If your beer-making endeavor hits a snag when fermentation stalls, it's crucial to act swiftly. Understanding the potential causes, such as temperature fluctuations or yeast issues, is key. You might need to adjust the fermentation temperature or even restart the process with fresh yeast. Patience and careful monitoring are essential, as is consulting brewing resources or experts for tailored advice to get your beer back on track.

What You'll Learn

- Temperature Control: Check and adjust fermentation temperature to ensure yeast activity

- Oxygen Management: Limit oxygen exposure to prevent off-flavors and stalling fermentation

- Nutrient Supplementation: Add yeast nutrients to support yeast health and fermentation completion

- Fermentation Time: Monitor and manage fermentation duration for optimal beer flavor

- Troubleshooting Yeast Issues: Identify and address yeast problems like dead yeast or poor nutrition

Temperature Control: Check and adjust fermentation temperature to ensure yeast activity

If your beer fermentation process stalls, temperature control is a critical factor to address. Yeast, the microorganism responsible for fermentation, is highly sensitive to temperature variations. When the temperature is too low, yeast activity slows down, and fermentation can halt. Conversely, high temperatures can also inhibit yeast function and may even kill the yeast cells. Therefore, maintaining an optimal temperature range is essential to ensure the yeast's vitality and the successful completion of the fermentation process.

The ideal temperature range for yeast fermentation varies depending on the specific yeast strain. For most ale yeasts, a temperature range of 65–75°F (18–24°C) is generally recommended. Lager yeasts, on the other hand, thrive in slightly cooler conditions, typically between 50–60°F (10–15°C). It's crucial to monitor the temperature regularly and make adjustments as needed to keep the yeast active and healthy.

One effective method to control temperature is by using a fermentation chamber or a dedicated fermentation refrigerator. These appliances provide precise temperature control, ensuring the yeast remains within the optimal range throughout the fermentation process. If you don't have access to such specialized equipment, you can use a simple technique like placing the fermenter in a larger container filled with warm water. This method helps regulate the temperature by absorbing heat from the surrounding environment.

Additionally, monitoring the temperature of the wort (the sugary liquid extracted from the grains) is essential. If the wort temperature is too high, it can stress the yeast and potentially kill them. Similarly, if it's too cold, the yeast may become inactive. Aim to keep the wort temperature within a degree or two of the desired fermentation temperature. You can use a precision thermometer to accurately measure and adjust the temperature.

In summary, temperature control is a critical aspect of troubleshooting beer fermentation issues. By maintaining the appropriate temperature range, you can ensure the yeast's optimal performance, leading to a successful fermentation process and a well-crafted beer. Regular monitoring and adjustments will help you achieve the desired results.

Fermenting Beer: Optimal Storage Solutions for Your Brew

You may want to see also

Oxygen Management: Limit oxygen exposure to prevent off-flavors and stalling fermentation

Oxygen management is a critical aspect of brewing that can significantly impact the flavor and quality of your beer. When it comes to preventing off-flavors and stalling fermentation, limiting oxygen exposure is key. Here's a detailed guide on how to manage oxygen in your brewing process:

Understanding the Issue:

Oxygen can be a double-edged sword in brewing. While a small amount is necessary for yeast to perform its magic, excess oxygen can lead to several problems. It can cause oxidation, resulting in off-flavors and aromas, and it may also lead to a phenomenon known as "stalling" or "lagging" fermentation. This occurs when the yeast becomes inactive or stressed, causing the fermentation process to slow down or halt.

Managing Oxygen Exposure:

- Use Oxygen-Free Equipment: Start by ensuring that your brewing equipment is free from oxygen. This includes using oxygen-free water, which can be achieved by boiling and cooling water in an oxygen-free environment or by using deionized water. Additionally, consider using oxygen-free containers and tubing for transferring and storing beer.

- Sanitize Thoroughly: Proper sanitation is essential to prevent any unwanted microbial activity that might consume oxygen and affect the fermentation process. Use sanitizers like iodine or bromine solutions to ensure a clean and oxygen-free environment. Pay close attention to surfaces, equipment, and utensils that come into contact with the beer.

- Airlock Fermentation: When transferring beer to the fermenter, use an airlock to create an anaerobic environment. An airlock allows carbon dioxide to escape while preventing oxygen from entering. This simple technique can significantly reduce oxygen exposure during the fermentation process.

- Minimize Aeration: During the brewing process, especially when adding ingredients or making adjustments, be mindful of aeration. Avoid excessive stirring or agitation that might introduce oxygen into the beer. Use a gentle hand and minimize the time the beer is exposed to air.

- Consider Yeast Type: Different yeast strains have varying oxygen requirements. Some yeasts, like ale yeasts, are more sensitive to oxygen and may benefit from additional precautions. Research the specific yeast you're using and adjust your oxygen management strategy accordingly.

Troubleshooting:

If you suspect that oxygen exposure is causing issues, there are a few signs to look out for. Off-flavors such as metallic, cardboard-like, or "green" tastes may indicate oxidation. Stalling fermentation, where the yeast slows down or stops, can be a result of excessive oxygen. In such cases, consider reducing the amount of oxygen in your system and monitoring the fermentation closely.

Mastering oxygen management is an art in brewing, and it requires attention to detail and a systematic approach. By limiting oxygen exposure, you can ensure a successful fermentation and a beer that tastes as intended. Remember, the goal is to provide just enough oxygen for yeast activity while minimizing the risk of off-flavors and fermentation stalls.

BudLight's Ingredient List: Unveiling the Mystery Behind the Beer

You may want to see also

Nutrient Supplementation: Add yeast nutrients to support yeast health and fermentation completion

If your beer fermentation process stalls, nutrient supplementation with yeast nutrients can be a crucial step to get the process back on track. Yeast nutrients provide essential elements that may be lacking in your brewing environment, helping to support yeast health and ensure fermentation completion. Here's a detailed guide on how to approach this:

Understanding Yeast Nutrient Requirements: Yeast, like any living organism, has specific nutritional needs. These requirements can vary depending on the yeast strain and the brewing conditions. Yeast nutrients typically include vitamins, minerals, and amino acids that are essential for yeast growth and fermentation. Common yeast nutrients include vitamin B complexes, magnesium, sulfur, and various trace elements. Understanding the specific needs of your yeast strain is key to successful supplementation.

Identifying Nutrient Deficiencies: Before adding nutrients, it's important to identify any potential deficiencies. You can do this by analyzing the brewing water profile and the yeast's performance. If the yeast is not showing signs of stress or slow fermentation, it might indicate a lack of specific nutrients. For example, a deficiency in magnesium can lead to slow fermentation, while a lack of sulfur can affect yeast activity. Testing the yeast's growth rate and fermentation speed can help pinpoint these issues.

Adding Yeast Nutrients: Once you've identified the nutrient deficiencies, it's time to add the appropriate supplements. Yeast nutrients are typically available in liquid or dry forms, making them easy to incorporate into your brewing process. Here's a general approach:

- Liquid Nutrients: Add a small amount of liquid yeast nutrient solution to the wort before or during the boil. This allows the nutrients to dissolve and be readily available to the yeast. Follow the instructions on the nutrient package for the correct dosage.

- Dry Nutrients: If using dry yeast nutrients, sprinkle them over the wort before or after pitching the yeast. Ensure the nutrients are evenly distributed throughout the wort.

- Regular Monitoring: After adding the nutrients, closely monitor the fermentation process. Yeast health and activity should improve, leading to a more robust and efficient fermentation.

Benefits of Nutrient Supplementation: Providing yeast with the necessary nutrients can have several advantages. Firstly, it can prevent yeast stress and improve overall yeast health, making the yeast more resilient to varying brewing conditions. Secondly, nutrient supplementation can enhance yeast activity, leading to faster fermentation times. This is particularly beneficial if you're working with high-gravity brews or yeast strains that are known to be sensitive to nutrient deficiencies.

Prevention and Maintenance: To ensure consistent fermentation, consider making nutrient supplementation a regular part of your brewing routine. Regularly testing your yeast's performance and adjusting nutrient levels accordingly can help maintain a healthy brewing environment. Additionally, keeping a record of your yeast nutrient additions and their effects can provide valuable insights for future brews.

Secondary Fermentation: Why and How to Use a Secondary Fermenter for Beer

You may want to see also

Fermentation Time: Monitor and manage fermentation duration for optimal beer flavor

Monitoring and managing the fermentation process is crucial for achieving the desired flavor and quality in your beer. Fermentation time can vary depending on several factors, including the style of beer, yeast type, and ingredient composition. While some beers may ferment quickly, others might take longer, and it's essential to understand the typical fermentation range for your specific beer recipe.

The duration of fermentation is directly linked to the yeast's activity and the beer's overall health. Yeast plays a vital role in breaking down sugars and converting them into alcohol and carbon dioxide. During this process, it's essential to maintain optimal conditions for yeast growth and activity. A typical fermentation process can range from one to two weeks for simple lagers to several weeks for more complex styles like stouts or wheat beers. However, it's not uncommon for beers to ferment faster or slower than expected.

To ensure optimal flavor development, it's crucial to monitor the fermentation process closely. Regularly check the beer's temperature, as yeast activity is temperature-sensitive. Most yeast strains thrive in a specific temperature range, typically around 65-75°F (18-24°C). If the temperature deviates significantly, it can impact fermentation speed and quality. Use a fermentation thermometer to accurately measure and maintain the desired temperature.

Another critical aspect is the yeast's feeding schedule. Yeast requires a steady supply of nutrients to function optimally. Ensure you provide the appropriate yeast food or nutrient source according to the recipe guidelines. This step is especially important for high-gravity beers or those with complex flavor profiles, as it can enhance fermentation efficiency and flavor development.

Additionally, keep an eye on the beer's clarity and appearance. During fermentation, the beer should become clearer as the yeast settles and the sediment is separated. If the beer remains hazy or cloudy, it might indicate incomplete fermentation or the presence of wild yeast strains. In such cases, consider extending the fermentation time or taking corrective measures to address the issue.

Managing fermentation time is an art that requires practice and experimentation. By closely monitoring temperature, yeast activity, and beer clarity, you can fine-tune the process and produce beers with exceptional flavor profiles. Remember, each batch of beer is unique, and understanding the nuances of fermentation will help you create remarkable brews.

Mastering the Art of Beer Fermentation: A Visual Guide

You may want to see also

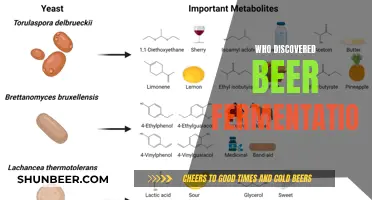

Troubleshooting Yeast Issues: Identify and address yeast problems like dead yeast or poor nutrition

When dealing with yeast issues in beer fermentation, it's crucial to identify the problem early on to ensure a successful brew. One common issue is dead yeast, which can occur due to various factors such as improper storage, excessive heat, or poor yeast health. If you suspect dead yeast, there are a few signs to look out for. Firstly, check the appearance of the yeast; if it appears clumpy, cloudy, or has a foul odor, it may indicate that the yeast is no longer active. Another telltale sign is a lack of fermentation activity; if the beer doesn't start bubbling or shows minimal activity after the expected fermentation time, it's a strong indicator of dead yeast.

To address dead yeast, you have a few options. One approach is to restart the fermentation process by using a new batch of yeast. This involves pitching a fresh yeast culture into your beer, ensuring that you follow the specific instructions for the yeast strain you're using. It's essential to maintain proper yeast storage and handling practices to prevent this issue in the future. Keep your yeast refrigerated and always follow the manufacturer's guidelines for rehydration and pitching rates.

Poor nutrition is another potential cause of yeast issues. Yeast requires specific nutrients to thrive and perform its fermentation duties effectively. If your yeast is not receiving adequate nutrition, it may struggle to complete the fermentation process. Common signs of poor nutrition include slow fermentation, off-flavors, and a lack of carbonation. To improve yeast nutrition, consider adding a yeast nutrient blend to your beer during the brewing process. This blend typically includes essential minerals and vitamins that yeast needs to ferment efficiently.

Additionally, ensuring that your brewing water is properly treated and has the right mineral content can significantly impact yeast health. Hard water with higher mineral content can provide the necessary nutrients, while soft water may require the addition of specific minerals like calcium and magnesium. Regularly monitoring and adjusting your water chemistry can help create an optimal environment for yeast fermentation.

In summary, troubleshooting yeast issues requires a systematic approach. Dead yeast can be revived by restarting the fermentation with fresh yeast, while poor nutrition can be addressed by providing the necessary nutrients through yeast blends and proper water treatment. By identifying and rectifying these problems, you can ensure a successful beer fermentation and avoid the disappointment of a beer that doesn't ferment properly. Remember, proper yeast management and nutrition are key to achieving the desired beer flavor and quality.

The Great Beer Conundrum: To Add 'S' or Not to Add 'S

You may want to see also

Frequently asked questions

Beer fermentation is a process that relies on yeast to convert sugars into alcohol and carbon dioxide. If your beer has stopped fermenting, it could be due to several reasons. Common causes include using inactive or unhealthy yeast, incorrect yeast temperature, insufficient yeast, or a lack of oxygen during the fermentation process.

If you suspect your beer is stuck, there are a few troubleshooting steps you can take. First, ensure that the yeast is active and healthy by using a yeast starter or rehydrating the yeast according to the package instructions. Maintain a consistent temperature in the fermentation vessel and monitor the fermentation progress. If the issue persists, consider adding a small amount of nutrients or enzymes to stimulate the yeast.

Carbonation is an essential aspect of beer, and if your beer is not carbonating, it might be due to a few factors. Check the fermentation process to ensure it was completed successfully. If the beer is still in the fermentation stage, wait for the yeast to complete the process. After fermentation, transfer the beer to a secondary fermenter and add a small amount of sugar to encourage natural carbonation.

Yes, there are ways to revive a stalled fermentation. One method is to use a new batch of yeast, ensuring it is fresh and active. Maintain a controlled temperature and monitor the fermentation closely. You can also try adding a small amount of yeast nutrient or a specific enzyme blend designed for stuck fermentations. Always follow the instructions provided by the yeast manufacturer for the best results.