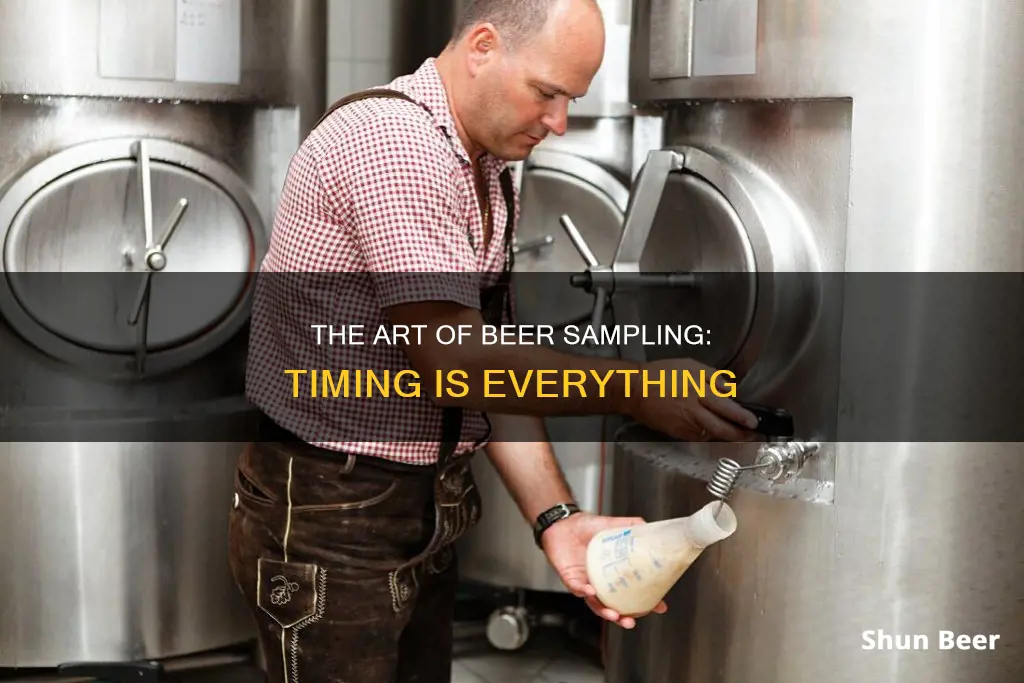

When it comes to the art of brewing, sampling beer during the fermentation process is a crucial step that can significantly impact the final product. But how often should brewers sample their beer during fermentation? This question delves into the delicate balance between monitoring progress and avoiding interference. While some brewers prefer to sample every few hours to ensure the yeast is working optimally, others opt for a more cautious approach, sampling only once or twice a day to avoid disrupting the fermentation process. The frequency of sampling can vary depending on the style of beer being brewed, the yeast strain used, and the brewer's personal preferences. In this exploration, we'll uncover the optimal sampling schedule to achieve the perfect beer.

What You'll Learn

- Fermentation Timing: Beer sampling during fermentation can vary based on the yeast type and desired flavor profile

- Aroma Development: Regular sampling helps identify when aromas peak, guiding the fermentation process

- Alcohol Content: Monitoring alcohol levels through sampling ensures the beer reaches the target strength

- Clarity and Cloudiness: Sampling reveals when the beer becomes clear, indicating successful fermentation

- Carbonation Levels: Frequent sampling allows for adjusting carbonation as fermentation progresses

Fermentation Timing: Beer sampling during fermentation can vary based on the yeast type and desired flavor profile

The process of sampling beer during fermentation is an art that requires careful consideration and timing, especially when it comes to achieving the desired flavor profile. The frequency and timing of these samples can significantly impact the final product, making it a crucial aspect of the brewing journey. When it comes to fermentation, the type of yeast used plays a pivotal role in determining the sampling strategy. Different yeast strains have unique characteristics and fermentation profiles, which can influence the beer's flavor development. For instance, ale yeasts tend to produce fruity esters, while lager yeasts result in cleaner, crisper profiles. Understanding these nuances is essential for brewers to make informed decisions about sampling.

For beginners, it's recommended to start with a more frequent sampling schedule, perhaps every 2-3 days, to closely monitor the fermentation process. This is particularly important when using wild or specialty yeasts, as they can be unpredictable and may require more attention. During this initial phase, you'll be able to catch any off-flavors or unexpected developments early on, allowing for adjustments to be made promptly. As the fermentation progresses, you can gradually space out the sampling intervals. For example, after the first week, you might sample every 4-5 days, and later, every 5-7 days, depending on the yeast's activity and the beer's condition.

The desired flavor profile is another critical factor in determining fermentation sampling frequency. If you're aiming for a crisp, clean lager, you might want to sample more frequently to ensure the beer doesn't over-ferment and develop unwanted esters. Conversely, for a rich, fruity ale, sampling less often might be beneficial to capture the desired esters and allow for a more complex flavor profile to develop. It's a delicate balance, and brewers often rely on their sensory skills and experience to make these decisions.

In addition to the yeast type and flavor goals, the brewing process and equipment can also influence sampling intervals. For instance, if you're using a temperature-controlled fermenter, you might be able to maintain a consistent fermentation temperature, allowing for less frequent sampling. However, if you're using open-air fermentation or traditional methods, more frequent monitoring might be necessary to account for external factors that could impact the beer's character.

Mastering the art of fermentation timing and sampling is a skill that brewers develop over time. It involves a combination of scientific understanding, sensory analysis, and intuition. By paying close attention to the yeast's activity, the beer's aroma, and its overall condition, brewers can make informed decisions about when to sample and how to adjust their processes to create the perfect beer. This iterative approach to brewing is what makes the craft so fascinating and rewarding.

Maximizing Beer Flow: Optimal Placement for Keezer Collar Taps

You may want to see also

Aroma Development: Regular sampling helps identify when aromas peak, guiding the fermentation process

Regular sampling during the fermentation process is an essential practice for brewers aiming to craft beers with exceptional aroma profiles. This technique allows for a deep understanding of the fermentation dynamics and enables precise control over the beer's development. By frequently sampling the beer, brewers can closely monitor the transformation of the wort into a complex and enticing beverage.

The frequency of sampling is crucial as it directly impacts the ability to pinpoint the optimal moment for aroma peak. Aroma development is a dynamic process, and the beer's scent can change rapidly as yeast consumes sugars and produces alcohol and carbon dioxide. Typically, brewers recommend sampling the beer every 12 to 24 hours during the early stages of fermentation. This regular interval provides valuable insights into the yeast's activity and the beer's progress. As the fermentation progresses, the sampling frequency can be adjusted based on the beer's characteristics and the brewer's goals.

During these sampling sessions, brewers should pay close attention to the beer's appearance, color, and clarity, as well as its aroma. The aroma is a critical aspect of beer quality, and its development is influenced by various factors, including yeast strain, fermentation temperature, and the presence of esters and other volatile compounds. By regularly assessing the aroma, brewers can identify when the beer reaches its peak aromatic intensity. This knowledge is invaluable for making informed decisions about the fermentation process, such as adjusting yeast activity or considering the addition of flavorings or hop additions to enhance or modify the aroma.

Moreover, regular sampling allows brewers to detect any off-flavors or unwanted aromas early in the process. This is essential for producing high-quality beer, as even minor deviations can significantly impact the final product's character. By identifying these issues promptly, brewers can take corrective actions, such as adjusting fermentation parameters or implementing specific yeast management techniques, to ensure the beer's aroma remains desirable and consistent.

In summary, regular sampling during fermentation is a critical practice for aroma development in beer. It enables brewers to make data-driven decisions, ensuring the beer's aroma peaks at the desired time and maintains a high level of quality. This process requires attention to detail and a deep understanding of the fermentation dynamics, ultimately contributing to the creation of exceptional beers that delight the senses.

Unlocking Flavor: The Art of Yeast Timing in Beer Brewing

You may want to see also

Alcohol Content: Monitoring alcohol levels through sampling ensures the beer reaches the target strength

The process of brewing beer involves a delicate balance of ingredients and techniques to achieve the desired flavor profile and alcohol content. One crucial aspect of brewing is monitoring the alcohol levels during fermentation, as it directly impacts the beer's strength and overall quality. Sampling beer during fermentation is an essential practice that allows brewers to ensure their beer reaches the target alcohol content.

Alcohol content is a critical factor in beer style and character. Different beer styles have specific alcohol by volume (ABV) ranges, and achieving the target strength is essential for consistency and quality. For example, a light American lager typically aims for an ABV of around 4-5%, while a robust imperial stout can have an ABV of 8-10% or higher. Regular sampling and testing are necessary to hit these targets.

During fermentation, yeast consumes sugars and produces alcohol and carbon dioxide. Brewers must carefully manage this process to control the alcohol levels. Sampling beer at various stages of fermentation provides valuable insights into the yeast's activity and the beer's progress. By taking samples, brewers can estimate the alcohol content and make adjustments if needed. This might involve adding more sugar to increase the alcohol level or taking corrective action if the fermentation is off-target.

The frequency of sampling depends on various factors, including the brewing process, yeast type, and desired alcohol content. Typically, brewers start sampling early in the fermentation process and continue at regular intervals. For example, sampling every 24 hours is common, but some brewers may sample more frequently, especially if they are closely monitoring a specific batch. Advanced brewing software and digital tools can also assist in tracking and predicting alcohol levels, providing brewers with real-time data to make informed decisions.

In summary, monitoring alcohol levels through sampling is a critical step in brewing beer to ensure the final product meets the desired strength and quality. It allows brewers to fine-tune their processes, make necessary adjustments, and ultimately produce beer that consistently meets the target alcohol content. This practice is an art and science, requiring attention to detail and a deep understanding of the fermentation process.

Brewed Adventure: A Guide to Stuffing Beer in Turkey

You may want to see also

Clarity and Cloudiness: Sampling reveals when the beer becomes clear, indicating successful fermentation

The process of brewing beer involves a delicate balance of science and art, and one of the key aspects to master is fermentation. During this stage, yeast consumes sugars and transforms them into alcohol and carbon dioxide, creating a magical transformation from wort to beer. However, the success of this process is not always immediately apparent, and that's where sampling comes into play.

Sampling beer during fermentation is an essential practice for brewers to ensure the desired outcome. It provides valuable insights into the fermentation process and helps identify potential issues early on. The frequency of sampling can vary depending on the style of beer being brewed and the brewer's preferences, but a general guideline is to take samples every 24 to 48 hours. This regular monitoring allows brewers to track the progress of fermentation and make informed decisions.

The primary goal of sampling is to observe the clarity and cloudiness of the beer, which are strong indicators of successful fermentation. As the yeast works its magic, it produces a variety of compounds, including proteins and sediment. Initially, the beer may appear hazy or cloudy due to these byproducts. However, as fermentation progresses, the beer gradually clears up. This change in appearance is a sign that the yeast is actively metabolizing sugars and that the beer is on the right track.

Brewers should take note of the specific moment when the beer becomes clear. This clarity indicates that the yeast has efficiently converted the available sugars, and the beer is no longer in an active fermentation state. At this point, the beer is ready for packaging or further aging, depending on the desired outcome. It's important to remember that the timing of clarity can vary, so consistent sampling is crucial to catching this pivotal moment.

In summary, sampling beer during fermentation is a critical step in the brewing process. By regularly observing the clarity and cloudiness of the beer, brewers can determine when the yeast has completed its work and the beer has reached a state of equilibrium. This practice ensures that the final product meets the desired standards and allows for adjustments to be made if any issues arise during fermentation. With careful sampling, brewers can consistently produce high-quality beers that delight beer enthusiasts.

Crafting the Perfect Beer Gift Basket: A Guide to Delightful Surprises

You may want to see also

Carbonation Levels: Frequent sampling allows for adjusting carbonation as fermentation progresses

Frequent sampling during the fermentation process is crucial for achieving the desired carbonation levels in beer. Carbonation is a delicate balance that can significantly impact the overall quality and character of the final product. By regularly monitoring the fermentation, brewers can make precise adjustments to ensure the beer reaches the optimal carbonation level.

The carbonation process in beer is primarily influenced by the activity of yeast, which produces carbon dioxide as a byproduct of fermentation. This CO2 is dissolved in the beer, creating the fizz and sparkle that beer enthusiasts appreciate. However, the rate of carbonation development can vary, and frequent sampling allows brewers to control this process. During the early stages of fermentation, the yeast may produce a significant amount of CO2, leading to a rapid increase in carbonation. As the fermentation progresses, the rate of CO2 production typically slows down, and the focus shifts to managing the remaining carbonation.

Regular sampling enables brewers to take multiple readings throughout the fermentation, providing a comprehensive understanding of the carbonation trend. By taking samples at various stages, brewers can identify any deviations from the desired carbonation profile. For instance, if the carbonation level is rising too quickly, it might indicate an over-carbonated beer, which could lead to a sharp, biting sensation that some consumers find unpleasant. Conversely, if the carbonation development is too slow, the beer may lack the desired effervescence. Adjustments can then be made to the fermentation parameters, such as adjusting the yeast type or temperature, to bring the carbonation back in line with the target.

The art of carbonation management becomes even more critical when dealing with specific beer styles. For example, a light, crisp session beer may require a more delicate approach to carbonation, ensuring a refreshing drinking experience without overwhelming the palate. In contrast, a robust, dark ale might benefit from a higher carbonation level to balance its rich flavors. Frequent sampling allows brewers to tailor the carbonation to the specific style and preferences of the target market.

In summary, frequent sampling during fermentation is an essential practice for brewers to fine-tune the carbonation levels in their beer. It empowers them to make real-time adjustments, ensuring the final product meets the desired quality and style standards. This meticulous approach to carbonation management is a key factor in producing beers that delight consumers with their perfect balance of flavor and fizz.

Beer Snorkel: Crafting the Perfect Setup for Your Next Adventure

You may want to see also

Frequently asked questions

Sampling beer during fermentation is a crucial step in the brewing process, and it should be done regularly to ensure the desired outcome. It is recommended to take samples at least once a week, but more frequent sampling (every 2-3 days) is ideal, especially for homebrewers. This allows you to monitor the fermentation progress, check for any signs of contamination, and make adjustments as needed. Regular sampling helps you understand the beer's flavor development, alcohol content, and overall quality.

Sampling beer during fermentation serves multiple purposes. Firstly, it helps brewers assess the fermentation rate, which is essential for achieving the desired alcohol content and flavor profile. By taking samples, you can measure the specific gravity of the beer, which indicates the remaining fermentable sugars and the overall progress of the fermentation. Secondly, sampling allows you to detect any off-flavors or signs of bacterial contamination early on, enabling you to take corrective actions promptly. This process ensures a clean and consistent beer.

Absolutely! Here are some tips for successful beer sampling:

- Use sanitized equipment to avoid any contamination.

- Take samples from multiple points in the fermenter to get a representative reading.

- Label the samples with the date and specific gravity for easy reference.

- Store samples in a cool place to maintain the beer's integrity.

- Compare the samples to the original wort to identify any changes or deviations.

- Consider using a hydrometer for accurate specific gravity measurements.

- Keep a fermentation log to track the progress and make informed decisions.