Secondary fermentation is a crucial step in the brewing process, especially when it comes to kit beers. This process involves transferring the beer from the primary fermentation vessel to a secondary container, where additional yeast is added to enhance flavor and carbonation. While some brewers may opt for a single fermentation process, others believe that secondary fermentation is essential for achieving the desired taste and quality. In this paragraph, we will explore the benefits and potential drawbacks of secondary fermentation with kit beers, examining whether it is a necessary step or simply a matter of personal preference.

| Characteristics | Values |

|---|---|

| Definition | Secondary fermentation is an additional fermentation process used in brewing, typically with kit beers, to enhance flavor, aroma, and carbonation. |

| Purpose | To refine the beer's taste, improve mouthfeel, and add complexity. |

| Process | After primary fermentation, the beer is transferred to a secondary vessel, where it is fermented again with a specific yeast strain or a blend of yeasts. |

| Time | Secondary fermentation can last from a few days to several weeks, depending on the style and desired outcome. |

| Yeast | Common yeasts used include ale yeasts (e.g., Wyeast 3522, White Labs WLP099) and specialty yeasts like Brettanomyces. |

| Flavor Profile | Results in a smoother, more balanced beer with enhanced fruity, estery, or spicy notes. |

| Carbonation | Often increases carbonation levels, making the beer more refreshing. |

| Kit Beers | Kit beers, also known as homebrew kits, provide pre-measured ingredients and instructions, making secondary fermentation accessible to homebrewers. |

| Benefits | Allows for more precise control over the brewing process, enabling brewers to experiment with different yeast strains and fermentation techniques. |

| Considerations | Requires careful monitoring of temperature and oxygen levels to avoid off-flavors. |

What You'll Learn

- Fermentation Process: Understanding the role of yeast in secondary fermentation

- Kit Beer Ingredients: Exploring the components of kit beers and their impact

- Flavor Development: How secondary fermentation affects the taste and aroma of the beer

- Carbonation: The effect of secondary fermentation on carbonation levels in kit beers

- Kit Beer Consistency: Ensuring consistent results with kit beers through secondary fermentation techniques

Fermentation Process: Understanding the role of yeast in secondary fermentation

The secondary fermentation process is a crucial step in the production of beer, especially when it comes to kit beers, which are designed to be accessible and convenient for home brewers. This stage involves the use of yeast, a microscopic organism that plays a pivotal role in transforming the beer's flavor, aroma, and overall quality. Yeast is responsible for the fermentation process, which is the conversion of sugars into alcohol and carbon dioxide. In the context of kit beers, secondary fermentation is often an essential step to enhance the beer's characteristics and ensure a consistent and desirable final product.

When it comes to kit beers, the primary fermentation typically occurs in the initial stages of brewing. During this phase, the yeast consumes the sugars present in the wort (the sugary liquid extracted from malted grains) and produces alcohol and carbon dioxide. However, the yeast used in primary fermentation might not always be the most efficient or desirable for the beer's intended style. This is where secondary fermentation comes into play.

Secondary fermentation is an optional step that allows brewers to fine-tune the beer's flavor and aroma. It involves transferring the beer from the primary fermentation vessel to a new container, often a secondary fermenter or a bottle. Here, a different strain of yeast is introduced, which can contribute to the beer's unique characteristics. This additional fermentation process can last anywhere from a few days to several weeks, depending on the desired outcome and the yeast's activity. The yeast used in secondary fermentation may be a specialized strain, such as a Belgian ale yeast or a British ale yeast, each bringing its own distinct flavor profile.

The purpose of secondary fermentation is twofold. Firstly, it allows for the development of complex flavors and aromas that might not be fully realized during primary fermentation. This is particularly important for styles like Belgian tripels, wheat beers, or certain fruit-infused beers, where a secondary fermentation can add depth and character. Secondly, it provides an opportunity to clarify the beer by removing any remaining yeast or sediment, resulting in a smoother and more refined final product.

In the context of kit beers, secondary fermentation can be a game-changer. It enables home brewers to experiment with different yeast strains and create beers with unique profiles. For instance, a kit beer might benefit from a secondary fermentation with a yeast that adds a hint of fruitiness or a subtle spice note, transforming a basic kit beer into a more sophisticated and personalized brew. This process empowers brewers to craft beers that match their preferences, even when using pre-packaged kit ingredients.

Mastering Fermentation: Signs of Completeness Without a Hydrometer

You may want to see also

Kit Beer Ingredients: Exploring the components of kit beers and their impact

The world of homebrewing and craft beer enthusiasts has embraced the convenience and accessibility of kit beers, which offer a simplified brewing process. These kits typically include a pre-measured blend of malt, hops, yeast, and sometimes additional ingredients, designed to be mixed and brewed at home. While kit beers provide an entry point into the art of brewing, understanding the ingredients and their roles is essential for both novice and experienced brewers.

One of the key components in kit beers is the malt. Malted grains, usually barley, are the foundation of beer, providing the sugars necessary for fermentation. The malt in kit beers is often a combination of base and specialty malts. Base malt, typically pale malt, forms the backbone of the beer, contributing to its color and flavor. Specialty malts, such as caramel or chocolate malts, add depth and complexity to the beer's character. The ratio and types of malt used can significantly influence the final beer's taste, body, and color.

Hops play a crucial role in kit beers, providing bitterness, flavor, and aroma. They are added during the brewing process to balance the sweetness of the malt. Different varieties of hops offer distinct characteristics; for instance, Citra hops provide tropical fruit notes, while Cascade hops contribute citrusy and piney flavors. The timing of hop additions is essential; hops added early in the boil contribute more to bitterness, while late additions or dry-hopping can enhance aroma and flavor without excessive bitterness.

Yeast is another critical ingredient in kit beers, responsible for fermentation and the conversion of sugars into alcohol. Kit beers often include a specific yeast strain tailored to the beer style. For example, an ale yeast will ferment at higher temperatures, producing a more fruity and estery beer. Lager yeasts, on the other hand, ferment at cooler temperatures, resulting in a cleaner and crisper flavor profile. The choice of yeast can significantly impact the beer's overall character.

In addition to the primary ingredients, kit beers may include other components to enhance flavor, mouthfeel, and overall quality. These can include dry hops, which are added late in the brewing process to boost aroma without adding bitterness. Some kits also include specialty ingredients like fruit purees or extracts, which can add unique flavors to the beer. For instance, a cherry or raspberry puree can create a fruity wheat beer.

Understanding the ingredients in kit beers is essential for brewers to make informed decisions and customize their brews. While kit beers provide a convenient and accessible entry point, exploring and experimenting with different ingredients can lead to the creation of unique and personalized beer styles. By grasping the impact of each component, brewers can craft beers that suit their tastes and preferences, fostering a deeper appreciation for the art of brewing.

Uncorking the Magic: Beer's Microbial Fermentation Journey

You may want to see also

Flavor Development: How secondary fermentation affects the taste and aroma of the beer

Secondary fermentation is a crucial step in the beer-making process that significantly influences the final flavor profile of the beverage. This process involves transferring the beer from the primary fermentation vessel to a second container, often a carboy or a barrel, where it continues to ferment with the addition of a yeast or a specific blend of yeasts. The duration and conditions of this secondary fermentation can greatly impact the beer's taste and aroma, offering brewers a powerful tool to craft unique and desirable flavors.

One of the primary effects of secondary fermentation is the development of more complex and nuanced flavors. During the primary fermentation, the yeast primarily focuses on converting sugars into alcohol and carbon dioxide. However, in the secondary stage, the yeast has more time to interact with the beer's components, leading to the production of additional flavor compounds. This process can enhance the beer's overall taste by adding layers of complexity, such as fruity esters, spicy notes, or even a subtle sweetness. For example, in wheat beers, secondary fermentation can contribute to the characteristic banana and clove aromas, while in Belgian ales, it may result in a richer, more robust flavor profile.

The aroma of the beer also undergoes significant transformation during this stage. As the beer matures in the secondary fermenter, volatile compounds are released, contributing to the beer's fragrance. This can lead to the emergence of new aromas that were not present during primary fermentation. For instance, secondary fermentation can produce higher levels of esters, which are responsible for the fruity and floral notes often associated with Belgian-style beers. Additionally, the process can also reduce harsher flavors, making the beer more balanced and appealing to the palate.

The duration of secondary fermentation is a critical factor in flavor development. Longer fermentation periods allow for more extensive yeast activity, resulting in a more pronounced flavor impact. However, brewers must be cautious not to over-ferment, as this can lead to off-flavors and a loss of desired characteristics. Optimal conditions, such as temperature control and oxygen levels, are essential to ensure the yeast's activity is harnessed effectively without causing negative side effects.

In the context of kit beers, which are designed for homebrewers, secondary fermentation can be a game-changer. These kits often provide a solid foundation for primary fermentation but may lack the complexity and depth of flavor that experienced brewers can achieve. By extending the fermentation time and carefully managing the secondary stage, homebrewers can elevate the taste and aroma of their kit-brewed beers, making them more comparable to commercially produced craft beers. This process allows for customization and experimentation, enabling brewers to create unique and satisfying beer styles.

Unraveling the Fermentable Nature of Beer: Carbohydrates and Beyond

You may want to see also

Carbonation: The effect of secondary fermentation on carbonation levels in kit beers

Secondary fermentation is a crucial step in the brewing process, especially for kit beers, as it significantly impacts the carbonation levels in the final product. This process involves transferring the beer from the primary fermentation vessel to a secondary container, where the yeast continues to work on the remaining sugars, producing carbon dioxide (CO2) as a byproduct. The level of carbonation in a beer is a critical factor in its taste and overall quality, and secondary fermentation plays a pivotal role in achieving the desired carbonation.

In kit beers, which are designed for homebrewers and often come in a pre-measured, ready-to-brew form, secondary fermentation is essential. These beers typically have a lower initial carbonation level, which is then enhanced during the secondary fermentation stage. The process is carefully controlled to ensure the beer reaches the desired carbonation without over-fermentation, which can lead to off-flavors and a less-than-ideal drinking experience. The duration and temperature of this secondary fermentation are critical factors, as they directly influence the amount of CO2 produced.

During secondary fermentation, the yeast continues to metabolize sugars, primarily glucose, and fructose, which are present in the beer's wort. As the yeast consumes these sugars, it releases CO2, which dissolves in the beer, increasing its carbonation. The longer the secondary fermentation, the more CO2 is produced, and the higher the carbonation level. However, it's a delicate balance, as prolonged fermentation can also lead to a loss of flavor and aroma compounds, affecting the beer's overall character.

The temperature at which this process occurs is another critical aspect. Warmer temperatures generally speed up the fermentation process, leading to a faster increase in carbonation. However, if the temperature is too high, it can cause the yeast to become inactive or even die, halting the fermentation process. Therefore, brewers must carefully monitor the temperature to ensure optimal conditions for yeast activity and carbonation development.

In summary, secondary fermentation is a vital step in kit beer brewing, as it directly influences the carbonation levels. By carefully controlling the duration and temperature of this process, brewers can achieve the desired carbonation, ensuring a refreshing and enjoyable drinking experience. Understanding and managing these factors are essential for homebrewers and commercial brewers alike to produce high-quality kit beers.

Uncorking the Mystery: Raw Eggs in Beer, Fact or Fiction?

You may want to see also

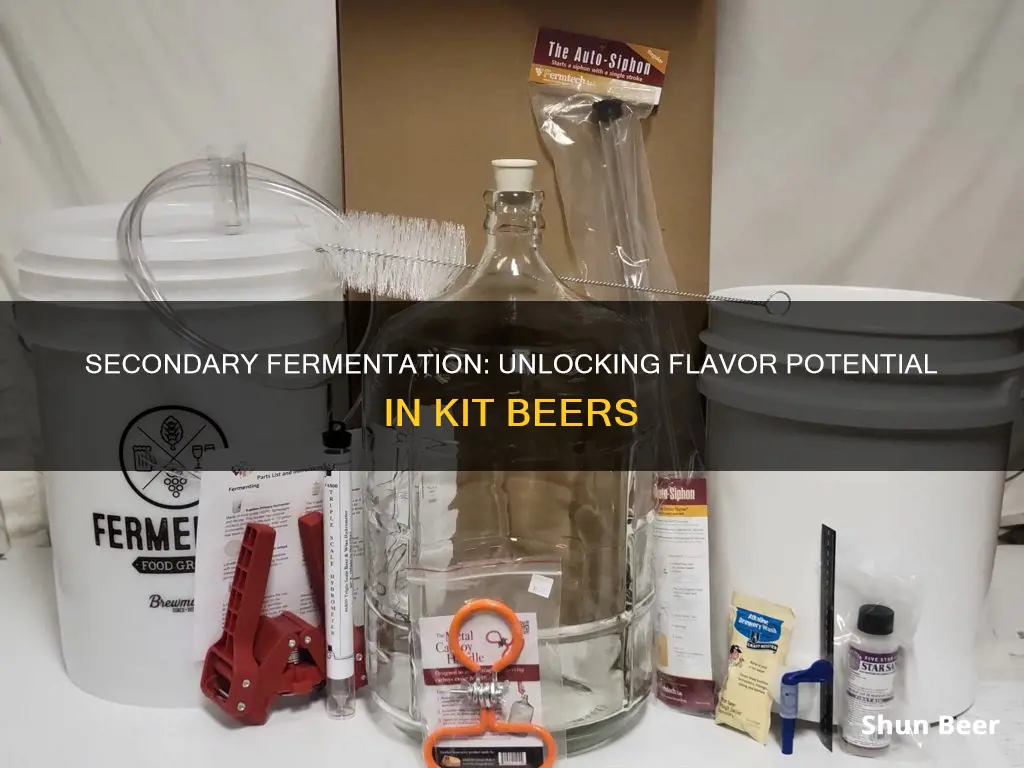

Kit Beer Consistency: Ensuring consistent results with kit beers through secondary fermentation techniques

The process of secondary fermentation is an essential technique for kit beer enthusiasts and home brewers alike, aiming to achieve consistent and high-quality results. While kit beers are designed to be user-friendly and accessible, understanding and implementing secondary fermentation can elevate the brewing experience and the final product. This technique is particularly crucial for those seeking to refine and optimize their kit beer recipes, ensuring a more controlled and predictable outcome.

Secondary fermentation involves transferring the partially fermented beer from the primary fermentation vessel to a second container, often a carboy or a food-grade plastic bucket. This step is taken to further mature and condition the beer, allowing for the development of complex flavors and aromas. By separating the beer from the spent yeast and sediment, the secondary fermentation process can enhance clarity and improve the overall taste. It is a crucial phase that can make or break the final beer's character.

One of the key benefits of secondary fermentation is the ability to fine-tune the beer's attributes. During this stage, brewers can experiment with different yeast strains, adjust temperatures, and control the duration of fermentation. This level of control is especially important for kit beers, as it allows brewers to customize the beer's style and characteristics. For instance, a longer secondary fermentation can result in a smoother, more robust beer, while a shorter period might produce a lighter, more crisp beverage.

To ensure consistent results, it is imperative to maintain proper sanitation throughout the process. Any contamination can negatively impact the beer's quality. Before transferring the beer, thoroughly clean and sanitize both the primary and secondary fermentation vessels. Use a suitable sanitizing agent, such as iodine or a quaternary ammonium compound (QUAT), to eliminate any potential bacteria or wild yeast. Additionally, consider using a hydrometer to monitor the specific gravity of the beer, ensuring it aligns with the desired target.

When performing the transfer, be gentle to avoid disturbing the yeast and sediment. Sediment can be left in the primary fermenter if it has settled, but it's best to remove it periodically to maintain clarity. After the transfer, secure the secondary fermenter with an airlock to allow carbon dioxide to escape while preventing unwanted microorganisms from entering. Regularly inspect the beer's progress, tasting and adjusting as needed, until the desired flavor profile is achieved.

In summary, secondary fermentation is a powerful tool for kit beer enthusiasts to refine and customize their brews. By implementing this technique, brewers can achieve consistent and exceptional results, transforming a good kit beer into a remarkable, personalized beverage. It is a process that requires attention to detail, proper sanitation, and a keen understanding of the beer's characteristics, ultimately rewarding brewers with a satisfying and unique drinking experience.

Freezing Beer Mugs: A Simple Guide to Chilling Your Drink

You may want to see also

Frequently asked questions

Secondary fermentation is not a universal requirement for all kit beers. It depends on the specific brewing process and the desired outcome. Some kit beers may benefit from a secondary fermentation stage to enhance flavor, carbonation, and overall quality.

Secondary fermentation is an additional fermentation process that occurs after the primary fermentation. It allows for further maturation and can help refine the beer's character. During this stage, the beer is transferred to a new container, often a secondary fermenter, where it can develop more complex flavors and aromas.

The duration of secondary fermentation can vary widely depending on the beer style and the brewer's preferences. It typically ranges from a few days to several weeks. Some beers may only require a short period of secondary fermentation, while others might benefit from an extended period to achieve the desired flavor profile.

Yes, it is possible to brew a high-quality beer without secondary fermentation. Many kit beers are designed to be brewed in a single-step process, where primary and secondary fermentation occur simultaneously or in quick succession. Skipping secondary fermentation can save time and effort, but it may limit the beer's potential for complexity and flavor development.

While it is possible to brew a successful beer without secondary fermentation, there might be some trade-offs. The beer may lack the depth of flavor and complexity that a secondary fermentation can provide. Additionally, certain beer styles, such as certain wheat beers or Belgian-style ales, often benefit from an extended fermentation period to achieve their characteristic flavors and mouthfeel.