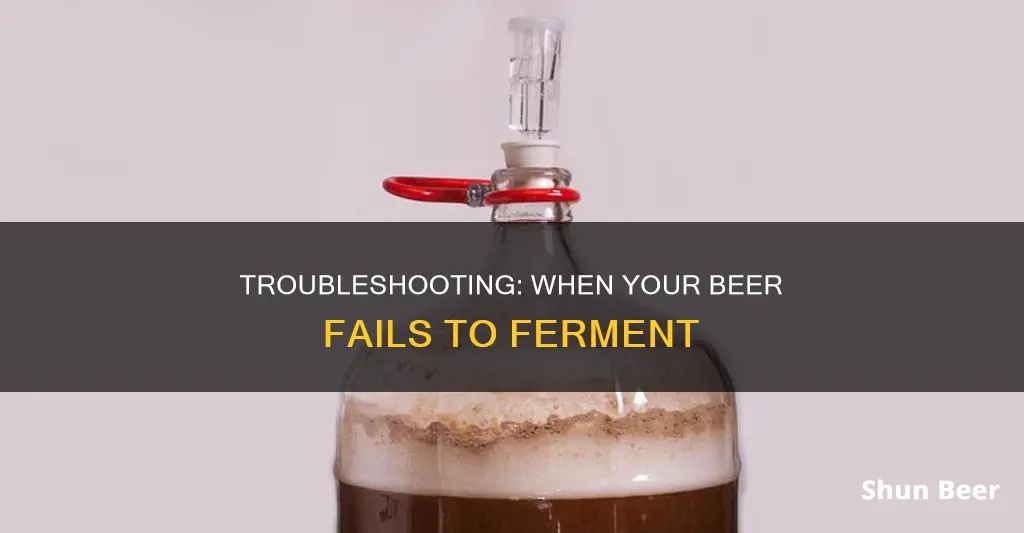

If you've ever brewed beer and encountered a situation where fermentation doesn't occur as expected, it can be frustrating and confusing. Understanding the potential reasons behind this issue and knowing how to troubleshoot it is crucial for any homebrewer. In this paragraph, we'll explore common causes of non-fermentation, such as issues with yeast, temperature control, or ingredient quality, and provide practical steps to address these problems. By the end, you'll have a clearer idea of how to get your beer fermenting and ensure a successful brewing process.

What You'll Learn

- Check Ingredients: Verify all ingredients are fresh and properly measured

- Temperature Control: Ensure fermentation temperature is optimal and consistent

- Oxygen Management: Avoid excessive oxygen exposure during fermentation

- Yeast Health: Use healthy yeast and monitor its activity

- Fermentation Time: Allow sufficient time for fermentation to complete

Check Ingredients: Verify all ingredients are fresh and properly measured

When dealing with a beer that doesn't ferment, one of the first steps is to carefully examine the ingredients used in the brewing process. This is a crucial step that can help identify potential issues and ensure the quality of your final product. Here's a detailed guide on how to verify the ingredients:

Ingredient Freshness: Start by checking the freshness of all the ingredients. Yeast, for example, is a live organism and its viability is crucial for fermentation. Check the yeast's expiration date and ensure it is not past its prime. Similarly, inspect other ingredients like hops, malt, and water for any signs of spoilage or degradation. Fresh ingredients are essential to maintain the desired flavor and aroma in your beer.

Precision in Measurement: Accurate measurement of ingredients is vital for successful fermentation. Go through your recipe and double-check that all ingredients were measured correctly. Even a slight miscalculation can significantly impact the fermentation process. Pay attention to the weight and volume of each ingredient, especially when using a scale for precise measurements. Consistency in measurements ensures that the beer's flavor profile remains consistent and predictable.

Water Quality: Water is a fundamental component in brewing, and its quality can greatly affect fermentation. Test your water for mineral content and pH levels. Different beer styles may require specific water profiles, so ensure that your water chemistry aligns with the desired recipe. Adjusting water chemistry can sometimes be necessary to promote healthy yeast activity and optimal fermentation conditions.

Sanitation: Proper sanitation is often overlooked but plays a critical role in fermentation. Ensure that all equipment and ingredients are clean and sanitized before use. Contaminants can hinder fermentation and introduce off-flavors. Pay attention to cleaning your fermenter, bottles, and any other brewing gear to create a sterile environment for the yeast to work its magic.

By thoroughly checking the ingredients and following these steps, you can identify potential issues and take corrective actions to improve the fermentation process. This attention to detail will contribute to the overall success of your beer-making endeavor.

The Art of Flavoring Beer: When and Why

You may want to see also

Temperature Control: Ensure fermentation temperature is optimal and consistent

Temperature control is a critical aspect of the brewing process, especially when troubleshooting why your beer might not be fermenting as expected. Fermentation is a delicate process where yeast consumes sugars and produces alcohol and carbon dioxide. This process is highly sensitive to temperature variations, and maintaining the right conditions is essential for successful fermentation. Here's a detailed guide on how to ensure optimal and consistent temperature control during the fermentation process:

Understanding the Ideal Fermentation Temperature: Different beer styles have specific temperature requirements for optimal fermentation. Generally, most beer fermentations thrive in a temperature range of 65°F to 75°F (18°C to 24°C). At this range, yeast activity is vigorous, and the fermentation process proceeds efficiently. If the temperature is too low, fermentation slows down, and if it's too high, it can lead to off-flavors and potential yeast death.

Monitoring and Maintaining Temperature: Accurate temperature monitoring is crucial. Invest in a reliable brewing thermometer and regularly check the temperature of your fermenter. Place the thermometer in the middle of the fermenter to get an accurate reading of the liquid's temperature. If you're using a cooler, ensure it's set to the desired temperature and maintain a consistent airflow to prevent temperature fluctuations.

Consistency is Key: Consistency in temperature is vital. Try to keep the fermentation temperature as stable as possible. Sudden temperature changes can shock the yeast and disrupt the fermentation process. If you need to adjust the temperature, do it gradually. For example, if you're using a heat source, slowly increase the temperature over a few hours, and if cooling is required, allow the yeast to adapt to the cooler temperature gradually.

Using Temperature-Controlled Equipment: Consider investing in temperature-controlled brewing equipment, such as a fermentation chamber or a temperature-controlled fermenter. These devices maintain a consistent temperature, ensuring that your beer ferments optimally. They are especially useful for home brewers who want precise control over the fermentation environment.

Troubleshooting Temperature Issues: If you suspect temperature-related issues are hindering fermentation, here are some steps to take: First, check your yeast's viability and ensure it's fresh and active. Second, verify that your brewing water is at the correct pH and mineral content, as this can impact yeast performance. Finally, inspect your brewing equipment for any issues that might affect temperature, such as blocked pipes or faulty cooling systems.

By implementing these temperature control measures, you can create an optimal environment for yeast fermentation, leading to a successful beer brewing process and a delicious final product. Remember, consistency and attention to detail are key when it comes to temperature management in brewing.

Brewing Basics: Adding Oxygen to Your Beer for a Crisp, Refreshing Flavor

You may want to see also

Oxygen Management: Avoid excessive oxygen exposure during fermentation

Oxygen management is a critical aspect of brewing that can significantly impact the fermentation process and the final quality of your beer. While oxygen is essential for yeast to perform its magical transformation of sugars into alcohol, an excess of this element can be detrimental. When it comes to fermentation, the goal is to create an environment that encourages the yeast to work efficiently without overwhelming it.

During the fermentation process, yeast cells are highly sensitive to oxygen levels. Excessive oxygen exposure can lead to a phenomenon known as "oxygen toxicity," where the yeast cells are damaged or killed, halting the fermentation process. This can result in a stuck fermentation, where the beer fails to reach its desired alcohol content and may even exhibit off-flavors. To avoid this, brewers must be mindful of the oxygen levels in their wort.

One effective way to manage oxygen exposure is by using an airlock. An airlock allows carbon dioxide to escape while preventing oxygen from entering the fermenter. This simple device is a crucial component of any brewing setup, especially for beginners. By ensuring a tight seal with the airlock, you create an anaerobic environment, which is ideal for yeast fermentation. Regularly check the airlock to ensure it functions properly, as a clogged airlock can introduce oxygen and disrupt the fermentation.

Additionally, the choice of fermentation vessel plays a role in oxygen management. Glass carboys, for instance, are transparent and may allow some light to pass through, potentially increasing oxygen exposure. In contrast, plastic or stainless steel fermenters are more opaque and provide better protection against light, reducing the risk of oxygen contamination. When using glass carboys, consider adding a small amount of isinglass or other fining agents to the wort, which can help absorb any residual oxygen.

Lastly, proper sanitization techniques are essential to prevent any unwanted microbial activity that could compete with or inhibit the yeast's fermentation process. Sanitize all equipment and containers before use to eliminate any potential sources of contamination. This includes rinsing with hot water and using a suitable sanitizer, ensuring that the yeast has a clear path to ferment the sugars without interference. By implementing these oxygen management strategies, you can create an optimal environment for yeast fermentation, increasing the chances of a successful beer-making process.

Beer Traps for Slugs: The Optimal Frequency

You may want to see also

Yeast Health: Use healthy yeast and monitor its activity

Using healthy yeast is crucial for successful fermentation in beer brewing. Yeast is the microorganism responsible for converting sugars into alcohol and carbon dioxide, and its health directly impacts the quality and character of the final product. Here's a guide on how to ensure yeast health and monitor its activity:

Select High-Quality Yeast: Start by choosing reputable yeast sources. Opt for commercially available brewing yeasts specifically designed for ale or lager fermentation. These yeasts are typically laboratory-cultured and tested for optimal performance. Avoid wild yeast strains or those with limited documentation, as they may lack the necessary consistency and reliability.

Storage and Activation: Proper storage and activation of yeast are essential. Always store yeast packets in a cool, dry place, away from direct sunlight. Once you're ready to brew, activate the yeast by rehydrating it in warm water. Follow the instructions provided by the yeast manufacturer for the optimal water temperature and activation time. This step ensures that the yeast is active and ready to ferment.

Monitor Yeast Activity: Throughout the fermentation process, closely observe the yeast's activity. Healthy yeast should be active and visible, forming a dense, frothy head on the wort (the sugary liquid before fermentation). If the yeast appears inactive or there is a lack of foam, it may indicate an issue with the yeast's health or the fermentation environment.

Maintain Optimal Conditions: Yeast thrives in specific temperature and nutrient conditions. Ensure that your fermentation vessel is at the appropriate temperature for your chosen yeast strain. Most brewing yeasts prefer a range of 65-75°F (18-24°C). Additionally, provide a balanced nutrient environment by using a good-quality yeast nutrient or a properly formulated brewing water.

Regularly Check for Contamination: Contamination can significantly impact fermentation. Regularly inspect the yeast and fermentation vessel for any signs of contamination, such as off- odors, colors, or the presence of other microorganisms. Sanitize your equipment and practice good hygiene to minimize the risk of contamination.

Monitor Fermentation Progress: Keep an eye on the fermentation progress by regularly taking gravity readings. This will help you determine if the yeast is actively consuming sugars and producing alcohol. If fermentation stalls or slows down significantly, it may be a sign of yeast health issues or other problems, requiring further investigation and potential adjustments.

By focusing on yeast health and closely monitoring its activity, you can ensure a successful fermentation process and ultimately produce high-quality beer. Remember, healthy yeast is the foundation of a great brew!

Exploding Engines: The Dangers of Pouring Beer in Your Gas Tank

You may want to see also

Fermentation Time: Allow sufficient time for fermentation to complete

Fermentation is a crucial process in brewing beer, and it's essential to understand that it requires time and patience. If your beer doesn't ferment as expected, it could be due to various factors, and one of the primary reasons is insufficient fermentation time. Here's a detailed guide on how to address this issue:

Understanding Fermentation: Fermentation is the magical process where yeast transforms sugars derived from malt into alcohol and carbon dioxide. This transformation is a delicate balance of science and art. Yeast, the star player in this process, requires specific conditions to thrive and complete the fermentation cycle. It's a time-sensitive process, and rushing it might lead to incomplete or faulty fermentation.

The Importance of Time: Allowing adequate fermentation time is vital for several reasons. Firstly, it ensures that the yeast has enough time to consume all the available sugars, resulting in a balanced and flavorful beer. Incomplete fermentation can lead to a range of issues, including off-flavors, higher alcohol content, and a lack of carbonation. Secondly, sufficient fermentation time allows for the development of the beer's character and aroma, ensuring a well-rounded and enjoyable drinking experience.

Signs of Insufficient Fermentation: There are several indicators that your beer might not be fermenting properly. One common sign is a lack of carbonation, which can be a result of insufficient yeast activity. You might also notice that the beer remains cloudy or has an off-taste, suggesting that the yeast hasn't had enough time to work its magic. Additionally, monitoring the specific gravity of your beer regularly can provide valuable insights. If the specific gravity doesn't drop significantly over time, it could indicate a problem with fermentation.

Troubleshooting and Solutions: If you suspect that your beer isn't fermenting adequately, there are a few steps you can take. Firstly, ensure that your yeast is active and healthy. Check the yeast's freshness and storage conditions, as stale or damaged yeast can hinder fermentation. Consider using a different yeast strain if you're consistently facing fermentation issues. Secondly, maintain a consistent temperature during fermentation. Yeast thrives in specific temperature ranges, and deviations can slow down or halt the process. Finally, monitor the fermentation process closely. Take regular samples to check for signs of fermentation, and adjust your brewing process accordingly.

Remember, fermentation is a natural process, and it requires time and care. By allowing sufficient fermentation time, you'll be rewarded with a well-fermented, delicious beer. Always be mindful of the yeast's needs and adjust your brewing techniques to ensure a successful fermentation every time.

Unraveling Beer's Magic: The Three Fermentation Phases Explained

You may want to see also

Frequently asked questions

If your beer is not fermenting, it could be due to several reasons, such as an issue with the yeast, temperature control, or ingredient ratios. First, ensure that you are using the correct yeast strain for the style of beer you are brewing. Check the yeast's activation temperature and make sure the brewing water is within the appropriate pH range. Fermentation temperature is crucial; if it's too cold, the yeast may be inactive, and if it's too warm, it can lead to off-flavors. Monitor the fermentation process and adjust the temperature accordingly. If the beer still doesn't ferment after a few days, consider using a different yeast or seeking advice from experienced brewers or online brewing communities for troubleshooting tips.

Troubleshooting a non-fermenting beer can be a process of elimination. Start by checking the ingredients and their measurements. Ensure that the grain bill and water chemistry are correct for the style. Verify that the yeast is viable and active by performing a yeast health check. Look for signs of contamination, such as a cloudy appearance or off-odors, which could indicate a problem with the brewing process or equipment. If the yeast is active, consider adjusting the fermentation temperature or using a different yeast strain. It's also essential to maintain proper sanitation throughout the brewing process to prevent any unwanted microbial activity.

Yes, there are a few common mistakes that brewers should avoid to ensure successful fermentation. One is not allowing enough time for the yeast to work; some yeast strains require more time to ferment than others. Another mistake is over-oxygenating the wort during the brewing process, which can lead to off-flavors and potential contamination. Additionally, using old or compromised yeast can result in poor fermentation. Always store yeast properly and follow the instructions provided by the yeast manufacturer. Lastly, not monitoring the fermentation process and making necessary adjustments can lead to a stuck fermentation, so regular checks are essential.