When fermenting beer, contamination is a common concern for brewers, but not all forms of contamination are immediately visible. While some signs of contamination, such as off-flavors or cloudiness, may be apparent early on, other types of contaminants can remain hidden for a while. This can lead to unexpected results and potentially affect the beer's quality. Understanding the different types of contaminants and their sources is crucial for brewers to take preventive measures and ensure the fermentation process remains clean and controlled.

What You'll Learn

- Clarity and Cloudiness: Visible sediment or cloudiness may indicate yeast activity or bacterial contamination

- Color Changes: Alterations in beer color can signal contamination, especially from bacteria like Lactobacillus

- Off-Flavors: Contamination often results in unpleasant tastes like sulfur, vinegar, or cardboard

- Sediment Formation: Sediment at the bottom of the fermenter can be a sign of yeast or bacterial activity

- Visual Inspection: Regularly examine the beer for any unusual appearance, including haze, foam, or scum

Clarity and Cloudiness: Visible sediment or cloudiness may indicate yeast activity or bacterial contamination

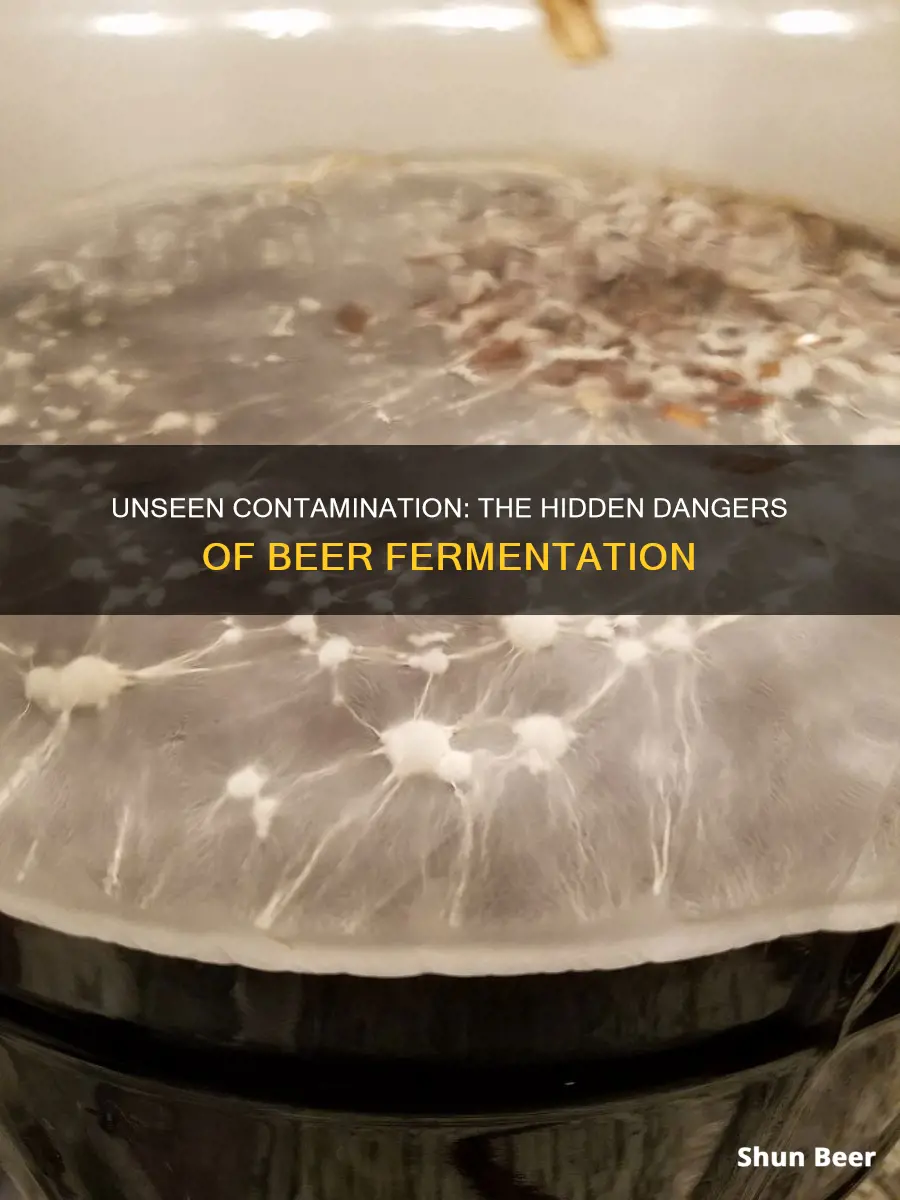

When it comes to the fermentation process of beer, clarity and cloudiness can provide valuable insights into the health and activity of the yeast and the potential presence of contaminants. While some level of cloudiness is normal and expected during fermentation, excessive cloudiness or the appearance of visible sediment can indicate underlying issues.

Visible sediment or cloudiness in the beer can be a sign of yeast activity. Yeast plays a crucial role in fermentation, converting sugars into alcohol and carbon dioxide. As yeast consumes the sugars, it may leave behind solid particles or sediment, which can be observed in the beer. This is particularly common in styles of beer that use high-temperature brewing methods, as the yeast may struggle to survive at higher temperatures, leading to a more rapid fermentation and the subsequent formation of sediment.

However, it's important to distinguish between yeast-induced cloudiness and bacterial contamination. Bacterial contamination can also result in cloudiness and sediment formation. Bacteria can enter the beer during the brewing process or through improper sanitation practices. When bacteria are present, they can produce proteins and other compounds that cause the beer to become cloudy and may even lead to off-flavors and aromas. Bacterial contamination often requires more aggressive measures to address, as it can be more challenging to eradicate once established.

To identify the cause of cloudiness, brewers can perform simple visual inspections. If the cloudiness is uniform throughout the beer and appears as a fine suspension, it is likely due to yeast activity. Yeast-induced cloudiness typically clears up as the fermentation progresses and the yeast settles. On the other hand, if the cloudiness is more pronounced and accompanied by a distinct sediment layer, it may indicate bacterial contamination. In such cases, further investigation and appropriate corrective actions are necessary to ensure the quality and safety of the beer.

Understanding the relationship between clarity, cloudiness, and sediment formation is essential for brewers to maintain the desired characteristics of their beer. By recognizing the signs of yeast activity and bacterial contamination, brewers can take appropriate measures to manage fermentation, improve beer quality, and prevent potential off-flavors or health concerns. Regular monitoring and proper sanitation practices are key to achieving consistent and desirable beer fermentation outcomes.

The Ultimate Guide to Toppings for Beer Bread: A Cheesy Delight

You may want to see also

Color Changes: Alterations in beer color can signal contamination, especially from bacteria like Lactobacillus

When it comes to brewing beer, contamination is a serious concern that can significantly impact the final product's quality and taste. While some forms of contamination may not always be immediately visible, certain signs, such as color changes, can indicate the presence of unwanted microorganisms, particularly bacteria like Lactobacillus. This bacterium is particularly notorious for its ability to cause a range of issues in beer fermentation.

Lactobacillus bacteria are commonly associated with souring and can produce lactic acid, which is responsible for the characteristic sourness in certain beer styles, such as lambics and some Belgian ales. However, the presence of Lactobacillus can also lead to more undesirable outcomes, including color changes in the beer. As the bacteria metabolize sugars and produce organic acids, they can alter the beer's color, making it appear darker or more turbid. This is because the bacteria can break down certain pigments and compounds in the malt, leading to a change in the beer's visual appearance.

The color alteration caused by Lactobacillus contamination can vary in intensity and may not always be uniform throughout the beer. In some cases, the contamination might result in a hazy or cloudy appearance, especially if the bacteria produce enzymes that break down the beer's proteins or polysaccharides. This can lead to a loss of clarity and a less appealing visual presentation. Additionally, the color change might be more pronounced in certain beer styles, such as pale ales or lagers, where the natural color is lighter and more susceptible to alteration.

Brewers should be vigilant and monitor their beer's color during fermentation, especially when using ingredients or techniques that might increase the risk of contamination. If a color change is observed, it could indicate an active bacterial infection, and immediate action should be taken to prevent further spoilage. This might include adjusting the brewing process, such as adding preservatives or using specific yeast strains known for their resistance to certain bacteria.

In summary, while not all beer contamination is immediately visible, color changes can serve as a critical indicator of bacterial infection, particularly from Lactobacillus. Brewers must remain attentive to these visual cues and take appropriate measures to ensure the production of high-quality, contaminant-free beer. Regular monitoring and a thorough understanding of the brewing process can help minimize the risks associated with contamination and maintain the integrity of the final product.

Mastering Beer's Balance: Stopping Yeast Fermentation

You may want to see also

Off-Flavors: Contamination often results in unpleasant tastes like sulfur, vinegar, or cardboard

Contamination during the brewing process can lead to a range of off-flavors that may be unpleasant to the palate. One of the most common off-flavors associated with contamination is the presence of sulfur compounds. These compounds can give the beer a "skunky" or "green" aroma and a slightly sour or metallic taste. The sulfur compounds are often produced by certain yeast strains or bacteria that can be present in the brewing environment. While some brewers may intentionally add sulfur-producing ingredients to create unique flavors, such as in the case of Belgian witbiers, unintended sulfur contamination can be detrimental to the beer's quality.

Another off-flavor often linked to contamination is the vinegar-like taste, which can be a result of various factors. One common cause is the presence of acetic acid bacteria, which can thrive in conditions where the beer's pH is not properly controlled. These bacteria can convert sugars into acetic acid, leading to a sharp, acidic, and unappealing flavor profile. This type of contamination is particularly problematic in homebrewing scenarios where equipment and sanitation may not be as precise as in a professional brewery.

Cardboard is a unique off-flavor that can be attributed to contamination as well. This flavor is often described as dry, paper-like, and slightly bitter. It is typically caused by the presence of mycotoxins, which are toxic compounds produced by certain fungi. Mycotoxins can contaminate the beer during the brewing process, especially if the environment is not properly sanitized. Cardboard flavors can be off-putting and are often a result of poor sanitation practices, such as using contaminated water or equipment.

Understanding these off-flavors and their causes is crucial for brewers to maintain high-quality beer production. Contamination can occur at any stage of the brewing process, from the ingredients used to the final fermentation stage. By recognizing the signs and implementing proper sanitation techniques, brewers can minimize the risk of off-flavors and ensure that their beer tastes as intended. Regular cleaning and sanitization of equipment, using high-quality ingredients, and monitoring the brewing environment are essential practices to prevent contamination and maintain the desired flavor profile.

Mastering the Art of Hex Beer Nut: A Comprehensive Guide

You may want to see also

Sediment Formation: Sediment at the bottom of the fermenter can be a sign of yeast or bacterial activity

Sediment formation is a common occurrence during the brewing process and can be an indicator of both yeast and bacterial activity. When yeast ferments the sugars in the wort, it produces alcohol and carbon dioxide, and this process can leave behind solid particles, which we refer to as sediment. This sediment is essentially the yeast cells, dead yeast cells, and other solid matter that has not been fully converted into alcohol. It is a natural part of the fermentation process and is often visible at the bottom of the fermenter.

The appearance of sediment can vary depending on the style of beer being brewed and the specific yeast strain used. In some cases, a small amount of sediment is expected and even desirable, as it contributes to the complexity and flavor of the beer. For example, in the production of certain wheat beers and Belgian ales, a higher level of sediment is often present, and this is considered a characteristic feature. However, excessive sediment can indicate a problem, such as an over-fermentation or a lack of proper yeast nutrition.

Bacterial activity can also lead to sediment formation. Bacteria can contaminate the wort during the brewing process, and their presence can result in the production of various compounds, including organic acids and esters. These bacterial by-products can sometimes settle at the bottom of the fermenter, creating visible sediment. While some bacterial activity is beneficial and contributes to the unique flavors of certain beer styles, excessive bacterial growth can lead to off-flavors and aromas, making the beer undrinkable.

It's important to note that the visibility of sediment is not always an indication of contamination. As mentioned earlier, sediment is a natural part of the fermentation process, and its presence can be expected and even desirable in certain beer styles. However, if the sediment is accompanied by other signs of contamination, such as an off-odor or taste, or if it is excessive and not typical for the style of beer being brewed, then it may indicate a problem that requires attention.

To manage sediment formation, brewers can employ various techniques. One common practice is to rack the beer, which involves transferring the beer from the fermenter to a secondary vessel, leaving the sediment behind. This process can be done manually or using specialized equipment. Additionally, some brewers may choose to filter the beer to remove any unwanted sediment before packaging. Proper yeast management, including adequate nutrition and monitoring of fermentation temperature, can also help control sediment formation and ensure a clean and flavorful beer.

Unraveling the Mystery: Why Beer Labels Matter

You may want to see also

Visual Inspection: Regularly examine the beer for any unusual appearance, including haze, foam, or scum

Visual inspection is a crucial step in monitoring the fermentation process and ensuring the quality of your beer. It allows you to identify any potential issues or signs of contamination that may not be immediately apparent through other methods. Here's a detailed guide on how to perform regular visual inspections:

When examining the beer, look for any deviations from its expected appearance. Freshly brewed beer typically has a clear, bright color, ranging from pale golden to deep amber, depending on the style. If you notice any cloudiness or haziness, it could indicate the presence of yeast or other particles that have not properly settled. This is a common issue and usually resolves as the beer ages, but it's essential to monitor this during fermentation.

Pay close attention to the foam and scum formation. Healthy fermentation should produce a steady, consistent foam head. If you observe excessive foam or a thick, sticky layer of scum on the surface, it might suggest an over-fermentation or the presence of wild yeast strains. These visual cues can help you take corrective action before the beer's flavor is compromised.

Regularly checking the beer's appearance throughout the fermentation process is vital. Start by observing the initial batch immediately after bottling or transferring to the fermenter. Look for any signs of sedimentation, which may indicate poor yeast health or an imbalance in the fermentation environment. Over time, you'll develop an eye for subtle changes, allowing you to catch potential issues early on.

Additionally, keep an eye out for any unusual colors or odors. While some variation in color is expected due to ingredients and brewing techniques, a drastic change or an odd hue could signal contamination. Similarly, if the beer develops an off-putting smell, such as a strong sulfur or metallic odor, it may indicate a problem with the yeast or the fermentation process.

By regularly inspecting the beer's visual characteristics, you can quickly identify and address any fermentation issues. This practice ensures that your beer maintains its desired quality and flavor profile, providing a more enjoyable drinking experience. Remember, visual inspection is a powerful tool in the art of brewing, helping you create consistently excellent beers.

Lime Oil in Beer: A Refreshing Twist or a Disaster?

You may want to see also

Frequently asked questions

No, beer contamination is not always visible. Contamination can occur at any stage of brewing, and it often happens when microorganisms, such as bacteria or wild yeast, come into contact with the beer. These microorganisms can be present in the water, air, or even on the equipment, and they can cause off-flavors, aromas, and textures in the final product.

Preventing contamination is crucial to maintaining the quality of your beer. Here are some key practices:

- Sanitize all brewing equipment thoroughly before use.

- Use filtered or boiled water to minimize the presence of unwanted microorganisms.

- Control the temperature and time of fermentation to create an environment that discourages contamination.

- Consider using a yeast starter or a yeast-start fermentation technique to ensure a healthy yeast culture.

Contaminated beer may exhibit various undesirable characteristics. These signs can include:

- Unpleasant odors: Contaminants might produce off-putting smells, such as sulfur, vinegar, or cardboard-like aromas.

- Flavor defects: Contaminated beer may have a metallic, bitter, or sour taste, or it might lack the expected flavor profile.

- Cloudiness or sediment: Contamination can cause the beer to appear cloudy or leave sediment at the bottom of the glass.

- Rapid fermentation: An unexpected increase in fermentation speed could indicate the presence of unwanted yeast or bacteria.

Saving a contaminated beer is challenging, but it's not impossible. If you notice any signs of contamination early on, you might be able to salvage the batch by:

- Racking the beer to a clean vessel, separating it from the yeast and sediment.

- Using a yeast clarifier or fining agent to remove any remaining particles.

- Starting a new batch with fresh ingredients and sanitizing the equipment again.

- Experimenting with different yeast strains or brewing techniques to identify and address the source of contamination.