Fermenting beer is a delicate process that requires precise control of temperature and other environmental factors. One crucial aspect of successful fermentation is storing the beer in a cool location. This practice is essential because beer fermentation is a biological process that relies on specific temperature ranges to thrive. Cool temperatures slow down the yeast's activity, allowing for a more controlled and gradual fermentation process. Storing beer in a cool environment also helps to prevent rapid fermentation, which can lead to off-flavors and a loss of desired characteristics. Additionally, keeping the beer at a consistent, lower temperature can enhance the overall quality and flavor profile, ensuring a more enjoyable and consistent beer-drinking experience.

What You'll Learn

- Temperature Control: Fermentation Efficiency: Maintaining a cool environment during fermentation enhances yeast activity and flavor development

- Flavor Preservation: Beer Stability: Cold temperatures slow down oxidation, preserving the beer's unique flavors and aromas

- Sedimentation Prevention: Clear Beer: Chilling encourages sediment to settle, resulting in a clearer, more enjoyable beverage

- Carbonation Enhancement: Carbonic Gas Retention: Cool storage increases carbon dioxide retention, leading to a naturally carbonated beer

- Energy Conservation: Yeast Activity Regulation: Lower temperatures reduce yeast metabolism, conserving energy and maintaining beer quality

Temperature Control: Fermentation Efficiency: Maintaining a cool environment during fermentation enhances yeast activity and flavor development

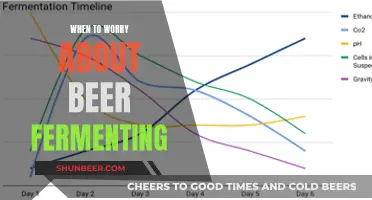

The temperature at which beer is stored during fermentation is a critical factor in the brewing process, significantly impacting the final product's quality and character. Maintaining a cool environment is essential for achieving optimal fermentation efficiency and developing the desired flavors in the beer.

When yeast, the microorganism responsible for fermentation, is exposed to cooler temperatures, it becomes more active. This increased activity leads to a faster fermentation process, which is advantageous for brewers. Warmer temperatures can slow down fermentation, potentially leading to off-flavors and a less desirable beer. By keeping the fermentation temperature low, brewers can control the yeast's activity, ensuring a clean and efficient process. This control is particularly important in the early stages of fermentation, where the yeast's activity directly influences the beer's flavor and aroma development.

The art of brewing involves a delicate balance of various factors, and temperature control is a key element in this balance. Cooler fermentation temperatures contribute to the development of complex flavors and aromas in the beer. As the yeast metabolizes sugars, it produces a range of compounds that contribute to the beer's overall character. Lower temperatures during this process can enhance the formation of esters, which are responsible for fruity and floral notes, and also promote the production of higher alcohols, adding complexity to the beer's flavor profile. This is why many traditional and craft breweries opt for cooler fermentation temperatures, aiming to create beers with rich, nuanced flavors.

Additionally, temperature control during fermentation helps in preventing the growth of unwanted bacteria and wild yeast strains. These microorganisms can introduce off-flavors and aromas, making the beer taste sour, acidic, or even produce a 'brett' character, which is undesirable in many beer styles. By maintaining a cool environment, brewers can inhibit the growth of these spoilage agents, ensuring the beer remains clean and true to its intended style.

In summary, storing fermenting beer in a cool location is a crucial practice in brewing, as it directly impacts fermentation efficiency and flavor development. Cooler temperatures stimulate yeast activity, leading to faster and more controlled fermentation. This process allows for the creation of beers with complex and desirable flavor profiles while also helping to prevent the introduction of unwanted flavors and aromas. Understanding and implementing proper temperature control is an essential skill for any brewer aiming to produce high-quality, consistent beer.

Uncovering the Mystery: Why Rice Enhances Beer's Flavor

You may want to see also

Flavor Preservation: Beer Stability: Cold temperatures slow down oxidation, preserving the beer's unique flavors and aromas

Storing fermenting beer in a cool location is a crucial practice in the brewing process, primarily aimed at preserving the beer's unique flavors and aromas. This technique is especially important during the fermentation stage, as it directly impacts the beer's overall quality and character. Cold temperatures play a pivotal role in this process by significantly slowing down oxidation, which is a natural chemical reaction that can degrade the beer's sensory qualities.

Oxidation is an undesirable process that can lead to the loss of flavor and aroma compounds in beer. When beer is exposed to air, especially at higher temperatures, these compounds can break down, resulting in a flat, dull taste and a loss of the beer's characteristic fragrance. By storing the beer in a cool environment, brewers can effectively minimize this oxidation process. The slower rate of chemical reactions at lower temperatures means that the beer's delicate flavor and aroma profiles remain intact, ensuring that the final product is a true reflection of the brewer's vision.

The impact of cold storage is particularly significant for beers with high hop content, such as IPAs and stouts. Hops contribute to the beer's bitterness, flavor, and aroma, and they are highly susceptible to oxidation. When stored in a cool location, these beers retain their hoppy character, ensuring a more robust and satisfying drinking experience. Similarly, beers with fruity esters, which are common in wheat beers and certain styles of ale, benefit from cold storage as it helps preserve these unique flavor notes.

Additionally, cold temperatures contribute to the overall stability of the beer. Lower temperatures slow down the growth of bacteria and other microorganisms that can contaminate the beer, ensuring that it remains clean and safe to consume. This is especially critical during the fermentation process, as any unwanted microbial activity can negatively impact the beer's flavor and quality.

In summary, storing fermenting beer in a cool location is a vital technique for brewers to maintain the beer's integrity and character. By slowing down oxidation, they can preserve the beer's unique flavors and aromas, ensuring that the final product meets the high standards expected by beer enthusiasts. This simple yet effective practice is a cornerstone of the brewing art, contributing to the creation of exceptional beers that delight the senses.

Mastering Fermentation: Tips for Raising Beer Bucket Temperatures

You may want to see also

Sedimentation Prevention: Clear Beer: Chilling encourages sediment to settle, resulting in a clearer, more enjoyable beverage

Chilling beer during storage is a common practice in the brewing industry, but it can inadvertently lead to a problem known as sedimentation. This occurs when yeast and other particles settle at the bottom of the container, clouding the once-clear beverage. While sedimentation is a natural process, it can be prevented by understanding the science behind it and implementing a few simple techniques.

The primary reason chilling encourages sedimentation is the temperature's effect on the beer's viscosity. When beer is cold, its molecules slow down, making it more susceptible to settling. This is especially true for beers with higher alcohol content or those that have gone through a secondary fermentation process, as these beers often contain more yeast and sediment. As the beer ages, the yeast gradually sinks to the bottom, creating a layer of sediment that can range from a light haze to a thick, cloudy appearance.

To prevent sedimentation, brewers and beer enthusiasts can employ several strategies. Firstly, proper aeration is crucial. Oxygenating the beer during the fermentation process helps the yeast work more efficiently and can reduce the amount of sediment formed. This can be achieved by carefully controlling the fermentation temperature and duration. Additionally, using a yeast that is less prone to sedimentation can make a significant difference. Some yeast strains, like certain Belgian or British ale yeasts, are known for their clarity-promoting characteristics.

Another effective method is to store the beer at a slightly warmer temperature, typically around 15-18°C (59-64°F). This warmer environment encourages the yeast to remain active and dispersed throughout the beer, preventing it from settling. However, it's essential to maintain a consistent temperature to avoid any off-flavors or unwanted fermentation byproducts. Regularly agitating the beer during storage can also help keep the yeast suspended, ensuring a clear and crisp beverage.

In conclusion, while chilling beer is beneficial for preservation and flavor, it can inadvertently lead to sedimentation. By understanding the science behind this process and implementing techniques such as proper aeration, using suitable yeast strains, and storing beer at optimal temperatures, brewers and beer lovers can enjoy a clear, sediment-free drinking experience. These simple practices contribute to the overall quality and enjoyment of the beverage, ensuring a consistent and satisfying product.

Fridge Organization: The Best Spots for Your Beer

You may want to see also

Carbonation Enhancement: Carbonic Gas Retention: Cool storage increases carbon dioxide retention, leading to a naturally carbonated beer

Storing fermenting beer in a cool environment is a crucial practice in the brewing process, and it significantly impacts the beer's carbonation and overall quality. One of the primary reasons for this practice is the enhancement of carbonation through the retention of carbonic gas. When beer is fermented, it undergoes a transformation where sugars are converted into alcohol and carbon dioxide (CO2) as a byproduct. This CO2 is what gives beer its characteristic fizz and contributes to its refreshing character.

The process of carbonation is a delicate balance between the production of CO2 and its retention in the beer. During fermentation, CO2 is released into the air, and as the beer is stored, it begins to dissolve into the liquid. Cool temperatures play a vital role in this process. When beer is stored at lower temperatures, the CO2 becomes more soluble, allowing it to dissolve into the beer more effectively. This is because the solubility of gases in liquids increases with a decrease in temperature, a principle known as Henry's Law. As a result, the beer becomes naturally carbonated, providing a satisfying effervescence without the need for forced carbonation techniques.

The cool storage environment also contributes to the overall quality of the beer. Lower temperatures slow down the fermentation process, allowing for a more controlled and gradual transformation of sugars. This results in a cleaner, crisper flavor profile, as the beer is not rushed through the fermentation stage. Additionally, cool storage helps to preserve the beer's delicate aromas and flavors, ensuring that the final product is well-balanced and appealing to the palate.

Furthermore, the retention of CO2 in cool storage is essential for maintaining the beer's carbonation over time. As beer ages, the CO2 naturally dissipates, leading to a loss of carbonation. However, when stored at lower temperatures, the CO2 remains more stable, preserving the beer's effervescence for an extended period. This is particularly important for styles of beer that rely on natural carbonation, such as certain craft beers and traditional ales.

In summary, storing fermenting beer in a cool location is a critical step in the brewing process, offering multiple benefits. It enhances carbonation by increasing CO2 retention, resulting in a naturally carbonated beer with a satisfying fizz. Cool temperatures also contribute to the beer's overall quality, ensuring a well-balanced and flavorful product. By understanding the science behind this practice, brewers can optimize their processes and deliver exceptional beers that delight beer enthusiasts.

Uncorking the Mystery: Why CO2 Fermentation is a Game-Changer for Beer

You may want to see also

Energy Conservation: Yeast Activity Regulation: Lower temperatures reduce yeast metabolism, conserving energy and maintaining beer quality

Storing fermenting beer in a cool location is a crucial practice in the brewing process, primarily due to its positive impact on energy conservation and yeast activity regulation. Lowering the temperature during fermentation is a strategic move that offers multiple benefits, ensuring the beer's quality and the efficiency of the brewing process.

Yeast, the microorganism responsible for fermentation, is highly sensitive to temperature changes. When the temperature is lowered, yeast metabolism slows down, which is a natural response to the cooler environment. This reduction in metabolic activity is advantageous for several reasons. Firstly, it conserves energy. Yeast, like all living organisms, requires energy to carry out its functions. By reducing their metabolic rate, yeast cells require less energy, which translates to energy savings for the brewing process. This is particularly important in large-scale brewing operations where energy consumption can be significant.

Secondly, lower temperatures help maintain the quality of the beer. During fermentation, yeast converts sugars into alcohol and carbon dioxide. At cooler temperatures, this process occurs more slowly, allowing for better control over the fermentation rate. Slower fermentation can result in a more precise and consistent beer, as it provides brewers with the ability to fine-tune the process. This is especially crucial for achieving the desired alcohol content and flavor profiles. For example, in the production of certain styles of beer, such as wheat or Belgian ales, a slower fermentation process can contribute to a smoother, more balanced taste.

Additionally, storing beer at lower temperatures can prevent the formation of off-flavors and aromas, which often occur due to the over-activity of yeast. When yeast is active at higher temperatures, it can produce compounds that contribute to negative flavor profiles, such as esters and higher alcohols. By keeping the fermentation temperature cool, brewers can minimize these unwanted compounds, ensuring a cleaner and more desirable beer.

In summary, the practice of storing fermenting beer in a cool location is a strategic one, offering energy conservation and improved beer quality. Lower temperatures regulate yeast activity, reducing metabolism and energy requirements while allowing for better control over the fermentation process. This results in a more consistent and flavorful beer, highlighting the importance of temperature management in brewing.

Understanding Beer's Final Stage: Post-Fermentation Beer Strength

You may want to see also

Frequently asked questions

Fermenting beer requires a controlled environment to maintain the desired temperature, typically between 65°F and 75°F (18°C and 24°C). Cooler temperatures slow down the yeast's activity, allowing for a more gradual fermentation process. This helps to develop complex flavors and aromas while preventing the beer from becoming overly carbonated or "flabby."

Absolutely! Yeast is sensitive to temperature changes, and consistent cool temperatures during fermentation can enhance its activity. This results in a cleaner and more precise fermentation, ensuring the beer's desired character is achieved. Warmer temperatures might cause the yeast to become dormant or die, leading to a stuck fermentation or off-flavors.

Storing beer at room temperature or warmer can lead to rapid fermentation, which may cause the beer to become overly carbonated and potentially result in a "flabby" or flat taste. Higher temperatures can also accelerate the growth of bacteria, leading to off-flavors and potential spoilage. Additionally, warmer conditions might cause the beer to lose its carbonation more quickly.

The duration of cooling storage depends on the beer style and the yeast used. Generally, primary fermentation can take anywhere from 5 to 14 days, while secondary fermentation, if desired, can last for several weeks. It's essential to monitor the beer's progress and adjust the storage temperature accordingly to achieve the best results.