When is beer fermentation complete? Beer fermentation is a crucial process in brewing, where yeast converts sugars into alcohol and carbon dioxide. However, determining when fermentation is complete can be a complex and nuanced task. Factors such as yeast type, starting gravity, temperature control, and desired beer style all play a role in the fermentation timeline. While some beers may ferment out in a few days, others can take weeks or even months to reach completion. Understanding the nuances of fermentation is essential for brewers to achieve the desired flavor, alcohol content, and clarity in their final product.

What You'll Learn

- Temperature Impact: Fermentation speed varies with temperature, typically faster at warmer temperatures

- Sugar Consumption: Fermentation ends when all available sugars are converted to alcohol and carbon dioxide

- Alcohol Content: Higher alcohol levels can slow down fermentation as yeast becomes less active

- Oxygen Levels: Adequate oxygen is crucial for yeast to function, influencing fermentation completion

- Yeast Type: Different yeast strains have unique fermentation characteristics, affecting the final product

Temperature Impact: Fermentation speed varies with temperature, typically faster at warmer temperatures

The temperature of the fermentation environment significantly influences the speed at which beer fermentation occurs. This process, which transforms the sugary liquid known as wort into alcohol, is highly temperature-dependent. Generally, higher temperatures accelerate fermentation, while lower temperatures slow it down. This phenomenon is primarily attributed to the effect of temperature on the yeast, the microorganism responsible for fermentation.

When the temperature of the wort is increased, the yeast cells become more active. This increased activity is due to the higher kinetic energy of the yeast molecules, which allows them to metabolize sugars more rapidly. As a result, the fermentation process proceeds at a faster pace, converting sugars into alcohol and carbon dioxide more quickly. This is why many brewers opt for warmer fermentation temperatures to expedite the process.

Conversely, lower temperatures can significantly slow down fermentation. At these cooler temperatures, the yeast cells have reduced metabolic activity, leading to a slower rate of sugar conversion. This can result in a longer fermentation period, which may be undesirable for some beer styles that require a more rapid fermentation to achieve the desired flavor and character.

The optimal temperature range for beer fermentation varies depending on the specific beer style and the yeast strain used. For instance, ale yeasts typically ferment more rapidly at warmer temperatures, often between 65°F and 75°F (18°C to 24°C). In contrast, lager yeasts are more active at cooler temperatures, usually between 50°F and 55°F (10°C to 13°C). Understanding these temperature-dependent fermentation rates is crucial for brewers to control the fermentation process and achieve the desired beer quality.

In summary, temperature plays a critical role in the fermentation of beer, affecting the speed and efficiency of the process. By manipulating the fermentation temperature, brewers can influence the flavor, clarity, and overall quality of the final beer product. Therefore, monitoring and controlling the temperature during fermentation is essential for achieving consistent and high-quality beer.

Fridge Organization: The Best Spots for Your Beer

You may want to see also

Sugar Consumption: Fermentation ends when all available sugars are converted to alcohol and carbon dioxide

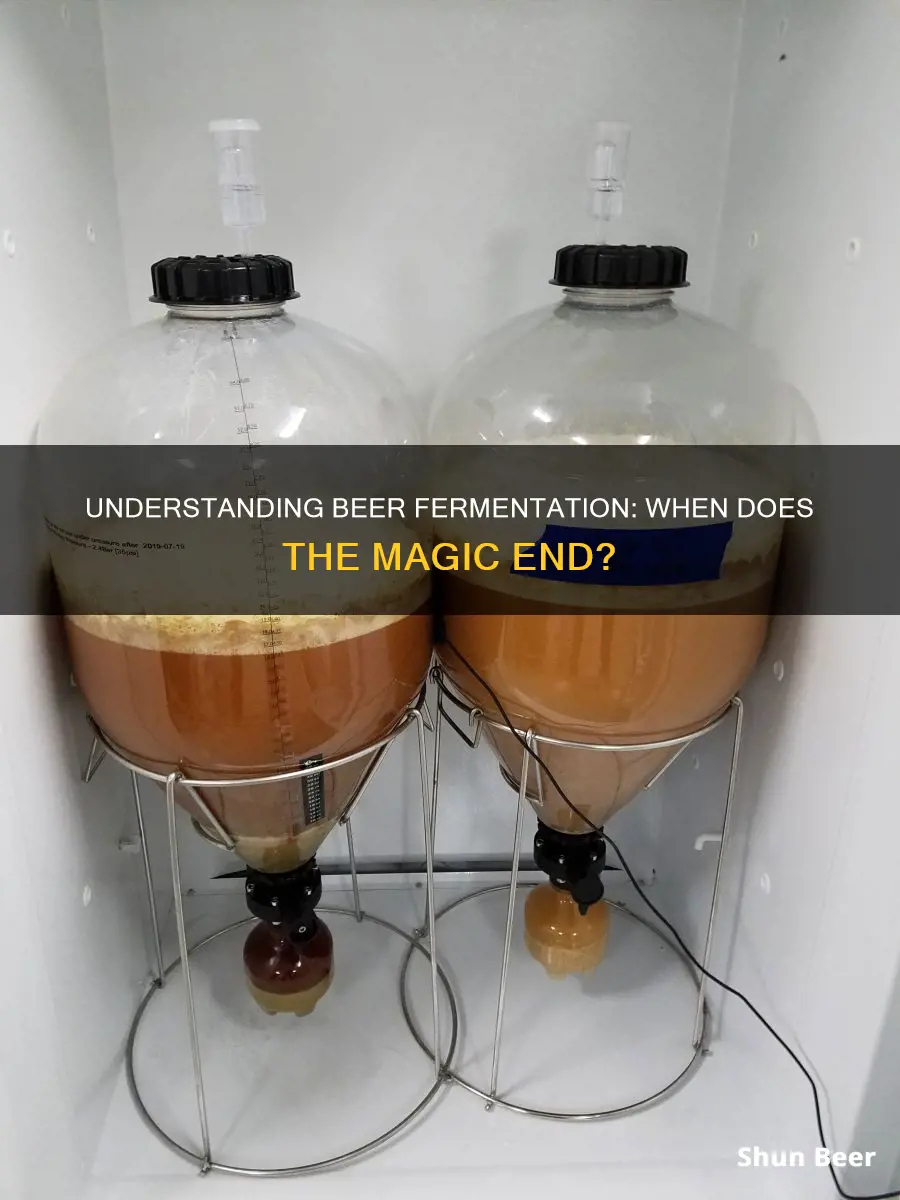

The process of fermentation in beer production is a fascinating transformation where sugars are converted into alcohol and carbon dioxide. This natural chemical reaction is a cornerstone of brewing, and understanding when it is complete is crucial for achieving the desired beer style and quality. At its core, fermentation is driven by yeast, which consumes the sugars present in the wort (the sugary liquid extracted from malted grains).

The key to determining when fermentation is complete lies in the consumption of sugars. Yeast, through its metabolic processes, breaks down various sugars, primarily maltose, into simpler compounds. As the yeast population increases, so does the rate of sugar consumption. However, this process is not infinite; there is a limit to the amount of sugar that can be utilized. When all the available sugars in the wort have been converted, fermentation comes to a halt. This point is critical for brewers as it indicates the beer has reached its desired alcohol content and flavor profile.

During the fermentation process, the yeast's activity can be monitored through several methods. One common approach is to measure the specific gravity of the wort. As fermentation progresses, the specific gravity decreases as the sugars are converted to alcohol and carbon dioxide. When the specific gravity stabilizes and no further significant changes occur, it suggests that fermentation is nearing completion. Additionally, brewers often use yeast-specific gravity charts, which provide a reference point for different yeast strains and their respective fermentation characteristics.

Another indicator of fermentation completion is the beer's appearance and flavor. As fermentation progresses, the beer's clarity improves, and any cloudiness or haze dissipates. The beer's flavor also evolves, becoming less sweet and more alcoholic. When the beer reaches the desired flavor and aroma profile, and no further changes are observed, it is a strong indication that fermentation is complete.

In summary, the end of fermentation is marked by the complete conversion of available sugars into alcohol and carbon dioxide. This process is carefully monitored by brewers who use various techniques to track sugar consumption, specific gravity changes, and the beer's overall characteristics. Achieving the perfect fermentation profile is an art and a science, ensuring that the final product meets the desired standards of quality and taste.

Uncovering the Magic: Rice Beer's Fermentation Process

You may want to see also

Alcohol Content: Higher alcohol levels can slow down fermentation as yeast becomes less active

The process of beer fermentation is a fascinating journey, and understanding its intricacies is key to crafting exceptional brews. When it comes to the question of when fermentation is complete, the alcohol content plays a crucial role. Higher alcohol levels in the wort (the sugary liquid extracted from malted grains) can significantly impact the fermentation process, primarily by affecting the yeast's activity.

As the yeast ferments the sugars, it produces alcohol and carbon dioxide as byproducts. However, when the alcohol concentration in the wort increases, it can act as a natural preservative, making the environment less hospitable for the yeast. Yeast, being sensitive to high alcohol levels, may become less active and efficient in converting sugars into alcohol. This reduced activity can lead to a slower fermentation process, where the beer may not reach its desired alcohol level as quickly.

In brewing, brewers often aim for a specific alcohol by volume (ABV) percentage, which is a measure of the alcohol content in the final product. For instance, a typical lager might have an ABV of around 4-5%, while a stronger ale could range from 8% to 10% or even higher. When targeting higher alcohol levels, brewers must carefully manage the fermentation process to ensure the yeast remains active and efficient. This might involve using specialized yeast strains that can tolerate higher alcohol concentrations or adjusting the fermentation temperature to optimize yeast performance.

Additionally, the impact of alcohol content on fermentation can be further understood through the concept of 'fermentation lock.' When the alcohol level is too high, the yeast may struggle to metabolize the sugars, leading to a state where fermentation temporarily stalls. This can be a challenge for brewers, as it may require additional steps to restart the fermentation process or adjust the recipe to accommodate the higher alcohol levels.

In summary, higher alcohol levels in beer can influence the completion of fermentation by affecting yeast activity. Brewers must carefully consider the alcohol content and choose appropriate yeast strains and fermentation techniques to ensure a successful and timely fermentation process. Understanding these dynamics allows brewers to create beers with the desired alcohol levels and unique flavor profiles.

Mastering the Beer Transfer: Tips for a Smooth Secondary Fermentation

You may want to see also

Oxygen Levels: Adequate oxygen is crucial for yeast to function, influencing fermentation completion

Oxygen plays a critical role in the fermentation process of beer, and understanding its impact is essential for brewers to ensure optimal results. Yeast, the microorganism responsible for fermentation, requires a specific environment to function effectively. One of the key factors is the availability of oxygen. When yeast is introduced to the wort (the sugary liquid extracted from malted grains), it begins the process of converting sugars into alcohol and carbon dioxide. This transformation is highly dependent on the presence of oxygen.

Initially, during the early stages of fermentation, yeast consumes oxygen to produce energy. This phase is crucial as it helps yeast cells become active and efficient. However, as fermentation progresses, the yeast's demand for oxygen increases. If oxygen levels are insufficient, the yeast may struggle to complete the fermentation process, leading to an incomplete or sluggish fermentation. This can result in a beer with off-flavors, a higher alcohol content, or even a stuck fermentation, where the process halts prematurely.

Brewers often employ various techniques to manage oxygen levels. One common method is the use of aeration systems, which introduce a controlled amount of oxygen into the wort. This ensures that the yeast has an adequate supply of oxygen during the early stages, promoting rapid and efficient fermentation. Additionally, the size and design of the fermentation vessel can influence oxygen transfer. Larger vessels may require more oxygen to support the yeast's metabolic needs.

Maintaining the right oxygen levels is a delicate balance. Excessive oxygen can lead to the production of off-flavors and higher levels of volatile acids, negatively impacting the beer's quality. On the other hand, a lack of oxygen can hinder the fermentation process, causing delays or incomplete conversions. Brewers often monitor the fermentation process closely, making adjustments to oxygen levels as needed to ensure a successful and consistent beer production.

In summary, adequate oxygen is vital for yeast to function optimally during beer fermentation. It influences the rate and quality of the fermentation process. Brewers must carefully manage oxygen levels to create the ideal environment for yeast, ensuring a complete and efficient transformation of sugars into the desired beer characteristics. Understanding and controlling oxygen availability is a key aspect of brewing, contributing to the art and science of crafting high-quality beers.

One Beer: Is It Legal? Understanding the Limits

You may want to see also

Yeast Type: Different yeast strains have unique fermentation characteristics, affecting the final product

The type of yeast used in brewing significantly influences the fermentation process and the resulting beer. Different yeast strains possess distinct fermentation characteristics, which can impact the beer's flavor, aroma, and overall quality. Here's an overview of how yeast type plays a crucial role in fermentation:

Ale Yeast: Ale yeasts are commonly used in brewing and are known for their high-temperature fermentation capabilities. These yeasts can ferment at temperatures ranging from 55°F to 75°F (13°C to 24°C). During this process, they convert sugars present in the wort (the sugary liquid extracted from malted grains) into alcohol and carbon dioxide. Ale yeasts produce a wide range of flavors and aromas, depending on the strain. For example, American ale yeasts often contribute fruity esters, while European ale yeasts may result in more neutral flavors. The fermentation time with ale yeasts typically ranges from 5 to 14 days, allowing for a controlled and gradual transformation of the wort.

Lager Yeast: Lager yeasts, on the other hand, are used for bottom-fermentation processes and are adapted to lower temperatures. They ferment at temperatures between 45°F and 65°F (7°C to 18°C). This slower fermentation process takes place primarily in the later stages of brewing. Lager yeasts are known for their clean and crisp fermentation profiles, producing minimal off-flavors. The fermentation duration with lager yeasts can vary, but it often takes longer than ale fermentation, sometimes extending up to 21 days or more.

Specialized Yeasts: Some brewers opt for specialized yeast strains to achieve specific fermentation outcomes. For instance, Brettanomyces yeasts are used to create unique, complex flavors and aromas in certain beer styles. These yeasts can produce fruity, spicy, or even sour notes, adding distinct character to the final product. Similarly, wild yeasts, such as those found in Belgian beers, contribute to the complex and often fruity flavors associated with these styles. Each yeast strain has its own fermentation profile, and brewers carefully select them to match the desired beer style and flavor profile.

Understanding the fermentation characteristics of different yeast strains is essential for brewers to control and predict the outcome of the fermentation process. By selecting the appropriate yeast, brewers can influence the beer's flavor, aroma, and overall quality, ensuring a consistent and desirable product. This knowledge also allows for experimentation and creativity in crafting unique and diverse beer styles.

Fermentation's Magic: Unlocking Beer's Flavor Potential

You may want to see also

Frequently asked questions

Beer fermentation is considered complete when the yeast has finished converting sugars into alcohol and carbon dioxide. One common method to check this is by using a hydrometer. Take a sample of the beer and measure its specific gravity. If the reading remains stable or shows a slight decrease over several days, it indicates that fermentation is nearing completion.

Incomplete fermentation can lead to various issues. One sign is a consistently high specific gravity reading, suggesting that the yeast is still active and converting sugars. Another indicator is a strong, sweet aroma in the beer, which may be due to residual sugars. Additionally, if you notice a sudden increase in temperature during fermentation, it could be a sign that the yeast is still active and requires more time to complete the process.

Yes, there are a few techniques to encourage faster fermentation. One method is to use a higher yeast concentration, as this can increase the rate of fermentation. Another approach is to maintain a consistent temperature, as yeast generally ferments faster in warmer conditions. However, be cautious not to exceed the optimal temperature range for your chosen yeast strain. Additionally, ensuring proper aeration and nutrient availability can also promote faster fermentation.

Leaving beer fermentation incomplete can result in several negative outcomes. The yeast may continue to consume sugars, leading to a higher alcohol content, which can be undesirable. Additionally, incomplete fermentation can cause off-flavors and aromas, making the beer taste flat or sweet. Over time, the beer may also develop a cloudy appearance due to the presence of unfermented sugars. It is essential to monitor the fermentation process to ensure the desired flavor, clarity, and alcohol level are achieved.