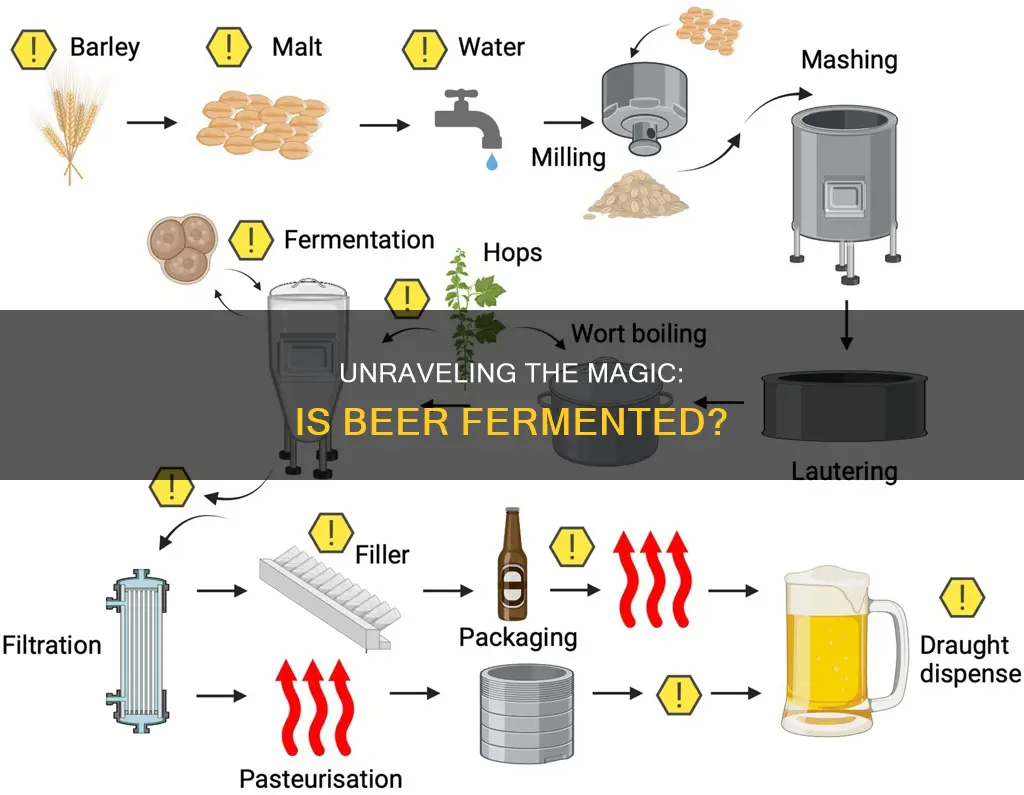

Beer is a beloved beverage enjoyed by many, but have you ever wondered what makes it so unique? The answer lies in its fermentation process. Beer is indeed a fermented beverage, a fascinating transformation that begins with the simple ingredients of water, grains, and hops. Through a delicate dance of science and art, yeast plays a pivotal role in breaking down sugars, resulting in the carbonation and distinct flavors we associate with beer. This process not only gives beer its characteristic fizz but also contributes to its diverse range of styles and flavors, making it a truly captivating drink.

What You'll Learn

- Yeast Fermentation: Yeast converts sugars into alcohol and carbon dioxide, a key process in beer fermentation

- Malting: Malting grains activates enzymes to break down starches, a crucial step before fermentation

- Brewing Techniques: Different brewing methods impact the fermentation process and beer flavor profiles

- Fermentation Time: Longer fermentation periods can enhance beer flavors and aromas

- Alcohol Content: Fermentation determines the alcohol by volume (ABV) in beer

Yeast Fermentation: Yeast converts sugars into alcohol and carbon dioxide, a key process in beer fermentation

Yeast fermentation is a fundamental process in the art of brewing beer, where yeast plays a pivotal role in transforming simple sugars into the complex beverage we know and love. This intricate process begins with the breakdown of carbohydrates, primarily malted grains, which are rich in sugars. Through a series of biochemical reactions, yeast acts as a catalyst, facilitating the conversion of these sugars into two primary products: alcohol and carbon dioxide. This transformation is a cornerstone of beer fermentation, setting the stage for the diverse flavors and aromas that define different beer styles.

The yeast's metabolic activities are a delicate balance of chemical reactions. In the presence of oxygen, yeast undergoes aerobic respiration, generating energy for its growth and reproduction. However, in the absence of oxygen, yeast enters anaerobic respiration, where it utilizes sugars without oxygen, producing alcohol and carbon dioxide as byproducts. This anaerobic process is the essence of beer fermentation, as it allows for the accumulation of alcohol and the formation of carbonation.

During beer fermentation, yeast populations can vary, leading to different fermentation profiles. Top-fermenting yeasts, such as those used in ale brewing, thrive near the surface and produce a more rapid fermentation with higher alcohol content. On the other hand, bottom-fermenting yeasts, commonly used in lager production, ferment at lower temperatures and produce a cleaner, crisper flavor with lower alcohol levels. This diversity in yeast strains contributes to the vast array of beer styles available today.

The yeast fermentation process is a delicate dance of science and art. Brewers carefully select yeast strains based on their desired beer style and flavor profile. For instance, Belgian yeasts are known for their fruity esters, while German yeasts produce a cleaner, crisper beer. The fermentation temperature also plays a crucial role, as warmer temperatures can enhance flavor development, while cooler temperatures may result in a more subtle, balanced beer.

In conclusion, yeast fermentation is the magical process that transforms sugars into the essence of beer. It is a complex interplay of yeast metabolism, sugar breakdown, and the careful craftsmanship of brewers. Through this fermentation, beer gains its characteristic alcohol content, carbonation, and unique sensory characteristics, making it a beloved beverage worldwide. Understanding yeast fermentation is key to appreciating the intricate art of brewing and the diverse world of beer.

The Mystery of Donny's Locker: Who Added the Beer?

You may want to see also

Malting: Malting grains activates enzymes to break down starches, a crucial step before fermentation

Malting is a fundamental process in the art of brewing, and it plays a pivotal role in transforming simple grains into the complex and flavorful beverage we know as beer. This ancient technique involves a series of precise steps that unlock the potential of grains, particularly barley, to create the basis of beer.

At its core, malting is the process of soaking and germinating grains, typically barley, to initiate the growth of enzymes. These enzymes are the key to unlocking the starches within the grain's structure. Starch, a complex carbohydrate, is the primary source of energy for the yeast during fermentation. However, starches are not directly fermentable by yeast. This is where malting comes into play, as it prepares the grains for the next stage of the brewing process.

When grains are malted, they are soaked in water and allowed to germinate. This germination process activates enzymes, such as amylase, which begin to break down the starches into simpler sugars. The most common starch found in barley is maltose, a two-sugar molecule that is highly fermentable. By breaking down the starches, the malted grains convert the complex carbohydrates into a form that yeast can utilize, making the subsequent fermentation process more efficient.

The duration and conditions of the malting process are carefully controlled to ensure optimal enzyme activity. Typically, malted grains are dried and roasted to different degrees, depending on the desired flavor and color profile of the beer. Lighter roasts preserve more of the malt's natural sweetness, while darker roasts contribute to the rich, caramelized flavors often associated with stouts and porters.

In summary, malting is a critical step in the brewing process, as it activates enzymes that break down starches in grains, converting them into fermentable sugars. This process is essential for the successful fermentation of beer, where yeast transforms these sugars into alcohol and carbon dioxide, creating the beloved beverage that has captivated palates for millennia.

Why You Should Never Chill Your Beer in a Yeti Cooler

You may want to see also

Brewing Techniques: Different brewing methods impact the fermentation process and beer flavor profiles

The brewing process is an intricate art that significantly influences the final beer's character and taste. One of the most crucial aspects of brewing is the fermentation stage, which is where the magic happens, transforming simple ingredients into a diverse range of beer styles. The fermentation process is primarily driven by yeast, which plays a pivotal role in breaking down sugars and creating alcohol and carbon dioxide. However, the brewing method employed can significantly impact the fermentation process and, consequently, the beer's flavor profile.

One of the most common brewing techniques is all-grain brewing, which involves mashing malted grains to extract sugars. This method produces a sweet liquid known as wort, which is then boiled and cooled before fermentation. During fermentation, ale yeasts convert the wort's sugars into alcohol and carbon dioxide, creating a refreshing, crisp beer. The type of yeast used and the fermentation temperature can greatly affect the beer's flavor. For instance, using a high-alcohol yeast strain can result in a more robust, fruity beer, while a cooler fermentation temperature might lead to a cleaner, crisper profile.

In contrast, extract brewing is a method that uses pre-made malt extract, bypassing the mashing process. This technique is often associated with homebrewing and offers convenience and speed. The wort is boiled directly, and then yeast is added for fermentation. While this method may not provide the same level of control over the fermentation process as all-grain brewing, it still allows for a wide range of beer styles. For example, using a lager yeast at a lower temperature can produce a clean, crisp lager, while a higher fermentation temperature might result in a more vibrant, fruity ale.

Another brewing technique that influences fermentation is the use of specialty grains and ingredients. Brewers often incorporate roasted malts, hops, and other additives to create unique flavor profiles. For instance, adding a small amount of roasted malt can provide a subtle coffee or chocolate note, while hops contribute bitterness and aromatic compounds. These ingredients can affect the yeast's activity, sometimes leading to a more complex fermentation process. For example, the presence of hops can inhibit yeast growth, requiring specific yeast strains that can handle these additional challenges.

Additionally, the brewing process can vary based on the desired beer style. For instance, the German-style lager brewing process involves a longer, cooler fermentation period, resulting in a clean, crisp beer. In contrast, English-style ales often use a higher gravity wort and a warmer fermentation temperature, leading to a more full-bodied, fruity beer. These variations in brewing methods and fermentation conditions showcase the art of brewing and how it directly influences the diverse world of beer flavors.

Unraveling the Mystery: Why Men Store Beer at the Bottom of the Fridge

You may want to see also

Fermentation Time: Longer fermentation periods can enhance beer flavors and aromas

Fermentation is a crucial process in the production of beer, and the duration of this process significantly impacts the final product's characteristics. Longer fermentation periods have been a subject of interest among brewers, as they can lead to more complex and nuanced flavors and aromas in the beer. This extended time allows for a deeper transformation of the sugars present in the wort, resulting in a more refined and sophisticated beverage.

During the fermentation process, yeast consumes the sugars in the wort and produces alcohol and carbon dioxide. As the fermentation progresses, the yeast's activity can be influenced by the time it has to work. Initially, the yeast is highly active, rapidly converting sugars, but as the fermentation period extends, the yeast's metabolism slows down. This change in yeast activity is a natural process and is essential for developing the beer's desired characteristics.

With more time, the yeast has the opportunity to produce a wider range of flavor compounds. For example, in ale brewing, longer fermentation can lead to the development of fruity esters, which contribute to the beer's aroma. These esters are produced when the yeast ferments certain sugars, resulting in a more fragrant and appealing beer. Similarly, in lager brewing, extended fermentation can enhance the maltiness and hoppiness of the beer, creating a more balanced and complex flavor profile.

The impact of fermentation time on beer quality is particularly notable in the creation of specialty beers. For instance, in the production of Belgian ales, a longer fermentation period is often employed to achieve the desired high alcohol content and rich, fruity flavors. Similarly, in the craft beer movement, brewers experiment with extended fermentation to create unique and distinctive beer styles, such as Belgian tripels and American wild ales.

In summary, longer fermentation periods play a vital role in the art of brewing, allowing for the development of intricate flavors and aromas. By providing the yeast with extended time, brewers can influence the beer's character, creating a more sophisticated and enjoyable drinking experience. This process is a delicate balance, as too short a fermentation time may result in a less developed beer, while an overly long period can lead to off-flavors. Thus, understanding and controlling fermentation time is essential for brewers to craft beers that meet the desired quality standards.

Pour the Perfect Draft: A Guide to Installing a Beer Tap at Home

You may want to see also

Alcohol Content: Fermentation determines the alcohol by volume (ABV) in beer

The alcohol content in beer is a result of the fermentation process, which is a crucial step in the brewing journey. This process involves yeast consuming sugars present in the wort (the sugary liquid extracted from malted grains) and converting them into alcohol and carbon dioxide. The more efficient the fermentation, the higher the alcohol by volume (ABV) in the final product.

During fermentation, the yeast acts as a catalyst, breaking down carbohydrates like maltose into simpler sugars, which are then fermented into ethanol (alcohol) and CO2. The type of yeast used and the brewing techniques employed significantly influence the alcohol level. For instance, ale yeasts typically produce a higher ABV compared to lager yeasts. Additionally, the duration of fermentation plays a role; longer fermentation periods often result in higher alcohol concentrations.

The alcohol content is measured as a percentage of the total volume of the beverage. For example, a beer with an ABV of 5% contains 5% alcohol by volume, meaning 5% of the liquid is pure alcohol. This measurement is essential for consumers to understand the strength of the beer they are drinking. Brewers carefully control the fermentation process to achieve the desired ABV, which can range from as low as 0.5% (in some light beers) to over 10% (in stronger craft beers).

Understanding the alcohol content is vital for both brewers and beer enthusiasts. Brewers need to manage fermentation to meet specific ABV targets, ensuring their beers appeal to the intended market. For consumers, knowing the ABV helps in making informed choices, especially when it comes to pairing beer with food or managing alcohol consumption.

In summary, fermentation is the key to determining the alcohol content in beer. The process, influenced by yeast types and brewing techniques, directly impacts the ABV, which is a critical aspect of the beer's character and appeal. This relationship between fermentation and alcohol content is a fascinating aspect of the art and science of brewing.

Exploding Engines: The Dangers of Pouring Beer in Your Gas Tank

You may want to see also

Frequently asked questions

Fermentation is a natural process where yeast converts sugars present in the beer's ingredients, typically malted grains, into alcohol and carbon dioxide. This process is crucial in the brewing process, as it not only produces the alcohol content but also contributes to the unique flavors and aromas that make beer a beloved beverage.

The fermentation process significantly influences the flavor profile of beer. Different yeast strains and fermentation techniques can result in various beer styles. For example, a top-fermenting yeast might produce a more robust, fruity flavor, while a bottom-fermenting yeast could yield a cleaner, crisper taste. This diversity in fermentation methods is what allows brewers to create an extensive range of beer varieties.

Yes, all beer is made through the fermentation process. However, the type of yeast and fermentation method can vary, leading to different beer styles. Some beers, like lagers, are fermented at lower temperatures, resulting in a slower fermentation process and a cleaner taste. In contrast, ales are typically fermented at higher temperatures, leading to faster fermentation and a more robust flavor.