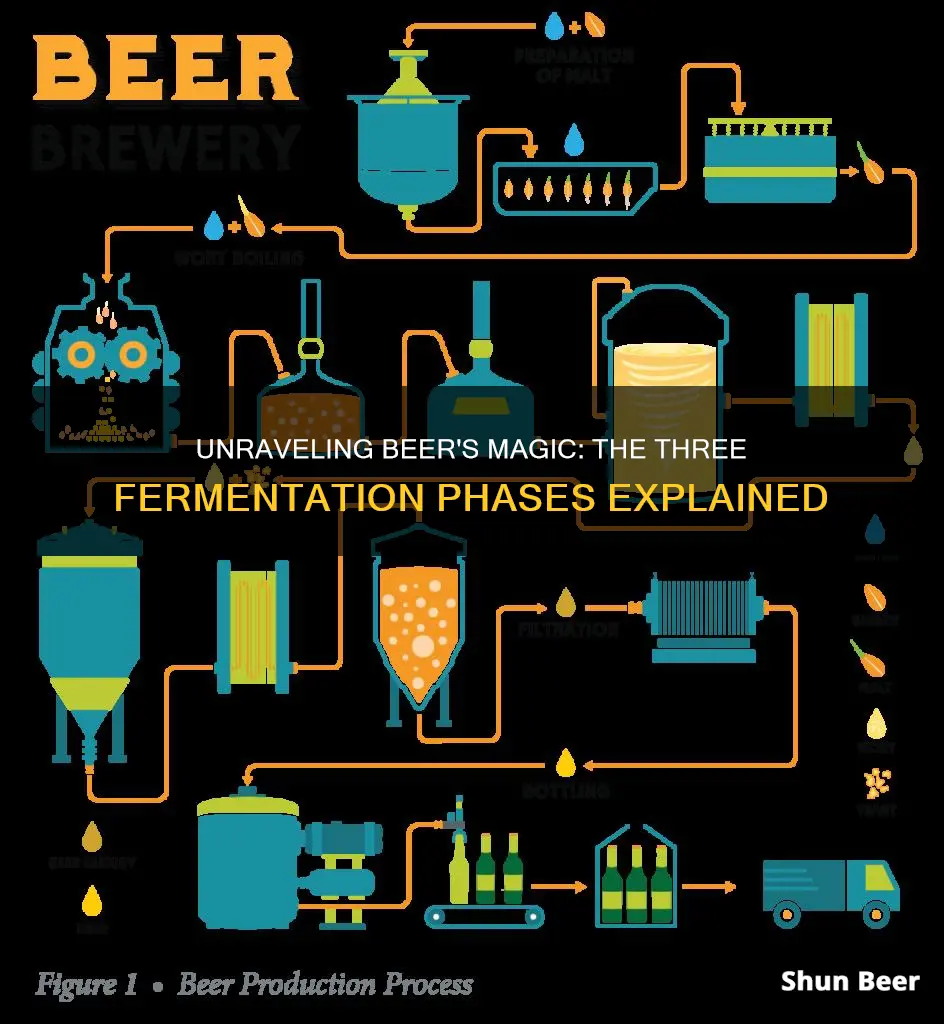

The process of brewing beer involves a fascinating chemical transformation known as fermentation, which is divided into three distinct phases. The first phase, known as primary fermentation, occurs in the brew kettle and involves the conversion of sugars derived from malted grains into alcohol and carbon dioxide by yeast. This phase is crucial for developing the beer's alcohol content and carbonation. The secondary fermentation, or conditioning, takes place in the fermenter and is where the beer's flavor and aroma are refined. Here, the yeast continues to work, producing complex flavors and aromas, and the beer is aged to achieve the desired character. Finally, the tertiary fermentation, or packaging, is the final stage where the beer is transferred to bottles or cans, and any remaining yeast or sediment is separated, resulting in the final product that beer enthusiasts enjoy.

| Characteristics | Values |

|---|---|

| Phase 1: Alcoholic Fermentation | This is the primary fermentation stage where yeast converts sugars (glucose and maltose) into ethanol and carbon dioxide. It typically occurs at a higher temperature, around 65-75°F (18-24°C). |

| Duration | Can range from 5-14 days, depending on the yeast strain and beer style. |

| Sugar Consumption | Yeast consumes most of the fermentable sugars, leaving a small amount of residual sugars. |

| Flavor Development | Produces alcohol, contributes to the beer's flavor and aroma, and determines the alcohol content. |

| Carbonation | Carbon dioxide is released, which can be captured during packaging or carbonation. |

| Phase 2: Secondary Fermentation | An optional phase where the beer is transferred to a secondary fermenter to refine and mature the flavor. |

| Temperature | Often done at a cooler temperature, around 55-65°F (13-18°C), to slow down the process. |

| Duration | Can last from a few days to several weeks. |

| Purpose | To further develop flavors, clarify the beer, and reduce alcohol content slightly. |

| Phase 3: Aging and Maturation | The beer is aged in the fermenter or transferred to a conditioning vessel. |

| Temperature | Typically aged at refrigerator temperature (40-50°F/4-10°C) to slow down any remaining yeast activity. |

| Duration | Can vary from a few weeks to several months, depending on the beer style and desired flavor complexity. |

| Flavor Development | Allows flavors to mature, smoothen out, and develop more complex characteristics. |

| Clarification | Sediments and yeast settle, making the beer clearer. |

What You'll Learn

- Malting: Grains are soaked, germinated, and dried to convert starches into sugars

- Mashing: Malts are mixed with water to extract sugars, creating a sugary liquid

- Boiling: The sugary liquid is boiled to sterilize and concentrate the wort

- Fermentation: Yeast consumes sugars, producing alcohol and carbon dioxide

- Aging: Beer is aged in barrels or tanks to develop flavor and clarity

Malting: Grains are soaked, germinated, and dried to convert starches into sugars

Malting is a crucial process in the art of brewing, where grains, typically barley, undergo a series of transformations to unlock their full potential for fermentation. This intricate process begins with soaking, a step that may seem simple but is fundamental to the entire brewing journey. When grains are soaked, they absorb water, triggering a remarkable biological response. This initial soaking period allows the grains to swell and initiate the breakdown of their complex structures.

The next phase is germination, a process that brings the grains to life. During germination, the soaked grains are exposed to specific conditions, often in a controlled environment, where they sprout and develop. This stage is critical as it activates enzymes within the grains, initiating the conversion of starches into fermentable sugars. Enzymes, nature's catalysts, play a pivotal role in breaking down the starch molecules, transforming them into simpler sugars like maltose, which is essential for the brewing process.

After germination, the grains undergo a delicate drying process. This step is crucial as it halts the germination process and prepares the grains for the subsequent stages of brewing. The grains are carefully dried to ensure they retain the newly formed sugars while eliminating excess moisture. This drying process requires precision to maintain the desired moisture content, as it directly influences the flavor and quality of the final beer.

The malting process is a delicate balance of science and art, where each step contributes to the overall character of the beer. By soaking, germinating, and drying the grains, brewers unlock the natural sugars locked within, creating the foundation for the fermentation process. This phase sets the stage for the subsequent steps, where yeast will play its part in transforming these sugars into the diverse array of beers we enjoy today.

Chili Without Beer: Creative Alternatives for a Flavorful Dish

You may want to see also

Mashing: Malts are mixed with water to extract sugars, creating a sugary liquid

Mashing is a crucial step in the beer-making process, where the magic of transforming grains into a fermentable liquid begins. This process involves a careful and precise technique to extract the sugars locked within the malted grains. Here's a detailed breakdown of the mashing process:

In the heart of the brewery, the malted grains, typically barley, are the stars of this stage. These grains have been carefully selected and prepared to ensure optimal brewing. The process starts with a mixture of crushed malt and hot water, creating a sweet liquid known as 'wort'. This mixture is then agitated, a process called 'mashing in', which ensures even extraction of sugars. The temperature and duration of this stage are critical; typically, the mash is maintained at a specific temperature, often around 60-65°C (140-150°F), for a period of 60-90 minutes. During this time, enzymes within the malt break down complex starches into simpler sugars, primarily maltose. This enzymatic reaction is a delicate balance, and brewers carefully control the parameters to achieve the desired sugar content.

The mashing process is not just about extracting sugars; it also involves separating the solid malt particles from the sugary liquid. This is achieved through a process called 'lauteration', where the wort is drained from the malt, leaving behind a solid residue. The lauteration process ensures that the final product is a clear, sweet liquid, free from any solid grain particles.

After lauteration, the sugary liquid, now known as 'sweet liquid' or 'wort', is ready for the next phase. This liquid is then boiled, which not only sterilizes it but also initiates the evaporation of water, concentrating the sugars and creating the base for the beer's flavor profile. The boiled wort is then cooled and prepared for the fermentation stage, where yeast will transform these sugars into alcohol and carbon dioxide, giving beer its characteristic fizz and character.

Mashing is an art and a science, requiring precision and attention to detail. It is a fundamental step that sets the foundation for the unique flavors and characteristics of different beer styles. The process is carefully monitored and adjusted to ensure the desired sugar content and quality, making it a critical aspect of the beer-making journey.

Mastering Beer Carbonation: Tips for Post-Secondary Fermentation

You may want to see also

Boiling: The sugary liquid is boiled to sterilize and concentrate the wort

The boiling process is a crucial step in the brewing of beer, as it serves multiple essential functions. When the sugary liquid, known as the wort, is boiled, it undergoes a transformation that is both chemical and physical in nature. Firstly, the high temperature of the boil (typically around 150-160°F or 65-71°C) acts as a sterilizing agent, effectively killing any remaining yeast or bacteria that might have survived the previous steps. This is a critical step to ensure that the beer's flavor and quality are not compromised by unwanted microbial activity. Boiling also helps to concentrate the wort, reducing its volume and increasing its sugar content. This concentration is vital as it provides the necessary sugars for the yeast to ferment and produce alcohol and carbon dioxide.

During the boil, brewers often add hops, which contribute to the beer's bitterness, flavor, and aroma. Hops are boiled along with the wort, allowing their bittering agents to dissolve into the liquid. This process not only adds flavor but also acts as a natural preservative, further sterilizing the wort and preventing spoilage. The duration of the boil can vary, but it typically lasts for 60 to 90 minutes, during which the wort is continuously stirred to ensure even heating and to prevent the formation of a bitter, dark-colored 'bitterness' at the bottom of the brew.

The boiling process also facilitates the separation of the wort from the spent grain and other solid brewing materials. As the wort is boiled, the sugars are extracted and dissolved, making it easier to separate the liquid from the solids. This separation is crucial for the subsequent steps in brewing, as it allows for the isolation of the wort, which will be fermented to create the beer.

In summary, boiling is a critical phase in the brewing process, serving to sterilize the wort, concentrate its sugar content, and extract essential flavors and aromas. It is a meticulous process that requires careful temperature control and timing to ensure the desired outcome. This step lays the foundation for the subsequent fermentation and aging processes, ultimately determining the character and quality of the final beer.

Understanding Beer Fermentation: When to Expect Bubbles

You may want to see also

Fermentation: Yeast consumes sugars, producing alcohol and carbon dioxide

The process of fermentation in beer production is a fascinating journey that transforms simple sugars into the complex flavors and aromas we associate with our favorite brews. At the heart of this transformation is yeast, a microscopic organism that plays a pivotal role in the creation of alcohol and carbon dioxide.

During the fermentation process, yeast cells metabolize the sugars present in the wort, which is the sugary liquid extracted from malted grains. This metabolic process is a delicate dance of chemistry. Yeast enzymes break down complex sugars, such as maltose, into simpler sugars like glucose and fructose. These simpler sugars are then readily available for the yeast to consume. As the yeast feasts on these sugars, it undergoes a series of biochemical reactions.

In the first stage, known as the 'Alcoholic Fermentation,' yeast converts glucose into ethanol (alcohol) and carbon dioxide (CO2). This reaction is represented by the equation: C6H12O6 (glucose) + 2 ADP + 2 Pi → 2 C2H5OH (ethanol) + 2 CO2 + 2 ATP. Here, glucose, a six-carbon sugar, is transformed into ethanol and CO2, releasing energy in the form of ATP (adenosine triphosphate), which is essential for the yeast's metabolic activities. This phase is crucial as it determines the alcohol content and contributes to the beer's overall character.

As the fermentation progresses, the yeast continues to work its magic. In the 'Secondary Fermentation,' the yeast focuses on refining the beer's flavor and aroma. During this stage, the yeast may produce additional compounds, such as esters and higher alcohols, which contribute to the beer's unique characteristics. This phase allows brewers to manipulate the fermentation process to achieve specific flavor profiles.

The final phase, 'Maturation,' involves the aging and conditioning of the beer. After the primary fermentation, the beer is often transferred to a secondary vessel for further maturation. During this time, the yeast continues to work on any remaining sugars, and the beer develops its final attributes. Maturation can take place in the same vessel or in a separate aging barrel, allowing the beer to rest and mature, resulting in a smoother, more refined flavor.

In summary, fermentation is a complex process where yeast acts as a catalyst, converting sugars into alcohol and carbon dioxide. The three phases of fermentation—Alcoholic Fermentation, Secondary Fermentation, and Maturation—each play a vital role in shaping the beer's character, from the initial alcohol production to the final refinement of flavors and aromas. Understanding these processes is essential for brewers to craft beers with distinct and desirable qualities.

The Ultimate Guide to Lime-Infused Beer: A Refreshing Twist

You may want to see also

Aging: Beer is aged in barrels or tanks to develop flavor and clarity

The aging process is a crucial step in the transformation of beer, allowing it to mature and develop its unique characteristics. After fermentation, beer is carefully transferred to aging vessels, such as oak barrels or stainless steel tanks, where it undergoes a period of rest and refinement. This stage is essential for enhancing the beer's flavor profile and achieving the desired clarity.

Aging in barrels is a traditional method that imparts a rich, complex flavor to the beer. Oak barrels, in particular, contribute a distinct oaky aroma and a subtle sweetness to the beverage. The interaction between the beer and the wooden barrel allows for the extraction of flavors and the development of a smooth, velvety texture. This process can take anywhere from a few weeks to several months, depending on the desired outcome and the type of beer being aged. During this time, the beer's color may darken slightly, and the flavors become more robust and well-rounded.

In tanks, beer aging is often employed for larger-scale production or when a more controlled environment is required. Stainless steel tanks provide a sterile setting, ensuring the beer remains free from unwanted contaminants. Here, the beer can be aged for extended periods, allowing for the maturation of flavors and the clarification of the liquid. The temperature and duration of tank aging can be precisely controlled, enabling brewers to achieve specific taste profiles and mouthfeel.

The aging process is an art that requires careful consideration of various factors. Brewers must decide on the type of aging vessel, the duration of the process, and the desired outcome in terms of flavor and clarity. The goal is to create a harmonious blend of flavors, ensuring the beer is well-balanced and appealing to the palate. This stage allows for the beer's character to shine, offering a unique drinking experience that sets it apart from the initial fermented product.

Through aging, beer transforms from a raw, freshly fermented beverage into a refined, complex drink. The process is a delicate balance of science and art, where the beer's flavors evolve and mature, captivating the senses of beer enthusiasts worldwide. Whether in barrels or tanks, aging is an essential step in the journey from grain to glass, making it an integral part of the beer-making process.

The Strange Practice of Adding Fruit to Beer: Who Does This?

You may want to see also

Frequently asked questions

The fermentation of beer typically occurs in three distinct phases: primary, secondary, and maturation. The primary fermentation involves the conversion of sugars to alcohol and carbon dioxide by yeast, creating a dense, cloudy beer. This phase is crucial for developing the beer's flavor and alcohol content. Secondary fermentation, if used, is an optional step where the beer is transferred to a new vessel to further refine and stabilize the flavor. Maturation is the final phase, where the beer ages and develops its characteristic flavors, colors, and aromas over time.

Yeast plays a vital role in fermentation by converting the sugars present in the wort (the sugary liquid extracted from malted grains) into alcohol and carbon dioxide. During fermentation, yeast consumes the available sugars, such as maltose, and produces ethanol and CO2 as byproducts. This process not only creates the alcohol content in beer but also contributes to the unique flavors and aromas associated with different yeast strains.

Secondary fermentation is an additional step in the brewing process that allows for further refinement and improvement of the beer's quality. After the primary fermentation, the beer is often transferred to a new vessel, where it can undergo a secondary fermentation. This phase helps to clarify the beer by reducing cloudiness and can also enhance the overall flavor profile. It is a crucial step for achieving a well-balanced, smooth beer with a clean finish.