Beer is a beloved beverage with a rich history and a fascinating production process. At its core, beer is crafted through a unique blend of fermentation and distillation techniques. While many associate beer with the fermentation of grains and hops, the distillation process is often overlooked. This introduction aims to explore the relationship between fermentation and distillation in the creation of beer, shedding light on the intricate processes that transform simple ingredients into the diverse array of beers we enjoy today.

What You'll Learn

- Fermentation Process: Yeast converts sugars into alcohol and carbon dioxide

- Distillation Techniques: Alcohol is separated and concentrated through distillation

- Brewing Ingredients: Malts, hops, and water are key to fermentation

- Alcohol Content: Distilled beer can have higher alcohol by volume

- Flavor Profiles: Fermentation and distillation create unique flavor characteristics

Fermentation Process: Yeast converts sugars into alcohol and carbon dioxide

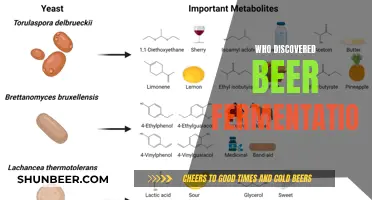

The fermentation process is a crucial step in the production of beer, and it is primarily driven by the magic of yeast. This process is an ancient technique that has been used for millennia to transform simple sugars into the beloved beverage we know as beer. At its core, fermentation is a biological conversion process where yeast, a microscopic organism, plays a pivotal role.

In the context of brewing, yeast is introduced to the sugary liquid, known as the wort, extracted from malted grains. These grains, typically barley, are first malted, a process that activates enzymes, allowing the breakdown of complex sugars into simpler ones. The wort is then separated from the spent grain, creating a sugary liquid ready for fermentation. When yeast is added to this environment, it initiates a remarkable transformation.

The yeast cells metabolize the sugars present in the wort, primarily maltose, through a series of biochemical reactions. This process is called anaerobic respiration, as it occurs in the absence of oxygen. During fermentation, yeast breaks down maltose into two simpler sugars: glucose and fructose. The yeast then utilizes these sugars through a process called glycolysis, producing a small amount of ATP (adenosine triphosphate), the energy currency of cells. This is just the beginning of the magic.

As the glycolysis process continues, the yeast cells then convert the glucose into ethanol (alcohol) and carbon dioxide (CO2) through a series of reactions. This is the key to the beer-making process. The ethanol is what gives beer its characteristic alcoholic content, while the CO2 is responsible for the carbonation, a feature many beer enthusiasts cherish. The yeast's role is so vital that different strains are used to create various beer styles, each with its unique flavor and character.

The fermentation process is not just about the conversion of sugars but also about the control of temperature and time. Brewers carefully manage these factors to influence the yeast's activity and the resulting beer's flavor profile. Warmer temperatures can lead to faster fermentation, while cooler temperatures may slow it down, allowing for more complex flavor development. This intricate dance between yeast, sugars, and environmental conditions is what makes the fermentation process both a science and an art.

Exploring the Risks: What Happens When You Put Beer in Your Rear?

You may want to see also

Distillation Techniques: Alcohol is separated and concentrated through distillation

Distillation is a process that involves the separation and concentration of alcohol through the use of heat and evaporation. This technique is commonly used in the production of spirits and other alcoholic beverages, and it plays a crucial role in the transformation of beer into various distilled drinks. When it comes to the question of whether beer is distilled or fermented, it's important to understand the difference between these two processes. Fermentation is a biological process where yeast converts sugars into alcohol and carbon dioxide, while distillation is a physical process that separates and purifies alcohol.

In the context of beer, the initial fermentation process is what gives it its alcohol content. Yeast consumes the sugars present in the malted grains and produces alcohol and carbon dioxide as byproducts. However, this alcohol is not yet in a concentrated or pure form. This is where distillation comes into play. Distillation is an art and science that involves the following steps:

- Heating and Evaporation: The first step in distillation is to heat the beer to a specific temperature, typically around 80-90°C (176-194°F). This heat causes the alcohol in the beer to evaporate, separating it from the water and other components. The vapor containing the alcohol is then collected.

- Condensation: The vapor is then cooled and condensed back into a liquid state. This is achieved by passing the vapor through a cooling system, often a coil or a series of plates, which can be cooled by water or air. As the vapor cools, it loses its heat energy and transforms back into a liquid, now enriched with a higher alcohol concentration.

- Collection and Purification: The distilled liquid, often referred to as a distillate, is then collected and further purified. This may involve additional filtration or treatment to remove any remaining impurities. The distillate is then ready for further use or consumption. Distillation allows for the creation of spirits with a higher alcohol content and a more concentrated flavor profile compared to the original beer.

Distillation techniques can vary depending on the desired outcome and the type of spirit being produced. For example, in the production of whiskey, distillation is often done in a continuous still, where the beer is continuously fed into the system, and the distillate is collected as it rises. In contrast, rum and vodka production may involve batch distillation, where the beer is distilled in batches, and the distillate is collected and then redistilled to achieve the desired purity.

Understanding the distillation process is essential for appreciating the transformation of beer into various spirits. It showcases how a simple fermentation process can be enhanced through distillation to create a diverse range of alcoholic beverages, each with its unique characteristics and flavors.

Beer Traps for Slugs: The Optimal Frequency

You may want to see also

Brewing Ingredients: Malts, hops, and water are key to fermentation

The process of brewing beer is an art that has been perfected over centuries, and at its core are three essential ingredients: malts, hops, and water. These components are the foundation of fermentation, the magical transformation that turns simple grains into the beloved beverage we know as beer.

Malts, derived from grains like barley, wheat, and rye, undergo a crucial process called malting. This involves soaking the grains in water and allowing them to germinate, which activates enzymes that break down complex starches into simpler sugars. After germination, the grains are dried and crushed, releasing the enzymes and preparing the starches for fermentation. Malts provide the essential sugars, such as maltose, which serve as the primary energy source for the yeast during the fermentation process. The type and quality of malt used significantly influence the flavor, color, and overall character of the beer.

Hops, another vital ingredient, contribute more than just bitterness to the brew. They are packed with aromatic compounds and essential oils, which add unique flavors and aromas to the beer. Hops also act as a natural preservative, helping to stabilize the beer and prevent spoilage. During brewing, hops are added at different stages of the process, including the boil, to extract their bittering and aromatic qualities. The amount and variety of hops used can create a wide range of beer styles, from crisp and refreshing lagers to rich, hop-forward IPAs.

Water, often overlooked, is the backbone of brewing. The mineral content and pH level of water can significantly impact the flavor and quality of the beer. Brewers carefully select water sources and may even treat the water to adjust its mineral composition. Soft water, for example, tends to produce more delicate flavors, while hard water can contribute to a fuller body and higher foam retention. The water's mineral content, such as calcium and sulfate, can influence the beer's mouthfeel, clarity, and overall character.

The combination of these three ingredients—malt, hops, and water—is carefully measured and mixed in a precise process known as mashing. This step involves heating the malted grains in hot water to convert the starches into sugars, creating a sweet liquid called wort. The wort is then separated from the spent grain, which is discarded or used for animal feed. This wort is now ready for the fermentation stage, where yeast plays a pivotal role in transforming the sugars into alcohol and carbon dioxide, resulting in the magical creation of beer.

Egg in Beer: Uncovering the Surprising Science Behind This Ancient Practice

You may want to see also

Alcohol Content: Distilled beer can have higher alcohol by volume

The process of brewing beer involves fermentation, where yeast converts sugars derived from grains into alcohol and carbon dioxide. This is why beer is typically classified as an alcoholic beverage with an alcohol by volume (ABV) ranging from 2% to 8%, depending on the style and brewing techniques. However, when we consider the concept of distilled beer, the alcohol content can be significantly higher.

Distillation is a process that separates and purifies substances, including alcohol, by using heat and pressure. In the context of beer, distillation can be applied to the fermented liquid to increase its alcohol concentration. This process involves heating the beer to a specific temperature, causing the alcohol to evaporate and then condense back into the liquid, resulting in a higher ABV. Distilled beer can have an alcohol content ranging from 40% to 95% or even higher, making it much stronger than traditional beer.

The higher alcohol content in distilled beer is achieved through the removal of water and other volatile compounds, leaving behind a more concentrated and potent beverage. This process can be done through various distillation methods, such as pot still distillation or column distillation, each producing different results in terms of flavor and alcohol strength. Distilled beer often has a smoother and more intense flavor profile compared to regular beer, as the distillation process can enhance and preserve the desired compounds while removing others.

It's important to note that distilled beer is not a common or traditional beverage. It is more of a specialty or experimental drink, often created for specific events or by craft breweries experimenting with unique production methods. The high alcohol content can make distilled beer a strong and potent drink, requiring careful consumption and appreciation.

In summary, the alcohol content of beer can be significantly increased through distillation, resulting in distilled beer with an ABV ranging from 40% to 95% or higher. This process involves separating and purifying the fermented liquid, creating a stronger and more concentrated beverage with a unique flavor profile. While not a common drink, distilled beer offers an intriguing and intense drinking experience for those who appreciate the art of brewing and experimentation.

Mastering Fermentation: Tips for Raising Beer Bucket Temperatures

You may want to see also

Flavor Profiles: Fermentation and distillation create unique flavor characteristics

Fermentation and distillation are two distinct processes that significantly impact the flavor profiles of various beverages, particularly beer. While both methods are essential in the brewing and distilling industries, they result in unique taste characteristics that set them apart. Understanding these processes is key to appreciating the diverse flavors found in different alcoholic drinks.

Fermentation: A Natural Transformation

Fermentation is a natural process where yeast converts sugars present in the base ingredients, typically malted grains, into alcohol and carbon dioxide. This process is crucial in brewing beer and contributes to its distinct flavor profiles. During fermentation, various compounds are produced, including esters, which give off a fruity aroma, and higher alcohols, which can result in a spicy or warm sensation. For example, the fermentation of malted barley in beer production yields a range of flavors, from the sweet and bready notes of maltose to the slightly bitter and hoppy flavors that contribute to the beer's overall character. The yeast strains used also play a vital role, as different yeasts can produce unique flavor compounds, such as the fruity esters associated with Belgian beers or the clean, crisp flavors of German pilsners.

Distillation: Intensifying Flavors

Distillation, on the other hand, is a process that involves separating and concentrating the desired components of a liquid mixture, often resulting in a higher alcohol content. This method is commonly used in the production of spirits and liquors. When applied to beer, distillation can create entirely new flavor profiles. For instance, the distillation of beer can result in a more intense, concentrated flavor, often with a higher alcohol by volume (ABV). The process can enhance the inherent flavors of the beer, making it more robust and complex. Distilled spirits derived from beer can exhibit a wide range of tastes, from the sweet and caramelized notes of distilled ales to the more robust, oaky flavors of distilled stouts.

The Art of Flavor Enhancement

Both fermentation and distillation contribute to the art of flavor enhancement in beverages. Fermentation introduces a diverse array of flavors and aromas, while distillation can intensify and transform these flavors. The yeast strains and fermentation techniques used in brewing directly impact the flavor profiles of the beer, creating a vast spectrum of tastes and aromas. Similarly, the choice of grains, distillation methods, and aging processes in distilling influence the final flavor of the spirit.

In summary, fermentation and distillation are fundamental processes that shape the unique flavor profiles of beer and spirits. Fermentation brings forth a natural, diverse range of flavors, while distillation can intensify and transform these flavors, creating entirely new taste experiences. Understanding these processes allows enthusiasts and connoisseurs to appreciate the intricate and diverse world of flavors found in various alcoholic beverages.

Fish in Beer: A Surprising Aquatic Adventure

You may want to see also

Frequently asked questions

No, beer is not distilled. It is a fermented beverage, which means the alcohol content is produced through a process of fermentation, where yeast converts sugars derived from grains into ethanol and carbon dioxide.

The alcohol in beer is created through the fermentation process. Grains, typically malted barley, are first malted, soaked in water, and then dried. These malted grains are then milled and mixed with hot water in a process called mashing, which extracts sugars. Yeast is then added to the sugary liquid (wort) to initiate fermentation, resulting in the production of alcohol.

Fermentation is a biological process where microorganisms, such as yeast, convert carbohydrates into alcohol and carbon dioxide. This is the primary method used in brewing beer. Distillation, on the other hand, is a chemical process that involves separating and purifying substances by their different boiling points. It is commonly used in the production of spirits and is not a part of the beer-making process.

While it is not a common practice, beer can be distilled to create a stronger, more concentrated alcoholic beverage. This process is known as beer distillation and is used to produce certain types of spirits or to create a higher-proof beer. However, this is not a standard part of the brewing process and is typically done as a separate step.

Yes, there are some specialty beers that are distilled, often referred to as "distilled beers" or "spirited beers." These beers are typically brewed with a higher alcohol content and then distilled to further increase the alcohol by volume. Examples include some craft beers and limited-edition releases from breweries that experiment with distillation.