Testing beer during the fermentation process is crucial for ensuring the desired flavor, aroma, and alcohol content. This guide will explore various methods and tools to evaluate the progress and quality of your beer while it's still in the fermenter. From measuring specific gravity and alcohol by volume (ABV) to using sensory analysis and visual cues, you'll learn how to make informed decisions about your brewing process and achieve the perfect beer.

What You'll Learn

- Visual Inspection: Check for cloudiness, color changes, and sediment formation

- Smell and Aroma: Assess for off-odors and desired yeast aromas

- Taste and Mouthfeel: Evaluate bitterness, sweetness, and carbonation

- Specific Gravity: Measure to determine fermentation progress

- Alcohol Content: Use a hydrometer to measure final ABV

Visual Inspection: Check for cloudiness, color changes, and sediment formation

When testing beer that is still in the fermenter, visual inspection is a crucial step to assess the fermentation process and the overall health of your brew. Here's a detailed guide on how to perform this inspection:

Cloudiness: One of the primary visual cues is the clarity of the beer. Take a moment to observe the liquid in the fermenter. Cloudy or hazy beer indicates that the yeast is actively fermenting sugars, which is a good sign. This cloudiness is often caused by the yeast releasing carbon dioxide and alcohol, as well as the breakdown of sugars. However, if the beer becomes excessively cloudy, it might suggest a problem, such as a high yeast concentration or an imbalance in the fermentation process. In such cases, you may need to adjust the yeast or consider adding a clarifying agent to improve the beer's clarity.

Color Changes: Monitoring color variations is essential to understanding the fermentation dynamics. As the yeast consumes sugars, the beer's color may undergo subtle changes. Initially, the beer might appear slightly darker due to the presence of unfermented sugars and malt extract. Over time, as fermentation progresses, the color should gradually lighten. If you notice a significant color change or a rapid darkening, it could indicate an issue with the yeast or a potential infection. Keep an eye on these color shifts to ensure the beer is fermenting as expected.

Sediment Formation: Sedimentation is a natural part of the fermentation process, especially in yeast-fermented beers. As the yeast works, it may produce solid particles, including dead yeast cells and other fermentation byproducts. These particles can settle at the bottom of the fermenter, creating a layer of sediment. Regularly inspect the fermenter to check for sediment formation. If you notice a thick layer of sediment, it's a positive sign that the yeast is actively working. However, if the sediment is excessive or if it doesn't settle, it might indicate a need for yeast replenishment or a potential issue with the fermentation temperature.

During the visual inspection, it's essential to compare the beer's appearance with previous samples or known good batches. This comparison will help you identify any deviations from the expected fermentation behavior. Remember, each beer batch may have unique characteristics, so understanding the specific trends for your particular brew is key to successful fermentation testing.

Unveiling the Mystery: Does Beer Ferment in the Dark?

You may want to see also

Smell and Aroma: Assess for off-odors and desired yeast aromas

When testing beer in the fermenter, the sense of smell is an invaluable tool for assessing the health and quality of the brew. The aroma profile can provide insights into the fermentation process and the presence of any off-odors or desired yeast aromas. Here's a detailed guide on how to utilize your sense of smell for this purpose:

Identify Off-Odors: The first step is to recognize any unpleasant or unexpected smells. Off-odors can indicate issues with the fermentation process or the presence of bacteria. Common off-odors to look out for include sulfurous notes (like rotten eggs), acetaldehyde (a sharp, fruity smell), and ethyl acetate (a nail polish remover-like odor). These aromas can be detrimental to the beer's flavor and overall quality. If you detect any of these, it's crucial to investigate further to identify the cause and take corrective action.

Evaluate Yeast Aromas: Yeast plays a significant role in the fermentation process, and its activity can be assessed through aroma. Different yeast strains produce distinct aromas, which can contribute to the beer's character. For example, some yeasts may impart fruity notes, such as banana or apple, while others might add spicy or clove-like aromas. Desired yeast aromas can enhance the beer's complexity and uniqueness. Take note of any pleasant, yeast-derived smells, as these indicate a healthy fermentation and the yeast's active contribution to the beer's flavor development.

Sniff and Compare: As you smell the beer, compare the aromas to known standards or reference beers. This comparison can help you identify any deviations from the expected profile. For instance, if you're brewing a Belgian ale, you should be able to detect the characteristic fruity esters produced by the yeast. If the beer lacks these aromas or has an off-smell, it may indicate a problem with the yeast or fermentation process.

Monitor Fermentation Progress: The smell of the beer can also provide clues about the fermentation's progress. As fermentation progresses, the aroma may change. Initially, you might detect a neutral or slightly sweet smell, but as the yeast becomes more active, the aroma can evolve. Keep a record of these changes to track the fermentation's advancement and ensure it aligns with your expectations.

Practice and Familiarization: Developing your olfactory skills takes practice. Spend time with different beer styles and learn to distinguish between various aromas. Familiarize yourself with the typical yeast-derived aromas for different beer styles, as this knowledge will aid in making accurate assessments during the brewing process.

Crafting a Community: A Guide to Nonprofit Beer Garden Success

You may want to see also

Taste and Mouthfeel: Evaluate bitterness, sweetness, and carbonation

When testing beer in the fermenter, evaluating taste and mouthfeel is crucial to ensure the beer's quality and character. Here's a detailed guide on how to assess these aspects:

Bitterness: Bitterness is a key flavor component in beer, often derived from hops. To evaluate bitterness, take a small sip of the beer and let it coat your tongue. Identify the presence of bitter notes, which can range from subtle to intense. Consider the duration of the bitterness on your palate. Is it a quick burst or a lingering sensation? Take note of the specific hop varieties used in the recipe, as different hops contribute distinct bitterness profiles. For example, Citra hops are known for their tropical fruit-like bitterness, while Cascade hops offer a more piney and resinous character.

Sweetness: Sweetness in beer can come from various sources, including malt sugars, honey, or other sweeteners. Look for the presence of malt-derived sweetness, which might be balanced or dominant, depending on the beer style. Sweetness can range from subtle to prominent, and it often contributes to the overall drinkability of the beer. For instance, a well-balanced amber ale might showcase a harmonious blend of malt sweetness and hop bitterness.

Carbonation: Carbonation is a critical aspect of beer, impacting both taste and mouthfeel. It refers to the presence of dissolved carbon dioxide in the beer. To assess carbonation, take a sip and pay attention to the sensation on your tongue and palate. Carbonated beer should feel lively and refreshing, with a crisp, tingling sensation. The level of carbonation can vary, from highly effervescent to gently fizzy. Note that the carbonation level is often influenced by the fermentation process and the type of yeast used.

During your evaluation, it's essential to consider the beer's overall balance. A well-crafted beer should exhibit a harmonious interplay of bitterness, sweetness, and carbonation, creating a pleasing and memorable drinking experience. Take notes on your observations, as this will help you refine the brewing process and consistently produce high-quality beer.

Mastering Fermentation: Tips for Raising Beer Bucket Temperatures

You may want to see also

Specific Gravity: Measure to determine fermentation progress

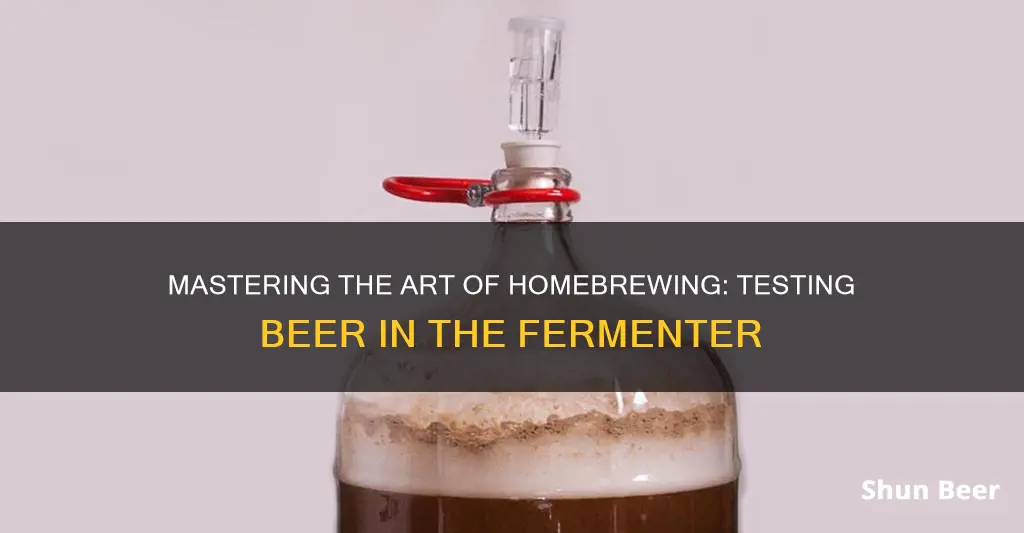

Specific gravity is a fundamental measurement in brewing, offering a clear indication of the fermentation process's progress. It is a simple yet powerful tool that every homebrewer should be familiar with. This measurement provides insight into the concentration of sugars in the beer, which directly correlates to the level of fermentation activity.

The specific gravity of a beer is determined by comparing the weight of the liquid to the weight of an equal volume of water. This ratio is expressed as a decimal or a percentage. Initially, when you brew your beer, it has a higher specific gravity due to the presence of sugars from the malt. As fermentation begins, yeast consumes these sugars, gradually lowering the specific gravity.

To measure specific gravity, you'll need a hydrometer, a specialized instrument designed for this purpose. It is typically a glass tube with a weighted end, allowing it to float in the beer. The hydrometer measures the beer's density, and by comparing this value to a standard scale, you can determine the specific gravity. It's important to calibrate the hydrometer before each use to ensure accurate readings.

The ideal specific gravity for a fully fermented beer varies depending on the style. For example, an American pale ale might aim for a final specific gravity of around 1.010, while a wheat beer could target a slightly higher value of 1.040. Monitoring the specific gravity during fermentation helps you understand when the process is nearing completion. As the yeast exhausts the available sugars, the specific gravity will stabilize, indicating that fermentation is complete.

Additionally, specific gravity measurements can help identify potential issues. If the specific gravity remains consistently high, it may suggest that the yeast is not effectively fermenting the sugars, indicating a problem that needs to be addressed. Conversely, a rapid and significant drop in specific gravity could be a sign of an over-fermented beer, where the yeast has consumed too much sugar, leading to an unbalanced flavor profile. Thus, monitoring specific gravity is a critical aspect of brewing, ensuring the beer's quality and character.

Unveiling the Chemistry of Beer: Exploring Added Ingredients

You may want to see also

Alcohol Content: Use a hydrometer to measure final ABV

To accurately determine the alcohol content of your beer while it's still in the fermenter, using a hydrometer is a reliable method. This tool measures the specific gravity of the liquid, which is then used to calculate the alcohol by volume (ABV). Here's a step-by-step guide on how to do this:

First, ensure you have a hydrometer suitable for the specific gravity range of beer. Different hydrometers are calibrated for various types of beverages, so choose one designed for beer. It should have a scale that measures specific gravity, typically ranging from 1.000 to 1.120 for beer.

Next, you'll need to take a sample of the beer from the fermenter. Sanitize your equipment to avoid any contamination. Carefully pour a small sample into a hydrometer jar or a clean container. The sample should be representative of the beer's current state.

Now, gently swirl the sample to ensure it's well-mixed, and then submerge the hydrometer into the beer. Read the specific gravity value where the hydrometer's neck intersects the liquid. This measurement represents the beer's current specific gravity.

Using the specific gravity reading, you can calculate the ABV. The formula is: ABV = (1 - (specific gravity / 1.000)) * 100. For example, if your specific gravity is 1.050, the calculation would be: ABV = (1 - (1.050 / 1.000)) * 100, which equals approximately 5%.

It's important to note that this measurement provides an estimate of the beer's final alcohol content, assuming the fermentation process is complete. If the beer is still actively fermenting, the specific gravity will continue to change, and you may need to take multiple samples over time to get an accurate reading of the final ABV.

Fermenting Beer: Optimal Storage Solutions for Your Brew

You may want to see also

Frequently asked questions

One of the most common methods to check fermentation is by using a hydrometer. Take a sample of the beer from the fermenter and measure its specific gravity. If the reading is stable and close to 1.010 (or 1.040 for higher-gravity beers), it indicates that fermentation is complete. A steady reading over several days suggests the beer is fully fermented.

Active fermentation can be identified by a few key indicators. Firstly, the beer's specific gravity should be decreasing as sugars are consumed by yeast. You might also notice a continuous rise in alcohol by volume (ABV) and a persistent carbonation level. Additionally, a bubbling or frothing appearance in the fermenter is a clear sign of active yeast activity.

Yes, visual observations can provide valuable insights. During fermentation, you should see a healthy, active yeast colony forming on the surface of the beer, often referred to as a 'yeast cake' or 'trub'. This indicates that the yeast is actively working. Additionally, look out for any signs of contamination, such as an off-color or cloudy appearance, which could suggest an issue with the brewing process or ingredients.

Absolutely! A refractometer can be a useful tool for monitoring fermentation. It measures the beer's sugar concentration, which directly relates to the yeast's activity. As the yeast consumes sugars, the refractometer reading will decrease. Aim for a consistent reading over time, indicating complete fermentation. However, it's important to calibrate the refractometer regularly for accurate results.

Prolonged or stuck fermentation can be concerning. If you notice that the beer's specific gravity hasn't stabilized or is fluctuating, it might indicate an issue. Check for any signs of yeast starvation, such as a lack of yeast activity or a thin yeast layer. You may need to add more yeast or adjust the fermentation temperature to encourage the yeast to continue the process. Regular monitoring and adjustments are crucial to ensure a successful fermentation.