During the fermentation process, beer undergoes a fascinating transformation, but it can also be a bit perplexing when you notice those tiny bubbles forming. This phenomenon is a natural part of the fermentation process, where yeast consumes sugars and produces alcohol and carbon dioxide. As the yeast works its magic, it releases carbon dioxide as a byproduct, which gets dissolved in the liquid. When the fermentation slows down or stops, the dissolved carbon dioxide starts to form bubbles, creating a frothy, bubbly beer. This process is crucial for the development of the beer's character and flavor, as it contributes to the carbonation and overall mouthfeel. Understanding why beer bubbles during fermentation is essential for both homebrewers and professional brewers, as it ensures the final product meets the desired quality standards.

What You'll Learn

- Yeast Metabolism: Yeast consumes sugars, producing alcohol and carbon dioxide, causing bubbles

- Carbon Dioxide Production: Fermentation byproducts, including CO2, form bubbles in the beer

- Fermentation Temperature: Higher temperatures accelerate fermentation, increasing CO2 production and bubbling

- Oxygen Levels: Limited oxygen can lead to off-flavors and excessive bubbling during fermentation

- Yeast Health: Healthy yeast ensures efficient fermentation, preventing defects that cause bubbling issues

Yeast Metabolism: Yeast consumes sugars, producing alcohol and carbon dioxide, causing bubbles

The process of fermentation in beer production is a fascinating interplay of yeast metabolism and the transformation of sugars into alcohol and carbon dioxide. This natural phenomenon is at the heart of why beer bubbles during fermentation. When yeast is introduced to the sugary liquid, a complex biochemical reaction occurs. Yeast, a single-celled microorganism, has an extraordinary ability to break down carbohydrates, primarily maltose, which is the main sugar component in beer. Through a series of enzymatic reactions, yeast cells convert maltose into simpler sugars, such as glucose. This is a crucial step as it provides the energy source for the yeast to carry out its metabolic activities.

As the yeast consumes the sugars, it initiates a two-step process. Firstly, the yeast enzymes break down glucose into pyruvate, a molecule that carries energy within the cell. This step is known as glycolysis. Secondly, in a process called the Krebs cycle or the citric acid cycle, pyruvate is further oxidized, releasing carbon dioxide as a byproduct. This carbon dioxide is what causes the beer to bubble. The yeast cells also convert some of the glucose into ethanol, commonly known as alcohol, which is the desired product in beer fermentation. This alcohol production is a result of the yeast's metabolic pathway, where enzymes like zymase catalyze the conversion of sugars to alcohol.

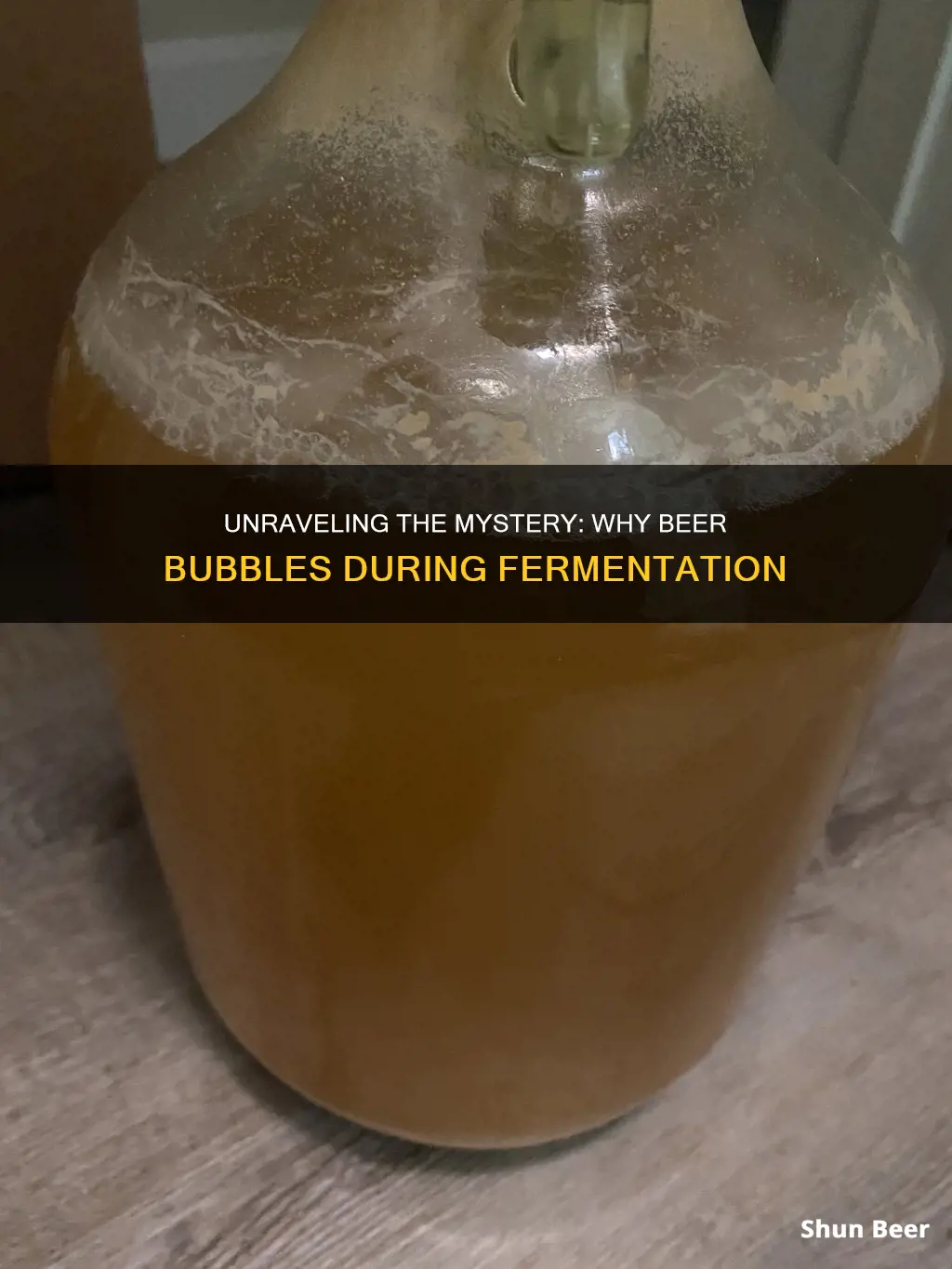

The bubbling phenomenon is a visual indicator of this metabolic process. As carbon dioxide is produced, it forms small gas bubbles within the liquid. These bubbles are a result of the gas being released from the yeast cells and becoming trapped in the liquid. The intensity of bubbling can vary depending on the yeast strain, fermentation temperature, and the specific beer recipe. Some yeast strains are known for their high carbonation potential, leading to more vigorous bubbling.

Understanding yeast metabolism is crucial for brewers to control and optimize the fermentation process. By managing factors such as yeast type, temperature, and nutrient availability, brewers can influence the rate of sugar consumption, alcohol production, and ultimately, the level of carbonation in the final beer product. This knowledge allows for the creation of beers with desired characteristics, from crisp and light lagers to rich and complex stouts.

In summary, the bubbling of beer during fermentation is a direct result of yeast metabolism. Yeast consumes sugars, primarily maltose, and through a series of biochemical reactions, it produces alcohol and carbon dioxide. The carbon dioxide released by the yeast cells forms bubbles, contributing to the unique and desirable characteristics of beer. This natural process showcases the intricate relationship between microorganisms and the transformation of raw materials into a beloved beverage.

Mastering Beer Gravity: A Guide to Fermentation Monitoring

You may want to see also

Carbon Dioxide Production: Fermentation byproducts, including CO2, form bubbles in the beer

The process of fermentation in beer production is a fascinating natural phenomenon that results in the formation of bubbles, primarily due to the production of carbon dioxide (CO2). This CO2 is a byproduct of the yeast's metabolic activities during fermentation, where sugars are converted into alcohol and various fermentation byproducts. Here's a detailed explanation of why beer bubbles during fermentation:

During the fermentation process, yeast plays a crucial role in breaking down the sugars present in the wort (the sugary liquid extracted from malted grains). As yeast ferments these sugars, it undergoes a series of biochemical reactions. One of the key products of this fermentation is ethanol (alcohol), but the process also generates a significant amount of CO2. This CO2 is formed as a result of the yeast's conversion of sugars into energy and the subsequent release of carbon dioxide as a waste product. The yeast cells themselves also produce small amounts of CO2 through their metabolic activities.

As the fermentation progresses, the CO2 produced accumulates in the beer. This is because the yeast's activity is not a continuous process; it operates in cycles of activity and rest. During active fermentation phases, CO2 is produced and released into the beer. Over time, the concentration of CO2 in the beer increases, leading to the formation of bubbles. These bubbles are a result of the CO2 dissolving in the beer and then being released as small gas bubbles when the pressure is reduced during the bottling or kegging process.

The formation of bubbles is an essential aspect of the beer's character and quality. It contributes to the beer's carbonation, which is a desirable trait in many beer styles. Carbonation adds a refreshing, tingling sensation to the beer, enhancing the overall drinking experience. The level of carbonation can vary depending on the beer style, the fermentation process, and the desired outcome. Some beers are naturally more carbonated due to their brewing methods, while others may be artificially carbonated after fermentation.

Understanding the role of CO2 in beer fermentation is crucial for brewers to control and optimize the process. By managing the fermentation conditions, such as temperature, yeast strain, and fermentation duration, brewers can influence the amount of CO2 produced. This control allows for the creation of beers with specific carbonation levels, ensuring a consistent and desirable product. Additionally, the study of CO2 production during fermentation has led to advancements in brewing techniques, enabling brewers to craft beers with unique flavors and characteristics.

Unraveling the Fermentable Nature of Beer: Carbohydrates and Beyond

You may want to see also

Fermentation Temperature: Higher temperatures accelerate fermentation, increasing CO2 production and bubbling

The process of fermentation in beer production is a fascinating yet complex journey, and temperature plays a pivotal role in this transformation. When it comes to the question of why beer bubbles during fermentation, the answer lies in the intricate dance of yeast and temperature. Higher temperatures act as a catalyst, significantly accelerating the fermentation process. This acceleration is a double-edged sword; while it speeds up the transformation of sugars into alcohol and carbon dioxide, it also intensifies the CO2 production, leading to those noticeable bubbles.

In the world of brewing, yeast is the star performer. It feeds on sugars, primarily maltose, and through a series of biochemical reactions, it produces alcohol and carbon dioxide as byproducts. The rate of this reaction is directly proportional to the temperature; higher temperatures provide the yeast with more energy, prompting it to work at a faster pace. As a result, the beer's sugars are converted more rapidly, leading to a quicker rise in alcohol content and, consequently, more bubbling.

The bubbling phenomenon is a visual indicator of the fermentation process's progress. As the yeast consumes sugars, it releases CO2, which forms bubbles within the beer. This is why, during the fermentation stage, brewers often observe a rise in the beer's volume, especially when the temperature is elevated. The increased temperature not only speeds up the fermentation but also contributes to a more vigorous bubbling action.

However, it's essential to strike a balance. While higher temperatures are beneficial for accelerating fermentation, excessive heat can be detrimental. Prolonged exposure to high temperatures may cause the yeast to become stressed, leading to a decrease in fermentation efficiency and potential off-flavors. Therefore, brewers often employ precise temperature control to optimize the fermentation process, ensuring a balanced and flavorful beer.

In summary, the bubbling of beer during fermentation is a direct consequence of higher temperatures, which stimulate yeast activity and CO2 production. This natural process is a testament to the intricate relationship between temperature and the art of brewing, where precision and control are key to crafting the perfect beer. Understanding these temperature-driven phenomena allows brewers to fine-tune their processes and create beers that not only bubble but also delight the senses.

Uncovering the Mystery: Why Beer's Bottom Shelf Appeal to Men

You may want to see also

Oxygen Levels: Limited oxygen can lead to off-flavors and excessive bubbling during fermentation

Oxygen is a critical element in the fermentation process of beer, and its availability can significantly impact the final product's quality. When brewing beer, the primary goal is to encourage the growth of desired yeast strains, which convert sugars into alcohol and carbon dioxide (CO2). However, limited oxygen during fermentation can lead to several undesirable outcomes.

One of the most noticeable effects is the excessive bubbling that occurs in the fermentation vessel. This bubbling is a result of the yeast's metabolic activity, where it consumes sugars and produces CO2 as a byproduct. In an oxygen-limited environment, the yeast may struggle to efficiently perform this process, leading to an overproduction of CO2. This excess CO2 can cause the beer to become highly carbonated, often resulting in a harsh, sharp taste that some beer enthusiasts find unpleasant.

Moreover, low oxygen levels can also contribute to off-flavors in the beer. Yeast requires oxygen to produce certain compounds that contribute to the desired flavor profiles of beer. For instance, the presence of oxygen is essential for the formation of esters, which are responsible for fruity and floral notes in some beer styles. Without sufficient oxygen, the yeast may not produce these desirable flavor compounds, leading to a beer that lacks the expected character and aroma.

To mitigate these issues, brewers often employ various techniques. One common practice is to ensure a well-oxygenated environment during the fermentation process. This can be achieved by using oxygen-rich fermentation media, adding oxygen directly to the fermenter, or utilizing specific yeast strains that are more efficient in low-oxygen conditions. Additionally, monitoring the fermentation temperature and duration can also help manage the yeast's activity and prevent excessive bubbling and off-flavors.

In summary, maintaining optimal oxygen levels during fermentation is crucial for producing high-quality beer. Limited oxygen can result in excessive bubbling due to increased CO2 production and off-flavors caused by the yeast's inability to produce desired compounds. By understanding these effects, brewers can take appropriate measures to ensure a successful fermentation process and deliver a beer that meets the desired standards.

Exploring the Science: What Happens When Salt Meets Supercooled Beer

You may want to see also

Yeast Health: Healthy yeast ensures efficient fermentation, preventing defects that cause bubbling issues

Yeast health is a critical factor in the fermentation process of beer, and it directly impacts the quality and clarity of the final product. When yeast is healthy, it performs its role in converting sugars into alcohol and carbon dioxide efficiently, resulting in a smooth and controlled fermentation process. This efficiency is essential to prevent the formation of unwanted byproducts and defects that can lead to bubbling issues.

One of the primary reasons beer bubbles during fermentation is the presence of defective yeast. Yeast cells can become damaged or stressed due to various factors, such as poor nutrition, extreme temperatures, or exposure to harsh chemicals. When yeast is compromised, it may not function optimally, leading to incomplete fermentation. This means that sugars are not fully converted, leaving residual sugars in the beer, which can cause bubbling and off-flavors.

Maintaining yeast health involves providing the right environment and nutrients. Yeast requires a balanced pH, adequate oxygen levels, and the appropriate temperature range for optimal growth and activity. Brewers often use specialized yeast starters and nutrients to ensure the yeast is robust and capable of handling the fermentation process. Proper yeast management also includes monitoring and controlling the fermentation temperature, as extreme temperatures can stress the yeast and disrupt its functionality.

Additionally, yeast health can be supported through the use of yeast-specific enzymes and nutrients. These additives can help yeast cells maintain their structural integrity and enhance their ability to ferment sugars effectively. By promoting yeast health, brewers can minimize the risk of defects and ensure a clean, clear beer with minimal bubbling.

In summary, healthy yeast is the cornerstone of successful fermentation in beer production. It ensures that the yeast cells are robust and capable of efficiently converting sugars, preventing the formation of defects that cause bubbling and off-flavors. Proper yeast management, including nutrition, temperature control, and the use of yeast-specific additives, is essential to achieving consistent and high-quality beer.

Understanding Colorado's Legal Limit: How Many Beers Before You're Over?

You may want to see also

Frequently asked questions

Beer bubbles during fermentation are a natural and expected part of the process. These bubbles are primarily caused by the production of carbon dioxide (CO2) as a byproduct of yeast fermentation. Yeast consumes sugars from the wort and produces alcohol and CO2. The CO2 forms small bubbles that rise to the surface, creating a frothy appearance. This is a sign that the yeast is actively working and the fermentation is progressing as intended.

Not necessarily. While excessive bubbling can be a sign of an active fermentation, it doesn't always indicate a problem. However, if the bubbling is accompanied by other signs of distress, such as a strong sulfur smell, a cloudy appearance, or a sudden drop in temperature, it might suggest an issue. In such cases, it's best to monitor the fermentation closely and take appropriate measures to ensure the beer's quality.

Controlling bubble formation can be challenging, but there are a few techniques to consider. Firstly, ensure that your yeast is healthy and active by using a good starter culture and maintaining proper temperature control. Secondly, consider using a fermentation lock or airlock to allow CO2 to escape while preventing other contaminants from entering the fermenter. Additionally, proper sanitization of equipment and ingredients can help prevent wild yeast strains that may cause excessive bubbling.

Yes, bubbles during fermentation can be beneficial. They indicate that the yeast is actively metabolizing the sugars and producing alcohol and carbonation. This process contributes to the overall flavor development and carbonation level in the final beer. However, excessive bubbling might lead to a higher risk of contamination, so monitoring and managing the process is crucial.

A decrease in bubbling could be a sign that the yeast is running out of nutrients or facing other challenges. It's essential to monitor the fermentation temperature and ensure it remains within the optimal range for your chosen yeast strain. If the bubbling significantly slows down, consider adding more yeast or checking for any potential issues with the fermentation setup, such as a clogged airlock or a faulty fermenter.