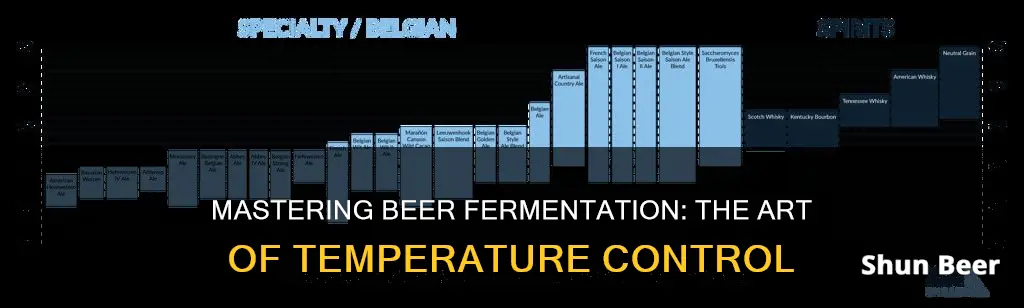

Fermentation is a crucial step in the beer-making process, and controlling temperature is essential to achieving the desired flavor and character. Beer fermentation typically occurs at specific temperature ranges, which can vary depending on the style and desired outcome. In this guide, we will explore the optimal temperature conditions for fermenting beer, providing insights into the science behind fermentation and offering practical tips for homebrewers to create exceptional brews. Understanding the temperature dynamics will empower you to craft beers with unique profiles and flavors.

What You'll Learn

- Temperature Control: Maintain a precise temperature range for optimal fermentation

- Yeast Selection: Choose yeast suited to the desired beer style and temperature

- Fermentation Time: Ferment at specific temps for desired flavor and alcohol content

- Monitoring: Regularly check temperature and fermentation progress

- Carbonation: Adjust temperature for carbonation levels during the fermentation process

Temperature Control: Maintain a precise temperature range for optimal fermentation

Temperature control is a critical aspect of the beer fermentation process, as it directly influences the efficiency and quality of the final product. Fermentation is a biological process where yeast converts sugars into alcohol and carbon dioxide, and maintaining the right temperature is essential for this transformation to occur optimally. The ideal temperature range for beer fermentation varies depending on the style and yeast strain used, but generally, it falls between 65°F and 75°F (18°C and 24°C).

During the initial stages of fermentation, a warmer temperature, around 68-72°F (20-22°C), is often recommended. This slightly elevated temperature range accelerates the fermentation process, allowing the yeast to work more rapidly and efficiently. It encourages the yeast to produce a higher alcohol content and a more robust flavor profile. However, it's crucial to monitor the temperature closely during this phase, as any deviation from the target range can impact the fermentation's success.

As the fermentation progresses, a gradual temperature drop is typically desired. This is achieved by lowering the temperature to the optimal range of 65-70°F (18-21°C). This temperature range promotes a slower, more controlled fermentation, which is beneficial for achieving a cleaner, more refined beer. The yeast continues to work at this temperature, producing a well-balanced beer with the desired alcohol content and flavor characteristics.

Maintaining precise temperature control is achieved through various methods. One common approach is to use a fermentation chamber or a dedicated brewing appliance that can be set to the desired temperature. These devices often feature temperature probes and controllers to ensure accuracy. Additionally, brewers may employ temperature-controlled fermentation vessels, such as insulated fermenters or carboys, which help regulate the temperature of the beer during the fermentation process.

It is essential to monitor the temperature regularly and make adjustments as needed. If the temperature rises above the target range, it can lead to off-flavors and a slower fermentation process. Conversely, if the temperature drops too low, the yeast may become inactive, halting the fermentation. Therefore, brewers should be vigilant in their temperature management to ensure a successful and consistent beer fermentation.

The Art of Carbonation: Tips for Perfectly Bubbly Beer

You may want to see also

Yeast Selection: Choose yeast suited to the desired beer style and temperature

Yeast selection is a critical step in the beer-making process, as it directly influences the flavor, aroma, and overall character of the final product. When fermenting beer at a specific temperature, it's essential to choose a yeast strain that is well-suited to the desired style and temperature range. This ensures optimal fermentation and the desired beer profile. Here's a guide to understanding yeast selection and its impact on temperature-specific fermentation:

Understanding Yeast and Temperature: Yeast is a microorganism that plays a vital role in fermentation. It metabolizes sugars present in the wort (the sugary liquid extracted from malted grains) and converts them into alcohol and carbon dioxide. Different yeast strains have unique characteristics and temperature preferences. Some yeasts thrive in warmer conditions, while others perform best at cooler temperatures. The fermentation temperature can significantly impact the flavor development and the overall fermentation process.

Choosing Yeast for Specific Beer Styles: The beer style you aim to create is a primary factor in yeast selection. Here's a brief overview:

- Ale Yeast: For ale beers, such as IPAs, pale ales, and stouts, ale yeasts are commonly used. These yeasts can handle a wide range of temperatures but often perform best between 65°F and 75°F (18°C to 24°C). Popular ale yeasts include American Ale yeast (Saccharomyces cerevisiae) and British Ale yeast (Saccharomyces pastorianus).

- Lager Yeast: Lagers, such as pilsners and lagers, typically use lager yeasts. These yeasts are more sensitive to temperature and usually ferment best at cooler temperatures around 50°F to 60°F (10°C to 15°C). German lager yeast (Saccharomyces pastorianus) and American lager yeast (Saccharomyces carlsbergensis) are common choices.

- Wheat Beer Yeast: For wheat beers like German-style hefeweizens, a wheat beer yeast is ideal. These yeasts can handle slightly warmer temperatures and are known for their fruity esters.

Temperature-Specific Yeast Considerations:

- Warm Fermentation (68-72°F or 20-22°C): If you're aiming for a high-alcohol beer or a style that benefits from warm fermentation, such as certain Belgian ales, you might consider using a yeast with a higher temperature tolerance. Some ale yeasts can handle temperatures up to 75°F (24°C) or even higher.

- Cool Fermentation (59-63°F or 15-17°C): For lagers and wheat beers, cooler fermentation temperatures are preferred. Lager yeasts are adapted to these conditions and will produce clean, crisp flavors.

When selecting yeast, it's essential to consider the specific requirements of the beer style and the desired fermentation temperature range. This ensures that the yeast will perform optimally, resulting in a well-balanced and flavorful beer. Remember that proper yeast management, including pitch rate and fermentation temperature control, is crucial for achieving the best outcomes in your brewing journey.

The Perfect Beer Companion: Orange Slice Edition

You may want to see also

Fermentation Time: Ferment at specific temps for desired flavor and alcohol content

Fermentation is a crucial step in the beer-making process, and controlling temperature is key to achieving the desired flavor profile and alcohol content. The duration and temperature of the fermentation process significantly impact the final beer's character. Here's a guide to understanding how temperature affects fermentation and how to manipulate it to your advantage:

Understanding Fermentation: Fermentation is the process of converting sugars into alcohol and carbon dioxide. Yeast plays a vital role in this process, and its activity is highly temperature-dependent. Different yeast strains have optimal temperature ranges, and deviating from these can result in off-flavors or even a failed fermentation. For example, ale yeasts typically thrive in warmer temperatures (around 65-75°F or 18-24°C), while lager yeasts prefer cooler conditions (55-65°F or 13-18°C).

Temperature's Impact on Flavor: Temperature affects the rate of fermentation and the yeast's activity, which in turn influences the beer's flavor. Warmer temperatures generally lead to faster fermentation, resulting in a cleaner and crisper taste. This is often desired for pale ales and lagers. Conversely, cooler temperatures can slow down fermentation, allowing for more complex flavor development, which is common in Belgian-style beers and some stouts. Higher temperatures can also enhance the production of esters, creating fruity or spicy notes, while lower temperatures might suppress these flavors.

Alcohol Content and Fermentation Time: The relationship between temperature and fermentation time is crucial for achieving the desired alcohol by volume (ABV). Higher temperatures can accelerate fermentation, reducing the overall time but potentially limiting the alcohol content. For beers with higher ABV targets, a slower fermentation process at a controlled, cooler temperature is often employed. This allows the yeast to work more efficiently and produce a higher alcohol content without compromising the beer's quality.

Practical Tips: When fermenting at specific temperatures, it's essential to monitor the process closely. Take daily temperature readings and adjust as needed. For instance, if you're aiming for a crisp, dry beer, a warmer fermentation temperature might be beneficial. However, be cautious not to exceed the yeast's optimal range, as this can lead to off-flavors or a stuck fermentation. Additionally, consider using a fermentation lock to prevent oxygen exposure, which can affect flavor.

Experimentation and Record-Keeping: Beer fermentation is an art and a science. Experimenting with different temperatures and yeast strains can help you understand their interactions. Keep detailed records of your processes, including temperatures, yeast types, and fermentation times. This data will enable you to replicate successful brews and make informed adjustments for future batches.

Pack Your Beer: A Guide to Traveling with Your Favorite Brew

You may want to see also

Monitoring: Regularly check temperature and fermentation progress

Monitoring the temperature and fermentation process is a critical aspect of brewing beer, especially when aiming for a specific temperature-controlled fermentation. This step ensures that your beer ferments optimally, developing the desired flavors and characteristics. Here's a detailed guide on how to effectively monitor these processes:

Temperature Control: Maintaining a consistent temperature is crucial during fermentation. Most beer fermentation processes thrive in a specific temperature range, typically between 65°F and 75°F (18°C and 24°C). Regularly check the temperature of your fermentation vessel using a reliable thermometer. Aim for a stable environment, and make adjustments as needed. If the temperature rises above the target range, consider using a cooling system to prevent the beer from overheating, which can lead to off-flavors. Conversely, if it drops below the desired temperature, you might need to apply gentle heat to maintain the process.

Fermentation Progress: Monitoring the fermentation progress is an art that requires patience and observation. Here's how you can do it:

- Visual Inspection: Regularly observe the beer's appearance. During fermentation, the beer should gradually clear, and the yeast should settle at the bottom of the fermenter. If the beer remains cloudy or the yeast doesn't settle, it might indicate a problem.

- Specific Gravity Measurements: Take specific gravity readings at regular intervals. This measurement indicates the concentration of sugars in the beer. As fermentation progresses, the specific gravity should steadily decrease. A consistent drop in specific gravity suggests healthy fermentation. If the reading remains stable or starts to increase, it could mean the yeast is inactive or something is amiss.

- Carbonation and Flavor Development: Pay attention to the beer's carbonation and flavor profile. As fermentation nears completion, the beer should start to carbonate, and the flavors should develop. Take samples at different stages to assess the progress and make any necessary adjustments to the recipe or fermentation parameters.

Regular monitoring allows you to catch potential issues early on. If the temperature deviates significantly, you might need to take corrective actions, such as adjusting the fermentation vessel's insulation or using temperature-controlled fermentation equipment. Additionally, keeping a log of your observations and measurements will help you identify patterns and refine your brewing process over time.

Remember, successful beer fermentation is a delicate balance of temperature control and careful monitoring. By regularly checking the temperature and fermentation progress, you can ensure that your beer ferments beautifully, resulting in a delicious and consistent product.

The Perfect Pour: Can You Chill Beer in a Hydro Flask?

You may want to see also

Carbonation: Adjust temperature for carbonation levels during the fermentation process

The temperature control during fermentation is a critical aspect of brewing beer, especially when aiming for the desired carbonation levels. Carbonation is a result of the fermentation process, where yeast consumes sugars and produces alcohol and carbon dioxide (CO2). The temperature at which this process occurs significantly influences the final carbonation of your beer.

In general, lower fermentation temperatures tend to produce more carbonated beers. When yeast ferments at cooler temperatures, it slows down, allowing for a more gradual release of CO2. This gradual release results in a beer with higher carbonation levels. For example, fermenting at around 55°F (13°C) can lead to a crisp, highly carbonated beer, which is often desirable for styles like pale ales and lagers. The slow fermentation at this temperature encourages the yeast to work at a steady pace, producing a clean and sharp flavor profile.

On the other hand, higher fermentation temperatures can also impact carbonation, but in a different way. Warmer temperatures can increase the rate of fermentation, which might seem counterintuitive for carbonation. However, this rapid fermentation can lead to a more aggressive CO2 release, resulting in a beer with lower carbonation. For instance, fermenting at 68°F (20°C) or higher can produce a beer with moderate carbonation, which is often preferred for fruity and spicy styles like wheat beers or certain Belgian ales.

To adjust carbonation levels, brewers often manipulate the fermentation temperature. A common technique is to start fermentation at a higher temperature to activate the yeast quickly, then gradually lower the temperature as the process progresses. This method allows for a controlled release of CO2, resulting in a beer with the desired carbonation. For instance, you might ferment the beer at 68°F (20°C) for the first few days, then drop the temperature to 59°F (15°C) for the remainder of the fermentation. This approach ensures a robust flavor development while still achieving the target carbonation.

Additionally, monitoring the fermentation temperature regularly is essential. Using a fermentation thermometer, you can keep track of the temperature and make adjustments as needed. This precision ensures that your beer reaches the desired carbonation level, contributing to the overall quality and character of the final product. Remember, the goal is to find the right balance between temperature and time to achieve the perfect carbonation for your beer style.

The Ultimate Guide to Packing Beer in Your Cooler

You may want to see also

Frequently asked questions

The optimal temperature for beer fermentation is typically between 65°F and 75°F (18°C and 24°C). This range is crucial for yeast health and fermentation efficiency. Yeast activity slows down significantly below 60°F, which can lead to a sluggish fermentation process. Conversely, temperatures above 78°F (26°C) can cause the yeast to die or become inactive, resulting in a stuck fermentation.

Temperature plays a vital role in the fermentation process. Yeast, the microorganisms responsible for fermentation, are sensitive to temperature changes. Warmer temperatures accelerate fermentation, reducing the overall fermentation time. However, it's essential to maintain a consistent temperature to avoid temperature shock, which can negatively impact yeast health. Cooler temperatures are generally preferred for longer fermentation periods, allowing for more complex flavor development.

While it is possible to ferment beer at temperatures outside the ideal range, it may not yield the best results. Fermenting at temperatures below 60°F can slow down the process and limit the yeast's activity, leading to a less efficient fermentation. On the other hand, fermenting at temperatures above 75°F can cause off-flavors and may even result in a failed fermentation. It's best to stick to the recommended temperature range for optimal beer fermentation.