Fermentation is a natural process that transforms simple ingredients into complex, flavorful beverages. When applied to beer, fermentation is a crucial step in the brewing process where sugars derived from malted grains are converted into alcohol and carbon dioxide by yeast. This process not only produces the alcohol content in beer but also contributes to the unique flavors and aromas that make different beer styles distinct. The fermentation process can vary depending on the type of yeast used and the specific brewing techniques employed, resulting in a wide range of beer flavors and characteristics.

What You'll Learn

- Fermentation Process: Yeast converts sugars in malt into alcohol and carbon dioxide

- Ingredients: Malted grains, water, hops, and yeast are essential for beer fermentation

- Brewing Stages: Fermentation occurs in the brew kettle and then in the fermenter

- Types of Yeast: Ale and lager yeasts produce different flavors and alcohol levels

- Fermentation Time: Duration varies, typically 5-14 days, depending on yeast and recipe

Fermentation Process: Yeast converts sugars in malt into alcohol and carbon dioxide

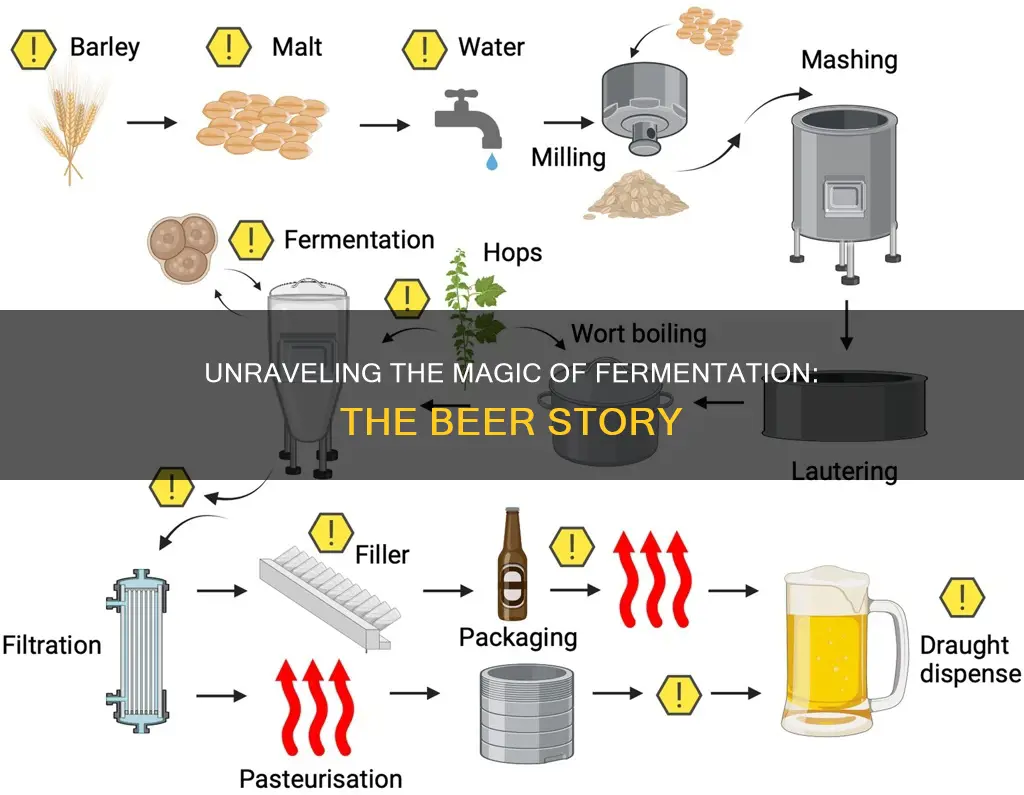

The fermentation process is a fundamental aspect of brewing beer, and it all begins with the malt. Malt is the primary ingredient in beer, derived from barley that has been germinated and then dried. During germination, the barley grains absorb water and begin to grow, activating enzymes that break down complex carbohydrates in the grain into simpler sugars. This process is crucial as it provides the yeast with the necessary food source for fermentation.

Once the malt is prepared, it is crushed to expose the starches within the grain's cells. This step is essential to create a large surface area for the yeast to interact with the malt's sugars. The crushed malt is then mixed with hot water in a process called mashing. This mashing process further breaks down the starches into fermentable sugars, primarily maltose. The temperature and duration of the mash are carefully controlled to ensure the desired sugar conversion rate.

After mashing, the sweet liquid, known as wort, is separated from the spent grain. This wort is now rich in sugars, ready to be fermented. This is where yeast plays a pivotal role. Yeast is a microscopic organism that thrives in sugary environments and is responsible for converting these sugars into alcohol and carbon dioxide. There are two primary types of yeast used in brewing: ale yeast and lager yeast. Ale yeasts are typically used for warmer fermentation temperatures and produce fruity and estery flavors, while lager yeasts are used for cooler temperatures and result in cleaner, crisper beers.

During the fermentation process, yeast consumes the maltose in the wort and produces ethanol (alcohol) and carbon dioxide as byproducts. This transformation is a delicate balance of science and art, as brewers carefully manage factors like temperature, yeast strain, and fermentation duration to achieve the desired beer style and character. The yeast's activity can be influenced by temperature; warmer temperatures generally speed up fermentation, while cooler temperatures slow it down, allowing for more nuanced flavor development.

After fermentation, the beer is separated from the yeast and any remaining sediment. This young beer, now called 'green beer,' is typically cloudy and unfiltered. It is then cooled and packaged or stored for conditioning. The carbon dioxide produced during fermentation remains dissolved in the beer, giving it its characteristic fizz. This process of fermentation and carbonation is what ultimately transforms the malted barley into the beloved beverage we know as beer.

Uncorking the Mystery: Exploring the Speed of Beer Fermentation

You may want to see also

Ingredients: Malted grains, water, hops, and yeast are essential for beer fermentation

The process of fermentation is fundamental to the creation of beer, transforming simple ingredients into a complex and flavorful beverage. At the heart of this transformation are four key components: malted grains, water, hops, and yeast. Each of these ingredients plays a unique and crucial role in the fermentation process, contributing to the unique characteristics of different beer styles.

Malted grains, typically barley, serve as the primary source of fermentable sugars in beer. Through a process called malting, the grains are soaked in water and allowed to germinate, activating enzymes that break down complex starches into simpler sugars. This process is essential as it provides the yeast with the necessary food source for fermentation. The malted grains are then dried and crushed, exposing the starches to enzymes that convert them into fermentable sugars, primarily maltose. This step significantly impacts the beer's flavor, color, and body, as the malt's characteristics, such as its enzyme content and roasting level, influence the final beer's profile.

Water, often overlooked, is a critical ingredient in beer fermentation. Its purity and mineral content are vital, as water with high mineral content can affect the beer's taste and clarity. Brewers carefully control the water's chemistry, adjusting its pH and mineral levels to suit the specific beer style. The water's profile can contribute to the beer's mouthfeel, bitterness, and overall balance, making it an essential component in the fermentation process.

Hops, another essential ingredient, contribute bitterness, flavor, and aroma to beer. They are added during the boiling stage of the brewing process, where they release bittering agents and essential oils. These bittering agents not only provide the characteristic hoppy flavor but also help balance the beer's sweetness, creating a harmonious taste. Additionally, hops contribute to the beer's stability and preservation, acting as natural preservatives and helping to prevent spoilage.

Yeast, the final key ingredient, is responsible for the fermentation process itself. It consumes the sugars derived from the malted grains and produces alcohol and carbon dioxide. There are two primary types of yeast used in brewing: ale yeast and lager yeast. Ale yeasts are used for higher-temperature fermentation, resulting in fruity and estery flavors, while lager yeasts ferment at cooler temperatures, producing cleaner and crisper beers. The choice of yeast significantly influences the beer's flavor, aroma, and overall character.

In summary, the fermentation of beer is a complex process that relies on the careful selection and combination of malted grains, water, hops, and yeast. Each ingredient contributes unique characteristics, from the malt's sugar content to the hops' bitterness and the yeast's fermentation capabilities. Understanding and mastering these ingredients are essential for brewers to create a wide range of beer styles, each with its distinct flavor profile and appeal.

Unveiling the Mystery: Formaldehyde in Beer - Fact or Fiction?

You may want to see also

Brewing Stages: Fermentation occurs in the brew kettle and then in the fermenter

The process of brewing beer is an intricate art, and fermentation is a crucial stage that transforms the raw ingredients into the beloved beverage. This stage involves the conversion of sugars derived from malted grains into alcohol and carbon dioxide, a process primarily driven by yeast.

In the initial phase of brewing, the malted grains are crushed and soaked in hot water in a process known as mashing. This mashing process extracts the sugars, primarily maltose, from the grains. The sweet liquid, now known as wort, is then separated from the spent grain and transferred to the brew kettle. Here, the real magic begins.

The brew kettle is where the wort is boiled, and this is the point where the fermentation process commences. During the boil, hops are added, contributing bitterness, flavor, and aroma to the beer. The boiling process also sterilizes the wort, creating an environment suitable for yeast to work its magic. As the wort cools, the yeast is introduced, and this is where the fermentation truly takes place.

The fermenter is the vessel in which the yeast ferments the sugars in the wort. Yeast, a microscopic organism, consumes the maltose and produces ethanol (alcohol) and carbon dioxide as byproducts. This process can take several days to a week, depending on the style of beer being brewed and the type of yeast used. During fermentation, the beer develops its characteristic flavors and aromas, which are influenced by the yeast strain and the brewing techniques employed.

After fermentation, the beer is ready for packaging or further conditioning. The carbon dioxide produced during fermentation is what gives beer its fizz, and it is this stage that determines the beer's final character. The brewmaster's skill lies in controlling the fermentation process, ensuring the beer's quality and consistency. This intricate dance of science and art is what makes brewing beer a fascinating and rewarding endeavor.

Taming the Tart: Tips to Smoothen Fruit Beer Before Fermentation

You may want to see also

Types of Yeast: Ale and lager yeasts produce different flavors and alcohol levels

The process of fermentation is fundamental to the production of beer, and at the heart of this process is yeast. Yeast is a microscopic organism that plays a crucial role in converting the sugars present in the malted grains into alcohol and carbon dioxide. This transformation is what gives beer its characteristic fizz and distinct flavor profiles. There are primarily two types of yeast used in brewing: ale yeast and lager yeast, each contributing unique characteristics to the final product.

Ale yeasts are known for their ability to ferment at warmer temperatures, typically ranging from 60°F to 75°F (15°C to 24°C). This type of yeast is responsible for the production of a wide range of beer styles, including pale ales, IPAs, and stouts. During fermentation, ale yeasts produce a more robust and fruity flavor profile, often resulting in beers with higher alcohol content. The esters produced by these yeasts contribute to the characteristic "ale" character, which can range from subtle to prominent, depending on the yeast strain and brewing techniques. For example, the famous British ale yeast, often used in traditional English ales, imparts a distinct fruity aroma and a smooth, full-bodied flavor.

On the other hand, lager yeasts thrive in cooler fermentation temperatures, usually between 50°F and 65°F (10°C to 18°C). Lagers, such as pilsners and helles, are produced using this type of yeast. Lager yeasts are known for their clean and crisp flavor, often resulting in beers with lower alcohol levels compared to ales. The fermentation process with lager yeasts is generally slower, allowing for a more gradual development of flavors. This slower fermentation also contributes to the crisp, refreshing character often associated with lagers.

The difference in fermentation temperatures and the resulting flavors and alcohol levels are primarily due to the unique metabolic processes of ale and lager yeasts. Ale yeasts, with their higher temperature tolerance, can undergo a more rapid fermentation, leading to the production of higher alcohol and fruity esters. In contrast, lager yeasts, adapted to cooler conditions, ferment at a slower pace, allowing for a more controlled and subtle flavor development.

Understanding the role of yeast in fermentation is essential for brewers to create the desired beer styles. By selecting the appropriate yeast strain, brewers can influence the flavor, aroma, and overall character of the beer. Ale yeasts offer a wide range of options for creating diverse beer profiles, while lager yeasts provide consistency and the classic crispness associated with lagers. This knowledge of yeast types and their effects is a cornerstone of the art and science of brewing.

The Science of Beer Fizz: Uncovering the Mystery

You may want to see also

Fermentation Time: Duration varies, typically 5-14 days, depending on yeast and recipe

Fermentation is a crucial process in brewing beer, transforming simple ingredients into the beloved beverage we all know and love. It is a natural process where yeast, a tiny microorganism, plays a vital role. This process involves breaking down sugars derived from malted grains, primarily barley, into alcohol and carbon dioxide. The duration of fermentation is a critical aspect of the brewing process, and it can vary significantly depending on several factors.

The length of fermentation is primarily determined by the type of yeast used. There are two main categories of yeast: ale yeast and lager yeast. Ale yeasts are generally faster, completing fermentation in a shorter time frame, typically around 5 to 7 days. These yeasts are known for their high-temperature fermentation, which results in a more robust and fruity flavor profile. On the other hand, lager yeasts are slower, taking 7 to 14 days or more to ferment. Lagers are characterized by their clean, crisp taste and are often used in traditional beer styles like pilsners and lagers.

The recipe or the specific ingredients used in the beer also influences fermentation time. Different beer styles require varying fermentation durations. For instance, a rich, dark stout may take longer to ferment due to its complex flavor profile and higher alcohol content. Conversely, a light, crisp wheat beer might ferment more quickly. Brewers carefully select yeast strains and adjust ingredient ratios to control the fermentation process, ensuring the desired beer style and quality.

During fermentation, the yeast consumes the sugars and produces alcohol and carbon dioxide. This process is exothermic, meaning it releases heat, which can significantly impact the yeast's activity. Brewers often monitor and control the temperature to optimize fermentation. Yeast activity slows down at lower temperatures, extending the fermentation time, while higher temperatures can speed up the process but may also lead to off-flavors or other issues.

Understanding the fermentation duration is essential for brewers to ensure the beer's quality and consistency. It allows them to schedule brewing processes, manage ingredients, and create the desired beer character. While the typical fermentation time for beer ranges from 5 to 14 days, this can vary widely, and brewers often experiment with different yeast strains and recipes to create unique and flavorful beer styles.

Mastering Fermentation: Tips for Raising Beer Bucket Temperatures

You may want to see also

Frequently asked questions

Fermentation is a crucial process in beer-making where yeast converts sugars derived from grains, typically malted barley, into alcohol and carbon dioxide. This process occurs in a controlled environment, often within the beer's fermentation vessel, and can take several days to a few weeks, depending on the beer style and desired characteristics.

Fermentation plays a significant role in developing the unique flavors and aromas associated with different beer styles. The type of yeast used and the fermentation conditions can influence the beer's taste, from fruity and estery to dry and crisp. For example, ale yeasts tend to produce more fruity esters, while lager yeasts result in cleaner, crisper profiles.

Top-fermenting yeasts, commonly used in ale brewing, thrive in warmer temperatures and float to the surface, where they can be easily separated from the beer. Bottom-fermenting yeasts, used in lager brewing, prefer cooler temperatures and sink to the bottom, requiring more complex separation methods.

Yes, fermentation can be controlled and paused to a certain extent. Brewers may use techniques like cooling the fermentation vessel or adding specific inhibitors to halt the process temporarily. This allows for the transfer of the partially fermented beer to another vessel for aging, carbonation, or further processing.

Fermentation is a fundamental step in most beer styles, but some variations, like lambics and certain wheat beers, may use spontaneous fermentation or wild yeasts, deviating from the traditional brewing process. These unique fermentation methods contribute to the diverse range of flavors and aromas found in the beer world.