuring and dissolving a controlled amount of sugar in a specific volume of water, creating a sugar syrup. This syrup is then added to the wort at various stages of fermentation, depending on the desired outcome. The timing and amount of sugar added can be adjusted to fine-tune the fermentation process, ensuring the beer's unique character is achieved. This technique showcases the brewer's skill and attention to detail, ultimately contributing to the creation of exceptional craft beers.

Unraveling the Mystery: Why Men Store Beer at the Bottom of the Fridge

You may want to see also

Fermentation Time: Monitor fermentation duration for desired alcohol content and flavor development

Monitoring the fermentation time is a critical aspect of brewing beer, as it directly influences the final product's alcohol content and flavor profile. The goal is to achieve a balanced and desirable beer, so understanding the fermentation process is essential. Here's a detailed guide on how to approach this stage:

Fermentation is the process where sugars in the wort (the liquid extracted from malted grains) are converted into alcohol and carbon dioxide by yeast. The duration of this process can vary significantly depending on the beer style, yeast type, and desired outcome. For instance, a light, crisp lager might ferment in a matter of days, while a rich, dark ale could take several weeks. The key is to monitor and manage this process to ensure the beer reaches the desired alcohol level and flavor complexity.

To begin, brewers should set a target fermentation time based on the beer style. This is often determined by experience and recipe guidelines. For example, a common target for many ales is a fermentation period of 1-2 weeks, while lagers might aim for 3-5 days. During this time, the yeast works to consume the available sugars, and the beer's gravity (measured by specific gravity) should decrease. A consistent decrease in gravity indicates healthy fermentation.

Regular monitoring is crucial. Brewers should take specific gravity readings at the beginning and end of the fermentation period, as well as at regular intervals in between. This data will help determine if the fermentation is progressing as expected. If the gravity doesn't decrease at a steady rate, it may indicate issues such as a yeast problem, contamination, or an imbalance in the recipe. Adjustments can then be made to correct the issue.

Additionally, keeping an eye on the yeast activity and health is essential. If the yeast is not active or is dying off, the fermentation will stall, and the beer's quality will suffer. This can often be identified by a lack of carbonation or a slow fermentation rate. In such cases, adding more yeast or adjusting the fermentation temperature can help revive the process.

In summary, successful beer fermentation requires a keen eye for detail and a methodical approach. By monitoring fermentation time, specific gravity, and yeast activity, brewers can ensure their beer reaches the desired alcohol content and flavor development. This process is a delicate balance, and with careful management, brewers can create exceptional beers that showcase their unique characteristics.

The Art of Rim Decor: Enhancing Your Pumpkin Beer Experience

You may want to see also

Frequently asked questions

The optimal temperature range for beer fermentation is between 65°F and 75°F (18°C and 24°C). This range allows for a healthy yeast activity and helps to produce a well-balanced beer. Keeping the temperature consistent throughout the fermentation process is crucial to achieving the desired flavor and character.

Monitoring the gravity of your beer is a common method to assess fermentation. You can use a hydrometer to measure the specific gravity before and after fermentation. If the gravity has dropped significantly, it indicates that the yeast is actively fermenting the sugars. Additionally, keeping an eye on the yeast activity, such as observing the formation of a healthy yeast flocculent, can be a good indicator of proper fermentation.

Racking is the process of transferring the beer from the primary fermentation vessel to a secondary one, leaving behind the yeast and sediment. This step is crucial as it allows for a clearer, more refined beer. By removing the yeast, you prevent it from re-fermenting sugars and potentially causing off-flavors. Racking also helps to separate the beer from any remaining yeast or sediment, resulting in a smoother and more enjoyable drinking experience.

It is generally not recommended to open the fermentation vessel during active fermentation. Yeast requires a controlled environment to function optimally. Opening the vessel can introduce oxygen, which may lead to oxidation and off-flavors in the beer. Additionally, it can disrupt the yeast's activity and slow down the fermentation process. It's best to wait until the fermentation is nearly complete and the beer has cleared before opening the vessel for any necessary transfers or additions.