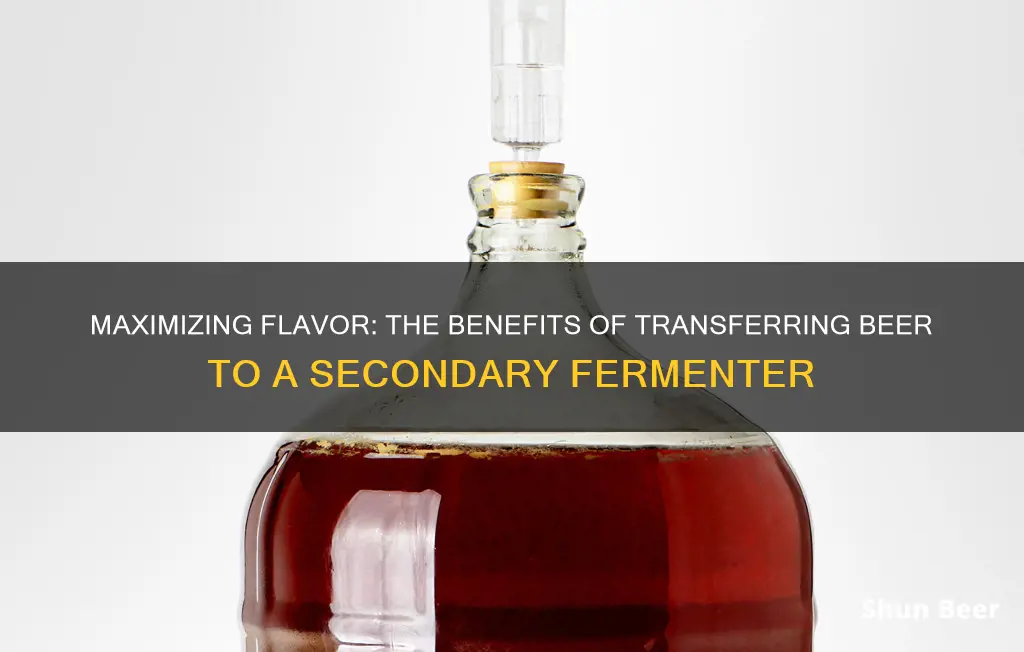

Transferring beer from the primary fermenter to a secondary fermenter is a crucial step in the brewing process, offering several benefits. This technique allows brewers to separate the beer from the spent yeast and spent grain, which can improve the clarity and flavor of the final product. By moving the beer to a secondary fermenter, brewers can further refine the beer's character, enhancing its taste, aroma, and overall quality. This process is an essential part of the brewing art, ensuring that the beer reaches its full potential and providing a more consistent and desirable outcome.

What You'll Learn

- Improved Flavor: Transferring beer to a secondary fermenter allows for maturation, enhancing flavors and aromas

- Clarity: Secondary fermentation can clarify beer by reducing sediment and cloudiness

- Carbonation: Transferring beer promotes carbonation, creating a refreshing, bubbly beverage

- Aromatic Development: Secondary fermentation encourages the development of desired aromas and flavors

- Reduced Contamination: Moving beer to a secondary fermenter minimizes the risk of contamination

Improved Flavor: Transferring beer to a secondary fermenter allows for maturation, enhancing flavors and aromas

Transferring beer to a secondary fermenter is a crucial step in the brewing process that significantly impacts the final product's flavor and quality. This technique, often overlooked by casual beer enthusiasts, is a key practice for brewers aiming to create exceptional beers. The primary reason for this transfer lies in the art of maturation, which plays a pivotal role in developing and enhancing the beer's flavors and aromas.

When beer is initially fermented, the primary focus is on achieving a robust and balanced base flavor. However, the beer's true potential is often unlocked during the secondary fermentation stage. This stage involves transferring the beer from the primary fermenter to a secondary container, typically a carboy or a larger fermenter. The process of transferring beer to a secondary fermenter introduces several advantages that contribute to improved flavor profiles.

One of the key benefits is the opportunity for further fermentation and maturation. In the secondary fermenter, yeast continues to work on any remaining sugars, producing additional flavors and aromas. This secondary fermentation can introduce complex notes, such as fruity esters, which are desirable in certain beer styles like wheat beers or Belgian ales. Moreover, the extended contact with the yeast allows for the development of more nuanced flavors, ensuring that the beer ages gracefully.

The secondary fermenter also facilitates the clarification of the beer. As the beer matures, it may develop a layer of sediment, which can be removed during this transfer process. This clarification step is essential for achieving a clear and crisp beer, especially in styles like lagers, where a pristine appearance is highly valued. By removing this sediment, the beer's overall quality and appeal are enhanced.

Additionally, transferring beer to a secondary fermenter allows brewers to experiment with dry hopping or adding additional ingredients. Dry hopping, for instance, can introduce citrusy or piney aromas, elevating the beer's sensory experience. This technique is commonly used in hop-forward styles like IPAs, where the goal is to create a vibrant and aromatic beer. The secondary fermenter provides a controlled environment to fine-tune these additions, ensuring they complement the beer's existing characteristics.

In summary, the practice of transferring beer to a secondary fermenter is a vital aspect of brewing that directly influences the beer's flavor and aroma. It enables brewers to refine and enhance the beer's profile, resulting in a more complex and satisfying drinking experience. This process is a testament to the art of brewing, where patience and attention to detail are rewarded with exceptional, handcrafted beers.

The Mystery of the Crisper: Who's Hiding Veggies in My Beer?

You may want to see also

Clarity: Secondary fermentation can clarify beer by reducing sediment and cloudiness

Secondary fermentation is a crucial step in the beer-making process that can significantly impact the final product's clarity and quality. When beer is transferred from the primary fermenter to a secondary fermenter, it undergoes a process that helps refine and improve its characteristics. One of the primary benefits of this transfer is the ability to enhance clarity, making the beer appear more polished and appealing to the eye.

The primary fermenter is where the initial fermentation takes place, converting sugars into alcohol and carbon dioxide. During this process, yeast consumes the sugars and leaves behind various byproducts, including proteins and other solids. Over time, these byproducts can settle at the bottom of the fermenter, causing sedimentation and cloudiness in the beer. This cloudiness can be undesirable, as it may obscure the beer's color and aroma, and it can also affect the overall drinking experience.

By transferring the beer to a secondary fermenter, brewers can separate the beer from the sediment. The secondary fermenter is typically used for a shorter period, allowing the beer to mature and clarify. During this stage, the beer is exposed to a controlled environment, often with a different yeast strain or a specific temperature, which encourages the growth of beneficial bacteria. These bacteria play a vital role in clarifying the beer by consuming the remaining yeast and other particles, effectively reducing the sediment.

The process of secondary fermentation can be achieved through various methods. One common technique is to use a hop-back or a hop-sparge, where hops are added to the beer to absorb and precipitate out proteins. This method is particularly useful for reducing haze and improving clarity. Another approach is to use a fining agent, such as isinglass or gelatin, which can attract and bind to the sediment particles, making them easier to remove.

Additionally, the temperature control during secondary fermentation is essential. Cooler temperatures can slow down the yeast's activity, allowing more time for the sediment to settle. This controlled environment ensures that the beer's clarity is improved without compromising its flavor or aroma. After the secondary fermentation, the beer is often filtered to remove any remaining sediment, resulting in a crystal-clear beverage.

In summary, transferring beer to a secondary fermenter is a critical step to enhance clarity. By reducing sediment and cloudiness, brewers can create a more visually appealing and enjoyable beer. This process involves careful management of yeast, bacteria, and temperature, ensuring that the beer's natural flavors and aromas are preserved while achieving optimal clarity.

Unraveling the Mystery: Why Eggs Belong in Beer

You may want to see also

Carbonation: Transferring beer promotes carbonation, creating a refreshing, bubbly beverage

Transferring beer to a secondary fermenter is a crucial step in the brewing process that significantly impacts the final product's carbonation level and overall quality. This technique is particularly important for achieving the desired level of carbonation, which is a key factor in the enjoyment of beer. Carbonation adds a refreshing, bubbly sensation to the beverage, enhancing its appeal and making it more palatable.

When beer is initially fermented, it undergoes a process where sugars are converted into alcohol and carbon dioxide. However, this initial fermentation might not result in the optimal carbonation level. The primary reason for this is that the yeast, responsible for fermentation, may not have fully converted all the sugars, leading to a lower carbon dioxide production. Additionally, the yeast might not have had the opportunity to interact with the beer in a controlled environment, which is essential for achieving the desired carbonation.

Transferring the beer to a secondary fermenter offers several advantages. Firstly, it provides a fresh medium for the yeast to continue its work. In the secondary fermenter, the yeast can efficiently convert the remaining sugars, ensuring a more complete fermentation process. This results in a higher production of carbon dioxide, which is then dissolved in the beer, leading to increased carbonation. The secondary fermenter also allows for better control over the fermentation temperature, which is crucial for managing the yeast's activity and optimizing carbonation.

The process of transferring beer to a secondary fermenter is a delicate one. It requires careful handling to avoid disturbing the yeast or introducing unwanted contaminants. Brewers often use a technique called "racking," where they gently pour the beer from the primary fermenter into the secondary fermenter, leaving behind any sediment or yeast that might have settled. This ensures that the beer in the secondary fermenter is clear and free from any unwanted particles.

By promoting a more thorough fermentation, transferring beer to a secondary fermenter directly contributes to the carbonation process. The increased carbon dioxide production during this stage results in a beer with a more pronounced, satisfying fizz. This level of carbonation is often preferred by beer enthusiasts, as it adds to the overall drinking experience, making the beverage more refreshing and enjoyable. This technique is a standard practice in brewing, ensuring that the final product meets the desired quality standards.

Fish Bladder in Beer: Uncovering the Truth

You may want to see also

Aromatic Development: Secondary fermentation encourages the development of desired aromas and flavors

The process of secondary fermentation is a crucial step in the beer-making journey, especially when it comes to enhancing the aromatic and flavor profiles of the final product. This technique involves transferring the beer from the primary fermentation vessel to a secondary fermenter, allowing for a more nuanced and complex flavor development. By doing so, brewers can unlock the full potential of their creations and create beers with exceptional character.

When beer is initially fermented, the primary focus is often on achieving a balanced and crisp taste. However, the secondary fermentation stage provides an opportunity to introduce new flavors and aromas, creating a more captivating drinking experience. This is particularly important for styles like IPAs, where the goal is to showcase a wide range of hop-derived aromas and flavors. By transferring the beer, brewers can encourage the growth of specific yeast strains or bacteria that contribute to these desired characteristics.

In the secondary fermenter, the beer can be exposed to a variety of factors that influence aroma development. One key aspect is the addition of specific yeast strains or yeast blends. Certain yeasts produce esters, which are volatile compounds responsible for fruity, spicy, or even bubblegum-like aromas. For example, the use of Belgian yeast can impart a distinctive fruity character, while British ale yeasts may contribute a more subtle, earthy aroma. By carefully selecting these yeast cultures, brewers can guide the beer's aromatic evolution.

Another factor that contributes to aromatic development is the duration of the secondary fermentation. Extending this period allows for a more gradual and controlled release of flavors and aromas. Longer fermentation times can result in a more complex beer, as the yeast has more time to interact with the ingredients and produce a wider range of compounds. This is especially beneficial for styles that require a delicate balance of flavors, such as wheat beers or certain fruit-forward ales.

Additionally, the temperature and oxygen levels in the secondary fermenter play a significant role in aromatic development. Warmer temperatures can stimulate yeast activity, leading to increased fermentation and the potential for off-flavors if not carefully managed. Maintaining optimal temperature control ensures that the beer's character is enhanced without introducing unwanted notes. Oxygen levels are also crucial, as they influence the yeast's ability to produce aromatic compounds. Adequate oxygenation encourages the growth of desired yeast strains, resulting in a more aromatic beer.

In summary, secondary fermentation is a powerful tool for brewers to enhance the aromatic and flavor profiles of their beers. By carefully selecting yeast cultures, managing fermentation duration, and controlling temperature and oxygen levels, brewers can create beers with exceptional character and a delightful sensory experience for beer enthusiasts. This process allows for the development of the desired aromas and flavors, making the beer truly memorable.

Wingstop's Secret: Does Beer Enhance the Bean Experience?

You may want to see also

Reduced Contamination: Moving beer to a secondary fermenter minimizes the risk of contamination

Transferring beer to a secondary fermenter is a crucial step in the brewing process that significantly reduces the risk of contamination, ensuring the final product is of high quality and consistency. This technique is particularly important for homebrewers and small-scale producers who aim to achieve professional-level results. By moving the beer to a secondary fermenter, brewers can create an environment that is less susceptible to unwanted microbial activity and external contaminants.

The primary reason for this transfer is to separate the beer from the spent yeast and sediment, which accumulate during the primary fermentation. In the primary fermenter, yeast ferments the sugars in the wort, producing alcohol and carbon dioxide. Over time, yeast cells and other particles settle at the bottom of the fermenter, creating a layer of sediment. If left in the primary fermenter, this sediment can re-enter the beer, leading to off-flavors, cloudiness, and potential contamination. By transferring the beer to a secondary fermenter, brewers can avoid these issues and maintain the beer's clarity and flavor profile.

The secondary fermenter provides a clean and sterile environment for the beer to mature. It allows for better control over the fermentation process, as the beer can be kept at a consistent temperature and oxygen levels can be carefully managed. This controlled environment minimizes the risk of wild yeast strains or bacteria from the air or equipment coming into contact with the beer. Wild yeast strains can introduce unique but often undesirable flavors, while bacteria can cause off-odors and flavors, making the beer unpalatable.

Additionally, transferring the beer to a secondary fermenter enables brewers to perform a final clarification step. After a few weeks in the secondary fermenter, the beer can be filtered or siphoned, removing any remaining yeast or sediment. This ensures that the final product is clear, smooth, and free from any unwanted particles. The process also allows for the addition of dry hops or other ingredients, enhancing the beer's aroma and flavor without the risk of contamination from the primary fermenter's environment.

In summary, moving beer to a secondary fermenter is a critical practice to minimize contamination and ensure the beer's quality. It provides a controlled and sterile environment, allowing brewers to fine-tune the fermentation process and achieve consistent, desirable results. This technique is a standard practice in the brewing industry and is essential for producing craft beers with complex flavors and a clean, crisp finish.

Anheuser-Busch's Beer Portfolio: Exploring the Wide Range of Brews

You may want to see also

Frequently asked questions

Transferring beer to a secondary fermenter is crucial for the maturation and conditioning process of beer. This step allows for the separation of the beer from the spent grain and yeast, which can improve clarity and flavor. It also provides an opportunity to fine-tune the beer's characteristics by adjusting the yeast and temperature during this phase.

Secondary fermentation offers several advantages. Firstly, it enhances the beer's overall quality by allowing for further maturation, which can result in a smoother taste and improved mouthfeel. Secondly, it enables brewers to make final adjustments, such as adding dry hops or specific flavors, to create a unique and personalized beer.

Transferring beer to a secondary fermenter can significantly impact its clarity. By removing the yeast and sediment, the beer becomes clearer. This process is especially beneficial for styles like IPAs or stouts, where cloudiness can be undesirable. The secondary fermentation also allows for the removal of any remaining yeast or proteins, ensuring a crisp and clear final product.

Skipping the secondary fermentation is possible, but it may not yield the best results. Primary fermentation produces a robust beer, but it can be cloudy and may require additional filtration. Secondary fermentation refines the beer, making it smoother and clearer. However, if time is a constraint, some brewers opt for a shorter secondary fermentation or a direct bottle/keg transfer, which can still produce a drinkable beer but may lack the complexity of a properly conditioned one.

Not transferring beer to a secondary fermenter might lead to several issues. Firstly, the beer may remain cloudy due to the presence of yeast and sediment, which can be unsightly. Secondly, the beer might not develop its full potential in terms of flavor and aroma, as the secondary fermentation allows for further maturation and flavor integration. Lastly, skipping this step could result in a less refined beer, potentially affecting the overall quality and enjoyment of the beverage.