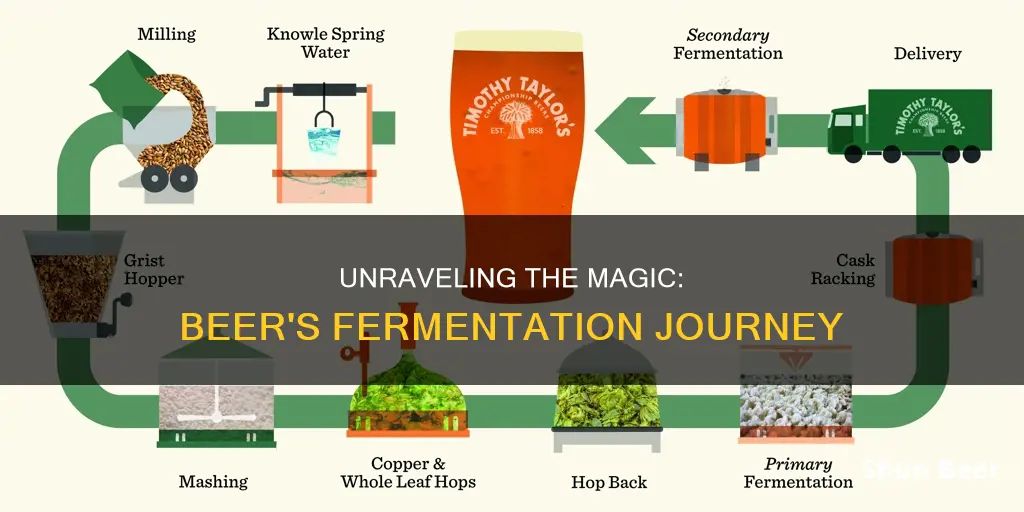

Beer fermentation is a crucial step in the brewing process, where the magic of transforming liquid malt extract into alcohol-infused beer begins. This process involves yeast, the unsung hero of fermentation, which feeds on sugars present in the wort, a sugary liquid extracted from malted grains. As yeast metabolizes these sugars, it produces alcohol and carbon dioxide, creating the beloved beverage we know as beer. The fermentation process can vary in duration and temperature, significantly impacting the beer's final character, from the crispness of a pale ale to the rich, dark flavors of a stout. Understanding the intricacies of fermentation is key to crafting the perfect brew.

What You'll Learn

- Yeast Metabolism: Yeast converts sugars into alcohol and carbon dioxide

- Fermentation Temperature: Optimal temperature range for yeast activity and flavor development

- Fermentation Time: Duration of fermentation affects beer's final alcohol content and clarity

- Yeast Strains: Different yeast strains produce unique flavors and aromas

- Carbonation: Carbon dioxide production contributes to beer's effervescence and mouthfeel

Yeast Metabolism: Yeast converts sugars into alcohol and carbon dioxide

Yeast metabolism is a fascinating process that lies at the heart of beer fermentation. This intricate biochemical transformation is primarily driven by yeast, a microscopic organism that plays a pivotal role in the brewing process. At its core, the yeast's metabolic activity revolves around a simple yet remarkable conversion: the transformation of sugars into alcohol and carbon dioxide. This process is not merely a chemical reaction but a complex series of biochemical events that occur within the yeast cells.

The yeast, specifically the species *Saccharomyces cerevisiae*, is an anaerobic microorganism, meaning it thrives in environments devoid of oxygen. In the context of beer fermentation, this characteristic is advantageous. When yeast is introduced to the sugary liquid known as wort, it begins its metabolic journey. The wort, derived from malted grains, contains a rich source of sugars, primarily maltose, which is the primary substrate for yeast's metabolic activities.

The conversion process commences with the yeast's ability to break down complex sugars. Enzymes secreted by the yeast, such as amylase, initiate the breakdown of maltose into simpler sugars like glucose and fructose. This initial step is crucial as it provides the yeast with the necessary energy source for subsequent metabolic reactions. As the yeast metabolizes these sugars, it enters a cycle of energy production, a process known as the glycolytic pathway. Here, glucose is converted into pyruvate, generating a small amount of ATP (adenosine triphosphate), the energy currency of cells.

However, the true magic of yeast metabolism unfolds in the subsequent steps. Pyruvate, the product of the glycolytic pathway, is then converted into alcohol (ethanol) and carbon dioxide through a process called fermentation. This is where the yeast's anaerobic nature comes into play. In the absence of oxygen, yeast employs an alternative pathway to generate energy, producing alcohol and CO2 as byproducts. This fermentation process is not only essential for the alcoholic content of beer but also for the carbonation, which is a desirable characteristic of many beer styles.

The alcohol produced during fermentation is a result of the yeast's ability to convert pyruvate into ethanol and carbon dioxide. This reaction is catalyzed by the enzyme pyruvate decarboxylase, which removes a carbon atom from pyruvate, forming acetaldehyde, and then further processes it to create ethanol and CO2. The carbon dioxide released during this process is what gives beer its characteristic fizz, making it a crucial aspect of the fermentation process.

In summary, yeast metabolism during beer fermentation is a complex and intricate process. It involves the breakdown of sugars, energy production through the glycolytic pathway, and the conversion of pyruvate into alcohol and carbon dioxide. This metabolic journey not only contributes to the unique flavor and character of beer but also showcases the remarkable adaptability of yeast in an anaerobic environment. Understanding these metabolic processes is essential for brewers to control and optimize the fermentation process, ultimately leading to the production of high-quality beer.

The Magic of Beer Bottles: How Bars Keep Beer Fresh

You may want to see also

Fermentation Temperature: Optimal temperature range for yeast activity and flavor development

Fermentation temperature plays a critical role in the beer-making process, significantly impacting yeast activity and flavor development. Yeast, the microorganism responsible for fermentation, thrives within a specific temperature range, and maintaining this range is essential for achieving the desired beer characteristics. The optimal temperature range for yeast activity in beer fermentation is generally considered to be between 65°F and 75°F (18°C and 24°C).

At these temperatures, yeast exhibits peak performance, efficiently converting sugars into alcohol and carbon dioxide. This process, known as ethanol fermentation, is fundamental to the beer-making process. During this phase, yeast consumes sugars derived from malted grains, producing alcohol and carbon dioxide as byproducts. The temperature range of 65°F to 75°F ensures that yeast remains active and healthy, facilitating a complete and efficient fermentation process.

Within this optimal temperature range, yeast undergoes various metabolic processes that contribute to flavor development. For instance, at these temperatures, yeast can produce a range of flavor compounds, including esters, which contribute to fruity aromas, and sulfur compounds, which can impart a slightly sour or 'brettanomyces' character to the beer. Additionally, yeast activity at these temperatures can influence the beer's color and body, as well as its overall mouthfeel and texture.

Maintaining the optimal fermentation temperature is crucial for achieving the desired beer style and character. Different beer styles often have specific temperature requirements during fermentation to enhance their unique flavor profiles. For example, ales typically ferment at warmer temperatures (around 68-72°F or 20-22°C) to promote estery and fruity notes, while lagers ferment at cooler temperatures (around 50-55°F or 10-13°C) to encourage cleaner, crisper flavors.

In summary, the optimal temperature range of 65°F to 75°F during beer fermentation is essential for yeast activity and flavor development. This temperature range ensures efficient sugar conversion, promotes the production of desired flavor compounds, and contributes to the overall character of the beer. Brewers must carefully control fermentation temperature to achieve the specific style and quality of beer they envision.

The Surprising Reason to Heat Your Beer with a Poker

You may want to see also

Fermentation Time: Duration of fermentation affects beer's final alcohol content and clarity

The duration of fermentation plays a crucial role in the transformation of beer, significantly impacting its final alcohol content and clarity. This process, which involves yeast converting sugars into alcohol and carbon dioxide, is a delicate balance that brewers carefully manage. Longer fermentation periods generally result in higher alcohol content, as the yeast has more time to work on the available sugars, producing a stronger, more robust beer. This is particularly evident in styles like Belgian Tripels and Imperial Stouts, where extended fermentation contributes to their high alcohol by volume (ABV) levels.

However, the length of fermentation also influences the beer's clarity. In shorter fermentation processes, the beer may retain more of its original clarity, as the yeast has less time to produce sediment and cloudiness. This is often desirable in lighter, more sessionable beers, where a clear appearance is appreciated. Conversely, longer fermentation times can lead to a hazy or cloudy appearance, which is common in styles like wheat beers and certain IPAs, where a cloudy, hazy look is often considered a sign of quality and authenticity.

The impact of fermentation time on beer's final characteristics is a result of the yeast's activity and the beer's overall stability. During extended fermentation, the yeast continues to metabolize sugars, reducing the overall sugar content and contributing to a drier, more alcoholic finish. This process also encourages the development of complex flavors and aromas, as the yeast interacts with the beer's components, creating a more nuanced and sophisticated beer.

Brewers often employ various techniques to control fermentation duration, such as adjusting yeast types and temperatures. For instance, using a higher-temperature yeast can speed up fermentation, while a cooler environment might encourage a slower, more controlled process. Additionally, the initial gravity of the wort (the sugar solution before fermentation) can influence the fermentation rate, with higher gravity worts typically resulting in faster fermentation times.

In summary, the fermentation time is a critical factor in beer production, offering brewers the ability to craft beers with specific alcohol levels and clarity. By understanding and manipulating this process, artisans can create a wide range of beer styles, each with its unique characteristics, ensuring there's a beer for every taste and preference.

Beer Cap Table: A Guide to Decorating with Caps

You may want to see also

Yeast Strains: Different yeast strains produce unique flavors and aromas

Yeast strains play a pivotal role in the fermentation process of beer, significantly influencing the final flavor profile and aroma of the beverage. Different strains of yeast possess distinct characteristics, leading to a wide array of beer styles and flavors. During fermentation, yeast consumes sugars present in the wort, a sugary liquid extracted from malted grains, and converts them into alcohol and carbon dioxide. This process is fundamental to beer production, and the choice of yeast can dramatically alter the outcome.

One of the most well-known yeast strains is Saccharomyces cerevisiae, commonly referred to as ale yeast. This strain is widely used in the production of a variety of beers, including lagers, pale ales, and wheat beers. Ale yeasts are known for their high fermentation temperatures, typically ranging from 55°F to 75°F (13°C to 24°C). During fermentation, these yeasts produce a range of esters, which contribute to the fruity and floral aromas often associated with ales. For instance, the presence of ethyl acetate, a common ester, can impart a characteristic apple or banana-like scent to the beer.

In contrast, lager yeasts, such as Saccharomyces pastorianus, are used for brewing lagers and pilsners. These yeasts ferment at lower temperatures, usually between 45°F and 60°F (7°C to 15°C). The result is a cleaner, crisper flavor profile compared to ales. Lager yeasts produce fewer esters, leading to a more neutral base note, which allows other ingredients, such as hops, to shine through. The use of specific yeast strains is a critical aspect of brewing, as it enables brewers to create beers with distinct characteristics and unique selling points.

Beyond the flavor and aroma, yeast strains also impact the mouthfeel and overall drinking experience of beer. Some yeasts contribute to a smoother, creamier texture, while others may add a hint of spice or a dry finish. For example, the use of Brettanomyces yeasts in certain beer styles can introduce a range of unique flavors, including fruity, spicy, and even slightly sour notes. This diversity in yeast strains allows brewers to experiment and innovate, creating beers that cater to a wide range of consumer preferences.

In summary, the selection of yeast strains is a critical decision in the beer-making process, as it directly influences the beer's flavor, aroma, and overall character. Different yeast strains offer brewers a palette of options to craft beers that are unique, memorable, and appealing to a diverse market. Understanding the characteristics of various yeast strains is essential for both novice and experienced brewers to create exceptional beers.

The Surprising Reason Paper Towels Are Placed on Beer

You may want to see also

Carbonation: Carbon dioxide production contributes to beer's effervescence and mouthfeel

The process of carbonation in beer is a fascinating aspect of fermentation, where the magic of bubbles is created. During the fermentation process, yeast plays a crucial role in converting sugars present in the wort (the sugary liquid extracted from malted grains) into alcohol and carbon dioxide (CO2). This CO2 is produced as a byproduct of the yeast's metabolic activities. The yeast feeds on the sugars, primarily maltose, and through a series of biochemical reactions, it breaks down these complex carbohydrates, releasing energy and producing alcohol and CO2.

As the yeast works its magic, the CO2 bubbles begin to form within the wort. This happens because the CO2 molecules are released into the liquid, and due to the low solubility of CO2 in water, they start to accumulate and form tiny bubbles. The more active the yeast, the more CO2 is produced, leading to a higher level of carbonation. This is why the health and vitality of the yeast culture are critical to achieving the desired level of carbonation.

The carbonation level in beer is carefully controlled during the brewing process. Brewers adjust the yeast strain, fermentation temperature, and duration to influence the amount of CO2 produced. Higher temperatures generally lead to more rapid fermentation and increased CO2 production, resulting in a more effervescent beer. Conversely, lower temperatures can slow down fermentation, allowing for more controlled carbonation levels.

Once the beer is fermented, the CO2 is trapped within the liquid, contributing to its effervescence. This is achieved through a process called carbonation stabilization, where the beer is placed under pressure, forcing the CO2 to dissolve into the liquid. The beer is then packaged, and the CO2 remains dissolved, providing the refreshing fizz that beer enthusiasts love.

The mouthfeel of a beer is also significantly influenced by carbonation. A well-carbonated beer has a refreshing, crisp sensation on the palate, enhancing the overall drinking experience. The fine bubbles on the tongue and in the mouth create a pleasant tingling sensation, which is a direct result of the dissolved CO2. This aspect of beer quality is often overlooked but is a key factor in the sensory appeal of the beverage.

The Surprising Effect of Eye Drops in Beer: A Tasty Experiment

You may want to see also

Frequently asked questions

Beer fermentation is a crucial step in the brewing process where yeast plays a vital role in converting sugars derived from malted grains into alcohol and carbon dioxide. This process occurs in two main stages: primary and secondary fermentation. During primary fermentation, the yeast consumes the sugars present in the wort (the sugary liquid extracted from malted grains) and produces alcohol and carbon dioxide. This stage typically takes a few days to a week. Secondary fermentation, if desired, can be used to refine the beer's flavor and clarity, often involving the addition of flavors or further aging.

Temperature control is critical during fermentation as it significantly impacts the yeast's activity and the beer's final characteristics. Yeast fermentation is an enzyme-catalyzed process, and different yeast strains have optimal temperature ranges. Generally, ale yeasts thrive in warmer temperatures (around 65-75°F or 18-24°C), while lager yeasts prefer cooler temperatures (around 50-55°F or 10-13°C). Maintaining the appropriate temperature range ensures proper fermentation, efficient carbonation, and the desired flavor profile.

Yeast is the key microorganism responsible for fermentation in beer brewing. There are two primary types of yeast used: ale yeasts and lager yeasts. Ale yeasts, such as Saccharomyces cerevisiae, are used for ale fermentation, which typically results in fruity and estery flavors. Lager yeasts, like Saccharomyces pastorianus, are employed for lager fermentation, producing cleaner and crisper beers. Yeast strains can vary in their fermentation characteristics, affecting the beer's flavor, aroma, and overall quality. Proper yeast selection and management are essential for achieving the desired beer style and characteristics.