Understanding when the fermentation process of beer has concluded is crucial for achieving the desired flavor and alcohol content. This guide will explore various methods to determine when fermentation has ceased, ensuring you can produce high-quality beer consistently. From measuring alcohol levels to observing yeast activity, these techniques will help you pinpoint the moment when fermentation is complete, allowing you to bottle or keg your beer at the optimal time.

What You'll Learn

- Visual Changes: Cloudiness or haze may indicate fermentation completion

- Carbonation: Rising bubbles and carbonation levels signal fermentation

- Temperature Drop: Fermentation slows as temperatures drop below room temperature

- Alcohol Content: Measuring alcohol by volume confirms fermentation

- Sulfur Compounds: Disappearance of sulfur compounds indicates fermentation's end

Visual Changes: Cloudiness or haze may indicate fermentation completion

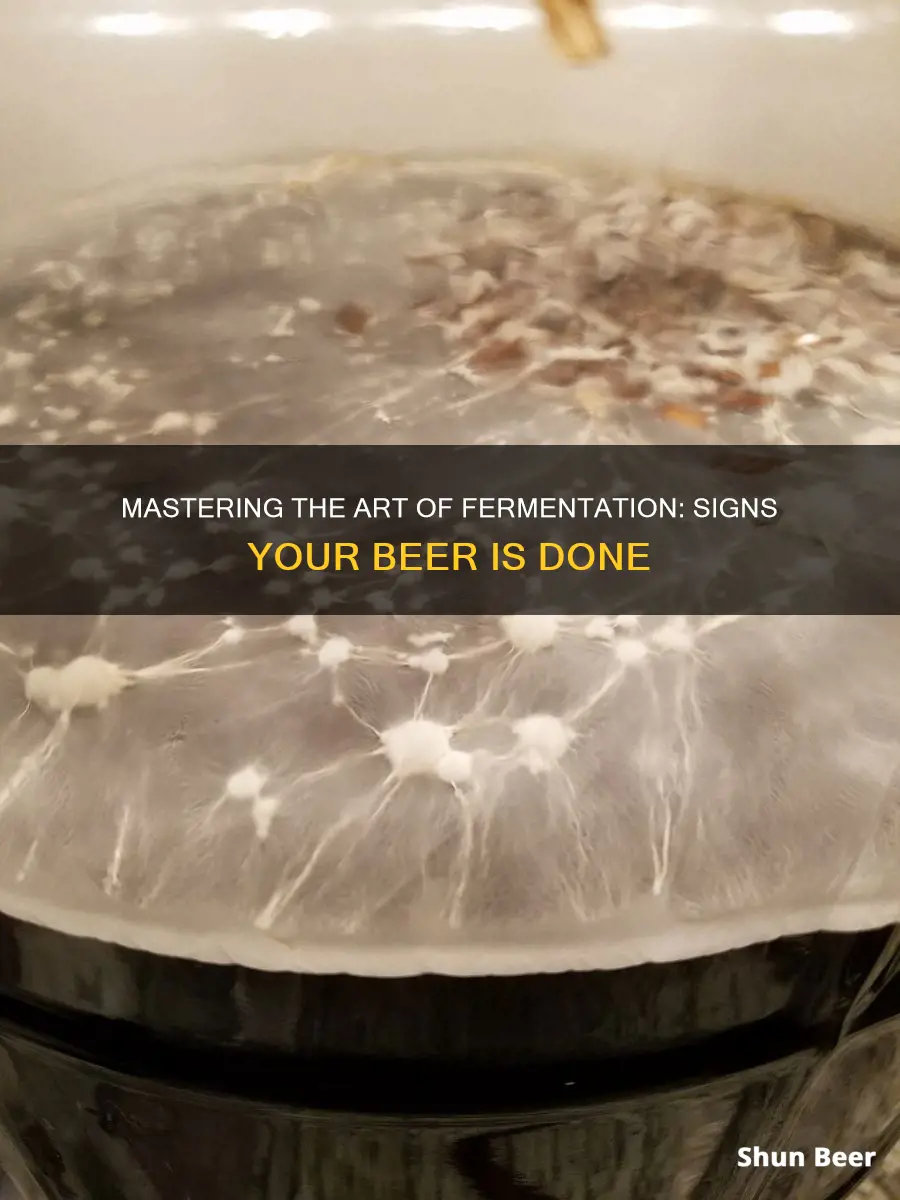

When it comes to brewing beer, understanding the fermentation process is crucial for achieving the desired flavor and quality. One of the visual cues that can indicate when fermentation has stopped is the appearance of cloudiness or haze in the beer. This phenomenon might seem counterintuitive, as one might expect a clear and pristine liquid after the fermentation process. However, this cloudiness is a sign of the beer's transformation and maturity.

During fermentation, yeast consumes sugars and produces alcohol and carbon dioxide. As this process occurs, the beer's composition changes, leading to the formation of various compounds. These compounds can include proteins, esters, and other byproducts that are not soluble in the liquid initially. As the fermentation progresses, these insoluble compounds may start to precipitate out of the beer, causing it to become cloudy. This cloudiness is often more pronounced in styles of beer that use higher amounts of malt or have more complex ingredient profiles.

The cloudiness or haze can be observed in the beer's appearance, especially when it is freshly poured. It might appear as a slight opaqueness or a subtle milky texture. This visual change is a result of the beer's natural clarification process, where the yeast and other solids settle at the bottom of the fermentation vessel. As the beer ages, the cloudiness may gradually dissipate, and the beer can become clearer, but this initial cloudiness is a positive sign of a well-fermented beer.

It is important to note that the level of cloudiness can vary depending on the brewing process and the style of beer. Some beers, like wheat beers or those with added fruits, are naturally more cloudy due to their ingredients. In such cases, the cloudiness is an expected characteristic and not an indication of an issue. However, if the beer becomes excessively cloudy or hazy, it might suggest incomplete fermentation or the presence of unwanted contaminants.

To confirm that fermentation has stopped, brewers can perform a simple gravity reading or use a hydrometer. These tools measure the specific gravity of the beer, which indicates the concentration of sugars. As fermentation progresses, the specific gravity should steadily decrease until it stabilizes at the desired level. When the specific gravity no longer changes significantly, it is a strong indication that fermentation has concluded. Combining this measurement with the visual cues of cloudiness or haze can provide brewers with a comprehensive understanding of their beer's fermentation status.

Brewing Beer from American Crabgrass: A Fermentation Guide

You may want to see also

Carbonation: Rising bubbles and carbonation levels signal fermentation

Understanding the fermentation process is key to knowing when your beer has reached its peak. One of the most reliable indicators of this process is the rise in carbonation levels. As yeast consumes sugars and converts them into alcohol, it also produces carbon dioxide, which gets dissolved in the beer. This dissolved CO2 is what gives beer its fizz and is a direct result of fermentation.

During the early stages of fermentation, you might notice a slight increase in carbonation, which is a good sign that the yeast is actively working. However, as fermentation progresses, the rate of carbon dioxide production should increase. This is because the yeast is more efficient at converting sugars, leading to a higher production of CO2. If you're monitoring your beer's fermentation, you'll likely see a steady rise in carbonation levels until it reaches a plateau.

The plateau in carbonation is a crucial sign that fermentation is complete. At this point, the yeast has consumed most of the available sugars, and the rate of CO2 production stabilizes. It's important to note that this doesn't mean the yeast has stopped working; it simply means that the yeast has finished its job and the beer is now at its optimal state.

To measure carbonation, you can use a hydrometer to measure the specific gravity of your beer. As fermentation progresses, the specific gravity should decrease, indicating that the beer is becoming less sugary and more alcoholic. When the specific gravity stabilizes, it's a strong indication that fermentation is complete.

Additionally, you can observe the beer visually. As fermentation progresses, you might notice a change in the beer's appearance, from a slightly hazy to a clear state. This is due to the yeast settling at the bottom of the fermenter, leaving the beer clearer. The beer might also develop a slight haze, which is a sign of healthy yeast activity.

In summary, monitoring carbonation levels is a practical and reliable method to determine when your beer has stopped fermenting. The rise in bubbles and carbonation indicates the yeast's activity, and the stabilization of these levels signals the completion of the fermentation process. This knowledge can help you time your brewing process more accurately and produce beer of consistent quality.

Fermenting Lager Beer: A Step-by-Step Guide to Crafting the Perfect Brew

You may want to see also

Temperature Drop: Fermentation slows as temperatures drop below room temperature

When it comes to homebrewing, monitoring the fermentation process is crucial to ensure your beer reaches the desired state of maturity. One key factor that significantly influences fermentation is temperature. As the temperature drops below room temperature, the fermentation process undergoes a natural slowdown, providing valuable insights into the beer's progress.

During the fermentation process, yeast plays a vital role in converting sugars into alcohol and carbon dioxide. This transformation is highly temperature-sensitive. When temperatures fall, the yeast's activity decreases, leading to a slower fermentation rate. This temperature-dependent behavior is a natural part of the brewing process and can be harnessed to determine when fermentation has concluded.

The slowdown in fermentation becomes evident as the beer's carbonation levels and alcohol content gradually increase. As the yeast becomes less active, the beer's clarity may also improve, revealing a smoother and more refined beverage. This change in appearance and taste is a clear indicator that the fermentation process is nearing its end.

It's important to note that the optimal temperature range for fermentation varies depending on the style of beer being brewed. For instance, some ales thrive at warmer temperatures, while lagers benefit from cooler conditions. Understanding your specific beer's requirements is essential for accurate fermentation monitoring.

In summary, the temperature drop below room temperature is a critical indicator of fermentation progress. As the yeast's activity slows, the beer's characteristics evolve, providing brewers with valuable feedback. By paying close attention to temperature changes, homebrewers can effectively manage the fermentation process and produce high-quality, flavorful beers.

The Art of Draft Beer: To Bailey or Not to Bailey?

You may want to see also

Alcohol Content: Measuring alcohol by volume confirms fermentation

The process of fermentation in beer is a fascinating transformation, and understanding when it's complete is crucial for achieving the desired alcohol content. One of the most reliable methods to determine this is by measuring the alcohol by volume (ABV). This measurement provides a direct indication of the beer's alcoholic strength and is a key indicator of successful fermentation.

Alcohol by volume is a standard way to express the volume of alcohol in a beverage relative to the total volume of the drink. For beer, this measurement is essential as it reflects the beer's final alcohol concentration after fermentation. When you measure the ABV, you're essentially gauging the efficiency of the fermentation process. As yeast consumes sugars and produces alcohol, the ABV will gradually increase until the fermentation process is complete.

To measure alcohol by volume, you can use a hydrometer, a simple tool specifically designed for this purpose. A hydrometer measures the specific gravity of the beer, which is the ratio of the density of the beer to the density of water. This specific gravity will change as the fermentation progresses, and by comparing it to a standard scale, you can determine the ABV. Typically, the specific gravity of water is 1.000, and as fermentation occurs, the specific gravity of the beer will decrease, indicating the presence of alcohol.

The beauty of using ABV as a measurement is its direct correlation with the fermentation process. As the yeast continues to ferment, the ABV will steadily rise until it stabilizes. This stabilization indicates that the yeast has consumed all available sugars and the fermentation process is complete. At this point, the beer has reached its maximum alcohol content, and any further fermentation would result in a loss of flavor and quality.

By regularly monitoring the ABV during the brewing process, you can ensure that your beer is fermented to perfection. This method provides a precise and scientific approach to brewing, allowing you to create beers with consistent and desired alcohol levels. It's a valuable technique for both homebrewers and professional brewers, offering a clear understanding of the fermentation process and the art of crafting beers with the right balance of flavor and alcohol strength.

Traveler's Dilemma: Can You Safely Pack Beer in Checked Luggage?

You may want to see also

Sulfur Compounds: Disappearance of sulfur compounds indicates fermentation's end

The disappearance of sulfur compounds is a reliable indicator that fermentation has concluded, and it's a crucial sign for brewers to monitor. Sulfur compounds, such as hydrogen sulfide (H2S) and mercaptans, are naturally occurring byproducts of the fermentation process, particularly in ale brewing. These compounds contribute to the unique flavors and aromas associated with certain beer styles, like wheat beers and some pale ales. However, their presence can also indicate an ongoing fermentation process.

As yeast consumes sugars and converts them into alcohol and carbon dioxide, it also produces these sulfur compounds as waste. The concentration of these compounds in the wort (the sugary liquid before fermentation) is initially high, but as fermentation progresses, the yeast's activity decreases, and the production of sulfur compounds slows down. This is a natural part of the fermentation cycle.

The key to determining when fermentation has ended is to observe the sulfur compound levels. Here's how:

- Sulfur Compound Detection: You can use various methods to detect sulfur compounds. One simple way is to smell the beer; sulfur compounds often have a distinct "skunky" or "rotten egg" odor. However, this method may not be as precise, especially in the early stages of fermentation. More accurate techniques include using specialized kits or instruments that can measure the concentration of these compounds.

- Monitoring Over Time: Take regular samples of the beer during the fermentation process. Record the sulfur compound levels at different stages. As fermentation progresses, you should notice a gradual decrease in these compound concentrations. When the levels become negligible or undetectable, it's a strong indication that fermentation has stopped.

- Visual and Sensory Changes: Along with sulfur compound disappearance, you may also observe other changes. The beer's appearance might become clearer, and the yeast should settle at the bottom of the fermenter. Additionally, the beer's flavor and aroma should become more stable, with no significant off-flavors or aromas.

It's important to note that the disappearance of sulfur compounds is just one of several signs that fermentation is complete. Other indicators include a stable alcohol content, a clear and stable beer, and the yeast's activity should be minimal or non-existent. By monitoring sulfur compounds, brewers can make informed decisions about when to bottle or package their beer, ensuring it is at its best in terms of flavor and quality.

The Secret to Modelo's Refreshing Twist: Lime's Role

You may want to see also

Frequently asked questions

There are several methods to check if fermentation is complete. One common technique is to use a hydrometer, which measures the specific gravity of the wort (the sugary liquid before fermentation). Take a reading before and after fermentation, and if the specific gravity has stabilized and is significantly lower, it indicates that fermentation is likely finished. Another way is to observe the beer's state; if there are no visible signs of fermentation, such as bubbling or a change in color, and the beer has reached a stable condition, it may be done.

Yes, monitoring the fermentation vessel can provide valuable insights. If the fermentation is active, you might notice a continuous rise in temperature, often referred to as 'fermentation temperature'. Additionally, look for any signs of yeast activity, such as a thick, cloudy appearance or a layer of sediment at the bottom of the fermenter. When fermentation slows down and stabilizes, these signs will diminish.

While a timer can help you keep track of time, it's not a reliable method to determine the end of fermentation. Fermentation duration varies depending on the style of beer, yeast type, and starting gravity. However, you can set a timer for a typical fermentation period and then use other methods, like specific gravity or visual cues, to confirm when it's complete. It's essential to monitor the process regularly to catch any signs of prolonged or stuck fermentation.