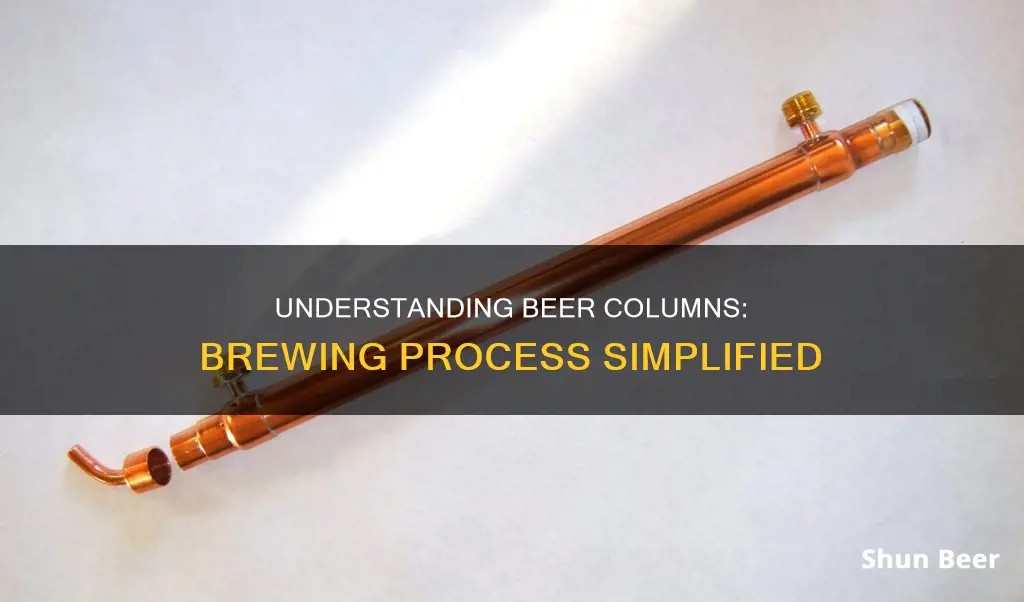

The process of distillation is one of the most important aspects of spirits production. Column stills, also known as patent, continuous, or Coffey stills, are often used for this process. They are more industrial-looking than pot stills, taller, and contain multiple chambers stacked on top of each other. The primary purpose of a beer column is to separate ethanol from water and solids in the beer stream. The beer to be distilled is pumped in near the top of the column, and steam is pumped up from the bottom of the column. The steam vaporizes the alcohol from the beer, which then flows to the top of the column, while the water and grain solids drip down to the bottom.

| Characteristics | Values |

|---|---|

| Purpose | Separation of solids from liquids, and separation of liquids into mostly-alcohol (to keep) and mostly-water (to recycle) |

| Parts | Perforated plates, steam, beer |

| Function | Beer is pumped in near the top of the column, and steam is pumped up from the bottom of the column |

| Beer Movement | Beer runs across each plate to the other side, flows down to the next plate and flows across it to the other side |

| Steam Movement | Steam vaporizes the alcohol from the beer (which then flows to the top of the column), while leaving the water and grain solids to keep dripping down to the bottom |

| Top Part of the Still | Beer does not enter the very top of the still but near the top. Above that point in the still, the steam is being rectified on those plates |

| Material | Stainless steel, but there needs to be interaction with copper at some point |

| Additional Refinement | Bubble caps, shredded copper or copper pieces |

| Second Distillation | Most bourbon undergoes a second distillation in a continuous pot still called a doubler or a thumper |

| Waste Product | Additional water |

| Ethanol | Ethanol boils at a lower temperature than water |

What You'll Learn

Beer is pumped in near the top of the column

The beer to be distilled is pumped into the column near the top. The beer runs across each plate to the other side, then flows down to the next plate and flows across it to the other side. This is made possible by the perforated plates that characterise column stills. While the plates are perforated, this lets the steam come up through the still, but the beer does not drip down through these holes.

The steam coming up through the column vaporises the alcohol from the beer, which then flows to the top of the column, while the water and grain solids drip down to the bottom. The perforated plates allow the ethanol to lose impurities like water and congeners before it reaches the top of the column in a very pure form. From here, the ethanol vapour exits, passing through a cooling condenser and into a collection vessel.

The beer is pumped in near the top of the column, but not at the very top. Above this point in the still, the steam is being rectified on those plates. It is up there where copper is crucial, and where "bubble caps" are found in stills. Bubble caps provide additional refinement of the spirit and increase contact with copper.

Column stills can be built from stainless steel but there needs to be interaction with copper at some point. In some stills, the part of the still where beer is being separated and distilled is stainless steel, and where the steam is being rectified there is copper.

Bottoms Up Beer Dispensers: How Do They Work?

You may want to see also

Steam rises from the bottom of the column

The steam is pumped into the bottom of the column, and the beer is pumped in near the top. The beer runs across each plate to the other side, then flows down to the next plate and flows across that. The steam comes up through the holes in the plates, but the beer does not drip down through the holes. The perforated plates allow the steam to rise through the column, but the beer does not follow the same path. Instead, it runs across each plate and down to the next level.

The steam rises through the column, vaporising the alcohol from the beer as it goes. The alcohol and other volatile molecules are forced up the column, while the water and grain solids are left behind and drip down to the bottom. This is because alcohol has a lower boiling point than water, so it evaporates off first. The steam provides the heat needed to vaporise the alcohol.

The steam rises and the alcohol vapours are drawn off into a condenser, where they are turned back into a liquid. The liquid alcohol is then collected. The steam rises from the bottom of the column, fuelling the process and allowing the continuous distillation to take place.

Bottom-Fill Beer: How Does It Work?

You may want to see also

Beer runs across each plate, flows down to the next plate, and flows across it

A column still is filled with perforated plates. Beer is pumped in near the top of the column, and steam is pumped up from the bottom. The perforated plates allow the steam to rise through the still, while the beer runs across each plate, flowing to the other side of the plate, then down to the next plate.

The beer does not drip down through the holes in the plates, but instead, runs across each plate and then down to the next plate. This process allows the steam to vaporize the alcohol from the beer, which then flows to the top of the column, while the water and grain solids drip down to the bottom.

The beer initially doesn't enter the very top of the still but enters near the top. Above that point in the still, the steam is being rectified on those plates. It is here that copper is crucial, and where "bubble caps" are found in stills.

The perforated plates in the column still allow the beer to be separated and distilled. The steam rises through the column, vaporizing the alcohol from the beer, while the water and grain solids drip down to the bottom. This process of distillation continues as the beer flows across each plate and down to the next plate in the column still.

Beer Enemas: Do They Work or Are They Dangerous?

You may want to see also

Steam vaporizes the alcohol from the beer

A column still is a type of still consisting of two columns. The first column, called the analyzer, has steam rising and wash descending through several levels. The second column, or rectifier, carries the alcohol from the wash, where it circulates until it can condense at the required strength.

The beer to be distilled is pumped in near the top of the column (but not at the very top), and steam is pumped up from the bottom of the column. The beer runs across each plate to the other side, flows down to the next plate, and flows across it to the other side. As the beer runs across the plates, the steam coming up through the column vaporizes the alcohol from the beer, which then flows to the top of the column. The steam vaporizes the alcohol by heating it up until it turns to vapour. The vapour then rises up the column, leaving the water and grain solids to drip down to the bottom of the still.

The top part of the still, above the point where the beer enters, is where the steam is rectified. This is also where you find "bubble caps" in stills. Bubble caps provide additional refinement of the spirit and increase contact with copper.

Beer Traps: Effective Snail Control or Urban Myth?

You may want to see also

Water and grain solids drip down to the bottom

The beer to be distilled is pumped in near the top of the column. While the plates are perforated, this lets the steam come up through the still, but the beer does not drip down through these holes. Instead, the beer runs across each plate to the other side, flows down to the next plate, and flows across it to the other side. As the beer flows down the column, the steam coming up through the column vaporizes the alcohol from the beer, which then flows to the top of the column. The water and grain solids are left behind and drip down to the bottom of the still.

The beer initially doesn't enter the very top of the still but near the top. Above that point in the still, the steam is being rectified on those plates. It is up there where copper is crucial, and where "bubble caps" are found in stills. Bubble caps provide additional refinement of the spirit and increase contact with copper.

The water and grain solids that drip down to the bottom of the still are known as "stillage". In the case of Kentucky bourbon, the stillage is added back into newly mashed beer in the fermenters.

The beer column is the first of three distillation columns. The remaining water and solids exit the bottom of the beer column and will eventually be turned into DDGS. The 50% ethanol, 50% water vapour (100 proof) that leaves the top of the column is sent over to the Rectifier Column for further purification.

Understanding Beer Staffs: A Guide to Their Functionality

You may want to see also